Abstract

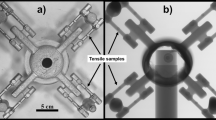

The effect of combined addition of carbon and titanium on structure and properties of Fe–7 wt%Al alloys has been studied. Pancakes of four alloys with nominal compositions, Fe–7Al–0.05C–0.2Ti (alloy-1), Fe–7Al–0.5C–2.0Ti (alloy-2), Fe–7Al–1.0C–4.0Ti (alloy-3) and Fe–7Al–2.0C–8.0Ti (alloy-4) were prepared by non-consumable arc melting. The arc melted pancakes were examined using scanning electron microscopy, electron probe microanalysis, and X-ray diffraction to understand the microstructure of these alloys. The dendritic solidification structure was observed in alloys 2–4. The microstructure of these alloys also revealed the presence of TiC precipitates, whereas no such phase was observed in alloy 1. The size and volume fraction of these precipitates increased with increase in the concentration of Ti and C. The yield strength of Fe–7 wt%Al alloy at both room temperature and at 873 K increases with increasing carbon and titanium.This may be due to the composite strengthening arising out of increased precipitations of hard TiC precipitates.

Similar content being viewed by others

References

Schneider A, Falat L, Southhoff G, Frommeyer G, Intermetallics 11 (2003) 443.

Falat L, and Schneider A, Southhoff G, Frommeyer G, Intermetallics 13 (2005) 1256.

Baligidad R G, Prakash U, and Radhakrishna A, Mater Sci Eng A 230 (1997) 188.

Baligidad R G, Prakash U, Radhakrishna A, Ramakrishna R V, Rao P K, and Ballal N B, Scr Metall 36 (1997) 667.

Sikka V K, Viswanathan S, and Vyas S, in High- Temperature Ordered Intermetallic Alloys I, (eds) Baker I, Darolia R, Whittenberger J D, and Yoo M H, Materials Research Society, Pittsburgh 288 (1993), p 971.

Khaple Shivkumar, Baligidad R G, Sankar M, and Satya Prasad V V, ISIJ Int 50, 10 (2010), 1483.

Herrmann J, and Inden G, Sauthoff G, Acta Mater 51 (2003) 2847.

Frommeyer G, Drewes E J, and Engl B, La Revue de Métallurgie 10 (2000) 1245.

Rana R, Liu C and Ray R K, Scr Mater 68 (2013) 354.

Pramanik Sudipta, and Suwas S, JOM 66(9) (2014) 1868.

Chen Y J, Mater Res 21 2 (2006) 375.

Liu Z, and Fredriksson H, Metall Mater Trans A 27 (1996) 407.

Karantzalis A E, Lekatou A, Georgatis E, Arni Z, and Dracopoulos V, Mater Charact 62 (2011) 1196.

Terry B S, and Chinyamakobvu O S, J Mater Sci 27 (1992) 5666.

Chen Y, and Wang H M, Mater Lett 57 (2003) 1233.

Chen Y, and Wang H M, Surf Coat Technol 168 (2003) 30.

Nukami Tetsuya, and Merton C, Metall Mater Trans A, 26 (1995) 1877.

Khaple S, Baligidad R G and Sambasiva RA, Trans IIM 62(2) (2009) 153.

Baligidad R G, Satya Prasad V V, and Sambasiva Rao A, Mater Sci Tech 23 (2007) 613.

Ko S H, and Hanada S, Intermetallics 7 (1998) 947.

Chaudhary S, Khaple S, Unpublished data, (2014).

Lipatnikov V N, Rempel A A, and Gusev A I, Int J Refract Metals Hard Mater 15 (1997) 61.

Acknowledgments

The authors are grateful to Defence Research and Development Organization (DRDO), Ministry of Defence, New Delhi for the financial support in carrying out this research work. The authors wish to thank Dr. Amol A Gokhale, Director DMRL Hyderabad for his interest and encouragement. The authors would like to thank fellow officers and staff of ERG (melting & casting), ACG (chemical analysis), MEG (sample making), SFAG (Metallography, EPMA & XRD), EMG (SEM & EDAX) and MBG (Compression).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chaudhary, S., Khaple, S., Satya Prasad, V.V. et al. Effect of Titanium and Carbon on Microstructure and Mechanical Properties of Disordered Solid Solution Fe–7 wt%Al Alloy. Trans Indian Inst Met 68, 809–815 (2015). https://doi.org/10.1007/s12666-015-0514-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0514-z