Abstract

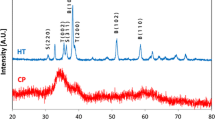

Copper–chromium carbide composites containing a carbide phase of 20–30 vol% were obtained with the use of solid- and liquid-phase mechanosyntheses, followed by magnetic pulse compaction (MPC) and spark plasma sintering. The morphology, structural-phase composition, density, hardness and electrical conductivity of the composites were investigated. The structure of composites obtained by MPC represents regions of copper matrix hardened by superfine carbide precipitates surrounded by a layer of chromium carbide. In the composites obtained by spark plasma sintering, the copper matrix hardened by superfine carbide precipitates was divided into areas surrounded by a copper–chromium layer. A composite obtained by the MPC of the powders synthesized using solid-phase mechanosynthesis (MS) (copper, chromium and graphite) had the highest values of Vickers microhardness (4.6 GPa) and Rockwell hardness (HRA 69). The best value of electrical conductivity (36% IACS) was achieved using liquid-phase MS (copper, chromium and xylene) and spark plasma sintering. Liquid-phase MS is the only way to synthesize the powder with a small amount of the carbide phase and without contamination.

Similar content being viewed by others

References

Mahbub Ullah, Md Eaqub Ali and Sharifah Bee Abd Hamid, 2014 Rev. Adv. Mater. Sci. 37 1

Yazovskikh K A and Lomayeva S F 2014 J. Alloys Compd. 586 565

Lomayeva S F, Yazovskikh K A, Maratkanova A N, Syugaev A V, Timoshenkova O R, Kaygorodov A S et al 2013 Inorg. Appl. Res. 4 138

Lomayeva S F, Syugaev A V, Eremina M A, Ul’yanov A L, Yurovskikh A S, Zayats S V et al 2014 Prot. Met. Phys. Chem. Surf. 50 352

Yazovskikh K A, Lomayeva S F and Syugaev A V 2014 Acta Phys. Pol. A 126 947

Eryomina M A, Lomayeva S F, Yelsukov E P, Ul’yanov A L and Chulkina A A 2014 Met. Mater. Int. 20 1123

Long B D, Othman R, Zuhailawati H and Umemoto M 2014 Adv. Mater. Sci. Eng. 2014 1

Kung Ch, Liao T-T, Tseng K-H, Chen K-Y and Chuang M-Sh 2009 Can. Soc. Mech. Eng. 33 361

Lopez M, Camurri C, Vergara V and Jimenez J A 2005 Rev. Metal. (Madrid, Spain) 41 308

Eryomina M A, Lomayeva S F, Yelsukov E P, Bodrova L E, Goida E Y and Pastukhov E A 2013 Khimicheskaia Fizika i Mezoskopiia 15 262

Eremina M A, Lomayeva S F and Elsukov E P 2013 Phys. Met. Metallogr. 114 928

Upadhyaya G S 2002 Powder metallurgy technology (Great Abington, England: Cambridge International Science Publishing)

Long B D, Umemoto M, Todaka Y, Othman R and Zuhailawati H 2011 Mater. Sci. Eng. A 528 1750

Lee G H, Rhee C K, Lee M K, Kim W W and Ivanov V V 2004 Mater. Sci. Eng. A 375 604

Zhang Zh-H, Wang F-Ch, Wang L and Li Sh-K 2008 Mater. Sci. Eng. A 476 201

Mironov V 1994 Magnetic pulse pressing of powders and shaping of powder products Proceed Intern Conf PM-94 ‘Sintering consolidation’, Paris, France

Olevsky E A, Bokov A A, Boltachev G S, Volkov N B, Zayats S V, Ilyina A M et al 2013 Acta Mech. 224 3177

Ivanov V, Kotov Y A and Samatov O H 1995 Nanostruct. Mater. 6 287

Zhang Z N, Wang F C, Lee S K, Liu Y, Cheng J W and Liang Y 2009 Mater. Sci. Eng. A 523 134

Briggs D and Seah M P 1990 Practical surface analysis Vol 1 (Chichester, UK: Wiley)

Beamson G and Briggs D 1992 High resolution XPS of organic polymers: The Scienta ESCA300 Database (New York: John Wiley & Sons)

Povstugar V I, Shakov A A, Mikhailova S S, Voronina E V and Elsukov E P 1998 J. Anal. Chem. 53 697

Shelekhov E V and Sviridova T A 2000 Mater. Sci. Heat. Treat. 42 309

Dorofeev G A, Povstugar I V, Protasov A V, Elsukov E P and Streletskii A N 2012 Colloid. J. 74 675

Acknowledgements

This work was supported by the Government of the Russian Federation (Federal Agency for Scientific Organizations) under the themes of the state task, no. 0389-2014-0002 and no. 0428-2014-0002 and by the Program of UD RAS, Project reg. no. AAAA-A17-117040610324-3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eryomina, M.A., Lomayeva, S.F., Paranin, S.N. et al. Effect of the method for producing \(\hbox {Cu}\)–\(\hbox {Cr}_{3}\hbox {C}_{2}\) bulk composites on the structure and properties. Bull Mater Sci 40, 1021–1028 (2017). https://doi.org/10.1007/s12034-017-1457-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-017-1457-2