Abstract

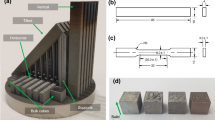

Cold uniaxial pressing of powder into a green body is a common forming process used in ceramic and pharmaceutical industries. Argillaceous particles are used as a model system to investigate granule failure during compaction. Indeed, the volume enclosed between the die and punches is reduced and the powder consolidates until a final height is obtained or a prescribed compacting pressure is reached. Desired properties of the green body are high strength, uniform density, no defects and fracture. In this work an experimental investigation has been focused on the ‘cracking cone’ fracture in powder compacts. This includes studies of crack propagation and determination of operating conditions to avoid the green body fracture. The numerical modelling is implemented using a finite element method based on the Von Mises criterion. A case of simulation is presented to demonstrate the ability of the model to compute the distribution of the relative stresses.

Similar content being viewed by others

References

Latella B A, O’Connor B H, Padture N P and Lawn B R 1997 J. Am. Ceram. Soc. 80 1027

Lee S C and Kim K T 2007 Mater. Sci. & Eng. A445-446 163

Liu J X and Davies T J 1997 Powder Metall. 40 48

Meyers M A, Mishra A and Benson D J 2006 Prog. Mater. Sci. 51 427

Miyashita M, Kim J Y, Kato Z, Uchida N and Uematsu K 1992 J. Ceram. Soc. Jap. 100 1357

Mori K 2006 Comput. Meth. Appl. Mech. Eng. 195 6737

Salman A D, Reynolds G K, Fu J S, Cheong Y S, Biggs C A, Adams M J, Gorham D A, Lukenics J and Hounslow M J 2004 Powder Technol. 143–144 19

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abid, S., Bouaziz, M. & Ksibi, H. Cracking cone fracture after cold compaction of argillaceous particles. Bull Mater Sci 32, 607–610 (2009). https://doi.org/10.1007/s12034-009-0093-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-009-0093-x