Abstract

Essential elements like Cu, Mn and Zn are extremely important for herbs’ growth and physiological functions; however, from a toxicological point of view, the exposure of these elements (as essential elemental impurities) can exhibit potential harmful effects for patients. In Europe, very popular are ointments with Marjoram herb extract (Majoranae herbae extractum) as herbal medicinal products for adjunctively in rhinitis (runny nose). Based on posology of ointments with Marjoram herb extract, the exposure to these elemental impurities may be high during long-term use. Hence, the aim of this article is the health risk assessment of essential elemental impurities (Cu, Mn and Zn) through the dermal exposure of ointments with Marjoram herb extract (Majoranae herbae extractum) as herbal medicinal products applied adjunctively in rhinitis available in Polish pharmacies. The investigated essential elements were determined by well-validated methodology (R > 0.997, recoveries, LOD and LOQ values were acceptable) based on flame atomic absorption spectrometry (FAAS). Our results indicated that all analysed herbal medicinal products with Marjoram herb extract available in Polish pharmacies contain relatively low levels of essential element impurities, i.e. Cu (0.14–0.49 mg/kg), Mn (0.31–2.57 mg/kg) and Zn (0.73–3.19 mg/kg). The estimated exposure of the investigated elemental impurities confirms the safety of all products. To the best of our knowledge, the study about Cu, Mn and Zn contents in HMPs with Majoranae herbae extractum is described for the first time. The applied methodology and results are extremely important from regulatory toxicology point of view due to ICH Q3D elemental impurity guideline for pharmaceuticals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

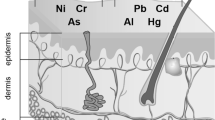

Origanum majorana L., herba (Marjoram) is an active pharmaceutical ingredient (API) in herbal medicinal products (HMPs)/phytotherapeutics used as a home remedy for adjunctively in rhinitis (runny nose). Usually, this kind of HMPs exists in semi-solid dosage forms for cutaneous use and are applied for relief of irritated skin around the nostrils [1]. The leaves of O. majorana L., herba has been traditionally used for the treatment of gastrointestinal disturbances, cough and bronchial diseases [2, 3]. However, the most important indication is rhinitis (runny nose). Based on posology, a small amount of the preparation should be spread around the nostrils, 2–4 times daily [1]. Hence, from toxicological point of view, there is a potential health risk related to dermal exposure. In this situation, potential health risks may be associated with elemental impurities (EIs). The appropriate control of EIs is currently required for quality assurance for the pharmaceutical industry. However, there is a lack of scientific original articles; there are only a few articles about this important issue [4,5,6,7]. Based on posology of ointments with Marjoram herb extract (Majoranae herbae extractum) mentioned earlier, exposure to EIs may be high during long-term use. From this point of view, essential EIs can be a very interesting problem and challenge. It is well-known that all herbs require essential elements for physiological functioning and growth [8]. It should be mentioned that essential elements cannot be synthesised by the plants itself; hence, uptake of these kind of elements is crucial [9]. These essential elements (especially Cu, Mn and Zn) are extremely important; however, from a toxicological point of view, the excess of these elements (as essential EIs) can exhibit potential harmful effects for patients [10]. For example, Cu has been recorded and shown to cause problems only under certain specific conditions, notably genetic disorders such as Wilson disease [5]. Additionally, the symptoms of Mn toxicity can result as manganism (a permanent neurological disorder) [5]. On the other hand, chronically high Zn intake can result in severe neurological diseases attributable to copper deficiency as the results of antagonism of both elements [5]. Hence, the aim of our work was the toxicological risk assessment of Cu, Mn and Zn as essential EIs in ointments with Marjoram herb extract (Majoranae herbae extractum) applied adjunctively in rhinitis. For this purpose, the levels of Cu, Mn and Zn in samples of HMPs available in Polish pharmacies were determined by atomic absorption spectrometry using flame atomisation (FAAS). To the best of our knowledge, the study about Cu, Mn and Zn contents in HMPs with Majoranae herbae extractum is described for the first time.

Materials and Methods

Samples

All available in Poland (n = 5), ointments with Marjoram herb extract (Majoranae herbae extractum) as herbal medicinal products applied adjunctively in rhinitis (runny nose) were investigated. The choice of HMPs was justified by the fact that this kind of pharmaceutical products is very popular in Poland, especially among young children and seniors. It should be underlined that ointments with Marjoram herb extract are monocomponent herbal medicinal products; hence, there is exclusion of other sources of EIs.

All traditional pharmaceutical products were collected from local pharmacies situated in the Lesser Poland Voivodeship (Kraków, Niepołomice, Bochnia, Wieliczka) in 2021. All the investigated samples were pharmaceutical product of individual manufacturers. To maintain the highest methodological standards, each sample was coded (A, B and so on). The short characteristics of the analysed samples was described in Table 1.

Reagents

All applied reagents were of analytical grade. For the preparation of all solutions, demineralised water (Millipore) was applied. Ultrapure demineralised water had been obtained by Milli-Q water purification system (Millipore, Bedford, MA, USA). Concentrated nitric acid (HNO3, 65%) from Merck (SupraPur, Darmstadt, Germany) was applied. The purge gas was argon at purity 99.99%. The certified reference material (Corn Flour, INCT-CF-3) was purchased from the Institute of Nuclear Chemistry and Technology—Department of Analytical Chemistry (Warsaw, Poland).

Instrumentation

To minimise any potential impurities from other sources, all steps during the sampling procedure were carried out in plastic equipment. Laboratory glasswares (volumetric flasks, funnels etc.) were kept overnight in a 10% nitric acid (HNO3) solution and rinsed with deionised water and air dried before use.

A CEM MDS-2000 microwave digestion system (CEM, Matthews, NC, USA) was applied for the digestion of ointments. All measurements for the determination of Cu, Mn and Zn were carried out using a Perkin-Elmer 5100 ZL spectrometer (Perkin-Elmer, Norwalk, CT, USA; FAAS). Cu, Mn and Zn hollow cathode lamps were used as the emission sources. Argon (99.999%) was applied as a purge gas. Background corrections were performed by Zeeman background correction. Further information about instrumentation and detailed parameters are described in Supplementary Material 1.

Sample Preparations

Before element determination, each ointment was homogenised. Because most of the ointments had an aluminium lid which could be a potential source of EIs, the first few centimetres of each ointment from the tube was discarded. Of each sample, 0.3 g was weighed, poured into Teflon vessels and digested with 5.0 mL of concentrated nitric acid (HNO3, 63%). The closed vessels were microwaved after 2 h. The detailed information about digestion procedure are described briefly in Supplementary Material 1. The samples were later cooled at room temperature (25 °C), and the final volume was made to 20 mL. The cooled samples were stored in plastic bottles as stock sample solutions until analysis. This methodology is based on our previously published articles [5, 11]. Five replications were kept and done for all samples to increase the precision of the result.

The Essential Elemental Impurity Determination and Toxicological Risk Assessment Procedure

All elemental impurities were determined in the digested ointment samples using FAAS (described earlier). All instrumentation and detailed parameters for this step are described briefly in Supplementary Material 1. The overview of our toxicological risk assessment has been schematically shown in Fig. 1.

Analytical Calibration and Quality Control Approaches

In all situations, very good linearity with good correlation coefficients (0.998 for Cu, 0.997 for Mn and 0.999 for Zn) were observed. The values of the correlation coefficients confirm the linearity of the AAS instrument for precision and accuracy of results. Five replications were performed for each sample. Additionally, the quality control and validation of applied methodology are confirmed by previously described studies using the same methodology and apparatus [5, 11]. The synthetic summary of analytical calibration parameters and quality control results are shown in Supplementary Material 1.

Data Analysis

The results of five independent replicates were expressed as the mean ± standard deviation. Additionally, the descriptive statistics were made (minimum, maximum, mean, skewness and kurtosis) using Origin 2021 Pro licenced by the Jagiellonian University in Krakow. All plots were made using Origin 2021 Pro licenced by the Jagiellonian University in Krakow.

Results and Discussion

The Elemental Impurity Profiles of Cu, Mn and Zn in Ointments with Marjoram Herb Extract

The elemental impurity profiles of analysed samples (n = 5; A–E) are presented in Fig. 2, as the graph for each element (mg/kg) determined in analysed HMPs available in Polish pharmacies. Additionally, the boxplot showing ranges of levels and violin plot showing log2 levels of all investigated elements are shown in Fig. 3A and B, respectively. The descriptive statistics of Cu, Mn and Zn contents in all samples is briefly described in Table 2.

In general, all investigated elemental impurities were present in all analysed samples below 3.5 mg/kg (in the range of 0.0142 to 3.19 mg/L).

The level of copper is extremely lower than other metals. The violin plot (Fig. 3B) showing log2 (concentration) values of indicate that level of copper is similar in all investigated samples (in the range of 0.0142 to 0.0492 mg/kg). On the other hand, the Mn level was different (in the range of 0.309 to 2.579 mg/kg; Fig. 3A). Additionally, the Zn level was also different (in the range of 0.363 to 3.19 mg/kg; Fig. 3A). The descriptive analysis of the overall content (Table 2) shows that Cu levels (mean = 0.032 mg/kg) were approximately 31 times lower than Mn levels (mean = 1.0029 mg/kg), and Cu content was approximately 40 times lower than Zn levels (mean = 1.283 mg/kg). Additionally, the levels of Mn and Zn were quite similar. The values of skewness and kurtosis confirm the distribution of results and their consistency.

Individual analysis of the content shows the lowest level of copper was in sample B (0.0142 ± 0.007 mg/kg) and the highest level was in sample C (approximately 0.0492 ± 0.006 mg/kg). The lowest level of manganese was in sample C (0.309 ± 0.06 mg/kg), and the highest content was in sample A (2.57 ± 0.06 mg/kg). Finally, the lowest level of Zn was in sample E (0.363 ± 0.07 mg/L), and the highest level was in sample A (3.19 ± 0.09 mg/L).

Considering the levels of limits for Cu in pharmaceutical products via oral route recommended by ICH Q3D guideline (30.0 μg/g [12, 13]), all of the investigated herbal medicinal products with Marjoram herb extract meet the requirements in the guideline. Hence, our results confirm the safety of Cu contents in all samples. On the other hand, manganese and zinc are classified by ICH Q3D guideline as other metals, i.e. ‘elemental impurities for which PDEs have not been established due to their low inherent toxicity and/or differences in regional regulations which are not addressed in this guideline’ [12, 13]. Therefore, required sources of information about the acceptable levels of these elemental impurities should be other guidelines and/or reginal documents like regulations. However, based on literature review, there is a lack of guidelines and/or regional regulations or other related documents about copper and manganese impurities in pharmaceuticals. Therefore, it is not possible to compare obtained values with any existing regulatory documents. Based on scientific literature review, only Sazakli et al. [14] described Mn levels in O. majorana, L. leaves (46.48–77.32 µg/g); however, we analysed the final pharmaceutical product (diluted); hence, it is not possible to compare our results with these values. Notwithstanding, it can be summarised that the contents of all impurities are at a very low level (< 3.5 mg/kg).

Estimation of Exposure of Elemental Impurities (Cu, Mn and Zn) in Ointments with Marjoram Herb Extract Available in Polish Pharmacies

Appropriate toxicological risk assessment of the investigated essential elemental impurities in this kind of pharmaceuticals should include two steps (Fig. 1):

-

1)

Estimation of single exposure (single dose) (µg/kg)

-

2)

Estimation of daily exposure (µg/day) and comparison with cutaneous permitted daily exposure (μg/day)

The required information in this situation is the actual level in the single dose of the product (approximately 0.25 g). The estimated levels of copper, manganese and zinc in the one-time administration of applied ointments are presented in Table 3.

This step of calculation is necessary for the next step of toxicological risk assessment, i.e. the daily dermal exposure of investigated elements (the maximum daily dose of applied pharmaceuticals). For this purpose, the data about frequency of use is required. Based on information in the leaflet for each ointment and information from assessment report on O. majorana L. from EMA [1], small amount of the ointment should be spread around the nostrils, two to four times daily. Based on this information, the estimated daily exposures to Cu, Mn and Zn through applied ointments were calculated considering the maximum use during the day (Table 4).

Table 4 shows that the estimated exposure of Cu levels in five samples is quite similar (14.20–40.20 ng/day). Also, the estimated exposure for Zn is similar (1623.38–2579.69 ng/day). On the other hand, exposure to Mn has been estimated to be variable for these samples (661.10–2570.59 ng/day).

The appropriate toxicological risk assessment is based on comparison of the obtained results with the cutaneous PDE. For this purpose, the generic and conservative approach has been applied for elemental impurities by ICH Q3D. This approach is based on a systematic adjustment of the parenteral PDE, which assumed 100% bioavailability, to derive a cutaneous permitted daily exposure by using a cutaneous modifying factor (in most cases, intact/irritated skin 10; 100%/10% = 10) (Eq. 1) [13]:

where:

CPDE is the cutaneous permitted daily exposure.

Parenteral PDE is the parenteral permitted daily exposure.

CMF is the cutaneous modifying factor.

Hence, the calculations of CPDE are only possible for copper (manganese and zinc are classified by ICH Q3D guideline as other metals, see earlier section) (Table 5).

Acronyms: PDE, permitted daily exposure; CMF, cutaneous modifying factor; CPDE, cutaneous permitted daily exposure.

The applied toxicological risk assessment approach confirms that the estimated dermal Cu daily exposure (μg/day) is below the CPDE value for this element (< 3000 μg/day) in all investigated herbal-based pharmaceutical products. Hence, the applied toxicological risk assessment confirms safety of investigated herbal medicinal product with Marjoram herb extract due to estimated daily exposure of this element.

Conclusions and Recommendations

To the best of our knowledge, the study about Cu, Mn and Zn contents in herbal medicinal products with Majoranae herbae extractum is described for the first time. The contents of Cu, Mn and Zn as impurities in all ointments with Marjoram herb extract (Majoranae herbae extractum) available in Polish pharmacies are at a very low level (< 3.5 mg/kg). The toxicological risk assessment approach confirms that the estimated dermal daily exposure of investigated metals is very low. The estimated dermal daily exposure for Cu in comparison to the CPDE in all products is far below established the EMA requirements. It is not possible to obtain CPDE values for Mn and Zn, but based on estimated daily exposures (< 3.0 µg/day), this exposure is very low. Hence, the obtained results are in accordance with the standards of ICH Q3D guideline. It can be concluded that all analysed products with Marjoram herb extract do not represent a health hazard to the patients. The advantages of our research are the (1) practical methodology and (2) relevance of the obtained results from regulatory toxicology point of view (ICH Q3D elemental impurities guideline for pharmaceutical industry). The disadvantage is the applied technique (FAAS) which is slower and more demanding in comparison to ICP-MS. Based on the review of scientific literature, it would be important to carry out a broader toxicological risk assessment including other important metallic impurities and different herbal medicinal products [6, 15,16,17,18,19,20].

Data Availability

All data generated or analysed during this study are included in this published article and its Supplementary Information file.

Code Availability

Educational Analysis Set SAS® 9 licenced by the Jagiellonian University in Krakow and Origin 2021 Pro licenced by the Jagiellonian University in Krakow.

Abbreviations

- AAS:

-

Atomic absorption spectrometry

- API:

-

Active pharmaceutical ingredient

- EI:

-

Elemental impurities

- FAAS:

-

Flame atomisation atomic absorption spectrometry

- HMP:

-

Herbal medicinal product

- ICH Q3D:

-

International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use

- PDE:

-

Permitted daily exposure

- TRA:

-

Toxicological risk assessment

References

EMA/HMPC/166517/2015 Committee on Herbal Medicinal Products (HMPC), European Union herbal monograph on Origanum majorana L., herba, Available 05 April 2021 at www.ema.europa.eu/en/documents/herbal-monograph/draft-european-union-herbal-monograph-origanum-majorana-l-herba_en.pdf. Accessed 20 June 2021

Cano JH, Volpato G (2004) Herbal mixtures in the traditional medicine of Eastern Cuba. J Ethnopharmacol 90:293–316. https://doi.org/10.1016/j.jep.2003.10.012

Vasudeva P (2015) Origanum majorana L.-phyto-phamacological review. Ind J Nat Prod 6(4):261–267

Jurowski K, Krośniak M, Fołta M, Cole M, Piekoszewski W (2019) The toxicological analysis of Pb and Cd by ETAAS in local anaesthetics for teething (teething gels) based on herbs available in Polish pharmacies. Trace Elem Biol Med 52:18–21. https://doi.org/10.1016/j.jtemb.2018.11.005

Jurowski K, Krośniak M, Fołta M, Tatar B, Cole M, Piekoszewski W (2019) The toxicological analysis of Cu, Mn and Zn as elemental impurities in pharmaceutical herbal products for teething available in pharmacies in Poland. J Trace Elem Med Biol 53:109–112. https://doi.org/10.1016/j.jtemb.2019.02.011

Jurowski K, Krośniak M, Fołta M, Tatar B, Cole M, Piekoszewski W (2019) Safety assessment of the trace element impurities Ni and Cr in pharmaceutical herbal products for teething from Polish pharmacies. Biol Trace Elem Res 191(2):517–521. https://doi.org/10.1007/s12011-019-1643-8

Jurowski K, Fołta M, Tatar B, Berkoz M, Krośniak M (2021) The toxicological risk assessment of lead and cadmium in Valeriana officinalis L., radix (Valerian root) as herbal medicinal product for the relief of mild nervous tension and sleep disorders available in Polish pharmacies. Biol Trace Elem Res. https://doi.org/10.1007/s12011-021-02691-5

Tanhan P, Kruatrachue M, Pokethitiyook P, Chaiyarat R (2007) Uptake and accumulation of cadmium, lead and zinc by Siam weed [Chromolaena odorata (L.) King & Robinson]. Chemosphere 68:323–329. https://doi.org/10.1016/j.chemosphere.2006.12.064

Antonijevic M, Dimitrijevic M, Milic S, Nujkic M (2012) Metal concentrations in the soils and native plants surrounding the old flotation tailings pond of the copper mining and smelting complex Bor (Serbia). J Environ Monit 14:866–877. https://doi.org/10.1039/c2em10803h

Jordan SA, Cunningham DG, Marles RJ (2010) Assessment of herbal medicinal products: challenges, and opportunities to increase the knowledge base for safety assessment. Toxicol Appl Pharmacol 243:198–216. https://doi.org/10.1016/j.taap.2009.12.005

Jurowski K, Krośniak M, Fołta M, Tatar B, Cole M, Piekoszewski W (2019) The analysis of Cu, Mn and Zn content in prescription food for special medical purposes and modified milk products for newborns and infants available in Polish pharmacies from toxicological and nutritional point of view. J Trace Elem Med Biol 53:144–149. https://doi.org/10.1016/j.jtemb.2019.03.001

International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) Q3D on elemental impurities, EMA/CHMP/QWP/115498/2017 Committee for Medicinal Products for Human use (CHMP). www.ema.europa.eu/en/documents/scientific-guideline/implementation-strategy-ich-q3d-guideline_en.pdf. Accessed 20 June 2021

ICH guideline Q3D (R2) on elemental impurities (2020), European Medicines Agency, EMA/CHMP/ICH/353369/2013; Endorsed on 25 September 2020, pp 5 -14. www.ema.europa.eu/en/documents/scientific-guideline/draft-ich-guideline-q3d-r2-elemental-impurities-step-2b_en.pdf. Currently under public consultation (June 2021) Accessed 20 June 2021

Sazakli E, Panagopoulou E, Leotsinidis M, Kalavrouziotis I, Varnavas S (2016) Αn investigation of the biogeochemical properties of the plant species Οriganum majorana in relation to its soil characteristics. Water Air Soil Pollut 227(5):152. https://doi.org/10.1007/s11270-016-2847-6 (1-12)

Jurowski K, Krośniak M, Fołta M, Cole M, Piekoszewski W (2019) The toxicological analysis of Cu, Mn and Zn as elemental impurities in pharmaceutical herbal products for teething available in pharmacies in Poland. J Trace Elem Med Biol 53:109–112. https://doi.org/10.1016/j.jtemb.2019.02.011

Jurowski K, Krośniak M, Fołta M, Cole M, Piekoszewski W (2019) The analysis of Cu, Mn and Zn content in prescription food for special medical purposes and modified milk products for newborns and infants available in Polish pharmacies from toxicological and nutritional point of view. J Trace Elem Med Biol 53:144–149. https://doi.org/10.1016/j.jtemb.2019.03.001

de Santos Júnior A F, Matos RA, Andrade EM, dos Santos WN, Magalhães HI, Costa F, Korn M (2017) Multielement determination of macro and micro contents in medicinal plants and phytomedicines from Brazil by ICP OES. J Braz Chem Soc 28(2):376–384. https://doi.org/10.5935/0103-5053.20160187

de Aragão TC, de Souza DF, Santana FB, Dos Santos D, Magalhães H, de Souza DF, Júnior A (2021) Multielement determination in medicinal plants and herbal medicines containing Cynara scolymus L., Harpagophytum procumbens DC, and Maytenus ilicifolia (Mart.) ex Reiss from Brazil using ICP OES. Biol Trace Elem Res 199:2330–2341. https://doi.org/10.1007/s12011-020-02334-1

Jurowski K, Fołta M, Tatar B, Berkoz M, Krośniak M (2021) Ni and Cr impurities profile in Valeriana officinalis L., radix-based herbal medicinal product available in Polish pharmacies due to ICH Q3D guideline. Reg Tox Phar. https://doi.org/10.1016/j.yrtph.2021.104945 (Online ahead of print)

Jurowski K, Fołta M, Tatar B, Berkoz M, Krośniak M (2021) The toxicological risk assessment of dermal exposure of patients exposed to nickel and chromium due to application of ointments with Marjoram herb extract (Majoranae herbae extractum) available in Polish pharmacies. Biol Trace Elem Res. (Accepted manuscript)

Author information

Authors and Affiliations

Contributions

KJ and MK wrote the manuscript; they took an active part in experimental research. MB checked the manuscript and made statistical adjustments. BT and MF determined the elements.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

All authors confirm ethical responsibilities.

Consent for Publication

Not applicable. Our research includes available pharmaceuticals in Polish pharmacies.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jurowski, K., Fołta, M., Tatar, B. et al. The Health Risk Assessment of Essential Elemental Impurities (Cu, Mn and Zn) Through the Dermal Exposure of Herbal Ointment Extracted from Marjoram Herb (Majoranae herbae extractum). Biol Trace Elem Res 200, 1981–1987 (2022). https://doi.org/10.1007/s12011-021-02842-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12011-021-02842-8