Abstract

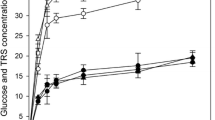

The potential of bioethanol generation using the mixture of waste French fries (WFF) and municipal wastewater (MWW) via separate hydrolysis and fermentation (SHF) was evaluated in this study. The effect of WFF substrate loading (SL, 10%, 16%, and 20%, w/v) on the SHF was also examined. Both glucose production and hydrolysis efficiency increased with increasing of SL from 10 to 16% and the maximum glucose yield of 0.236 g glucose/g WFF and hydrolysis efficiency of 91.9% were obtained at SL of 16%. However, the glucose production and hydrolysis efficiency decreased when the SL further increased to 20% due to the inhibition on enzyme caused by higher glucose production. The mixture hydrolysate was then used as feedstock for ethanol fermentation. The maximum ethanol production of 22.69 g/L was obtained from SL of 16%. The highest rate of glucose conversion to ethanol was 84.2%. The results demonstrated that the mixture of WFF and MWW could be used for ethanol production by the SHF.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Mandegari, M. A., Farzad, S., & Görgens, J. F. (2017). Economic and environmental assessment of cellulosic ethanol production scenarios annexed to a typical sugar mill. Bioresource Technology, 224, 314–326.

Liu, G., & Bao, J. (2017). Maximizing cellulosic ethanol potentials by minimizing wastewater generation and energy consumption: Competing with corn ethanol. Bioresource Technology, 245, 18–26.

Krishnan, C., Sousa Lda, C., Jin, M., Chang, L., Dale, B. E., & Balan, V. (2010). Alkali-based AFEX pretreatment for the conversion of sugarcane bagasse and cane leaf residues to ethanol. Biotechnology and Bioengineering, 107, 441–450.

Corona, A., Parajuli, R., Ambye-Jensen, M., Hauschild, M. Z., & Birkved, M. (2018). Environmental screening of potential biomass for green biorefinery conversion. Journal of Cleaner Production, 189, 344–357.

Martins, L. H. S., Rabelo, S. C., & da Costa, A. C. (2015). Effects of the pretreatment method on high solids enzymatic hydrolysis and ethanol fermentation of the cellulosic fraction of sugarcane bagasse. Bioresource Technology, 191, 312–321.

Kamoldeen, A. A., Lee, C. K., Wan Abdullah, W. N., & Leh, C. P. (2017). Enhanced ethanol production from mild alkali-treated oil-palm empty fruit bunches via co-fermentation of glucose and xylose, Renew. Energy, 107, 113–123.

Chen, S., Xu, Z., Li, X., Yu, J., Cai, M., & Jin, M. (2018). Integrated bioethanol production from mixtures of corn and corn stover. Bioresource Technology, 258, 18–25.

Demichelis, F., Laghezza, M., Chiappero, M., & Fiore, S. (2020). Technical, economic and environmental assessement of bioethanol biorefinery from waste biomass. Journal of Cleaner Production, 277, 124111.

Jin, M. J., Sousa, L. D., Schwartz, C., He, Y. X., Sarks, C., Gunawan, C., Balan, V., & Dale, B. E. (2016). Toward lower cost cellulosic biofuel production using ammonia based pretreatment technologies. Green Chemistry, 18, 957–966.

Moon, H. C., Song, I. S., Kim, J. C., Shirai, Y., Lee, D. H., & Kim, J. K. (2009). Enzymatic hydrolysis of food waste and ethanol fermentation. International Journal of Energy Research, 33, 164–172.

Ebrahimi, F., Khanahmadi, M., Roodpeyma, S., & Taherzadeh, M. J. (2008). Ethanol production from bread residues. Biomass and Bioenergy, 32, 333–337.

Condon, N., Klemick, H., & Wolverton, A. (2015). Impacts of ethanol policy on corn prices: A review and meta-analysis of recent evidence. Food Policy, 51, 63–73.

Han, W., Liu, Y. X., Xu, X. B., He, H., Chen, L., Tian, X. Q., Hou, P. Z., & Tang, J. H. (2020). A novel combination of enzymatic hydrolysis and microbial fuel cell for electricity production from bakery waste. Bioresource Technology, 297, 122387.

Bryant, D. N., Firth, E., Kaderbhai, N., Taylor, S., Morris, S. M., Logan, D., Garcia, N., Ellis, A., Martin, S. M., & Gallagher, J. A. (2013). Monitoring real-time enzymatic hydrolysis of distillers dried grains with solubles (DDGS) by dielectric spectroscopy following hydrothermal pre-treatment by steam explosion. Bioresource Technology, 128, 765–768.

Baral, N. R., & Shah, A. (2017). Comparative techno-economic analysis of steam explosion, dilute sulfuric acid, ammonia fiber explosion and biological pretreatments of corn stover. Bioresource Technology, 232, 331–343.

Vasquez, M.C. Martínez, A. Castillo, E.F. Silva, E.E. (2019) Holistic approach for sustainability enhancing of hydrotreated aviation biofuels, through life cycle assessment: a Brazilian case study. Journal of Cleaners Production 237.

Ohgren, K., Bura, R., Lesnicki, G., Saddler, J., & Zacchi, G. (2007). A comparison between simultaneous saccharifification and fermentation and separate hydrolysis and fermentation using steam-pretreated corn stover. Process Biochemistry, 42, 834–839.

Uckun Kiran, E., & Liu, Y. (2015). Bioethanol production from mixed food waste by an effective enzymatic pretreatment. Fuel, 159, 463–469.

Sluiter, A., Hames, B., Ruiz, R. O., Scarlata, C., Sluiter, J., & Templeton, D. (2004). Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure, 1617, 1–16.

Han, W., Fang, J., Liu, Z. X., & Tang, J. H. (2016). Techno-economic evaluation of a combined bioprocess for fermentative hydrogen production from food waste. Bioresource Technology, 202, 107–112.

Leung, C. C. J., Cheung, A. S. Y., Zhang, A. Y. Z., Lam, K. F., & Lin, C. S. K. (2012). Utilisation of waste bread for fermentative succinic acid production. Biochemical Engineering Journal, 65, 10–15.

Han, W., Hu, Y. Y., Li, S. Y., Huang, J. G., Nie, Q. L., Zhao, H. T., & Tang, J. H. (2017). Simultaneous dark fermentative hydrogen and ethanol production from waste bread in a mixed packed tank reactor. Journal of Cleaner Production, 141, 608–611.

Kim, J. H., Lee, J. C., & Pak, D. (2011). Feasibility of producing ethanol from food waste. Waste Management, 31, 2121–2125.

Zabed, H., Sahu, J. N., Suely, A., Boyce, A. N., & Faruq, G. (2017). Bioethanol production from renewable sources: Current perspectives and technological progress. Renewable and Sustainable Energy Reviews, 71, 475–501.

Yu, J. M., Xu, Z. X., Liu, L., Chen, S. T., Wang, S. W., & Jin, M. J. (2019). Process integration for ethanol production from corn and corn stover as mixed substrates. Bioresource Technology, 279, 10–16.

Wang, J., Gao, Q., Zhang, H., & Bao, J. (2016). Inhibitor degradation and lipid accumulation potentials of oleaginous yeast Trichosporon cutaneum using lignocellulose feedstock. Bioresource Technology, 218, 892–901.

Xu, Y., & Wang, D. (2017). Integrating starchy substrate into cellulosic ethanol production to boost ethanol titers and yields. Applied Energy, 195, 196–203.

Mikulski, D., & Klosowski, G. (2018). Efficiency of dilute sulfuric acid pretreatment of distillery stillage in the production of cellulosic ethanol. Bioresource Technology, 268, 424–433.

Xu, Y., Zhang, M., Roozeboom, K., & Wang, D. (2018). Integrated bioethanol production to boost low-concentrated cellulosic ethanol without sacrificing ethanol yield. Bioresource Technology, 250, 299–305.

Erdei, B., Galbe, M., & Zacchi, G. (2013). Simultaneous saccharification and co-fermentation of whole wheat in integrated ethanol production. Biomass and Bioenergy, 56, 506–514.

Funding

This work was supported by National Key Research and Development Program-International Cooperation Project (2019YFE0124600); Zhejiang Education Department and Research Foundation from Hangzhou Dianzi University (2021R407075).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by X Chen, X Zheng, and Y Pei. The first draft of the manuscript was written by X Chen and W Han. J Huang, J Tang, P Hou, and W Han commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics Approval

This is an observational study. The XYZ Research Ethics Committee has confirmed that no ethical approval is required.

Consent to Participate

Not applicable.

Consent to Publish

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Zheng, X., Pei, Y. et al. Ethanol Production from the Mixture of Waste French Fries and Municipal Wastewater via Separate Hydrolysis and Fermentation. Appl Biochem Biotechnol 194, 6007–6020 (2022). https://doi.org/10.1007/s12010-022-04084-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-022-04084-3