Abstract

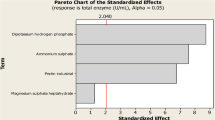

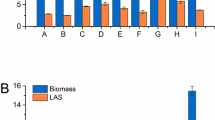

Aspergillus flavipes FP-500 grew up on submerged cultures using lemon peel as the only carbon source, developing several batch and pulsed fed-batch trials on a stirred tank reactor. The effect of carbon source concentration, reducing sugar presence and initial pH on exopectinase and endopectinase production, was analyzed on batch cultures. From this, we observed that the highest substrate concentration favored biomass (X max) but had not influence on the corresponding specific production (q p) of both pectinases; the most acid condition provoked higher endopectinase-specific productions but had not a significant effect on those corresponding to exopectinases; and reducing sugar concentrations higher than 1.5 g/L retarded pectinase production. On the other hand, by employing the pulsed fed-batch operation mode, we observed a prolonged growth phase, and an increase of about twofold on endopectinase production without a significant raise on biomass concentration. So, pulsed fed-batch seems to be a good alternative for obtaining higher endopectinase titers by using high lemon peel quantities without having mixing and repression problems to the system. The usefulness of unstructured kinetic models for explaining, under a theoretic level, the behavior of the fungus along the batch culture with regard to pectinase production was evident.

Similar content being viewed by others

Abbreviations

- μ max :

-

The specific growth rate of the microorganism. This parameter is calculated by the logistic model, by the corresponding algorithm, 1/h

- α:

-

The Luedeking–Piret parameter that indicates the enzyme production that is growth-related, or during the growth phase, U/gbiomass

- β:

-

The Luedeking–Piret parameter that indicates the enzyme production that is growth independent, occurs during the maintenance phase, U/h gbiomass

- q p :

-

The specific enzyme production, Uenzyme/gbiomass

References

Schäfer, T., Borchert, T. W., Nielsen, V. S., Skagerlind, P., Gibson, K., Wenger, K., & Xu, H. (2007). In R. Ulber & D. Sell (Eds.), White biotechnology, Industrial enzymes (pp. 59–131). Berlin: Springer.

Perrone, G., Susca, A., Cozzi, G., Ehrlich, K., Varga, J., Frisvad, J. C., & Samson, R. A. (2007). Biodiversity of Aspergillus species in some important agricultural products. Studies in Mycology, 59, 53–66.

Fontana, R. S., Salvador, S., & Moura da Silveira, M. (2005). Influence of pectin and glucose on growth and polygalacturonase production by Aspergillus niger in solid-state cultivation. Journal of Industrial Microbiology and Biotechnology, 32, 371–377.

Martínez-Trujillo, M. A., Arreguín-Rangel, L., García-Rivero, M., & Aguilar-Osorio, G. (2011). Use of fruit residues for pectinase production by Aspergillus flavipes FP-500 and Aspergillus terreus FP-370. Letters in Applied Microbiology, 53, 202–209.

Ramírez, O. T. (2004). In F. G. Bolívar Zapata (Ed.), Fundamentos y casos exitosos de la Biotecnología moderna, Ingeniería Bioquímica (pp. 249–297). México: El Manual Moderno.

Gibbs, P. A., Seviour, R. J., & Schmid, F. (2000). Growth of filamentous fungi in submerged culture: problems and possible solutions. Critical Reviews in Biotechnology, 20, 17–48.

Gummadi, S. N., & Kumar, D. S. (2008). Batch and fed batch production of pectin lyase and pectate lyase by novel strain Debaryomyces nepalensis in bioreactor. Bioresource Technology, 99, 874–881.

Martínez-Trujillo, A., Aranda, J. S., & Aguilar-Osorio, G. (2012). Polygalacturonases of Aspergillus flavipes FP-500: a kinetic analysis of batch culture systems based on unstructured models. International Journal of Chemical Reactor Engineering, 10(A61), 1–19.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428.

Göğüş, N., Hakgüder Taze, B., Demir, H., Tari, C., Ünlütürk, S., & Lahore, S. M. F. (2014). Evaluation of orange peel, an industrial waste, for the production of Aspergillus sojae polygalacturonase considering both morphology and rheology effects. Turkish Journal of Biology, 38, 537–548.

Mrudula, S., & Anitharaj, R. (2011). Pectinase production in solid state fermentation by Aspergillus niger using orange peel as substrate. Global Journal of Biotechnology & Biochemistry, 6, 64–71.

Patil, S. R., & Dayanand, A. (2006). Exploration of regional agrowastes for the production of pectinase by Aspergillus niger. Food Technology and Biotechnology, 44, 289–292.

Mamma, D., Kourtoglou, E., & Christakopoulos, P. (2008). Fungal multienzyme production on industrial by-products of the citrus-processing industry. Bioresource Technology, 99, 2373–2383.

Ruiz, H. A., Rodríguez Jasso, R. M., Rodríguez, R., Contreras Esquivel, J. C., & Aguilar, C. N. (2012). Pectinase production from lemon peel pomace as support and carbon source in solid-state fermentation column-tray bioreactor. Biochemical Engineering Journal, 65, 90–95.

Buyukkileci, A. O., Tari, C., & Fernandez Lahore, M. (2011). Enhanced production of exo-polygalacturonase from agro-based roducts by Aspergillus sojae. BioResources, 6, 3452–3468.

Tarango, V., Sánchez, V. E., & Pilosof, A. M. R. (2007). Combined effect of water activity depression and glucose addition on pectinases and protease production by Aspergillus niger. Biotechnological Letters, 19, 233–236.

Martínez-Trujillo, M. A., Aranda, J. S., Gómez-Sánchez, C., Trejo-Aguilar, B., & Aguilar-Osorio, G. (2009). Constitutive and inducible pectinolytic enzymes from Aspergillus flavipes FP-500 and their modulation by pH and carbon source. Brazilian Journal of Microbiology, 40, 40–47.

Bruno Bárcena, J. M., Lucca, M. E., Siñeriz, F., & Ramón, D. (2002). pH regulation of enzyme production in Aspergillus nidulans growing in aerobic batch fermenter. Biotechnological Letters, 24, 567–572.

Fontana, R. C., & Silveira, M. M. (2012). Influence of pectin, glucose, and pH on the production of endo- and exopolygalacturonase by Aspergillus oryzae in liquid medium. Brazilian Journal of Chemical Engineering, 29, 683–690.

Martínez-Trujillo, A., Aranda, J. S., & Aguilar-Osorio, G. (2008). Kinetic study on inducibility of polygalacturonases from Aspergillus flavipes FP-500. Electronic Journal of Biotechnology, 11, 1–8.

Acknowledgments

VEWM thanks COMECYT and EGG thanks CONACYT for the scholarship. This work was developed using funds from projects COMECYT EDOMEX-CO1-78011 and DGAPA IN219813.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wolf-Márquez, V.E., García-García, E., García-Rivero, M. et al. Batch and Pulsed Fed-Batch Cultures of Aspergillus flavipes FP-500 Growing on Lemon Peel at Stirred Tank Reactor. Appl Biochem Biotechnol 177, 1201–1215 (2015). https://doi.org/10.1007/s12010-015-1807-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1807-8