Abstract

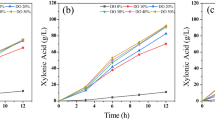

This work focuses on the kinetics of ethanol production by Scheffersomyces stipitis on xylose with the development of a mathematical model considering the effect of substrate and product concentrations on growth rate. Experiments were carried out in batch and continuous modes, with substrate concentration varying from 7.2 to 145 g L−1. Inhibitory effects on cell growth, substrate uptake, and ethanol production rates were found to be considerable. Kinetic parameters were obtained through linear and non-linear regression methods. Experiments in continuous mode were performed at different dilution rates to evaluate the inhibitory effect of ethanol. A mixed mathematical model which combined Andrews and Levenspiel's models, combining substrate and product inhibition, was used. A quasi-Newton routine was applied to obtain a more accurate fitting of kinetic parameters. The parameters such as cell to product factor (Y P/X) and limiting cell yield (Y X) were shown to be dependent on substrate concentration. The kinetic model fitted satisfactorily the experimental data.

Similar content being viewed by others

Abbreviations

- AA:

-

Acetic acid concentration (g L−1)

- K I :

-

Substrate inhibition coefficient (g L−1)

- K S :

-

Substrate saturation parameter (g L−1)

- m X :

-

Maintenance coefficient (g g−1 h−1)

- n :

-

Parameter describing product inhibition

- P :

-

Product concentration (g L−1)

- P f :

-

Final ethanol concentration (g L−1)

- P max :

-

Maximal product concentration when cell growth ceases (g L−1)

- S :

-

Substrate concentration (g L−1)

- S 0 :

-

Initial substrate concentration (g L−1)

- S f :

-

Final substrate concentration (g L−1)

- S*:

-

Substrate concentration at which the measured specific growth rate is maximum (g L−1)

- X :

-

Biomass concentration (g L−1)

- Xy:

-

Xylitol concentration (g L−1)

- Xyf :

-

Final xylitol concentration (g L−1)

- t T :

-

Fermentation total time (h)

- X 0 :

-

Initial biomass concentration (g L−1)

- X f :

-

Final biomass concentration (g L−1)

- D :

-

Dilution rate (h−1)

- r P :

-

Ethanol production rate (g L−1 h−1)

- r S :

-

Substrate uptake rate (g L−1 h−1)

- r X :

-

Cell growth rate (g L−1 h−1)

- Y P/X :

-

Cell to product conversion factor (g g−1)

- Y X :

-

Limiting cell yield (g g−1)

- Y X/S :

-

Biomass yield (g g−1)

- Y P/S :

-

Ethanol yield (g g−1)

- μ max :

-

Maximum specific growth rate as described by Monod's model (h−1)

- \( {\mu}_{{}_{\max}}^{\ast } \) :

-

The maximum specific growth rate related to each initial substrate concentration (h−1)

- μ X :

-

Specific growth rate (h−1)

- μ S :

-

Specific substrate uptake rate (h−1)

- μ P :

-

Specific ethanol production rate (h−1)

References

Ghaly, A. E., & El-Taweel, A. A. (1997). Kinetic modelling of continuos production of ethanol from cheese whey. Biomass and Bioenergy, 12(6), 461–472.

Prior, B. A., Kilian, S. G., & du Preez, J. C. (1989). Fermentation of d-xylose by the yeasts Candida shehatae and Pichia stipitis: prospects and problems. Process Biochemistry, 21–32.

Krishnan, M. S., Blanco, M., Shattuck, C. K., Nghiem, N. P., & Davison, B. H. (2000). Ethanol production from glucose and xylose by immobilized Zymomonas mobilis CP4(pZB5). Applied Biochemistry and Biotechnology, 86, 525–541.

Fu, N., Peiris, P., Markham, J., & Bavor, J. (2009). A novel co-culture process with Zymomonas mobilis and Pichia stipitis for efficient ethanol production in glucose/xylose mixtures. Enzyme and Microbial Technology, 45, 210–217.

Silva, J. P., Mussatto, S. I., Roberto, I. C., & Teixeira, J. A. (2012). Fermentation medium and oxygen transfer conditions that maximize the xylose conversion to ethanol by Pichia stipitis. Renewable Energy, 37, 259–265.

Mussatto, S. I., & Roberto, I. C. (2004). Optimal experimental condition for hemicellulosic hydrolyzate treatment with activated charcoal for xylitol production. BiotechnologyProgress, 20, 134–139.

Nigam, N. (2001). Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. Journal of Biotechnology, 87, 17–27.

Jeffries, T. W., & Van Vleet, J. R. H. (2009). Pichia stipitis genomics, transcriptomics, and gene clusters. FEMS Yeast Research, 9, 793–807.

Laplace, J. M., Delgenes, J. P., Moletta, R., & Navarro, J. M. (1991). Combined alcoholic fermentation of d-xylose and d-glucose by four selected microbial strain: process considerations in relation to ethanol tolerance. Biotechnology Letters, 13, 445–450.

Rouhollah, H., Iraj, N., Giti, E., & Sora, A. (2007). Mixed sugar fermentation by Pichia stipitis, Sacharomyces cerevisiae, and an isolated xylose fermenting Kluyveromyces marxianus and their co-cultures. African Journal of Biotechnology, 6, 1110–1114.

Pereira, F. B., Guimarães, P. M. R., Teixeira, J. A., & Domingues, L. (2010). Optimization of low cost medium for very high gravity ethanol fermentations by Saccharomyces cerevisiae using statistical experimental designs. Bioresource Technology, 101, 7856–7863.

Delgenes, J. P., Moletta, R., & Navarro, J. M. (1988). The ethanol tolerance of Pichia stipitisY7124 grown on a d-xylose, d-glucose and l-arabinose mixture. Journal of Fermentation Technology, 66, 417–422.

du Prezz, J. C., van Driessel, B., & Prior, B. A. (1989). The fermentation of d-xylose by Candida shehatae and Pichia stipitis at low dissolved oxygen level. Yeast, 5, 129–139.

Taniguchi, M., Tohma, T., Itaya, T., & Fuji, M. (1997). Ethanol production from a mixture of glucose and xylose by co-culture of Pichia stipitis and a respiratory-deficient mutant of Saccharomyces cerevisiae. Journal of Fermentation and Bioengineering, 83(84), 364–370.

Goldemberg, J., Coelho, S. T., Nastari, P. M., & Lucon, O. (2004). Ethanol learning curve—the Brazilian experience. Biomass & Bioenergy, 26, 301–304.

Costa, C. P., & Ferreira, M. C. (1991). Preservação de microrganismos. Review Brasil Microbiology, 22, 263–268.

Lee, S. S., Robinson, F. M., & Wang, H. Y. (1981). Rapid determination of yeast viability. Biotechnology and Bioengineering, 11, 641–649.

Balagurunathan, B., Jonnalagadda, S., Tan, L., & Srinivasan, R. (2012). Reconstruction and analysis of genome-scale metabolic model for Scheffersomyces stipitis. Microbial Cell Factories, 11, 27.

Lisha, K. P., & Sarkar, D. (2013). Dynamic flux balance analysis of batch fermentation: effect of genetic manipulations on ethanol production. Bioprocess and Biosystems Engineering. doi:10.1007/s00449-013-1027-y.

Liang, M., He, Q. P., Jeffries, T. W. and Wang, J. (2013). Elucidating xylose metabolism of Scheffersomyces stipitis by integrating principal component analysis with flux balance analysis. American Control Conference (ACC), Washington, DC, USA, June 17–19.

Garcia-Albornoz, M. A., & Nielsen, J. (2013). Application of genome-scale metabolic models in metabolic engineering. Industrial Biotechnology, 9(4), 203–214.

Roberto, I. C., Lacis, L. S., Barbosa, M. F. S., & Mancilha, I. M. (1991). Utilization of sugar cane bagasse hemicellulosic hydrolysate by Pichia stipitis for the production of ethanol. Process Biochemistry, 26, 15–21.

Barbosa, M. F. S., Medeiros, M. B., de Mancilha, Y. M., Schneider, H., & Lee, H. (1988). Screening of yeasts for production of xylitol from d-xylose and some factors which affect xylitol yield in Candida guilliermondii. Journal of Industrial Microbiology & Biotechnology, 3, 241–251.

Amaral Collaço, M. T., Girio, F. M., & Peito, M. A. (1989). Utilization of the hemicelluloses fraction of agro-industrial residues by yeasts. In: Enzyme systems for lignocellulosic degradation. London: Elsevier, 221:230.

Parajó, J. C., Dominguez, H., & Dominguez, J. M. (1996). Production of xylose from concentrated wood hydrolysates by Debaryomyces hansenii: effect of the initial cell concentration. Biotechnology Letters, 18, 593–598.

Slininger, P. J., Bothast, R. J., Okos, M. R., & Ladisch, M. R. (1985). Comparative evaluation of ethanol production by xylose-fermenting yeasts presented high xylose concentrations. Biotechnology Letters, 6, 431–436.

Linko, Y. Y., Kautola, S., Uotila, S., & Linko, P. (1986). Alcoholic fermentation of d-xylose by immobilized Pichia stipitis yeast. Biotechnology Letters, 8/1, 47–52.

Calleja, G. B., Levy-Rick, S., Mahmourides, G., Labelle, J., & Schneider, H. (1984). Rapid process for the conversion of xylose to ethanol. Canadian Patent, 1, 245–266.

Dellweg, H., Rizzi, M., Methner, H., & Debus, D. (1984). Xylose fermentation by yeasts. Biotechnology Letters, 6, 395–400.

Hinman, N. D., Wright, J. D., Hoagland, W., & Wyman, C. E. (1989). Xylose fermentation: an economic analysis. Applied Biochemistry and Biotechnology, 20/21, 391–401.

Caspeta, L., Shoaie, S., Agren, R., Nookaew, I., & Nielsen, J. (2012). Genome-scale metabolic reconstructions of Pichia stipitis and Pichia pastoris and in silico evaluation of their potentials. BMC Systems Biology, 6, 24.

Atala, D. I. P., Costa, A., Maciel, R., & Maugeri, F. (2001). Kinetics of ethanol fermentation with high biomass concentration considering the effect of temperature. Applied Biochemistry and Biotechnology, 91–93(1–9), 353–366.

Andrade, R. R., Rivera, E. C., Costa, A., Atala, D. I. P., Maugeri, F., & Maciel, R. (2007). Estimation of temperature dependent parameters of a batch alcoholic fermentation process. Applied Biochemistry and Biotechnology, 136(140), 753–763.

Rivera, E. C., Costa, A., Atala, D. I. P., Maugeri, F., Maciel, R. W., & Filho, R. M. (2006). Evaluation of optimization techniques for parameter estimation: application to ethanol fermentation considering the effect of temperature. Process Biochemistry, 41, 1682–1687.

Acknowledgments

The authors acknowledge Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farias, D., de Andrade, R.R. & Maugeri-Filho, F. Kinetic Modeling of Ethanol Production by Scheffersomyces stipitis from Xylose. Appl Biochem Biotechnol 172, 361–379 (2014). https://doi.org/10.1007/s12010-013-0546-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-013-0546-y