Abstract

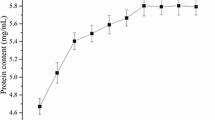

The present study is an attempt to demonstrate the feasibility of sal (Shorea robusta) deoiled cake—a forest-based industrial by-product—as a cheaper media supplement for augmented protease production from Aeromonas sp. S1 and application of protease in the treatment of kitchen wastewater. Under optimized conditions, protease production could successfully be enhanced to 5.13-fold (527.5 U mL−1) on using sal deoiled seed cake extract (SDOCE), as medium additive, compared to an initial production of 102.7 U mL−1 in its absence. The culture parameters for optimum production of protease were determined to be incubation time (48 h), pH (7.0), SDOCE concentration (3 % (v/v)), inoculum size (0.3–0.6 % (v/v)), and agitation rate (100 rpm). The enzyme was found to have an optimum pH and temperature of 8.0 and 60 °C, respectively. The protease preparation was tested for treatment of organic-laden kitchen wastewater. After 96 h of wastewater treatment under static condition, enzyme preparation was able to reduce 74 % biological oxygen demand, 37 % total suspended solids, and 41 % oil and grease. The higher and improved level of protease obtained using sal deoiled seed cake-based media hence offers a new approach for value addition to this underutilized biomass through industrial enzyme production. The protease produced using this biomass could also be used as pretreatment tool for remediation of organic-rich food wastewater.

Similar content being viewed by others

References

Pandey, A., Soccol, C. R., Nigam, P., & Soccol, V. T. (2000). Biotechnological potential of agro-industrial resources I: sugarcane bagasse. Bioresource Technology, 74, 69–80.

Kumar, P. K. A., et al. (2007). Bacterial synthesis of poly(hydroxybutyrate-co-hydroxyvalerate) using carbohydrate-rich mahua (Madhuca sp.) flowers. Journal of Applied Microbiology, 103, 204–209.

Mahanta, N., Gupta, A., & Khare, S. K. (2008). Production of protease and lipase by solvent tolerant Pseudomonas aeruginosa Pse A in solid-state fermentation using Jatropha curcus seed cake as substrate. Bioresource Technology, 99, 1729–1735.

Dwivedi, P., Vivekanand, V., Ganguly, R., & Singh, R. P. (2009). Parthenium sp. as a plant biomass for the production of alkalitolerant xylanase from mutant Penicillium oxalicum SAUE-3.510 in submerged fermentation. Biomass and Bioenergy, 33, 581–588.

Rajagopalan, G., & Krishnan, C. (2009). Optimization of agro-residual medium for α-amylase production from a hyper-producing Bacillus subtilis KCC103 in submerged fermentation. Journal of Chemical Technology and Biotechnology, 84, 618–625.

Mahdi, B. A., Bhattacharya, A., & Gupta, A. (2012). Enhanced lipase production from Aeromonas sp. S1 using Sal deoiled seed cake as novel natural substrate for potential application in dairy wastewater treatment. Journal of Chemical Technology and Biotechnology, 87, 418–426.

Patnaik, S., & Mohaptra, MD. Sal seed—a losing proposition or an untapped resource? Community forestry. http://www.banajata.org/pdf/articles. Accessed 03 May 2012.

Kant, P., Shuirong, W., Chaliha, S., & Jasrotia, R. (2011). Going beyond Jatropha: can an expanded land and feedstock base help India meet its ambitious biodiesel target? IGREC working paper IGREC-22, Institute of Green Economy, New Delhi. http://igrec.in/GoingBeyondJatropha.pdf. Accessed 18 May 2012.

Chandra, R., Vijay, V. K., & Subbarao, P. M. V. (2006). A study on biogas generation from non-edible oil seed cakes: potential and prospects in India (pp. 21–23). Bangkok, Thailand: 2nd Joint International Conference on Sustainable Energy and Environment. E-007 (P).

Gupta, A., Roy, I., Patel, R. K., Singh, S. P., Khare, S. K., & Gupta, M. N. (2005). One-step purification and characterization of an alkaline protease from haloalkaliphilic Bacillus sp. Journal of Chromatography. A, 1075, 103–108.

Bajaj, B. K., & Sharma, P. (2011). An alkali-thermotolerant extracellular protease from a newly isolated Streptomyces sp. DP2. New Biotechnology, 28, 725–732.

Turkdogan-Aydinol, F. I., Yetilnezsoy, K., & Comez, S. (2011). Effect of extracellular enzyme activity on digestion performance of mesophilic UASB reactor treating high-strength municipal wastewater. Bioprocess Biosystem Engineering, 34, 389–401.

Zouboulis, A. I., Loukidou, M. X., & Christodoulou, K. (2001). Enzymatic treatment of sanitary landfill leachate. Chemosphere, 44, 1103–1108.

Gupta, A., & Khare, S. K. (2007). Enhanced production and characterization of a solvent stable protease from solvent tolerant Pseudomonas aeruginosa PseA. Enzyme and Microbial Technology, 42, 11–16.

Kirschman, H. D., & Pomeroy, R. (1949). Determination of oil in oil-field wastewaters. Analytical Chemistry, 21, 793–797.

APHA. (1998). Standard methods for the examination of water and wastewater (20th ed.). Washington, DC: American Public Health Association, American Water Works Association, and Water Environment Federation.

Fong, K. P. Y., & Tan, H. M. (2000). Isolation of a microbial consortium from activated sludge for the biological treatment of food waste. World Journal of Microbiology and Biotechnology, 16, 441–443.

Baskar, G., Deeptha, V. T., & Rahman, A. A. (2009). Treatment of wastewater from kitchen in an institution hostel mess using constructed wetland. International Journal of Recent Trends in Engineering, 1, 54–58.

Central pollution control board, India. http://cpcb.nic.in/Industry-Specific-Standards/Effluent/433-1.pdf. Accessed 18 May 2012.

Kaur, S., Vohra, R. M., Kapoor, M., Beg, Q. K., & Hoondal, G. S. (2001). Enhanced production and characterization of a highly thermostable alkaline protease from Bacillus sp. P-2. World Journal of Microbiology and Biotechnology, 17, 125–129.

Kumar, C. G., & Parrack, P. (2003). Arrowroot (Marantha arundinacea) starch as a new low-cost substrate for alkaline protease production. World Journal of Microbiology and Biotechnology, 19, 757–762.

Beena, S. P., Basheer, S. M., Bhat, S. G., & Chandrasekaran, M. (2011). Garcina cambogia leaf and sea water for tannase production by marine Aspergillus awamorri BTMFW032 under slurry state fermentation. Natural Product Communications, 6, 1933–1938.

Gupta, R., Beg, Q. K., Khan, S., & Chauhan, B. (2002). An overview on fermentation, downstream processing and properties of microbial alkaline proteases. Applied Microbiology and Biotechnology, 60, 381–395.

Gandhi, V. M., Cherian, K. M., & Mulky, M. J. (1994). Detoxification of castor seed meal by interaction with sal seed meal. Journal of the American Oil Chemists' Society, 71, 827–831.

Oberoi, R., Beg, Q. K., Puri, S., Saxena, R. K., & Gupta, R. (2001). Characterization and wash performance analysis of an SDS resistant alkaline protease from a Bacillus sp. World Journal of Microbiology and Biotechnology, 17, 493–497.

Puri, S., Beg, Q. K., & Gupta, R. (2002). Optimization of alkaline protease production from Bacillus sp. using response surface methodology. Current Microbiology, 44, 286–290.

Srividya, S., & Majumdar, M. (2011). Influence of process parameters on the production of detergent compatible alkaline protease by a newly isolated Bacillus sp. Y. Turkish Journal of Biology, 35, 177–182.

Bossi, A., Rinalducci, S., Zolla, L., Antonioli, P., Righetti, G., & Zapparoli, G. (2007). Effect of tannic acid on Lactobacillus hilgardii analysed by a proteomic approach. Journal of Applied Microbiology, 102, 787–795.

Singh, S. K., Singh, S. K., Tripathi, V. R., Khare, S. K., & Garg, S. K. (2011). Comparative one-factor-at-a-time, response surface (statistical) and bench-scale bioreactor level optimization of thermoalkaline protease production from a psychrotrophic Pseudomonas putida SKG-1 isolate. Microbial Cell Factories, 10, 114.

Prakasham, R. S., Rao, C. S., & Sarma, P. N. (2006). Green gram husk—an inexpensive substrate for alkaline protease production by Bacillus sp. in solid state fermentation. Bioresource Technology, 97, 1449–1454.

Abusham, R. A., Rahman, R. N. Z. R. A., Salleh, A. B., & Basri, M. (2009). Optimization of physical factors affecting the production of thermo-stable organic solvent-tolerant protease from a newly isolated halo tolerant Bacillus subtilis strain Rand. Microbial Cell Factories, 8, 20.

Divakar, K., Priya, J. D. A., & Gautam, P. (2010). Purification and characterization of thermostable organic solvent stable protease from Aeromonas veronii PG01. Journal of Molecular Catalysis B: Enzymatic, 66, 311–318.

Bhattacharya, A., Saini, V., & Gupta, A. (2012). Novel application of Mahua (Madhuca sp.) flowers for augmented protease production from Aeromonas sp. S1. Natural Product Communications, 7, 1359–1362.

Rahman, R. N. Z. R., Geok, L. P., Basri, M., & Salleh, A. B. (2005). Physical factors affecting the production of organic solvent-tolerant protease by Pseudomonas aeruginosa strain K. Bioresource Technology, 96, 429–436.

Genckal, H., & Tari, C. (2006). Alkaline protease production from alkalophilic Bacillus sp. isolated from natural habitats. Enzyme and Microbial Technology, 39, 703–710.

Venil, C. K., & Lakshmanaperumalsamy, P. (2009). Application of response surface methodology in medium optimization for protease production by the new strain of Serratia marcescens SB08. Polish Journal of Microbiology, 58, 117–124.

Potumarthi, R., Subhakar, C., & Jetty, A. (2007). Alkaline protease production by submerged fermentation in stirred tank reactor using Bacillus licheniformis NCIM-2042: effect of aeration and agitation regimes. Biochemical Engineering Journal, 34, 185–192.

Jasvir, S., Gill, N., Devasahyam, G., & Sahoo, D. K. (1999). Studies on alkaline protease produced by Bacillus sp. NG312. Applied Biochemistry and Biotechnology, 76, 57–63.

Joo, H. S., Kumar, C. G., Park, G. C., Kim, K. T., Paik, S. R., & Chang, C. S. (2002). Optimization of the production of an extracellular alkaline protease from Bacillus horikoshii. Process Biochemistry, 38, 155–159.

Cammarota, M. C., & Freire, D. M. G. (2006). A review on hydrolytic enzymes in the treatment of wastewater with high oil and grease content. Bioresource Technology, 97, 2195–2210.

Cammarota, M. C., Teixeira, G. A., & Freire, D. M. G. (2001). Enzymatic prehydrolysis and anaerobic degradation of wastewaters with high oil contents. Biotechnology Letters, 23, 1591–1595.

Jung, F., Cammarota, M. C., & Freire, D. M. G. (2002). Impact of enzymatic pre-hydrolysis on batch activated sludge systems dealing with oily wastewaters. Biotechnology Letters, 24, 1797–1802.

Leal, M. C. M. R., Freire, D. M. G., Cammarota, M. C., & Jr Sant’Anna, G. L. (2006). Effect of enzymatic hydrolysis on anaerobic treatment of dairy wastewater. Process Biochemistry, 41, 1173–1178.

Acknowledgments

The financial support provided by TRIFED (Tribal Co-Operative Marketing and Development Federation of India Limited), Ministry of Tribal Affairs, Government of India is gratefully acknowledged. A.B. is grateful to the University Grants Commission (UGC), Government of India for a Senior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saini, V., Bhattacharya, A. & Gupta, A. Effectiveness of Sal Deoiled Seed Cake as an Inducer for Protease Production from Aeromonas sp. S1 for its Application in Kitchen Wastewater Treatment. Appl Biochem Biotechnol 170, 1896–1908 (2013). https://doi.org/10.1007/s12010-013-0323-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-013-0323-y