Abstract

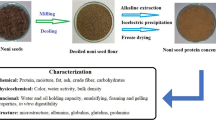

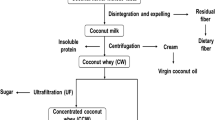

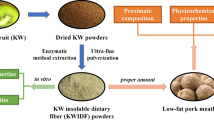

Virgin coconut oil (VCO) has been gaining popularity in recent times. During its production, byproducts such as coconut skim milk and insoluble protein are obtained which are underutilized or thrown away to the environment at present. This study deals with utilization of these byproducts to obtain a value-added product, namely, coconut protein powder. When coconut milk was subjected to centrifugation, three phases, namely, fat phase (coconut cream), aqueous phase (coconut skim milk), and solid phase (insoluble protein) were obtained. The coconut skim milk and insoluble protein were mixed and homogenized before spray drying to obtain a dehydrated protein powder. The proximate analysis of the powder showed high protein content (33 % w/w) and low fat content (3 % w/w). Protein solubility was studied as a function of pH and ionic content of solvent. Functional properties such as water hydration capacity, fat absorption capacity, emulsifying properties, wettability, and dispersibility of coconut protein powder were evaluated along with morphological characterization, polyphenol content, and color analysis. Coconut protein powder has shown to have good emulsifying properties and hence has potential to find applications in emulsified foods. Sensory analysis showed high overall quality of the product, indicating that coconut protein powder could be a useful food ingredient.

Similar content being viewed by others

References

Hagenmaier, R. N., Carter, C. M., & Mattil, K. F. (1973). Journal of Food Science, 38, 516–518.

Raghavendra S. N., Raghavarao, K. S. M. S., K Venkatesh Murthy, Rastogi N. K., Jayaprakashan S. G., Bhat K. K., and Vasanthkumar A. K. (2009). A process for the preparation of Virgin Coconut Oil. Indian Patent # 443/DEL/2009.

Raghavendra, S. N., & Raghavarao, K. S. M. S. (2010). Journal of Food Engineering, 97(3), 341–347.

Raghavendra, S. N, & Raghavarao, K. S. M. S. (2011). J Am Oil Chem Soc, 88(4), 481–487.

Hagenmaier, R. N., Carter, C. M., & Mattil, K. F. (1975). Journal of Food Science, 40, 717–720.

Kwon, K. S., Bae, D., Park, K. H., & Rhee, K. C. (1996). Journal of Food Science, 61, 753–756.

Sreenivasan, A., & Rajasekharan, N. (1967). Journal of Food Science & Technology, 4, 59–62.

Onsaard, E., Vittayanont, M., Srigam, S., & McClement, J. D. (2005). Journal of Agricultural and Food Chemistry, 53, 5747–5753.

Raghavendra, S. N., Rastogi, N. K., Raghavarao, K. S. M. S., & Tharanathan, R. N. (2004). European Food Research and Technology, 218, 563–567.

Raghavendra, S. N., Ramachandra Swamy, S. R., Rastogi, N. K., Raghavarao, K. S. M. S., Kumar, S., & Tharanathan, R. N. (2006). Journal of Food Engineering, 72, 281–286.

Moure, A., Sineiro, J., Domınguez, H., & Parajo, J. C. (2006). Food Research International, 39, 945–963.

Souza, C. R. F., & Oliveria, W. P. (2006). Drying Technology, 24(6), 735–749.

AOAC. (2000). Official method of analysis (17th ed.). Washington DC, USA: Association of Official Analytical Chemists.

Tang, C. (2007). Journal of Food Engineering, 82, 568–576.

Bradford, M. (1976). Analytical Biochemistry, 72, 248–254.

Quinn, J. R., & Paton, D. (1979). Cereal Chemistry, 56, 38–40.

Wang, J. C., & Kinsella, J. E. (1976). Journal of Food Science, 41, 286–292.

Pearce, K. N., & Kinsella, J. E. (1978). Journal of Agricultural and Food Chemistry, 26, 716–723.

Niro Atomizer Ltd (Denmark) Dairy Research Group (1978). Analytical methods for dry milk products. 4th ed. Copenhagen, Denmark: A/S Niro Atomizer. pp 26–33.

Jinapong, N., Suphantharika, M., & Jamnong, P. (2008). Journal of Food Engineering, 84, 194–205.

Kumatzawa, S., Hamasaka, T., & Nakayama, T. (2004). Food Chemistry, 84, 329–339.

Laemmli, U. K. (1970). Nature, 227, 680–685.

Edger Chambers, Mona Baker Wolf, ASTM Committee E-18 on Sensory Evaluation of Materials and Products (1996). Sensory testing methods (Issue 26 of ASTM manual series), 2nd Ed. E. Chambers and M. B. Wolf, (eds.). ASTM International. pp. 54–72.

Stone, H., & Sidel, J. (1998). Food Technology, 52, 48–52.

Hagenmaier, R. N., Mattil, K. F., & Carter, C. M. (1974). Journal of Food Science, 39, 196–199.

Anandharamakrishnan, C., Rielly, C. D., & Stapley, A. G. F. (2008). Lebensmittel-Wissenschaft und Technologie, 41, 270–277.

Pelegrine, D. H. G., & Gasparetto, C. A. (2005). Lebensmittel-Wissenschaft und Technologie, 38, 77–80.

Damodaran, S. (1997). in Food proteins and their applications, (Paraf, A. ed.), Marcel Dekker, New York pp. 1–21.

Al-Kahtani, H. A., & Abou-Arab, A. A. (1993). Cereal Chemistry, 70, 619–626.

Naczk, M., & Shahidi, F. (1997). American Chemical Society (Symposium series 662) Washington DC, pp.186–208.

Acknowledgements

Authors wish to thank the Director, CFTRI, for the encouragement and infrastructural facilities at the institute. Thanks are also due to Dr. Maya Prakash for sensory analysis. The authors, Aduja Naik and SN Raghavendra, acknowledge UGC and CSIR, Government of India for providing the UGC-SRF and CSIR-SRF fellowship, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naik, A., Raghavendra, S.N. & Raghavarao, K.S.M.S. Production of Coconut Protein Powder from Coconut Wet Processing Waste and its Characterization. Appl Biochem Biotechnol 167, 1290–1302 (2012). https://doi.org/10.1007/s12010-012-9632-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9632-9