Abstract

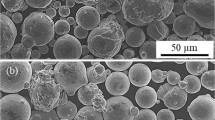

Components produced by direct metal laser sintering routinely contain porosities. This work aims to examine the various kinds of pores produced by laser powder bed fusion and compares various techniques for determining part density for the components manufactured using optimum parameters with various volumetric energy densities for Inconel 718 nickel-based superalloy. The porosity rate was quantified using three different techniques: Helium pycnometer, Archimedes method and micrographic observation. When comparing these techniques, it was found that the Archimedes method and the helium pycnometer technique produced comparable results, while the micrographic observations consistently underestimated the porosity rate. The relationship between porosity and mechanical properties is evaluated. The laser powder bed fusion additively manufactured Inconel 718 samples were able to attain high levels of densification, approximately 99.28% while maintaining a low porosity rate of around 0.47% and exhibited notable mechanical strength, including an ultimate tensile strength of 1246.984 MPa.

Similar content being viewed by others

References

Harun, W.S.W., Manam, N.S., Kamariah, M.S.I.N., Sharif, S., Zulkifly, A.H., Ahmad, I., Miura, H.: A review of powdered additive manufacturing techniques for Ti-6al-4v biomedical applications. Powder Technol. 331, 74–97 (2018). https://doi.org/10.1016/j.powtec.2018.03.010

Kohale, V., Jawade, S., Kakandikar, G.: Investigation on mechanical behaviour of inconel 718 manufactured through additive manufacturing. Int. J. Interact. Des. Manuf. 17, 1645–1651 (2023). https://doi.org/10.1007/s12008-022-01183-7

Dwivedi, A., Khurana, M.K., Bala, Y.G.: Effect of parameters on quality of IN718 parts using laser additive manufacturing. Mater. Sci. Technol. 40(8), 1–16 (2024). https://doi.org/10.1177/02670836231219865

Wang, P., Tan, X., He, C., Nai, M.L.S., Huang, S., Tor, S.B., Wei, J.: Scanning optical microscopy for porosity quantification of additively manufactured components. Addit. Manuf. 21, 350–358 (2018). https://doi.org/10.1016/j.addma.2018.03.019

Kasperovich, G., Haubrich, J., Gussone, J., Requena, G.: Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. JMADE. 105, 160–170 (2016). https://doi.org/10.1016/j.matdes.2016.05.070

Nguyen, H.D., Pramanik, A., Basak, A.K., Dong, Y., Prakash, C., Debnath, S., Shankar, S., Jawahir, I.S., Dixit, S., Buddhi, D.: A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 18, 4641–4661 (2022). https://doi.org/10.1016/j.jmrt.2022.04.055

Li, W., Liu, J., Zhou, Y., Li, S., Wen, S., Wei, Q., Yan, C., Shi, Y.: Effect of laser scanning speed on a Ti-45Al-2Cr-5Nb alloy processed by selective laser melting: Microstructure, phase and mechanical properties. J. Alloys Compd. 688, 626–636 (2016). https://doi.org/10.1016/j.jallcom.2016.07.206

Hosseini, E., Popovich, V.A.: A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 30, 100877 (2019). https://doi.org/10.1016/j.addma.2019.100877

Bean, G.E., Witkin, D.B., McLouth, T.D., Patel, D.N., Zaldivar, R.J.: Effect of laser focus shift on surface quality and density of Inconel 718 parts produced via selective laser melting. Addit. Manuf. 22, 207–215 (2018). https://doi.org/10.1016/j.addma.2018.04.024

Read, N., Wang, W., Essa, K., Attallah, M.M.: Selective laser melting of AlSi10Mg alloy : Process optimisation and mechanical properties development. Mater. Des. 65, 417–424 (2015). https://doi.org/10.1016/j.matdes.2014.09.044

Gong, H., Rafi, K., Gu, H., Starr, T., Stucker, B.: Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes Addit. Manuf. 1–4(87), 98 (2014). https://doi.org/10.1016/j.addma.2014.08.002

Abele, E., Kniepkamp, M.: Analysis and optimisation of vertical surface roughness in micro selective laser melting Analysis and optimisation of vertical surface roughness in micro selective laser melting. Surf. Topogr. Metrol. Prop. (2015). https://doi.org/10.1088/2051-672X/3/3/034007

Singhal, T.S., Jain, J.K., Kumar, M., Bhojak, V., Saxena, K.K., Buddhi, D., Prakash, C.: A comprehensive comparative review: welding and additive manufacturing. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-022-01152-0

Qi, H., Azer, M., Ritter, A.: Studies of Standard Heat Treatment Effects on Microstructure and Mechanical Properties of Laser Net Shape Manufactured. Metall. Mater. Trans. A 40, 2410–2422 (2009). https://doi.org/10.1007/s11661-009-9949-3

Li, W., Liu, W., Saleheen, K.M., Liu, H., Xia, Y., Al-Hammadi, G., Xue, L., Wang, F., Song, X., Zhang, Y.: Research and prospect of on-line monitoring technology for laser additive manufacturing. Int. J. Adv. Manuf. Technol. 125, 25–46 (2023). https://doi.org/10.1007/s00170-022-10758-3

Khairallah, S.A., Anderson, A.T., Rubenchik, A., King, W.E., et al.: Laser powder-bed fusion additive manufacturing : Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 108, 36–45 (2016). https://doi.org/10.1016/j.actamat.2016.02.014

Lun, C., Leung, A., Marussi, S., Atwood, R.C., Lee, P.D., Towrie, M., Withers, P.J.: Dynamics in laser additive manufacturing. Nat. Commun. 9, 1355 (2018). https://doi.org/10.1038/s41467-018-03734-7

Riedlbauer, D., Scharowsky, T., Singer, R.F., Steinmann, P., Körner, C., Mergheim, J.: Macroscopic simulation and experimental measurement of melt pool characteristics in selective electron beam melting of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 88, 1309–1317 (2017). https://doi.org/10.1007/s00170-016-8819-6

Martin, A.A., Calta, N.P., Khairallah, S.A., Wang, J., Depond, P.J., Fong, A.Y., Thampy, V., Guss, G.M., Kiss, A.M., Stone, K.H., Tassone, C.J., Weker, J.N., Toney, M.F., Buuren, T.V., Matthews, M.J.: Dynamics of pore formation during laser powder bed fusion additive manufacturing. Nat. Commun. 10, 1–10 (2019). https://doi.org/10.1038/s41467-019-10009-2

Zhao, C., Fezzaa, K., Cunningham, R.W., Wen, H., Carlo, F.D., Chen, L., Rollett, A.D., Sun, T.: Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci. Rep. 7, 1–11 (2017). https://doi.org/10.1038/s41598-017-03761-2

Yonehara, M., Kato, C., Ikeshoji, T.T., Takeshita, K., Kyogoku, H.: Correlation between surface texture and internal defects in laser powder–bed fusion additive manufacturing. Sci. Rep. 11, 1–10 (2021). https://doi.org/10.1038/s41598-021-02240-z

Debroy, T., Wei, H.L., Zuback, J.S., Mukherjee, T., Elmer, J.W., Milewski, J.O., Beese, A.M., Wilson-Heid, A., De, A., Zhang, W.: Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 92, 112–224 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.001

Fabbro, R.: Melt pool and keyhole behaviour analysis for deep penetration laser welding. J. Phys. D Appl. Phys. 43, 445501 (2010). https://doi.org/10.1088/00223727/43/44/445501

Wits, W.W., Carmignato, S., Zanini, F., Vaneker, T.H.J.: Porosity testing methods for the quality assessment of selective laser melted parts. CIRP Ann. Manuf. Technol. 65, 201–204 (2016). https://doi.org/10.1016/j.cirp.2016.04.054

Marques, A., Cunha, Â., Silva, M.R., Osendi, M.I., Silva, F.S., Carvalho, Ó., Bartolomeu, F.: Inconel 718 produced by laser powder bed fusion: An overview of the influence of processing parameters on microstructural and mechanical properties. Int. J. Adv. Manuf. Technol. 121, 5651–5675 (2022). https://doi.org/10.1007/s00170-022-09693-0

Xia, M., Gu, D., Yu, G., Dai, D., Chen, H., Shi, Q.: Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int. J. Mach. Tools Manuf 116, 96–106 (2017). https://doi.org/10.1016/j.ijmachtools.2017.01.005

Spierings, A.B., Schneider, M., Eggenberger, R.: Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 5, 380–386 (2011). https://doi.org/10.1108/13552541111156504

Sonawane, A., Roux, G., Blandin, J., Despres, A., Martin, G.: Materialia Cracking mechanism and its sensitivity to processing conditions during laser powder bed fusion of a structural aluminum alloy. Materialia. 15, 100976 (2021). https://doi.org/10.1016/j.mtla.2020.100976

Pastre, M.A.D., Quinsat, Y., Lartigue, C.: Effects of additive manufacturing processes on part defects and properties: A classification review. Int. J. Interact. Des. Manuf. 16, 1471–1496 (2022). https://doi.org/10.1007/s12008-022-00839-8

STM International: Standard test method for density of powder metallurgy (PM) materials containing less than two percent porosity. B311–13, 22 9414232 (2016)

Porous Materials INC 2020. https://pmiapp.com/products/pyc-100a/ (2020)

Wolff, S.J., Lin, S., Faierson, E.J., Liu, W.K., Wagner, G.J., Cao, J.: A framework to link localized cooling and properties of directed energy deposition (DED)-processed Ti-6Al-4V. Acta Mater. 132, 106–117 (2017). https://doi.org/10.1016/j.actamat.2017.04.027

Arvieu, C., Guen, C., Le, E., Lacoste, E.: Relative density of SLM-produced aluminum alloy parts: Interpretation of results. J. Manuf. Mater. Process. 4(3), 83 (2020). https://doi.org/10.3390/jmmp4030083

IOIML: International Alcoholometric Tables (2019)

Yan, F., Xiong, W., Faierson, E.J.: Grain structure control of additively manufactured materials. Materials. 10(11), 1260 (2017). https://doi.org/10.3390/ma10111260

Cherry, J.A., Davies, H.M., Mehmood, S., Lavery, N.P., Brown, S.G.R., Sienz, J.: Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. IJAMT. 76, 869–879 (2015). https://doi.org/10.1007/s00170-014-6297-2

Campanelli, S.L., Contuzzi, N., Angelastro, A., Ludovico, A.D.: Capabilities and performances of the selective laser melting process. In: Joo, M. (ed.) New Trends in Technologies: Devices, Computer, Communication and Industrial Systems. Sciyo (2010). https://doi.org/10.5772/10432

Tang, C., Tan, J.L., Wong, C.H.: Heat and mass transfer a numerical investigation on the physical mechanisms of single track defects in selective laser melting. Int. J. Heat Mass Transf. 126, 957–968 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.073

Tucho, W.M., Cuvillier, P., Kverneland, A.S., Hansen, V.: Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater. Sci. Eng. A 689, 220–232 (2017). https://doi.org/10.1016/j.msea.2017.02.062

Al-Maharma, A.Y., Patil, S.P., Markert, B.: Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express. 7(12), 122001 (2020). https://doi.org/10.1088/2053-1591/abcc5d

Acknowledgements

The authors are grateful to the Laser additive manufacturing lab, MSME Bhubaneswar and IIT Kanpur India for allowing us to conduct the LPBF additive manufacturing experiments.

Funding

No funding was received.

Author information

Authors and Affiliations

Contributions

This work was supported by the MNNIT Allahabad. Aman Dwivedi conceived the study design, data acquisition, experiments, data analysis and wrote the manuscript. M. K. Khurana and Y. G. Bala read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The first author of the article, on behalf of all the authors, declares that there are no potential conflicts of interest associated with the article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dwivedi, A., Khurana, M.K. & Bala, Y.G. A comparative study of porosity rate measurement methods and influence of energy density in Inconel 718 produced by laser powder bed fusion additive manufacturing process. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01875-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01875-2