Abstract

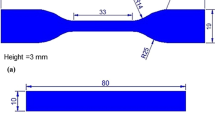

Fused Deposition Modelling (FDM) 3D printing has become popular in recent years due to its affordability, accessibility, and ability to rapidly fabricate complex geometries as observed in turbomachinery applications. Acrylonitrile Butadiene Styrene (ABS) is one widely used material in FDM 3D printing due to its durability, heat resistance, and mechanical properties. Researchers have attempted to investigate possibilities of 3D printed impeller using ABS and its composites. Impeller is a complex design in which the thickness of different features varies from 1 mm onwards and these features can orient in different directions. Orientation of parts or features has a significant impact on strength during 3D printing. While past studies in 3D printinghave studied the effects of various process parameters on 3D printed parts, limited research has focused specifically on the effect of build orientation of thin ABS parts. This study aims addressing this research gap by analysing thin ABS parts3D printed in different build orientations. The literature review provides a comprehensive background on FDM 3D printing, highlighting its advantages, limitations, and applications. Literature review highlights the effect of build orientation on mechanical properties of 3D printed parts. This research paper presents an analysis of tensile test results of FDM 3D printed thin ABS parts in various build orientations. The aim of this study is to understand the effect of build orientation on the tensile strength of thin ABS 3D printed parts. Five different build orientations are considered, including horizontal, horizontal inclined at 45°, vertical, vertical inclined at 45°, and sideways. Tensile tests are performed on these specimens using standardized protocols. The results of the comparative analysis revealed notable variations in the mechanical properties among the different build orientations. The sideways build orientation exhibited the highest ultimate load and ultimate tensile strength, followed by the horizontal-45° and horizontal build orientations. The vertical-45° and vertical build orientations demonstrated lower tensile strength in comparison.

Similar content being viewed by others

Data availability

The manuscript has no associated data or data will not be deposited.

References

Gibson, I., Rosen, D.W., Stucker, B.: Additive manufacturing technologies. Springer, Berlin (2010)

Peterson, A.M.: Review of acrylonitrile butadiene styrene in fused filament fabrication: a plastics engineering-focused perspective. Addit. Manuf. 27, 363–371 (2019). https://doi.org/10.1016/j.addma.2019.03.030

Rajan, K., Samykano, M., Kadirgama, K., et al.: Fused deposition modeling: process, materials, parameters, properties, and applications. Int. J. Adv. Manuf. Technol. 120, 1531–1570 (2022). https://doi.org/10.1007/s00170-022-08860-7

Zirak, N., Shirinbayan, M., Deligant, M., Tcharkhtchi, A.: Toward polymeric and polymer composites impeller fabrication. Polymers 14, 97 (2022). https://doi.org/10.3390/polym14010097

Farashi, S., Vafaee, F.: Effect of printing parameters on the tensile strength of FDM 3D samples: a meta-analysis focusing on layer thickness and sample orientation. Prog. Addit. Manuf. 7, 565–582 (2022). https://doi.org/10.1007/s40964-021-00247-6

ISO/ASTM 52921: Standard terminology for additive manufacturing - Coordinate systems and test methodologies

Quail, F.J., Scanlon, T., Strickland, M.: Development of a regenerative pump impeller using rapid manufacturing techniques. Rapid Prototyp. J. 16, 337–344 (2010). https://doi.org/10.1108/13552541011065731

Hernandez-Carrillo, I., Wood, C.J., Liu, H.: Advanced materials for the impeller in an ORC radial microturbine. Energy Procedia 129, 1047–1054 (2017). https://doi.org/10.1016/j.egypro.2017.09.241

Dwiyati, S.T., et al.: 2019 Influence of layer thickness and 3D printing direction ontensile properties of ABS material. J. Phys. Conf. Ser. 1402, 066014 (2019). https://doi.org/10.1088/1742-6596/1402/6/066014

Markiz, N., Horváth, E., Ficzere, P.: Influence of printing direction on 3D printed ABS specimens. Prod. Eng. Arch. 26, 127–130 (2020). https://doi.org/10.30657/pea.2020.26.24

Keleş, Ö., Blevins, C.W., Bowman, K.J.: Effect of build orientation on the mechanical reliability of 3D printed ABS. Rapid Prototyp. J. 23(2), 320–328 (2017). https://doi.org/10.1108/RPJ-09-2015-0122

Rayegani, F., Onwubolu, G.C.: Fused deposition modelling (FDM) process parameter prediction and optimization using group method for data handling (GMDH) and differential evolution (DE). Int. J. Adv. Manuf. Technol. 73, 509–519 (2014). https://doi.org/10.1007/s00170-014-5835-2

Durgun, I., Ertan, R.: Experimental investigation of FDM process for improvement of mechanical properties and production cost. Rapid Prototyp. J. 20(3), 228–235 (2014). https://doi.org/10.1108/RPJ-10-2012-0091

Raney, K., Lani, E., Kalla, D.K.: Experimental characterization of the tensile strength of ABS parts manufactured by fused deposition modeling process. Mater .Today: Proceed. 4(8), 7956–7961 (2017). https://doi.org/10.1016/j.matpr.2017.07.132

Uddin, M.S., et al.: Evaluating mechanical properties and failure mechanisms of fused deposition modeling acrylonitrile butadiene styrene parts. ASME J. Manuf. Sci. Eng. 139(8), 081018 (2017). https://doi.org/10.1115/1.4036713

Nabavi-Kivi, A., Ayatollahi, M.R., Schmauder, S., et al.: Fracture analysis of a 3D-printed ABS specimen: effects of raster angle and layer orientation. Phys. Mesomech. 26, 19–32 (2023). https://doi.org/10.1134/S1029959923010034

Mohd-Khairul-Nizam, M.A.N.B., Ismail, K.I.B., Yap, T.C.: The effect of printing orientation on the mechanical properties of FDM 3D printed parts. In: Abdul Sani, A.S., et al. (eds.) Enabling Industry 4.0 through Advances in Manufacturing and Materials. Springer, Singapore (2022). https://doi.org/10.1007/978-981-19-2890-1_8

Rybachuk, M., Mauger, C.A., Fiedler, T., Öchsner, A.: Anisotropic mechanical properties of fused deposition modeled parts fabricated by using acrylonitrile butadiene styrene polymer. J. Polym. Eng. 37(7), 699–706 (2017). https://doi.org/10.1515/polyeng-2016-0263

Tanoto, Y.Y., Anggono, J., Siahaan, I.H., Budiman, W.: The effect of orientation difference in fused deposition modeling of ABS polymer on the processing time, dimension accuracy, and strength. AIP Conf. Proceed. AIP Publish LLC (2017). https://doi.org/10.1063/1.4968304

Chockalingam, K., Jawahar, N., Praveen, J.: Enhancement of anisotropic strength of fused deposited ABS parts by genetic algorithm. Mater. Manuf. Process. 31, 2001–2010 (2016). https://doi.org/10.1080/10426914.2015.1127949

Cantrell, J., et al.: Experimental characterization of the mechanical properties of 3D printed ABS and polycarbonate parts. In: Yoshida, S., Lamberti, L., Sciammarella, C. (eds.) Advancement of optical methods in experimental mechanics, vol. 3. Springer, Cham (2017). https://doi.org/10.1007/978-3-319-41600-7_11

Syaefudin, E.A., et al.: The effect of orientation on tensile strength 3D printing with ABS and PLA materials. Conf. Ser. 2596, 012002 (2023). https://doi.org/10.1088/1742-6596/2596/1/0120023

Hernandez R, Slaughter D, Whaley D, Tate J, Asiabanpour B (2016) Analyzing the tensile, compressive, and flexural properties of 3D printed ABS P430 plastic based on printing orientation using fused deposition modeling. In: Solid Freeform Fabrication 2016 proceedings of the 26th annual international solid freeform fabrication symposium (2016), pp. 939–950

Bellini, A., Güçeri, S.: Mechanical characterization of parts fabricated using fused deposition modeling. Rapid Prototyp J (2003). https://doi.org/10.1108/13552540310489631

Raut, S., Jatti, V.S., Khedkar, N.K., Singh, T.P.: Investigation of the effect of built orientation on mechanical properties and total cost of FDM parts. Proc. Mater. Sci. 6, 1625–1630 (2014). https://doi.org/10.1016/j.mspro.2014.07.146

Anubhav Kumar, R., Nandi, S.K., Agrawal, A.: Influence of build orientation on tensile and flexural strength of FDM fabricated ABS component. In: Ramesh Babu, N., Kumar, S., Thyla, P.R., Sripriyan, K. (eds.) Advances in Additive Manufacturing and Metal Joining. Springer, Singapore (2023). https://doi.org/10.1007/978-981-19-7612-4_15

Górski, F., Wichniarek, R., Kuczko, W., Andrzejewski, J.: Experimental determination of critical orientation of ABS parts manufactured using fused deposition modelling technology. J. Mach. Eng. 15, 121–132 (2015)

Zou, R., Xia, Y., Liu, S., Hu, P., Hou, W., Hu, Q.: Isotropic and anisotropic elasticity and yielding of 3D printed material. Compos. B Eng. 99, 506–513 (2016). https://doi.org/10.1016/j.compositesb.2016.06.009

Dassault Systèmes Solid Works Corporation, https://www.solidworks.com/ (2024). Accessed 02 January 2024

ASTM Standard D638, Standard test methods for tensile properties of plastics, ASTM International, West Conshohocken, PA (2010)

UltimakerCura, https://ultimaker.com/software/ultimaker-cura (2024). Accessed 02 January 2024

Ender-3 3D Printer, https://www.creality.com/goods-detail/ender-3-3d-printer (2024). Accessed 02 January 2024

ANSYS, https://www.ansys.com (2024). Accessed 02 January 2024

Tensile Strength Tester, https://www.prestogroup.com/categories/tensile-strength-tester/ (2024). Accessed 02 January 2024

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Consent for publication

This article has not been submitted elsewhere for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Katiyar, P.C., Singh, B.P., Chhabra, M. et al. Analysis of tensile strength of thin ABS specimens 3-D printed in various build orientations for turbomachinery applications. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01869-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01869-0