Abstract

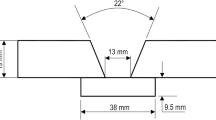

An alloy steel 15CDV6 finds more comprehensive applications in pressure vessels, aerospace structures, structural members, suspensions for sports cars components, etc., due to the low carbon content with good yield strength, toughness, and weldability. However, the 0.3%C-Cr-Mo-V (ESR MOD.15CDV6) steel is a modification of 15CDV6 and is a possible alternative for steels used in aerospace applications. The present paper focuses to study the influence of optimized process parameters and post weld heat treatments of 0.3%C-Cr- Mo-V steel on microstructure and mechanical properties. In this study, manual gas tungsten arc welding (GTAW) process is considered and design of experiments (DOE) is deployed wherein the optimized process parameters are obtained. Experiments are conducted on plates having combinations of process variables includes current, voltage, travel speed, number of passes (i.e., two, three and four passes), and root gap (i.e. 1 mm, 1.5 mm and 2 mm) respectively. Post experimentation, the weld samples were subjected to post weld heat treatment (PWHT) and cooling mediums (i.e., as welded, forced air and water) and correlated to microstructure and mechanical properties (i.e., Hardness, Tensile and Impact Test). On comparing the results, the process variables such as number of passes, root gap and cooling mediums play major significance on microstructural and mechanical properties. Further, the present study might provide an insight on thermal strategies of 0.3%C-Cr- Mo-V steel in additive manufacturing.

Similar content being viewed by others

References

Bandyopadhyay, R., Prabhu: Improvement in Mechanical properties of Standard 15CDV6 Steel by Increasing Carbon and Chromium Content and Inoculation with Titanium during ESR. Int. Sch. Res. Notices. 1–7 (2012). https://doi.org/10.5402/2012/572703

Maity, B., GoldhahnKawalla: Development of Ultra High Strength Low Alloy Steel through Electroslag Refining process. ISIJ Int. 49, 902–910 (2009)

Afkhami, S., Amraei, M., Javaheri, V., Ghafouri, M., Björk, T., Salminen, A., Zhao, X.L.: Flow and Hardening Behavior in the heat-affected zone of Welded ultra-high Strength Steels, pp. 1–16. Welding in the World (2024)

Sevvel, M., Satheesh, Srinivasan: Experimental investigation on the improvement of the properties of the AZ80A mg alloy joints using friction stir welding process. FME Trans. 47, 452–463 (2019)

Padmakumar, A., Madhavan, A.P., Joseph, J., Kailasamani, S.: Transient thermal analysis on Rotary Friction Welding of 15CDV6 Aerospace Steel. Trans. Indian Inst. Met. 76(3), 799–808 (2023)

Suresh, S.S., Ballal, Rao, Krishna: Study of welding characteristics of 0.3 C–Cr-Mo-V(ESR) ultrahigh strength steel. J. Mater. Sci. 42(14), 5602–5612 (2007)

Ramkumar, K., Gupta: Plasma Arc Welding of High Strength 0.3% C–Cr-Mo-V (ESR) Steel. Trans. Indian Inst. Met. 70, 1317–1322 (2017). https://doi.org/10.1007/s12666-016-0927-3

Saravanan, S., Kumar, Sharma, Sivakumar, R.R., Narayanan, Sreekumar, Sinha: Effect of Tempering temperature on strength and fracture toughness of 0.3 C-Cr-Mo-V(ESR) Steel. Mater. Sci. Forum. 710, 433–438 (2012). https://doi.org/10.4028/www.scientific.net/MSF.710.433

Jalaja, K., Ranjith, R., Krishna, S.C., Manwatkar, S.K., Gupta, R.K., Karthikeyan, M.K., Bajargan, G.: Investigation of crack-like Defect in 15CDV6 (ESR) Steel Forging for Aerospace Applications, p. 108040. Engineering Failure Analysis (2024)

Lyudmila Nyrkova, S., Osadchuk, T., Labur, M., Yavorska: Effect of microstructure on corrosion- mechanical endurance of welded joints of Aluminium Alloy V1341T produced by manual argon-Arc Welding. FME Trans. 49, 374–383 (2021)

Chandra Sekhar, S., Rao, D. Ramesh: Welding Development in ESR modified 15CDV6 material. Int. J. Mech. Eng. Robatic Res. 3, 499–504 (2014)

Yayla, E., Ural: Effect of Welding processes on the Mechanical Properties of HY 80 steel materials, Materials and design:1898–1906. (2007)

Arkadeb Mukhopadhyay, S., Sahoo: Corrosion Performance of Steel Rebars by Application of Electroless Ni-P-W Coating - an Optimization Approach using Grey Relational Analysis. FME Trans. 49, 445–455 (2021)

Sapthagiri, J., Rao, A., Reddy, S., Prabhakar: Comparison of Mechanical properties on 15CDV6 steel plates by TIG welding with or without copper coated filler wires. Int. J. Adv. Res. Foundation. 2, 1–7 (2015)

Naveen Kumar: Study on Dissimilar welding of 15CDV6 and SAE4130 Steel by Inter Pulse GTA welding, International Conference on Advances in Manufacturing and Materials Engineering, AMME 2014.Proceedia Material Science 5. (2014)

Chakraborty, D., Mahesh, S., Patil, M., Mastanaiah, P.: Microstructures and Mechanical Properties of Dissimilar Metal Gas Tungsten Arc Welds of 15CDV6 Steel and AISI 304 Stainless Steel. Trans. Indian Inst. Met. 73, 1701–1708 (2020)

Indrakanth, B., Pavuluri, S., Bhavan, A., Sireesha, S.C.: November. Experimental investigation on 15CDV6 austenitic stainless steel and SS321 low alloy steel dissimilar joints by gas tungsten arc welding. In AIP Conference Proceedings (Vol. 2821, No. 1). AIP Publishing. (2023)

Singh, R.K., Gangwar, S., Singh: Exploration of GRA based Multi objective optimization of magnetic abrasive finishing process using simulated annealing. FME Trans. 48, 195–203 (2020)

Kannan, G.R., Sathiya, P., Kannan, T.D.B., Kumar, M.B.: Welding Parameter Optimization by Whale Optimization Algorithm and Experimental Investigation on Microstructure and Mechanical Properties of Spin Arc Welded 15CDV6 HSLA Steel, pp. 1–17. Metals and Materials International (2023)

Srinivasan, L., Khan, M.C., Kannan, T.D.B., Sathiya, P., Biju, S.: Application of Genetic Algorithm Optimization Technique in TIG Welding of 15CDV6 Aerospace Steel, vol. 11, pp. 459–469. Silicon (2019)

Radhakrishnan, K., Muralidharan, V.: The Effect of quenching mediums on Heat Treatment properties of Multi-pass Welding of 0.3%C-Cr Mo V Steel. In: Ganippa, L., Karthikeyan, R., Muralidharan, V. (eds.) Advances in Design and Thermal Systems. Lecture Notes in Mechanical Engineering. Springer, Singapore (2021). https://doi.org/10.1007/978-981-33-6428-8_38

Radhakrishnan, K., Muralidharan, V.: A study on the Welding and Heat Treatment of 0.3%C-Cr-Mov Steel. In: Ganippa, L., Karthikeyan, R., Muralidharan, V. (eds.) Advances in Design and Thermal Systems. Lecture Notes in Mechanical Engineering. Springer, Singapore (2021). https://doi.org/10.1007/978-981-33-6428-8_39

ASTM: A 370 – 10 Standard Test methods and Definition for Mechanical Testing of Steel products

ASTM E 10–18: Standard Test Method for Brinell Hardness of Metallic Materials

ASTM E 8: Test Method for Tension Testing of Metallic Materials, ASTM E 23 Test Method for Notched Bar Impact Testing of Metallic Materials

ASTM E 165: Test Method for Liquid Penetrant Examination

AIR 9112/A Condition for Checking: and Receiving Steel parts and Assemblies made by Melting Welding

IQI EN462: -1/ISO19232 Image Quality Indicators

Schönmaier, H., Fleißner-Rieger, C., Krein, R., Schmitz-Niederau, M., Schnitzer, R.: On the impact of post weld heat treatment on the microstructure and mechanical properties of creep resistant 2.25 Cr–1Mo–0.25 V weld metal. J. Mater. Sci. 56, 20208–20223 (2021)

Suresh, M.R.: 0.3 C–CrMoV (ESR) steel: A New Ultrahigh Strength Steel. Trans. Indian Inst. Met. 64, 483–492 (2011)

Moinuddin, S.Q., Sharma, A.: Arc Stability and its Impact on Weld Properties and Microstructure in anti-phase Synchronised synergic-pulsed twin-wire gas Metal arc Welding, vol. 67, pp. 293–302. Materials & Design (2015)

Moinuddin, S.Q., Kapil, A., Kohama, K., Sharma, A., Ito, K., Tanaka, M.: On process–structure–property interconnection in anti-phase synchronised twin-wire GMAW of low carbon steel. Sci. Technol. Weld. Joining. 21(6), 452–459 (2016)

Moinuddin, S.Q., Sharma, A.: Effect of Welding Speed on Arc Stability and its Impact on Structure–Property in Anti-Phase Synchronized Twin-Wire GMAW Process. In The 72nd IIW Annual Assembly and International Conference, Bratislava, Slovakia. (2019)

Sarila, V.K., Moinuddin, S.Q., Cheepu, M., Rajendran, H., Kantumuchu, V.C.: Characterization of Microstructural Anisotropy in 17–4 PH Stainless Steel fabricated by DMLS Additive Manufacturing and Laser Shot Peening. Trans. Indian Inst. Met. 76(2), 403–410 (2023)

Moinuddin, S.Q., Machireddy, V.V., Raghavender, V., Kaniganti, T.B., Sarila, V., Ponnappan, S.M., Shanmugam, R., Cheepu, M.: Analysis on bonding interface during solid state additive manufacturing between 18Cr-8Ni and 42crmo4 high performance alloys. Metals, 13(3), p.488. (2023)

Ramkumar, P., Gupta, R.K., Kumar, A., V. and, Muthupandi, V.: Effect of pre-and post weld heat treatment on microstructure development and mechanical properties of 0.3% C-CrMoV (ESR) high-strength low-alloy steel. J. Mater. Eng. Perform. 30, 7835–7850 (2021)

Li, L.T., Yang, M.S., Ren, Y.: May. Research on Microstructure and Properties of Base Metal and Weld of Electron Beam Welding 0.30 C-Cr-W Steel. In: Materials Science Forum, vol. 817, pp. 238–245. Trans Tech Publications Ltd (2015)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Radhakrishnan, K., Hameed, S.S., Muralidharan, V. et al. Optimizing process parameters and a comparative study of post-weld heat treatments on the microstructure and mechanical properties of 0.3%C-Cr-Mo-V steel. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01797-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01797-z