Abstract

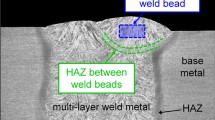

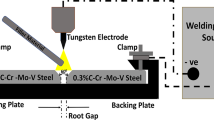

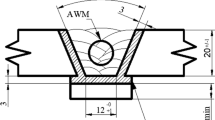

The development of new filler metals for offshore industry is challenging because high strength and toughness levels are required after post-welding heat treatment (PWHT) is applied to reduce residual stresses. The higher chromium contents added to the chemical composition of welding consumables to attain the required ultimate tensile strength are usually associated with reduced toughness. This work presents a comparative analysis of the behavior of two high strength steel weld metals with different Cr–Mo and Mn–Ni additions that were submitted to PWHT. Weld metals obtained by shielded metal arc welding process were evaluated using mechanical tests (Charpy-V notch and Vickers microhardness) and microstructural analysis (scanning electron microscopy and electron backscattered diffraction) conducted in samples removed from the center line of weld deposits, both in the as-welded and heat-treated (600 °C for 1 h) conditions. Although similar results were obtained in the as-welded condition, different behaviors were observed after PWHT. While impact toughness for Cr–Mo additions was reduced by carbide precipitation, as predicted by thermo-calc simulation, weld metal based on Ni–Mn addition exhibited improvements after PWHT because the predominantly martensite microstructure was tempered. This makes the latter more appropriate for weldments submitted to PWHT.

Similar content being viewed by others

References

X.L. Wang, Y.T. Tsai, J.R. Yang, Z.Q. Wang, X.C. Li, C.J. Shang, R.D.K. Misra, Effect of interpass temperature on the microstructure and mechanical properties of multi-pass weld metal in a 550-MPa-grade offshore engineering steel. Weld. World 61, 1155–1168 (2017). (in English)

L.J. Jorge et al., Mechanical properties and microstructure of SMAW welded and thermically treated HSLA-80 steel. J. Mater. Res. Technol. (2018). https://doi.org/10.1016/j.jmrt.2018.08.007. (in English)

E. Keehan, J. Zachrisson, L. Karlsson, Influence of cooling rate on microstructure and properties of high strength steel weld metal. Sci. Technol. Weld. Join. 15(3), 233–238 (2010). (in English)

C. Schneider, W. Ernst, R. Schnitzer, H. Staufer, R. Vallant, N. Enzinger, Welding of S960MC with undermatching filler material. Weld. World 62(4), 801–809 (2018). (in English)

P. Haslberger, W. Ernst, C. Schneider, S. Holly, R. Schnitzer, Influence of inhomogeneity on several length scales on the local mechanical properties in V-alloyed all-weld metal. Weld. World 62(6), 1153–1158 (2018). (in English)

L.E. Svensson, Consumables for welding high strength steels. Svetsaren 1, 30–33 (1999). (in English)

M.S. Zhao, S.P. Chiew, C.K. Lee, Post weld heat treatment for high strength steel welded connections. J. Constr. Steel Res. 122, 167–177 (2016). (in English)

Y. Peng, Y. Zhang, L. Zhao, C. Ma, Z. Tian, Effect of heat input and heat treatment on microstructure and mechanical properties of welded joint of TMCP890 steel. Weld. World 62(5), 961–971 (2018). (in English)

E.S. Mosa, H.M. Abdelaziz, M.A. Morsy, A.E. Abdelmaoula, A. Atlam, Investigation on the influence of post weld heat treatments on weldments between P191 and P11. Int. Res. J. Eng. Technol. 3(11), 833–841 (2016). (in English)

C. Zhang, S. Yang, B. Gong, C. Deng, D. Wang, Effects of post weld heat treatment (PWHT) on mechanical properties of C-Mn weld metal: experimental observation and microstructure-based simulation. Mater. Sci. Eng. 712, 430–439 (2018). (in English)

J.C.F. Jorge, J.L.D. Monteiro, A.J.C. Gomes, I.S. Bott, L.F.G. Souza, M.C. Mendes, L.S. Araújo, Influence of welding procedure and PWHT on HSLA steel weld metals. J. Mater. Res. Technol. 8(1), 561–571 (2019). (in English)

E. Bauné, C. Chovet, B. Leduey, C. Bonnet, Consumables for welding of (very) high strength steels mechanical properties of weldments in as-welded and stress-relieved applications. IIW Doc. II-1696-06 (2006) (in English)

J.C.F. Jorge, S.M. Faragasso, L.F.G. Souza, I.S. Bott, Effect of post-welding heat treatment on the mechanical and microstructural properties of extra high-strength steel weld metals, for application on mooring equipment. Weld. Int. 29, 521–529 (2015). (in English)

American Welding Society, Specification for Low Alloy Steel Electrodes for Shielded Metal Arc Welding, AWS 5.5 (AWS, Miami, 1996)

US Department of Defense, MIL-S-16216 K, Steel Plate, Alloy, Structural, High Yield Strength HY-80 and HY-100 (1987)

ISO 15792-1. Part 1, Test Methods for All-Weld Metal Test Specimens in Steel, Nickel and Nickel Alloys, 1st edn (2000)

M. Dias-Fuentes, A. Iza-Mendia, I. Gutiérrez, Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction. Study of their toughness behavior. Metall. Mater. Trans. A 34A, 2505–2516 (2003). (in English)

Y. Wang, L. Li, Microstructure evolution of fine-grained heat affected zone in type IV failure of P91 welds. Weld. J. 95(1), 27s–36s (2016). (in English)

Thermo-Calc Software, TCFE8 Steels/Fe-Alloys Database Version 8 (2017)

ASTM International, Standard Test Methods and Definitions for Mechanical Testing of Steel Products, ASTM A-370-05 (ASTM, West Conshohocken, 2005)

Y. Kang, G. Park, S. Jeong, C. Lee, Correlation between microstructure and low-temperature impact toughness of simulated reheated zones in the multi-pass weld metal of high-strength steel. Metall. Mater. Trans. A 49A, 177–186 (2018). (in English)

R. Cao, J.J. Yuan, Z.G. Xiao, J.Y. Ma, G.J. Mao, X.B. Zhang et al., Sources of variability and lower values in toughness measurements of weld metals. J. Mater. Eng. Perform. 26(6), 2472–2483 (2017). (in English)

H.Y. Song, G.M. Evans, S.S. Babu, Effect of microstructural heterogeneities on scatter of toughness in multi-pass weld metal of CMn steels. Sci. Technol. Weld. Join. 19(5), 37684 (2014). (in English)

B.K. Narayanan, L. Kovarik, M.A. Quintana, M.J. Mills, Characterization of ferritic weld microstructures using various electron microscopy techniques: a review. Sci. Technol. Weld. Join. 16(1), 13–22 (2011). (in English)

S. Park, K. Lee, K. Min, M. Kim, B. Lee, Characterization of phase fractions and misorientations on tempered bainitic/martensitic Ni–Cr–Mo low alloy RPV steel with various Nicontent. Met. Mater. Int. 19(1), 49–54 (2013). (in English)

S.L. Shrestha, A.J. Breen, P. Trimby, G. Proust, S.P. Ringer, J.M. Cairney, An automated method of quantifying ferrite microstructures using electron backscatter diffraction (EBSD) data. Ultramicroscopy 137, 40–47 (2014). (in English)

A. Rabiei, R.D. Haghighi, Studying the effect of PWHT on microstructural evolution and mechanical properties of welded A517 quenched and tempered Steel. J. Mater. Eng. Perform. 26, 4567–4577 (2017). (in English)

Y. Wang, R. Kannan, L. Zhang, L. Li, Microstructural analysis of the as-welded heat-affected zone of a grade 91 steel heavy section weldment. Weld. J. 96(6), 203s–219s (2017). (in English)

J. Jorge et al., Mechanical and microstructural behavior of C-Mn steel weld deposits with varying titanium contents. J. Mater. Res. Technol. (2019). https://doi.org/10.1016/j.jmrt.2019.08.010

R.S. Castro, R.A.S. Ferreira, I.R.V. Pedrosa, Y.P. Yadava, Effects of thermomechanical treatment on the occurrence of coincident site lattice boundaries in high strength low alloy steel. Mater. Res. 16(6), 1350–1354 (2013). (in English)

P. Zhou, B. Wang, L. Wang, Y. Hu, L. Zhou, Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel. Mater. Sci. Eng., A 722, 112–121 (2018). (in English)

K.L. Sham, Advanced characterization techniques in understanding the roles of nickel in enhancing strength and toughness of submerged arc welding high strength low alloy steel multiple pass welds in the as-welded condition, Ph.D. Thesis, Colorado School of Mines (2014), 201 p (in English)

S. Park, M. Kim, B. Lee, D. Wee, Correlation of the thermodynamic calculation and the experimental observation of NiMoCr low alloy steel changing Ni, Mo, and Cr contents. J. Nucl. Mater. 407, 126–135 (2010). (In English)

X. Liu, Z. Cai, S. Yang, K. Feng, Z. Li, Characterization on the microstructure evolution and toughness of TIG weld metal of 25Cr2Ni2MoV steel after post weld heat treatment. Metals 160(8), 2–11 (2018). (in English)

K. Lee, M. Jhung, M. Kim, B. Lee, Effect of tempering and PWHT on microstructure and properties of SA508 GR.4 N steel. Nucl. Eng. Technol. 46(3), 413–422 (2014). (in English)

Requirements concerning materials and welding, IACS W22. (International Association of Classification Societies, London, 2011)

T.V. Rodrigues, J.C.F. Jorge, L.F.G. Souza, P.M.C.L. Pacheco, Modeling post welding heat treatment for residual stresses relieving in welded steel plates using the finite element method, in Proceedings of the 6th National Congress of Mechanical Engineering, Campina Grande, Brazil, 18–20 August (2010) (in English)

X. Cheng, H. Chen, W. Liu, Z. Zhang, Influence of mooring chain steel strength on stress corrosion cracking. Appl. Mech. Mater. 404, 32–39 (2013). (in English)

A.F. Camarão, M.V. Pereira, F.A. Darwish, S.H. Motta, Structural mechanics applied to mooring components design, in Proceedings of the 15th European Conference on Fracture, Stockholm (2004)

S. Leng, Z. Miao, P. Sun, X. Ya, Study on CTOD and microstructure in flash welded joints for 630–730 MPa grade mooring chains, in 13th International Conference on Fracture June 1621, Beijing, China (2013), pp. 1–10

P. Haslberger, S. Holly, V. Ernst, R. Schnitzer, Microstructure and mechanical properties of high strength steel welding consumables with a minimum yield strength of 1100 MPa. J. Mater. Sci. 53(9), 6968–6979 (2018). (in English)

K.H. Lee, S.G. Park, M.C. Kim, B.S. Lee, Cleavage fracture toughness of tempered martensitic NiCrMo low alloy steel with different martensite fraction. Mater. Sci. Eng., A 534, 75–82 (2012). (in English)

P. Haslberger, S. Holly, W. Ernst, R. Schnitzer, Microstructure and mechanical properties of high strength steel welding consumables with a minimum yield strength of 1100 MPa. J. Mater. Sci. 53(9), 6968–6979 (2018). (in English)

E. Keehan, L. Karlsson, H.O. Andrén, Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals, Part 1—effect of nickel content. Sci. Technol. Weld. Join. 11, 1–8 (2006). (in English)

F.S. Jaberi, A.H. Kokabi, Influence of nickel and manganese on microstructure and mechanical properties of shielded metal arc-welded API-X80 steel. J. Mater. Eng. Perform. 21, 1447–1454 (2012). (in English)

G. Mao, R. Cao, C. Cayron, R. Logé, X. Guo, Y. Jiang, J. Chen, Microstructural evolution and mechanical property development with nickel addition in low-carbon weld butt joints. J. Mater. Process. Technol. 262, 638–649 (2018). (in English)

G.M. Evans, Predictive Charpy-V Toughness of the Manganese-Nickel Weld Metal Combination, Doc. II-C-546-18 Genoa, Italy (2018) (in English)

S. Holly, P. Haslberger, D. Zügner, R. Schnitzer, E. Kozeschnik, Development of high-strength welding consumables using calculations and microstructural characterization. Weld. World 62(3), 451–458 (2018). (in English)

A.J.M. Gomes, J.C.F. Jorge, L.F.G. Souza, I.S. Bott, Influence of chemical composition and post welding heat treatment on the microstructure and mechanical properties of high strength steel weld metals. Mater. Sci. Forum 759, 21–32 (2013). (in English)

H. Lee, H. Lee, Effect of Cr content on microstructure and mechanical properties of low carbon steel welds. Int. J. Electrochem. Sci. 10, 8028–8040 (2015). (in English)

R. Schnitzer, D. Zügner, P. Haslberger, W. Ernst, E. Kozeschnik, Influence of alloying elements on the mechanical properties of high-strength weld metal. Sci. Technol. Weld. Join. 22, 536–543 (2017). (in English)

M.H. Avazkonandeh-Gharavol, E.M. Haddad-Sabzevar, E.A. Haerian, Effect of chromium content on the microstructure and mechanical properties of multipass MMA, low alloy steel weld metal. J. Mater. Sci. 44, 186–197 (2009). (in English)

J.C.F. Jorge, L.F.G. Souza, J.M.A. Rebello, G.M. Evans, Effect of Chromium on the Mechanical Properties of Mn–Mo Steel Welds Containing Titanium, IIW DOC. II-1398-00, Conference: IIW Annual Assembly, At: Florence, Italy, June, 2000, Doc. II-1398-00 (in English)

E.S. Surian, J. Trotti, A. Cassaneli, L.A. de Vedia, Influence of chromium on the mechanical properties and microstructure of weld metal from a high strength SMA electrode. Weld. J. 74(3), 45s–53s (1994). (in English)

S. Kim, E. Lee, Y. Choi, S. Cho, S. Kim, A study of the material characteristics and the welding properties of the HSA800 steel. Int. J. Steel Struct. 17(2), 821–831 (2017). (in English)

X. Han, D. Wu, X. Min, X. Wang, B. Liao, F. Xiao, Influence of post-weld heat treatment on the microstructure, microhardness and toughness of a weld metal for hot bend. Metals 6(4), 1–11 (2016). (in English)

Q. Wang, C. Li, H. Peng, J. Chen, J. Zhang, Effect of tempering temperature on the microstructure and properties of Fe–2Cr–Mo–0.12C pressure vessel steel. J. Mater. Eng. Perform. 27, 1485–1493 (2018). (in English)

E.S. Surian, N.M.R. de Rissone, H.G. Svoboda, L.A. de Vedia, SMAW, FCAW and SAW high-strength ferritic deposits: the challenge is tensile properties. Weld. J. 89(3), 54s–64s (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gomes, A.J.C., Jorge, J.C.F., Bott, I.S. et al. Influence of Chemical Composition on the Mechanical and Microstructural Properties of High Strength Steel Weld Metals Submitted to PWHT. Metallogr. Microstruct. Anal. 8, 815–825 (2019). https://doi.org/10.1007/s13632-019-00592-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00592-7