Abstract

In the context of Industry 4.0 and Industry 5.0, the introduction of collaborative workplaces, where humans and robots work together, represents a growing trend to improve the productivity, adaptability, and flexibility of production plants. Indeed, human–robot collaboration (HRC) is a very deepened topic in the scientific community and the designing of collaborative workplaces is a challenging issue due to the high level of complexity and multidisciplinary of its features. This work tackles the complexity of collaborative workplaces and proposes a structured framework to support strategic decisions in designing. A multi-level designing framework is proposed as a supporting tool for designers. Within five domains of collaborative robotics, the elements of a collaborative workplace are identified and proposed in a framework in order to better consider human safety and working conditions during the designing process. A decomposition matrix and an adjacency matrix are used to develop a multi-level designing workflow. Finally, an interactive tool is presented, named “Smart Graph Interface” (SGI), to read and exploit the contents of the framework. The SGI is applied to three case studies from the literature, to spread out principal outcomes in terms of applicability and robustness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The technology-driven progress of Industry 4.0 and the new paradigm of Industry 5.0 [1], address the interaction and collaboration between humans and robots as an innovative production process. Indeed, this manufacturing plant leads to achieve an efficient human–robot collaboration (HRC) [2] towards the improvement of flexibility and productivity. As evidence of the high impact of this kind of application, HRC is spreading also in fields not directly connected with classic industrial environment [3]. In this context, the leftover approach of cooperation, designed over the principles of “how human is serving robot” or “is robot helping human”, is taken over by the human and robot co-existence [4].

Thus, a lot of matters are directly connected to collaborative robotics, and they need to be considered as single aspects and in an overall picture. Aspects like risk and safety are widely discussed [5], as well as human physical and mental stress [6], logistics, technological and operational requirements [7], product and process specification. All these have to be analyzed in order to accomplish environmental, social, and economic sustainability. For instance, experts in the field [8] investigated the innovation in the manufacturing context, and some authors [9] dealt with the possibility to include user interfaces to improve direct communication with robots. Other authors [10] focused mainly on ergonomics to identify possible trends in research. Not least, the concept of anthropocentric design or human-centric design [11] in collaborative robotics represents an important paradigm shift.

Long over the state of the art, there is currently the attempt of supporting the smart configurations of collaborative systems while proposing solutions for human-centered allocation [12], flexible configuration [13] and automatic layout generation [14]. This requires a multi-level analysis arranged inside a decision-supporting framework evolving over complex [15] and dynamic rules [16]. Indeed, in collaborative workspaces, different factors, and causal entities act. They evolve over domains (from their aggregate to detailed representation), regulated by parameters, configurations, and constraints, arranged to manifest benefits across their functionalities. Whenever collaboration between humans and robots is arranged in systems, severe implications on human, robot/machine and the environment are required [17]. Those influence the design of configurations and operational systems to support superior long-term performances in both employees and system outcomes. Therefore, the purpose of this work is to provide a well-defined process and a structured framework for collaborative robotics implementation and designing of collaborative workplaces, building upon and extending the findings of a previously published paper [18].

The work is structured in six Sections in addition to the introduction. Section 2 presents the state of the art about collaborative robotics. Section 3 depicts the aim of the paper and the adopted Knowledge-Based Approach (KBA). Section 4 discusses the multi-level framework for collaborative robotics. In Sect. 5 a tool to manage and exploit the knowledge about collaborative robotics named Smart Graph Interface (SGI) is presented. In Sect. 6, the methodology is tested on three test cases from the literature. Finally, in Sect. 7 main outcomes and conclusions are underlined.

2 State of art

As is known, the basis of knowledge related to collaborative robotics revolves around some main matters [2, 8]. Most of the information used in this research work comes from a process of knowledge acquisition, which consisted in the collection and critical analysis of a significant number of publications in order to extract the most relevant topics, in the HRC context, and their connections. In the following, some references are reported for the most relevant topics.

The most important issue to deal with, in collaborative robotics, is safety. Among the reference international standards about this point, the most relevant to HRC are the ISO/TS 15066:2016 [19], concerning collaborative operations, and the ISO 10218-1/2:2011 [20, 21], concerning collaborative robots and the working environment from the safety perspective. These are very useful guidelines that clarify the most important issues and features to take into account in the HRC context. Furthermore, not only international standards, but also independent researchers [5, 22] report approaches to address and ensure safety and risk assessment in collaborative workplaces, as proof of an effort still needed in this area.

Another relevant topic, strictly connected to safety, is ergonomics. Many authors focused on this matter dealing with both physical [23] and cognitive ergonomics [24]. At the same time, the assessment of ergonomic conditions inside a collaborative workplace is strongly considered in the scientific literature [25]. The need to improve ergonomic conditions drives very often the adoption of collaborative workplaces. For this reason, methodologies for the transition from traditional workplaces to collaborative workplaces [12, 26] and approaches for evaluating the performance of collaborative workplaces [27, 28] are widely proposed in the literature. Indeed, a collaborative workplace owns specific features with respect to manual or totally automatic workplaces, therefore it is required to introduce ad hoc criteria to evaluate the improvement in flexibility and safety, highlighting the different latent dimensions that characterize the HRC problem [29]. For instance, [27] introduces a criterion based on the shared time, whereas [28] applies a Design of Experiment to a collaborative workplace, as examples of approaches that lead to the evaluation of the goodness of the collaborative workplace.

Referring to collaborative robotics, one of the most significant aspects is related to the levels of interaction in a manufacturing context [30]. Many authors discussed this topic, providing different levels of interaction between human and robot. The authors of [31] proposed different degrees of interaction correlated to increasing levels of risk. On another hand, El Zaatari et al. and Matheson et al. [32, 33] proposed two different classifications of interaction taking into account not only safety-related issues. The categorization is based on the working conditions and interaction mode between humans and robots. Finally, Aaltonen et al. [34] proposes its own classification and reports different proposals in the literature, such as the idea of time-sharing and workspace-sharing.

The operations, as well as the task sequencing, are important topics, strongly related to the interaction. Indeed, allocating operations between humans and robots has an impact on almost all the other characteristics of a workplace. Mateus et al. and Xu et al. [35, 36] propose algorithms for task precedence in assembly and disassembly related to collaborative workplaces. Furthermore, in [37, 38] the capabilities of humans and robots are compared with a decision-making criterion to define the best task scheduling.

Another important aspect is how to manage the resources inside the workplace. The focus on the resources, intended as active and passive resources, represents a preparatory issue for collaborative workplace designing. Many research works pay attention to this aspect. In [39] and [40], active and passive resources are analyzed and used as inputs for subsequent stages. Moreover, Vitolo et al. [41] also examined the presence of an Autonomous Guided Vehicle (AGV) and its integration with a collaborative manipulator. The selection of resources is a crucial phase also for the designing framework proposed in this paper.

Layout designing and optimization are crucial for achieving an efficient and safe collaboration between humans and robots. Indeed, ISO 10218-2:2011 [21] pays attention to the working areas definition. It may produce an implicit risk reduction. In scientific literature, many authors focused on this issue. Some authors [4, 14] proposed methodologies for generating collaborative workplaces paying particular attention to the working areas resulting from the sharing of space between humans and robots with different degrees of collaborative areas. Some areas are dedicated to collaboration whereas others are restricted. On another hand, in [42, 43], an algorithm of spatial optimization is proposed to better arrange the resources in accordance with the context and inputs.

Besides, virtual reality (VR) and human–machine interface (HMI) are widely considered in HRC applications, especially for preliminary designing and preliminary assessment. In [44], an immersive VR environment is presented to simulate and visualize manufacturing tasks, whereas Tarallo et al. [45] proposes an experiment in VR to preliminary assess safety and health in manufacturing applications exploiting the real-time interaction in the collaborative workplace by means of HMI.

However, even though many topics are related to HRC, and several authors published works on matters around this topic, it is still missing a process that involves all the possible aspects during the designing of a collaborative workplace. Some authors propose designing workflow [46] to lead the designer through the whole process, whereas others present a framework that contemplates the elements and features of a collaborative workplace [14]. Different approaches propose action workflows based on an HRC paradigm that moves through all the elements in a collaborative workplace [43, 47]. These are all attempts to deal with a complex problem and solve a designing problem through the quantification of the process.

Therefore, to manage the knowledge around collaborative robotics, in many research works, as well as in the current work, tools like user interfaces are proposed. They are useful instruments that support designers and analysts dealing with collaborative workplace designing and re-designing [48]. Examples of this approach are reported by [14] and [18], where the authors respectively provide (i) an inference that interacts with a 3D visualization software to apply changes and (ii) a user interface that manages the knowledge collected around collaborative robotics. Despite the different employment, the approach by means of user interfaces brings towards the automatization of the designing process expanding the user-centered experience [49] and improving the design of the user interface by means of methods and guidelines proposed in literature [50].

3 Knowledge-based approach for collaborative robotics

Since the high level of complexity and differences respect to traditional manufacturing plants, collaborative robotics needs to be tackled by means of an inclusive and comprehensive approach. Generally speaking, the traditional designing processes tend to find a trade-off between safety and productivity. Mainly, they do not consider the relations among the elements of a collaborative workplace. Indeed, managing the process requires in-depth knowledge of the context of collaborative robotics. Therefore, a Knowledge-Based Approach (KBA) is adopted to face a topic characterized by high complexity.

KBA allows overcoming two important statements: (i) to manage the high number of connected elements involved in a complex field like collaborative robotics and (ii) to provide a structured framework and useful tools to support designers in facing collaborative workplace designing. Therefore, this approach is useful for managing complexity and supporting the designing of collaborative workplaces, by making the necessary knowledge available and exploitable in a user-friendly way. Indeed, a general and still valid solution to designing problems in presence of a large number of heterogeneous elements and information [51] often needs a lot of attempts and can be solved only by experts in the sector. That is why a systematic approach is required to overcome or at least reduce uncertainty and subjective choices.

The aim of the adopted KBA is to collect the knowledge necessary to approach the HRC and organize, in a structured way, the main information [52]. This leads towards the identification of general elements belonging to a collaborative robotics context and establishing well-defined relations that can support the designer during the development of a collaborative workplace [53], as depicted in [43]. Therefore, the adopted KBA is composed of the following three stages: (i) Knowledge acquisition, (ii) Knowledge management, and (iii) Knowledge exploitation.

In Fig. 1, the KBA is graphically explained. The first step is named “knowledge acquisition” and collects knowledge from industry, standards, and from the scientific community as raw information. This comes from the study of the state of the art briefly presented above. Consequently, the knowledge is organized in a structured way by means of several acknowledged methods and tools during the “knowledge management” and presented in Sect. 4. Once this knowledge is organized, it is conveyed towards the last stage, “knowledge exploitation”, where it is made available through interactive tools like matrices and user interfaces to support the designer (see Sect. 5). Furthermore, this process is recursive, coming back to a previous phase to fill up missing information or to better fix up the organization of the information according to effective and efficient exploitation of it. Hence, this work presents a consistent approach to support the designing of collaborative workplaces.

4 Collaborative workplace framework

4.1 Decomposition matrix: domains and elements of a collaborative workplace

Collaborative workplaces need to be treated differently from manual or fully automatic workplaces because of the obvious safety problems due to humans and robots sharing spaces. Managing all the aspects of a collaborative workplace at the same time complicates the achievement of effective collaboration between human beings and robots. Moreover, the designing of collaborative workplaces includes a huge and non-homogeneous number of issues that requires an architectural frame to represent all the social and technical aspects of a collaborative workplace. For this reason, this work proposes a framework that represents the collaborative workplace as the combination of five domains, containing the elements which are used to characterize it. Specifically, a domain meets a need inside of the problem, whereas the elements face specific functionalities. The whole collected and organized information is reported in a “Decomposition Matrix” (Table 1).

The domains of a collaborative workplace are the following:

-

Logistic domain focuses on the management of the collaborative workplace, which means spaces and flows.

-

Resources domain focuses on the resources adopted, the active resources (act an action) and passive resources (suffer an action).

-

Working domain focuses on the working needs, the aim of the workplace as the working process, task sequencing, and the interaction between humans and robots.

-

Safety domain focuses on the safeguarding and wellness of humans in collaborative workplaces, involving ergonomics, environmental conditions, and safety. It is strictly related to human presence in the workplace and depends on the degree of collaboration with the robot.

-

Value domain focuses on cost and performances.

Within these domains, twenty-one elements that characterize a collaborative workplace are identified by collecting and analyzing reference ISO standards, scientific literature, and industrial applications and grouped for similarity. They are graphically represented in Fig. 2. The details of each element are reported below:

-

1.

Physical limits: the available space within the whole workplace can be located, including size, shape, and obstacles [54, 55].

-

2.

Workspaces: information about layout and working areas division and the main spaces inside a workplace (human, robot, and logistic spaces) [4, 19, 54].

-

3.

Paths: information about access and exit points as well as paths for all the resources [19].

-

4.

Feeding: the type of supplying modality for workpiece and material [19].

-

5.

Workpiece: information about the piece to be worked, including characteristics, properties, and components [56, 57].

-

6.

Equipment: information about support instruments and furniture inside the workplace [56, 58].

-

7.

Usable devices: information about devices under the control of the operator, used to manage the workplace and robot [56].

- 8.

- 9.

-

10.

Autonomous Guided Vehicle (AGV): AGV and its characteristics [40, 56].

-

11.

Ergonomics: information about ergonomic constraints and requirements [59,60,61].

-

12.

Environment: information about environmental working conditions [21].

-

13.

Minimum distances: minimum distances to be set among fixed and mobile resources [21, 54, 55].

- 14.

-

15.

Safeguarding devices: devices not under the control of the operator [19, 21].

-

16.

Type of work: working operation to be executed on the workpiece [2, 62, 63].

-

17.

Task sequencing: a set of operations that must be performed by the active resources to carry out the entire working process [64].

-

18.

Human–robot collaboration (HRC): interaction modality between operator and robot [34].

-

19.

Human–machine interface (HMI): devices enabling the communication between operator and robot [19, 21].

-

20.

Costs: economic constraints.

-

21.

Benefits: key performance indicators (KPI), a selection of evaluation functions to estimate the performances of the collaborative workplace [27, 29].

These elements describe the aspects of a collaborative workplace as atomic parts of the whole system and enable the holistic modelling of the workplace.

4.2 Adjacency matrix: relations among its elements

The decomposition matrix previously presented reports the elements of a collaborative workplace as atomic entities with no relations. This section deals with the building of a network among the identified elements. The relations among the elements explain how they interact and define a prioritization of them. Indeed, each element as part of the network helps to describe the whole system as a complex of interactive components.

Therefore, a generic collaborative workplace is modelled as a graph (\(G= \{N, E\}\)) [65]. It is composed of nodes and edges. In the resulting network, a single node can have several incoming and outgoing edges [66]. The oriented edges give priority to nodes. In other words, they make evident the existence of a direct relation and causal relationship between two nodes.

The graph theory provides for a double representation. The relations among the identified elements are highlighted by means of a direct graph (digraph) or an adjacency matrix. The arrows suggest the direction and priority among the elements in a digraph, whereas the values 1 or 0 explain whether the element on the row has a direct connection with the element on the column. The value 1 suggests a dependency of the element on the column from the element on the row, which means a change in the latter causes a change in the previous. On another hand, the value 0 means that there is no direct relation between those nodes. The dependencies among the elements were identified by studying the reference regulatory framework and the scientific literature. These were discussed and refined on the basis of the authors’ experience. Previously, this step has been referred to as “knowledge acquisition”. In Table 2, the adjacency matrix that comes from the analysis of the acquired knowledge is represented. This matrix is a square matrix where on rows and columns there are the same elements.

Looking at the matrix, it is immediately noticeable that the first six nodes, i.e., workpiece, physical limits, ergonomics, environment, minimum distances, and cost, present no incoming edge. These nodes are intended as source nodes because they have no inputs or incoming information. In other words, they are information that comes from customers, firms and standards, they are external constraints or requirements to meet, which do not suffer the influence of other nodes. On another hand, only one node (Benefit) has a row with all zero elements, which means it is a sink node, it has no influence on other nodes.

To better clarify the dependencies among the 21 elements of the matrix, it is possible to imagine a general workplace in which collaborative robotics is used. Here, resources are designed depending on the job. It depends on the product (WP) that has to be realized. The workplace is, generally, designed from an ergonomics (ER) perspective. That can change over the safety rules related to the environment (EN) and set inside the Physical Limits (PL). ER depends on the operator’s stature (O), type of equipment (EQ), and usable and wearable devices (UD). The degree of ergonomics of systems results in benefits (B) and in the quality of performances. The degree of automation inside the environment changes over budget (C). It acts as an overall envelope constraint. The resources (Operators (O) and Robots (R) and movable logistics entities (AGV), equipment (EQ), wearable and usable (UD), and safety (SD) devices) amount does not result directly on performances. Those influence the type of work (TW) and its sequence (TS) that are planned on the collaborative rules (HRC). During the collaboration, the operator can make use of HMI for safety and effective acts with robots. The display may provide active control of robot variables (e.g., position and velocity, and acceleration) by changing the sequence of tasks (TS). Resources are allocated inside the layout with the main intent to reduce Not Valued Action due to travelling, respecting minimum distances (MD) provided by norms, standards and safety issues. The position of resources in systems is set over safeguarding perimeters (SP) to follow paths (P) the materials are using (WS). Physical or virtual frontiers (SP)- whenever augmented reality is used—may be tested for safety practices. The supplying modality (F) makes use of the free paths (P) inside the area (WS) and according to the main safety interaction principles (SD). The operator uses devices and cannot—arbitrarily—decide to refuse. Active (they are performing a job) and passive (they are servicing a job) resources are assigned to the task after a master set that follows the aggregate (in terms of family of workpieces) type of jobs the collaborative system can assist. Optimal outcomes are evaluated across the linked paths of main design features and principal (selected) results. KPI classifies the alternative arrangements over aggregate constraints.

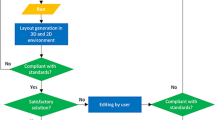

4.3 Multi-level designing process

After the elements of a collaborative workplace are arranged in a network where the relations among them are highlighted, a multi-level designing process that follows four main steps is defined (see Fig. 3). This process considers the twenty-one elements and organizes them according to a sequential criterion based on the author’s experience and the acquired knowledge with the aim of leading the designer alongside the development of a consistent and coherent collaborative workplace.

In the beginning, the “inputs”, intended as (i) constraints, (ii) customers’ needs and (iii) strategic requirements of the company, are set and combined in order to arrange the aggregate scenario. The Aggregate representation is the first level of the designing workflow which consists in the definition of a low-level vision of the workplace. Only the source nodes are considered. Therefore, the designer receives this information and uses it as the basis for solving designing problems.

The second level reports the master “configurations” of the framework. During this phase, the designer can select active and passive resources, set tasks sequence for jobs and define interaction and communication between humans and robots. This reports the main representation where are designed the master sets. Here, there is the majority of contribution from the designer, his knowledge, aims, and experience. For this reason, this stage can be considered the main part of the whole process.

Smart Graph Interface (SGI): 1) import the adjacency matrix; 2) graph (on left) and matrix (on right) displayed; 3) select the operation: extract a sub-graph or highlight all the connections of a node; 4) set input and/or output; 5) set the layout; 6) set the element to display; 7) update the graph; 8) reset

The third level provides the “manifestations” that come out of the previous statements. It is the level where are collected the nodes that can be forced in a process of automatizing. It includes the layout arrangement and safety requirements. Indeed, this is called resulting representation because it should be auto-generated across an expert knowledge-based system or through algorithms including meta-expert opinion implemented according to the needs of the company and the designer. Within the framework, this level can be customized according to the needs of the designer and the optimization algorithm most suitable for specific situations.

Finally, the “evaluation” level allows for assessing workplace performance. This is called evaluating representation because it represents the workplace through a score. Indeed, a set of suitable evaluation functions are connected to this level. That functions estimate Key Performance Indicators (KPI) in order to provide evidence of the performances of the collaborative workplace. The illustrated process recursively evolves updating the previous stages if some requirements are not met. Whenever inconsistency in results occurs, it is possible to return to the previous state that is logically and temporally preceding (e.g., the designer can modify the type and amount of factors and elements in order to optimize principal manifestation).

Finally, human presence is carefully considered in the first two phases. Indeed, they deal with the constraints—ergonomic requirements, environment, safety and health—that are very connected to the wellness and safety of the human as well as the task and resources. Indeed, the ergonomics, and human factor, in the first stage, guide and limits the designer’s choices in factors and elements in the next stage.

Therefore, the elements of the framework are grouped according to the presented multi-level designing process in constraints, configurations, manifestations, and evaluations. This categorization, using the designing methodology exposed above, creates a flow from the constraints to the evaluation.

5 The Smart Graph Interface for collaborative workplace designing

The framework for collaborative robotics described in the previous section finalizes knowledge management. This structured knowledge needs to be used and exploited by means of interactive tools and instruments in order to support analysis and lead the designer along the designing process. For this reason, the connections among the elements presented in the adjacency matrix are made explicit and open to manipulation in order to be able to handle the complexity of collaborative workplaces in a user-friendly manner and according to intended purposes.

The features of the graph theory are adopted and implemented inside a user interface developed in MATLAB AppDesigner. Indeed, as seen, a graph is composed of a set of nodes connected by edges (\(G= \{N, E\}, G: graph, N: nodes, E: edges\)) and has a double representation: through a matrix (adjacency matrix), where the relations among the nodes are explicated by the number (the row element has a direct effect on the element in the column), and through graphical representation where the elements are represented as nodes of an oriented network.

The User Interface, named Smart Graph Interface (SGI), is developed to easily exploit the structured information collected in the decomposition matrix (Sect. 4.1) and the adjacency matrix (Sect. 4.2). The interface presented in Fig. 4, allows the manipulation of the network in both representations. Once imported the adjacency matrix as a CSV file, the SGI reads the contents, recognizes the elements and generates the corresponding digraph and matrix. To make the information manageable, a list of checkboxes is automatically generated in the relative panel (number III). At this point, the user can exploit the information following two different paths: (i) to extract a sub-graph and (ii) to extract all inputs and/or outputs of a single node.

Therefore, the interface is structured in three main parts:

-

I.

The first part reports commands and features of the SGI, where the user can load the adjacency matrix and set how to manipulate the information uploaded. The user can select the kind of operation to perform and define the layout of the digraph as well.

-

II.

The second part collects the list of elements included in the adjacency matrix, and makes the user able to select the information he is interested in.

-

III.

The last part is a tab where the digraph and adjacency matrix are reported as it.

This kind of division is adopted due to lead the user in a linear path where he can follow always the same direction, from up-left to down-right. Indeed, following this path, the user can (i) set, (ii) see, (iii) select and (iv) update the information.

Figure 5 presents the SGI after uploading an adjacency matrix. After the user loaded data, he can display the graph and matrix. At this point, it is possible to set the operation to perform: extracting a sub-graph by selecting the nodes in panel “Elements” or displaying the connections (inputs and/or outputs) of a single node. By means of the “Update” bottom, a sub-graph is represented. By means of the “Reset” button, the SGI reports the entire graph.

The two operations described above have two different purposes: the first allows investigating a reduced system, by hiding elements that are out of interest; the second allows visualizing all elements directly connected to the selected node. All the node’s dependencies are highlighted. Therefore, the SGI can support designers and analysts in easily dealing with collaborative workplaces.

An example of the SGI interactivity is depicted in Figs. 6 and 7. In this case, all the inputs for the node “Workspaces”, which represents the working areas inside the collaborative workplace, are reported. In Fig. 6, it is proposed also a different layout representation. The point is that through the SGI, all the preparatory elements for the working areas definition inside the workplace are selected and displayed. In this way, the users can better understand the results of their decisions in the designing or redesigning of the collaborative workplace.

Finally, the last tab of the SGI, named “Workflow”, is introduced in this tool as further support for the user. In Fig. 8 (left), it is possible to see the user interface before uploading any adjacency matrix. It reports four spaces related to the levels of representation as described in Sect. 4.3. On another hand, in Fig. 8 (right), the spaces are filled with the elements of the framework. The user can select the elements of the framework to add to a certain level. The user selects the elements in the “Elements” panel by means of the checkboxes. In the panel “Manage level” inside the tab, the level is selected, then, the elements are added to that level. In this way, the user can set by himself the elements belonging to a certain level of representation according to the definition given in Sect. 4.3 and the specific conditions and exigences of the designing problem. Moreover, a button “Delete element” is provided. This button works in the same way. After selecting the element to delete and the level, the SGI removes the element from that level. The value of this feature is based on the possibility to check and control the elements of the collaborative workplace during the designing process.

6 Application on three case studies from literature

The proposed framework was applied to three case studies collected from the scientific literature. They are taken from three publications and present distinctive features that make them suitable for analysis by means of SGI. Indeed, each of them is selected to deepen only one representation stage of the multi-level workflow (Sect. 4.3).

Case study 1. Case study 1 is presented in [67]. It consists of an assembly station where a flywheel cover is assembled on an engine block. The process involves taking a machined flywheel cover, applying silicone on one surface, pressing a gasket into the cover, and finally assembling it to the engine block. According to the authors, the available floor space and the engine block position can not be changed. This information is collected in the node “Physical limits”, which includes available space and shape, obstacles and constrained positions. Furthermore, the case study reports also the active resources (operator and robot), passive resources (equipment and staff) and a well-defined task sequencing.

In this case study, only the “aggregate representation”, is considered. This level includes: workpiece, type of working, physical limits, ergonomics, environment, minimum distances, and costs. It is assumed that the assembly operation takes place on an engine block, the minimum distances among the resources are equal or greater than 500 mm [21], and the limits for ergonomic and environmental conditions, and costs are already set. In this example, only the effect of physical limits is examined. As already explained, “Physical limits” is a source node, therefore it does not depend on other nodes in the network. On another hand, it has an impact on others. Through SGI, in Fig. 9, the dependent nodes are “Workspaces” and “Safeguarding perimeter”. That means any change on that node produces an effect only on these two elements. Moreover, all the settings in the “main representation” are not influenced by this point. Therefore, independently from this very strict constraint, the designer can carry out all the configurations in the second level of representation. If a change occurs in the physical limits of the collaborative workplace, the settings still remain valid.

Case study 2. Case study 2, is an assembly and the sealing of a refrigerator [40]. The focus is on the second level or representation, the “main representation”. Differently from the majority of the case studies in literature, this employs two collaborative robots and two operators that work alongside the parts to be assembled on a conveyor: the workpiece comes on a conveyor, the operators prepare the components while the robots apply the sealant, then, humans assemble flexible components. Moreover, humans can directly manipulate the robots to apply any further necessary sealant.

The designing process follows the steps explained in Fig. 3. The “aggregate representation”, which consists in the definition of the context and constraints, is assumed already done. The “main representation”, requires the selection of the active and passive resources (equipment and usable devices), the type of interaction and communication between humans and robots, the feeding mode and task sequencing. In this case, two humans and two robots are set as active resources and a conveyor as a feeding device. The interaction between human and robot occurs as Power and Force Limiting (PFL) as indicated in ISO/TS 15066 [19] and the communication is performed by means of either a starting button or direct contact.

The SGI is used to investigate the inputs and outputs of nodes “operator” and “robot” as depicted in Fig. 10. It emerges that the selection of both the active resources depends mostly on (i) workpiece, (ii) task sequencing and (iii) type of working. Moreover, interaction (HRC) is another criterion for robots, as well as ergonomics and environmental conditions for operators. Finally, the “costs” element, which represents financial resources, is an input for both. Setting active resources leads to define equipment (and usable devices for operators) and workspaces, in other words, passive resources and working areas. Therefore, the decision on the number of active resources to adopt is a direct consequence of the operative issues and determines the layout definition. This is an important point to check because it can change all the characteristics of a collaborative workplace.

Case study 3. In case study 3, the “resulting representation” is examined. Indeed, this part is a direct effect of the statements carried out in the previous stage. After defining the context and setting the main elements of the collaborative workplace, the nodes belonging to the third level of representation can be the object of an optimization process. In [43], the authors proposed a modeling paradigm to support layout designing.

This use case concerns the inspection of welding points for quality check by means of ultrasonic technology. It involves an operator and a robot. The operator deals with carrying the workpiece, whereas the robot performs the quality inspection. Particular attention is given to the working areas definition. Therefore, after the aggregate representation, all the main configurations are carried out: active and passive resources, type of work, task sequencing, type of feeding, interaction and communication.

According to the authors, the disposal of all the resources in the workplace is optimized by means of a spatial optimization algorithm. By the use of the SGI, all the inputs of the node “workspaces” that represents the working areas are displayed (Fig. 11). Eleven related elements—used as inputs to optimize the layout—are recognized: type of working, task sequencing, HRC, robot, operator, feeding, equipment, HMI, usable devices, minimum distances, and physical limits. That makes evident the strict relation of the node “workspaces” to many other elements inside the collaborative workplace. The output provided by the interface may help in developing a suitable optimization algorithm to meet the requirements of this node.

7 Conclusions

The present research work deals with collaborative robotics as a complex manufacturing workplace. As evidenced by the state of the art, the complexity of collaborative workplaces is related to the high level of multidisciplinary and the non-homogeneity of available information. Indeed, many research works focus on specific aspects of this field, and very few tackle it in a comprehensive way. Therefore, this paper presents a Knowledge-Based Approach in order to manage this complexity and make knowledge available for use. A structured framework for collaborative robotics is proposed. It is composed of the decomposition matrix, which collects the main elements of a collaborative workplace, and the adjacency matrix, which reports the relations among these elements. Then, five domains involved in a collaborative workplace are identified and their relations are highlighted. Managing the collected information by means of decomposition and adjacency matrices represents significant support when approaching this kind of topic. Finally, a multi-level designing workflow, leading the designer during the application of the framework and the development of a whole collaborative workplace, is proposed.

An interactive tool, named Smart Graph Interface (SGI), which allows displaying and managing the information and knowledge around collaborative robotics, is presented to completion of this acquisition, management and knowledge exploitation activity. Indeed, the exploitation of knowledge presented by means of the SGI provides an innovative point of view on the design and analysis of collaborative workplaces. The knowledge, that is modelled through a matrix and visualized through a digraph, is a valid support to predict the impact of decisions on the designing process.

The workflow and the SGI are applied to three case studies about collaborative scenarios, to prove the benefit and effectiveness of these tools. It results in an example of the designing process of collaborative workplaces. The proposed structural approach confirms that it is possible to face complexity in a collaborative workplace while managing principal outcomes.

In conclusion, the approach and the SGI allow for assigning main elements of collaborative workplaces by selecting them from the domains of interest. According to the selected scenario, the user can either modify the entities to come out with alternative configurations in a what if scenario or predict the impact of modifications on the other elements of the collaborative workplace.

As further developments, it is important to repeat the definition of dependencies among the elements of the adjacency matrix with additional scholars and industrial experts in order to obtain the generality of the presented results.

Availability of data and materials

Not applicable.

Code Availability

References

Maddikunta, P.K.R., Pham, Q.-V., Prabadevi, B., Deepa, N., Dev, K., Gadekallu, T.R., Ruby, R., Liyanage, M.: Industry 5.0: a survey on enabling technologies and potential applications. J. Ind. Inf. Integr. (2021). https://doi.org/10.1016/j.jii.2021.100257

Villani, V., Pini, F., Leali, F., Secchi, C.: Survey on human–robot collaboration in industrial settings: safety, intuitive interfaces and applications. Mechatronics 55, 248–266 (2018). https://doi.org/10.1016/j.mechatronics.2018.02.009

Rega, A., Di Marino, C., Vitolo, F., Patalano, S., Lanzotti, A.: Towards the upscaling of biomanufacturing process enhanced by human–robot collaboration. In: International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, pp. 615–622. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-91234-5_61

Michalos, G., Makris, S., Tsarouchi, P., Guasch, T., Kontovrakis, D., Chryssolouris, G.: Design considerations for safe human–robot collaborative workplaces. Procedia CIRP 37, 248–253 (2015). https://doi.org/10.1016/j.procir.2015.08.014

Awad, R., Fechter, M., van Heerden, J.: Integrated risk assessment and safety consideration during design of HRC workplaces. In: 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), pp. 1–10. IEEE, Limassol (2017). https://doi.org/10.1109/ETFA.2017.8247648

Maurice, P., Padois, V., Measson, Y., Bidaud, P.: Human-oriented design of collaborative robots. Int. J. Ind. Ergon. 57, 88–102 (2017). https://doi.org/10.1016/j.ergon.2016.11.011

Zanella, A., Cisi, A., Costantino, M., Di Pardo, M., Pasquettaz, G., Vivo, G.: Criteria definition for the identification of HRC use cases in automotive manufacturing. Procedia Manuf. 11, 372–379 (2017). https://doi.org/10.1016/j.promfg.2017.07.120

Parente, M., Figueira, G., Amorim, P., Marques, A.: Production scheduling in the context of Industry 4.0: review and trends. Int. J. Prod. Res. 58(17), 5401–5431 (2020). https://doi.org/10.1080/00207543.2020.1718794

Prati, E., Peruzzini, M., Pellicciari, M., Raffaeli, R.: How to include User eXperience in the design of human–robot interaction. Robot. Comput. Integr. Manuf. 68, 102072 (2021). https://doi.org/10.1016/j.rcim.2020.102072

Di Marino, C., Tarallo, A., Vitali, A., Regazzoni, D.: Collaborative robotics and ergonomics: a scientific review. In: Proceedings of the ASME 2021 International Mechanical Engineering Congress and Exposition, vol. 6, pp. 1–5. American Society of Mechanical Engineers, Virtual (2021). https://doi.org/10.1115/IMECE2021-72919

Tan, Q., Tong, Y., Wu, S., Li, D.: Anthropocentric approach for smart assembly: integration and collaboration. J. Robot. 2019, 1–8 (2019). https://doi.org/10.1155/2019/3146782

Vitolo, F., Pasquariello, A., Patalano, S., Gerbino, S.: A Multi-layer approach for the identification and evaluation of collaborative robotic workplaces within industrial production plants. In: Design Tools and Methods in Industrial Engineering, pp. 719–730. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-31154-4_61

Krüger, J., Wang, L., Verl, A., Bauernhansl, T., Carpanzano, E., Makris, S., Fleischer, J., Reinhart, G., Franke, J., Pellegrinelli, S.: Innovative control of assembly systems and lines. CIRP Ann. 66(2), 707–730 (2017). https://doi.org/10.1016/j.cirp.2017.05.010

Tsarouchi, P., Spiliotopoulos, J., Michalos, G., Koukas, S., Athanasatos, A., Makris, S., Chryssolouris, G.: A decision making framework for human robot collaborative workplace generation. Procedia CIRP 44, 228–232 (2016). https://doi.org/10.1016/j.procir.2016.02.103

Di Marino, C., Rega, A., Vitolo, F., Patalano, S., Lanzotti, A.: A new approach to the anthropocentric design of human–robot collaborative environments. ACTA IMEKO 9, 80–87 (2020). https://doi.org/10.21014/acta_imeko.v9i4.743

Fruggiero, F., Riemma, S., Ouazene, Y., Macchiaroli, R., Guglielmi, V.: Incorporating the human factor within manufacturing dynamics. IFAC-PapersOnLine 49(12), 1691–1696 (2016). https://doi.org/10.1016/j.ifacol.2016.07.825

Neumann, W.P., Winkelhaus, S., Grosse, E.H., Glock, C.H.: Industry 4.0 and the human factor—a systems framework and analysis methodology for successful development. Int. J. Prod. Econ. 233, 107992 (2021). https://doi.org/10.1016/j.ijpe.2020.107992

Di Marino, C., Rega, A., Fruggiero, F., Pasquariello, A., Vitolo, F., Patalano, S.: A graph-based multi-level framework to support the designing of collaborative workplaces. In: Design Tools and Methods in Industrial Engineering II, pp. 641–649. Springer, Cham (2022). https://doi.org/10.1007/978-3-030-91234-5_64

ISO\(\backslash \)15066:2016. Robots and Robotic Devices: Collaborative Robots. International Organization for Standardization, Geneva, Switzerland

ISO 10218-1:2011. Robots and Robotic Devices -Safety requirements for industrial robots - Part 1: Robots. International Organization for Standardization, Geneva, Switzerland

ISO 10218-2:2011. Robots and robotic devices - Safety requirements for industrial robots - Part 2: Robot systems and integration. International Organization for Standardization, Geneva, Switzerland

Saenz, J., Behrens, R., Schulenburg, E., Petersen, H., Gibaru, O., Neto, P., Elkmann, N.: Methods for considering safety in design of robotics applications featuring human–robot collaboration. Int. J. Adv. Manuf. Technol. 107(5–6), 2313–2331 (2020). https://doi.org/10.1007/s00170-020-05076-5

Maurice, P., Malaisé, A., Amiot, C., Paris, N., Richard, G.-J., Rochel, O., Ivaldi, S.: Human movement and ergonomics: an industry-oriented dataset for collaborative robotics. Int. J. Robot. Res. 38(14), 1529–1537 (2019). https://doi.org/10.1177/0278364919882089

Ustunel, Z., Gunduz, T.: Human-robot collaboration on an assembly work with extended cognition approach. J. Adv. Mech. Des. Syst. Manuf. 11(5), 0057–0057 (2017). https://doi.org/10.1299/jamdsm.2017jamdsm0057

Gualtieri, L., Rauch, E., Vidoni, R.: Emerging research fields in safety and ergonomics in industrial collaborative robotics: a systematic literature review. Robot. Comput. Integr. Manuf. 67, 101998 (2021). https://doi.org/10.1016/j.rcim.2020.101998

Gualtieri, L., Rauch, E., Vidoni, R., Matt, D.T.: An evaluation methodology for the conversion of manual assembly systems into human–robot collaborative workcells. Procedia Manuf. 38, 358–366 (2019). https://doi.org/10.1016/j.promfg.2020.01.046

Boschetti, G., Bottin, M., Faccio, M., Minto, R.: Multi-robot multi-operator collaborative assembly systems: a performance evaluation model. J. Intell. Manuf. (2021). https://doi.org/10.1007/s10845-020-01714-7

Ore, F., Vemula, B., Hanson, L., Wiktorsson, M., Fagerström, B.: Simulation methodology for performance and safety evaluation of human-industrial robot collaboration workstation design. Int. J. Intell. Robot. Appl. 3(3), 269–282 (2019). https://doi.org/10.1007/s41315-019-00097-0

Gervasi, R., Mastrogiacomo, L., Franceschini, F.: A conceptual framework to evaluate human–robot collaboration. Int. J. Adv. Manuf. Technol. 108(3), 841–865 (2020). https://doi.org/10.1007/s00170-020-05363-1

Malik, A.A., Bilberg, A.: Developing a reference model for human–robot interaction. Int. J. Interact. Des. Manuf. 13(4), 1541–1547 (2019). https://doi.org/10.1007/s12008-019-00591-6

Bdiwi, M., Pfeifer, M., Sterzing, A.: A new strategy for ensuring human safety during various levels of interaction with industrial robots. CIRP Ann. 66(1), 453–456 (2017). https://doi.org/10.1016/j.cirp.2017.04.009

El Zaatari, S., Marei, M., Li, W., Usman, Z.: Cobot programming for collaborative industrial tasks: an overview. Robot. Auton. Syst. 116, 162–180 (2019). https://doi.org/10.1016/j.robot.2019.03.003

Matheson, E., Minto, R., Zampieri, E.G.G., Faccio, M., Rosati, G.: Human–robot collaboration in manufacturing applications: a review. Robotics 8(4), 100 (2019). https://doi.org/10.3390/robotics8040100

Aaltonen, I., Salmi, T., Marstio, I.: Refining levels of collaboration to support the design and evaluation of human–robot interaction in the manufacturing industry. Procedia CIRP 72, 93–98 (2018). https://doi.org/10.1016/j.procir.2018.03.214

Mateus, J.C., Claeys, D., Limère, V., Cottyn, J., Aghezzaf, E.-H.: Base part centered assembly task precedence generation. Int. J. Adv. Manuf. Technol. 107(1–2), 607–616 (2020). https://doi.org/10.1007/s00170-019-04864-y

Xu, W., Tang, Q., Liu, J., Liu, Z., Zhou, Z., Pham, D.T.: Disassembly sequence planning using discrete Bees algorithm for human–robot collaboration in remanufacturing. Robot. Comput. Integr. Manuf. 62, 101860 (2020). https://doi.org/10.1016/j.rcim.2019.101860

Raatz, A., Blankemeyer, S., Recker, T., Pischke, D., Nyhuis, P.: Task scheduling method for HRC workplaces based on capabilities and execution time assumptions for robots. CIRP Ann. 69(1), 13–16 (2020). https://doi.org/10.1016/j.cirp.2020.04.030

Mokhtarzadeh, M., Tavakkoli-Moghaddam, R., Vahedi-Nouri, B., Farsi, A.: Scheduling of human–robot collaboration in assembly of printed circuit boards: a constraint programming approach. Int. J. Comput. Integr. Manuf. 33(5), 460–473 (2020). https://doi.org/10.1080/0951192X.2020.1736713

Lietaert, P., Billen, N., Burggraeve, S.: Model-based multi-attribute collaborative production cell layout optimization. In: 2019 20th International Conference on Research and Education in Mechatronics (REM), pp. 1–7. IEEE, Wels, Austria (2019). https://doi.org/10.1109/REM.2019.8744136

Tsarouchi, P., Michalos, G., Makris, S., Athanasatos, T., Dimoulas, K., Chryssolouris, G.: On a human–robot workplace design and task allocation system. Int. J. Comput. Integr. Manuf. 30(12), 1272–1279 (2017). https://doi.org/10.1080/0951192X.2017.1307524

Vitolo, F., Rega, A., Di Marino, C., Pasquariello, A., Zanella, A., Patalano, S.: Mobile robots and cobots integration: a preliminary design of a mechatronic interface by using MBSE approach. Appl. Sci. 12(1), 419 (2022). https://doi.org/10.3390/app12010419

Rega, A., Vitolo, F., Di Marino, C., Patalano, S.: A knowledge-based approach to the layout optimization of human-robot collaborative workplace. Int. J. Interact. Des. Manuf. 15(1), 133–135 (2021). https://doi.org/10.1007/s12008-020-00742-0

Rega, A., Di Marino, C., Pasquariello, A., Vitolo, F., Patalano, S., Zanella, A., Lanzotti, A.: Collaborative workplace design: a knowledge-based approach to promote human-robot collaboration and multi-objective layout optimization. Appl. Sci. 11(24), 12147 (2021). https://doi.org/10.3390/app112412147

Matsas, E., Vosniakos, G.-C.: Design of a virtual reality training system for human–robot collaboration in manufacturing tasks. Int. J. Interact. Des. Manuf. 11(2), 139–153 (2017). https://doi.org/10.1007/s12008-015-0259-2

Tarallo, A., Di Gironimo, G., Gerbino, S., Vanacore, A., Lanzotti, A.: Robust interactive design for ergonomics and safety: R-IDEaS procedure and applications. Int. J. Interact. Des. Manuf. 13(4), 1259–1268 (2019). https://doi.org/10.1007/s12008-019-00584-5

Mateus, J.C., Claeys, D., Limère, V., Cottyn, J., Aghezzaf, E.-H.: A structured methodology for the design of a human–robot collaborative assembly workplace. Int. J. Adv. Manuf. Technol. 102(5), 2663–2681 (2019). https://doi.org/10.1007/s00170-019-03356-3

Michalos, G., Kousi, N., Karagiannis, P., Gkournelos, C., Dimoulas, K., Koukas, S., Mparis, K., Papavasileiou, A., Makris, S.: Seamless human robot collaborative assembly—an automotive case study. Mechatronics 55, 194–211 (2018). https://doi.org/10.1016/j.mechatronics.2018.08.006

Patalano, S., Lanzotti, A., Del Giudice, D.M., Vitolo, F., Gerbino, S.: On the usability assessment of the graphical user interface related to a digital pattern software tool. Int. J. Interact. Des. Manuf. 11(3), 457–469 (2017). https://doi.org/10.1007/s12008-015-0287-y

Gardan, J.: Definition of users’ requirements in the customized product design through a user-centered translation method. Int. J. Interact. Des. Manuf. 11(4), 813–821 (2017). https://doi.org/10.1007/s12008-015-0275-2

Filippi, S., Motyl, B.: Interactive redesign of products’ User eXperience: how to. Int. J. Interact. Des. Manuf. 16(1), 65–80 (2022). https://doi.org/10.1007/s12008-021-00805-w

Ralyté, J., Jeusfeld, M.A., Backlund, P., Kühn, H., Arni-Bloch, N.: A knowledge-based approach to manage information systems interoperability. Inf. Syst. 33(7–8), 754–784 (2008). https://doi.org/10.1016/j.is.2008.01.008

Favi, C., Garziera, R., Campi, F.: A rule-based system to promote design for manufacturing and assembly in the development of welded structure: method and tool proposition. Appl. Sci. 11(5), 2326 (2021). https://doi.org/10.3390/app11052326

Ansari, F., Hold, P., Khobreh, M.: A knowledge-based approach for representing jobholder profile toward optimal human–machine collaboration in cyber physical production systems. CIRP J. Manuf. Sci. Technol. 28, 87–106 (2020). https://doi.org/10.1016/j.cirpj.2019.11.005

ISO 13854:2017. Safety of machinery—minimum gaps to avoid crushing of parts of the human body. International Organization for Standardization, Geneva, Switzerland

ISO 12100:2010. Safety of machinery—general principles for design—risk assessment and risk reduction. International Organization for Standardization, Geneva, Switzerland

Marvel, J.A., Falco, J., Marstio, I.: Characterizing task-based human–robot collaboration safety in manufacturing. IEEE Trans. Syst. Man Cybern. Syst. 45(2), 260–275 (2015). https://doi.org/10.1109/TSMC.2014.2337275

Faccio, M., Minto, R., Rosati, G., Bottin, M.: The influence of the product characteristics on human-robot collaboration: a model for the performance of collaborative robotic assembly. Int. J. Adv. Manuf. Technol. 106(5), 2317–2331 (2020). https://doi.org/10.1007/s00170-019-04670-6

Wu, D.L., Zhu, H.M., Zhen, X.J., Fan, X.M.: Tools and equipment modelling for interactive assembling operating in a virtual environment. Int. J. Prod. Res. 49(7), 1851–1876 (2011)

Kim, W., Peternel, L., Lorenzini, M., Babič, J., Ajoudani, A.: A human–robot collaboration framework for improving ergonomics during dexterous operation of power tools. Robot. Comput. Integr. Manuf. 68, 102084 (2021). https://doi.org/10.1016/j.rcim.2020.102084

ISO 11228-1:2003. Ergonomics - Manual handling - Part 1: Lifting and carrying. International Organization for Standardization, Geneva, Switzerland

Baltrusch, S., Krause, F., de Vries, A., van Dijk, W., de Looze, M.: What about the human in human robot collaboration? A literature review on hrc’s effects on aspects of job quality. Ergonomics 65(5), 719–740 (2022)

Tan, J.T.C., Duan, F., Kato, R., Arai, T.: Collaboration Planning by Task Analysis in Human-Robot Collaborative Manufacturing System, pp. 113–132. IntechOpen, Rijeka, Croatia (2010)

Stanton, N.A.: Hierarchical task analysis: developments, applications, and extensions. Appl. Ergon. 37(1), 55–79 (2006). https://doi.org/10.1016/j.apergo.2005.06.003

Bänziger, T., Kunz, A., Wegener, K.: Optimizing human-robot task allocation using a simulation tool based on standardized work descriptions. J. Intell. Manuf. 31(7), 1635–1648 (2020). https://doi.org/10.1007/s10845-018-1411-1

Deo, N.: Graph Theory with Applications to Engineering and Computer Science. Dover Publications: Made available through hoopla, United States (2017). https://doi.org/10.3390/inventions5010010

Majeed, A., Rauf, I.: Graph theory: a comprehensive survey about graph theory applications in computer science and social networks. Inventions 5(1), 10 (2020). https://doi.org/10.3390/inventions5010010

Ore, F., Sánchez, J.L.J., Wiktorsson, M., Hanson, L.: Design method of human–industrial robot collaborative workstation with industrial application. Int. J. Comput. Integr. Manuf. 33(9), 911–924 (2020). https://doi.org/10.1080/0951192X.2020.1815844

Acknowledgements

The current paper represents an extended version of a conference proceeding titled “A Graph-Based Multi-level Framework to Support the Designing of Collaborative Workplaces” originally presented at ADM 2021. The earlier paper [18] is available for reference at https://link.springer.com/chapter/10.1007/978-3-030-91234-5_64. While building upon the foundation laid in the previous publication, this paper offers additional analysis and introduces novel contributions. Notably, the State of the Art section has been expanded, providing a comprehensive overview of relevant research. A new section on the Knowledge-based approach has been included as the theoretical basis for the presented work. The adjacency matrix has been reported, offering insights into the underlying graph structure. The Smart Graph Interface has been improved by adding two new panels containing decision-making support features. Finally, the paper proposes two further case studies, enriching the practical applicability of the work.

Funding

Open access funding provided by Università degli Studi di Napoli Federico II within the CRUI-CARE Agreement. This study was developed with the economic support of MIUR (Italian Ministry of Universities and Research) under the remit of Project ARS01_00861, ‘Integrated collaborative systems for smart factory - ICOSAF’.

Author information

Authors and Affiliations

Contributions

Authors contributed equally to this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Di Marino, C., Rega, A., Pasquariello, A. et al. An interactive graph-based tool to support the designing of human–robot collaborative workplaces. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01607-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01607-y