Abstract

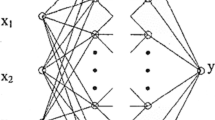

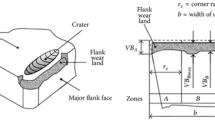

Manufacturing sector is always looking for higher level of automation in various operations. However, a few key challenges affects the whole machining process from being fully automated. One of these problems is the computerized tool wear monitoring. Automatic tool condition monitoring is becoming increasingly important in the metal cutting industry due to the wear on the tool impacts the efficiency of the manufactured component. Tool wear and life are major factors that influence part quality. To evaluate the useful life of the tool, most industries rely on historical data. Tool wear may be measured in two ways: directly and indirectly. The tool wear measured using the indirect approach uses parameter that impact tool life. Tool wear is traditionally assessed using microscope, which is time-consuming method. Direct method such as computer vision system is fast and reliable approach to monitor the condition of tool during machining. The goal of this research is to employ computer vision techniques to automate flank wear assessment, predict flank wear, and improve tool life prediction. The process of measuring and monitoring tool wear is automated using computer vision techniques using industrial camera with telecentric lens. Different algorithms related to feed forward back propagation neural network: Levenberg - Marquardt algorithm, Bayesian regularization and scaled conjugate gradient are utilized to predict the tool life. Performance evaluation of these algorithms is done to find most accurate algorithm for tool wear prediction system. The presented approach helps industries to detect the status of tool wear and can be a potential approach for estimating tool life in turning operations.

Similar content being viewed by others

Abbreviations

- NN:

-

Neural Network

- ANN:

-

Artificial neural network

- BPNN:

-

Back propagation neural networks

- CNC:

-

Computer numerical control

- RAM:

-

Random Access Memory

- TCM:

-

Tool condition monitoring

- AISI:

-

American Iron and Steel Institute

- T:

-

Tool life

- VBmax:

-

Maximum flank wear

- RTL:

-

Remaining Tool life

- MARE:

-

Mean absolute relative error

- MSE:

-

Mean squared error

- RMSE:

-

Root Mean Square Error

- WPC:

-

White Pixels Counts

- MAPE:

-

Mean Absolute Percentage Error

References

Siddhpura, A., Paurobally, R.: A review of flank wear prediction methods for tool condition monitoring in a turning process. Int. J. Adv. Manuf. Technol. 65, 1–4 (2013). doi: https://doi.org/10.1007/s00170-012-4177-1

Nath, C.: Integrated Tool Condition Monitoring Systems and Their Applications: A Comprehensive Review. Procedia Manuf. 48, 852–863 (2020). doi: https://doi.org/10.1016/j.promfg.2020.05.123

Thakre, A.A., Lad, A.V., Mala, K.: “Measurements of tool wear parameters using machine vision system,” Model. Simul. Eng., vol. pp. 1–10, 2019, doi: (2019). https://doi.org/10.1155/2019/1876489

Prabhu, S., Karthik Saran, S., Majumder, D., Siva Teja, P.V.: A Review on Applications of Image Processing in Inspection of Cutting Tool Surfaces. Appl. Mech. Mater. (2015). doi: https://doi.org/10.4028/www.scientific.net/amm.766-767.635

Mikołajczyk, T., Nowicki, K., Kłodowski, A., Pimenov, D.Y.: “Neural network approach for automatic image analysis of cutting edge wear,” Mech. Syst. Signal Process., vol. 88, no. October pp. 100–110, 2017, doi: (2016). https://doi.org/10.1016/j.ymssp.2016.11.026

Chethan, Y.D.D., Ravindra, H.V.V., Krishnegowda, Y.T.T.: “Optimization of machining parameters in turning Nimonic-75 using machine vision and acoustic emission signals by Taguchi technique,” Meas. J. Int. Meas. Confed., vol. 144, pp. 144–154, Oct. doi: (2019). https://doi.org/10.1016/j.measurement.2019.05.035

Mohanraj, T., Shankar, S., Rajasekar, R., Sakthivel, N.R., Pramanik, A.: Tool condition monitoring techniques in milling process-a review. J. Mater. Res. Technol. 9(1), 1032–1042 (2020). doi: https://doi.org/10.1016/j.jmrt.2019.10.031

Gouarir, A., Martínez-Arellano, G., Terrazas, G., Benardos, P., Ratchev, S.: “In-process tool wear prediction system based on machine learning techniques and force analysis,” Procedia CIRP, vol. 77, no. Hpc, pp. 501–504, doi: (2018). https://doi.org/10.1016/j.procir.2018.08.253

Dutta, S., Pal, S.K., Sen, R.: Tool condition monitoring in turning by applying machine vision. J. Manuf. Sci. Eng. Trans. ASME. 138(5), 1–17 (2016). doi: https://doi.org/10.1115/1.4031770

Serin, G., Sener, B., Ozbayoglu, A.M., Unver, H.O.: Review of tool condition monitoring in machining and opportunities for deep learning. Int. J. Adv. Manuf. Technol. 109, 3–4 (2020). doi: https://doi.org/10.1007/s00170-020-05449-w

Zhou, Y., Xue, W.: Review of tool condition monitoring methods in milling processes. Int. J. Adv. Manuf. Technol. 96, 5–8 (2018). doi: https://doi.org/10.1007/s00170-018-1768-5

Ambhore, N., Kamble, D., Chinchanikar, S., Wayal, V.: “Tool condition monitoring system: A review,” in Materials Today: Proceedings, vol. 2, no. 4–5. doi: (2015). https://doi.org/10.1016/j.matpr.2015.07.317

Dutta, S., Pal, S.K., Mukhopadhyay, S., Sen, R.: Application of digital image processing in tool condition monitoring: A review. CIRP J. Manuf. Sci. Technol. 6(3), 212–232 (2013). doi: https://doi.org/10.1016/j.cirpj.2013.02.005

Liu, Y., Guo, L., Gao, H., You, Z., Ye, Y., Zhang, B.: “Machine vision based condition monitoring and fault diagnosis of machine tools using information from machined surface texture: A review,” Mech. Syst. Signal Process., vol. 164, no. May p. 108068, 2022, doi: (2021). https://doi.org/10.1016/j.ymssp.2021.108068

Fong, K.M., Wang, X., Kamaruddin, S., Ismadi, M.Z.: “Investigation on universal tool wear measurement technique using image-based cross-correlation analysis,” Meas. J. Int. Meas. Confed., vol. 169, no. June p. 108489, 2021, doi: (2020). https://doi.org/10.1016/j.measurement.2020.108489

Yu, J., Cheng, X., Lu, L., Wu, B.: A machine vision method for measurement of machining tool wear. Measurement. 182, 109683 (2021). doi: https://doi.org/10.1016/j.measurement.2021.109683

Peng, R., Pang, H., Jiang, H., Hu, Y.: Study of Tool Wear Monitoring Using Machine Vision. Autom. Control Comput. Sci. 54(3), 259–270 (2020)

Yu, J., Zhou, J.: “A Machine vision method for non-contact Tool Wear Inspection,” Proc. – 2020 Chinese Autom. Congr. CAC 2020, pp. 1239–1243, doi: (2020). https://doi.org/10.1109/CAC51589.2020.9326846

Ong, P., Lee, W.K., Lau, R.J.H.: “Tool condition monitoring in CNC end milling using wavelet neural network based on machine vision,” Int. J. Adv. Manuf. Technol., vol. 104, no. 1–4, pp. 1369–1379, Sep. doi: (2019). https://doi.org/10.1007/s00170-019-04020-6

Hou, Q., Sun, J., Huang, P.: A novel algorithm for tool wear online inspection based on machine vision. Int. J. Adv. Manuf. Technol. 101, 9–12 (2019). doi: https://doi.org/10.1007/s00170-018-3080-9

Twardowski, P., Wiciak-Pikula, M.: Prediction of tool wear using artificial neural networks during turning of hardened steel. Mater. (Basel). 12(19) (2019). doi: https://doi.org/10.3390/ma12193091

Antić, A., Popović, B., Krstanović, L., Obradović, R., Milošević, M.: Novel texture-based descriptors for tool wear condition monitoring. Mech. Syst. Signal. Process. 98, 1–15 (2018). doi: https://doi.org/10.1016/j.ymssp.2017.04.030

Dai, Y., Zhu, K.: “A machine vision system for micro-milling tool condition monitoring,” Precis. Eng., vol. 52, no. May pp. 183–191, Apr. 2018, doi: (2017). https://doi.org/10.1016/j.precisioneng.2017.12.006

Mikołajczyk, T., Nowicki, K., Bustillo, A., Pimenov, D.Y.: Predicting tool life in turning operations using neural networks and image processing. Mech. Syst. Signal. Process. 104, 503–513 (2018). doi: https://doi.org/10.1016/j.ymssp.2017.11.022

García-Ordás, M.T., Alegre-Gutiérrez, E., Alaiz-Rodríguez, R., González-Castro, V.: “Tool wear monitoring using an online, automatic and low cost system based on local texture,” Mech. Syst. Signal Process., vol. 112, pp. 98–112, Nov. doi: (2018). https://doi.org/10.1016/j.ymssp.2018.04.035

Moldovan, O.G., Dzitac, S., Moga, I., Vesselenyi, T., Dzitac, I.: Tool-wear analysis using image processing of the tool flank. Symmetry (Basel). 9(12), 1–18 (2017). doi: https://doi.org/10.3390/sym9120296

García-Ordás, M.T., Alegre, E., González-Castro, V., Alaiz-Rodríguez, R.: A computer vision approach to analyze and classify tool wear level in milling processes using shape descriptors and machine learning techniques. Int. J. Adv. Manuf. Technol. 90, 5–8 (May 2017). doi: https://doi.org/10.1007/s00170-016-9541-0

Dutta, S., Pal, S.K., Sen, R.: On-machine tool prediction of flank wear from machined surface images using texture analyses and support vector regression. Precis Eng. 43, 34–42 (2016). doi: https://doi.org/10.1016/j.precisioneng.2015.06.007

Dutta, S., Pal, S.K., Sen, R.: Progressive tool flank wear monitoring by applying discrete wavelet transform on turned surface images. Meas. J. Int. Meas. Confed. 77, 388–401 (2016). doi: https://doi.org/10.1016/j.measurement.2015.09.028

Zhang, C., Yao, X., Zhang, J., Jin, H.: Tool condition monitoring and remaining useful life prognostic based on awireless sensor in dry milling operations. Sens. (Switzerland). 16(6) (2016). doi: https://doi.org/10.3390/s16060795

Szydłowski, M., Powałka, B., Matuszak, M., Kochmański, P.: Machine vision micro-milling tool wear inspection by image reconstruction and light reflectance. Precis Eng. 44, 236–244 (2016). doi: https://doi.org/10.1016/j.precisioneng.2016.01.003

Mehta, S., Singh, R.A.R.A., Mohata, Y., Kiran, M.B.B.: “Measurement and Analysis of Tool Wear Using Vision System,” in IEEE 6th International Conference on Industrial Engineering and Applications, ICIEA 2019, 2019, pp. 45–49. doi: (2019). https://doi.org/10.1109/IEA.2019.8715209

Marani, M., Zeinali, M., Kouam, J., Songmene, V., Mechefske, C.K.: Prediction of cutting tool wear during a turning process using artificial intelligence techniques. Int. J. Adv. Manuf. Technol. 111, 1–2 (2020). doi: https://doi.org/10.1007/s00170-020-06144-6

Shen, Y., et al.: Predicting tool wear size across multi-cutting conditions using advanced machine learning techniques. J. Intell. Manuf. 32(6), 1753–1766 (2021)

Fernández-Robles, L., Sánchez-González, L., Díez-González, J., Castejón-Limas, M., Pérez, H.: Use of image processing to monitor tool wear in micro milling. Neurocomputing. 452, 333–340 (2021). doi: https://doi.org/10.1016/j.neucom.2019.12.146

Baig, R.U., Javed, S., Khaisar, M., Shakoor, M., Raja, P.: Development of an ANN model for prediction of tool wear in turning EN9 and EN24 steel alloy. Adv. Mech. Eng. 13(6), 1–14 (2021). doi: https://doi.org/10.1177/16878140211026720

Cheng, M., Jiao, L., Shi, X., Wang, X., Yan, P., Li, Y.: “An intelligent prediction model of the tool wear based on machine learning in turning high strength steel,” Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., vol. 234, no. 13, pp. 1580–1597, doi: (2020). https://doi.org/10.1177/0954405420935787

Bergs, T., Holst, C., Gupta, P., Augspurger, T.: Digital image processing with deep learning for automated cutting tool wear detection. Procedia Manuf. 48, 947–958 (2020). doi: https://doi.org/10.1016/j.promfg.2020.05.134

Tiwari, K., Shaik, A., Arunachalam, N.: Tool wear prediction in end milling of Ti-6Al-4V through Kalman filter based fusion of texture features and cutting forces. Procedia Manuf. 26, 1459–1470 (2018). doi: https://doi.org/10.1016/j.promfg.2018.07.095

Kong, D., Chen, Y., Li, N.: Gaussian process regression for tool wear prediction. Mech. Syst. Signal. Process. 104, 556–574 (2018). doi: https://doi.org/10.1016/j.ymssp.2017.11.021

Xiong, G., Liu, J., Avila, A.: Cutting tool wear measurement by using active contour model based image processing. 2011 IEEE Int. Conf. Mechatronics Autom. ICMA 2011. 2, 670–675 (2011). doi: https://doi.org/10.1109/ICMA.2011.5985741

Acknowledgements

The authors would like to acknowledge the infrastructural facility and resources provided by Nirma University for carrying out the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bagga, P.J., Makhesana, M.A., Bhavsar, D.L. et al. Experimental investigation of different NN approaches for tool wear prediction based on vision system in turning of AISI 1045 steel. Int J Interact Des Manuf 17, 2565–2582 (2023). https://doi.org/10.1007/s12008-022-01072-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-01072-z