Abstract

Background

Charnley low-friction torque total hip arthroplasty (THA) remains the gold standard in THA. The main cause for failure is wear of the socket. Highly crosslinked polyethylene (HXLPE) has been associated with reduced wear rates. Also, oxidized zirconium has shown in vitro reduced wear rates. However, to our knowledge, there are no data comparing oxidized zirconium femoral heads with metal heads against HXLPE or ultrahigh-molecular-weight polyethylene (UHMWPE) when 22.25-mm bearings were used, which was the same size that performed so well in Charnley-type THAs.

Questions/purposes

We hypothesized that after a minimal 4-year followup (1) use of HXLPE would result in lower radiographic wear than UHMWPE when articulating with a stainless steel head or with an oxidized zirconium head; (2) use of oxidized zirconium would result in lower radiographic wear than stainless steel when articulating with UHMWPE and HXLPE; and (3) there would be no difference in terms of Merle d’Aubigné scores between the bearing couple combinations.

Methods

One hundred patients were randomized to receive cemented THA with either oxidized zirconium or a stainless steel femoral head. UHMWPE was used in the first 50 patients, whereas HXLPE was used in the next 50 patients. There were 25 patients in each of the four bearing couple combinations. All other parameters were identical in both groups. Complete followup was available in 86 of these patients. Femoral head penetration was measured using a validated computer-assisted method dedicated to all-polyethylene sockets. Clinical results were compared between the groups using the Merle d’Aubigné score.

Results

In the UHMWPE series, the median steady-state penetration rate from 1 year onward was 0.03 mm/year (range, 0.003–0.25 mm/year) in the oxidized zirconium group versus 0.11 mm/year (range, 0.03–0.29 mm/year) in the metal group (difference of medians 0.08, p < 0.001). In the HXLPE series, the median steady-state penetration rate from 1 year onward was 0.02 mm/year (range, −0.32 to 0.07 mm/year) in the oxidized zirconium group versus 0.05 mm/year (range, −0.39 to 0.11 mm/year) in the metal group (difference of medians 0.03, p < 0.001). The Merle d’Aubigné scores were no different between the groups with a median of 18 in each of the groups (range, 16–18).

Conclusions

This study demonstrated femoral head penetration was reduced by oxidized zirconium when compared with metal on both UHMWPE and HXLPE. However, apart the metal-UHMWE group, all other groups had a steady-state penetration rate well below the osteolysis threshold with a low difference between groups that might not be clinically important at this point. Longer-term followup is needed to warrant whether wear reduction will generate less occurrence of osteolysis and aseptic loosening.

Level of Evidence

Level II, therapeutic study.

Similar content being viewed by others

Introduction

The low-friction torque arthroplasty, pioneered by Sir John Charnley, has been associated with excellent implant survival up to 30-year followup using revision for aseptic loosening as the endpoint [1, 24, 25]. At the authors’ institution, a modified Charnley-type low-friction THA, using a 22.25-mm metal head articulating with a cemented all-polyethylene socket, has been used since 1972 [14]. Our previous results have been consistent with those reported by other groups, even in high-demand patient populations [9, 13]. We found, along with others, that the main reason for revision was socket loosening related to high polyethylene wear and periprosthetic osteolysis [23]. Several approaches have been proposed to decrease wear of ultrahigh-molecular-weight polyethylene (UHMWPE), including the development of highly crosslinked polyethylene (HXLPE) [10, 19, 22] and the reduction of the coefficient of friction and increased scratch resistance of the femoral head. Several clinical prospective controlled studies comparing HXLPE with UHMWPE in THA up to 10-year followup clearly indicate reduced wear for HXLPE [3, 7, 11, 15].

However, fewer data are available for modification to the femoral head component. Oxidized zirconium (Oxinium; Smith & Nephew, Memphis, TN, USA) was introduced in 1997 based on favorable in vitro data [2, 8]. We are aware of only three in vivo studies, including two randomized trials, that have assessed its actual clinical benefits in terms of reduced wear when compared with metal in primary THAs [5, 12, 21]. Also, these studies have been limited by their minimum followup of only 2 years, and none evaluated Charnley-type low-friction torque arthroplasty, which we define as a 22.25-mm femoral head articulating with an all-cemented polyethylene socket. However, Charnley-type arthroplasty deviates from the original Charnley device in terms of femoral head modularity, stem design including offset and range of sizes, but also cementing technique. We therefore performed a randomized controlled trial comparing the penetration rate of metal and oxidized zirconium femoral heads on UHMWPE and HXLPE.

We hypothesized that after a minimal 4-year followup, (1) use of HXLPE would result in lower radiographic wear than UHMWPE when articulating with a stainless steel head or with an oxidized zirconium head; (2) use of oxidized zirconium would result in lower radiographic wear than stainless steel when articulating with UHMWPE and HXLPE; and (3) there would be no difference in terms of Merle d’Aubigné scores between the bearing couple combinations.

Patients and Methods

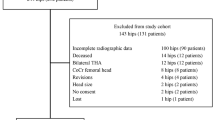

Between January 2006 and December 2006, we used a 22.25-mm femoral head and an all-polyethylene cemented socket in primary THAs for all patients in our practice. All patients were proposed to participate to this randomized clinical trial. The inclusion criteria were primary or secondary osteoarthritis of the hip requiring THA, age ≤ 75 years, and permanent residency in France to reduce the number of dropouts. Of the 143 patients operated using this approach during the study period, 100 were eligible and consented to enroll in this randomized clinical trial. Three patients (3%) had died from an unrelated cause, four (4%) had been lost to followup, seven (7%) had inadequate radiographs that were rejected by the software as a result of pelvic rotation of more than 25° between pairs of radiographs, whereas 86 patients (86%) were available for clinical and radiologic followup at a minimum of 4 years (median, 6 years; range, 4–8 years). Final group numbers were as follows: UHMWPE-stainless steel: 22 patients; UHMWPE-oxidized zirconium: 22 patients; HXLPE-stainless steel: 21 patients; and HXLPE-oxidized zirconium: 21 patients. Median followup for the UHMWPE groups was 7 years (range, 5–8 years). Median followup for the HXLPE groups was 6 years (range, 4–7 years).

There were 56 women and 44 men with a median age of 62 years (range, 21–75 years), a median height of 166 cm (range, 147–190 cm), a median weight of 75 kg (range, 48–115 kg), and a median body mass index of 26 kg/m2 (range, 17–38 kg/m2). The patients were randomized using a computer-generated block randomization scheme to receive either a metal or oxidized zirconium femoral head. The randomization was based on the order of patient presentation, so each patient was randomized individually, and was performed during baseline assessment. To avoid surgeon bias, randomization was stratified by surgeon so that each surgeon performed equivalent numbers. The first 50 patients had UHMWPE sockets, whereas the next 50 patients had HXLPE sockets of an identical design, all being all-cemented cups. This change in the polyethylene material occurred within a 6-month interval and was done as part of this randomized trial. There were 25 patients in each of the four bearing couple combinations. All other parameters were identical in both groups. The baseline demographics of the four groups were not different (Table 1). The CONSORT flow diagram is shown (Fig. 1). All patients had given informed consent, and the study was approved by our ethics committee.

UHMWPE (Smith & Nephew) cups were machined from compression-molded GUR 1050 UHMWPE and sterilized using ethylene oxide (EtO). The HXLPE (XLPE®; Smith & Nephew) cups were made from compression-molded GUR 1050 UHMWPE gamma irradiated to an absorbed dose level of 10 Mrads to promote crosslinking followed by melting at 150° C with final machining and terminally sterilized using EtO.

All patients received CMK21™ (Smith & Nephew) stems of M30NW stainless steel with a polished surface finish (Ra value 0.04 μm) and a quadrangular section. In all hips, a 22.25-millimeter diameter femoral head made either of oxidized zirconium (Oxinium; Smith & Nephew) or stainless steel (Smith & Nephew) with Ra of 0.01 μm was used.

The procedures were carried out by two of us (JPC, MH) through a lateral approach with a trochanteric osteotomy. The components were fixed with CMW Type 1 bone cement (DePuy 1, Exeter, Devon, IL, USA). The cement was mixed in air. On the acetabular side, the cement was hand-packed. On the femoral side, a second-generation cementing technique (distal plugging of the femoral canal, retrograde injection of cement into the femur, cement pressurization) was used according to the French paradox [4].

The postoperative management was identical for each group.

Femoral Head Penetration

The primary criterion for evaluation was linear head penetration measurement, as an assessment of true wear and creep of the material, using the Martell system [17]. In the current study, we used a specific version of the Martell software dedicated to all-polyethylene cups that has been recently validated according to the ASTM standards [16]. It has a mean bias of 0.089 ± 0.060 mm, a mean repeatability of 0.106 ± 0.292 mm, and a mean reproducibility of 0.112 ± 0.308 mm. All measurements were done on AP radiographs of the pelvis, made with the x-ray beam centered on the symphysis pubis. Radiographs were made with the patient supine within 6 weeks after the operation (baseline radiograph), at 1 year, and at the latest followup. The radiographs were digitized (digitizer Vidar VRX-plus; Vidar System Corporation, Herndon, VA, USA) using a pixel density of 150 dots per inch and linked to an IBM-compatible computer. The Martell Hip Analysis Suite Version 8.0.4.3 (University of Chicago Tech, Chicago, IL, USA) is a validated computer-assisted edge detection method. This software allows measurement of the linear vector of socket penetration and calculation of volumetric wear based on the magnitude of femoral head displacement, the direction of displacement with respect to the cup face, and the femoral head size. Steady-state wear was determined by the penetration of the femoral head between 1 year and the latest followup. We determined these values in the UHMWPE and HXLPE groups, respectively. The results of values of socket abduction were calculated with use of the Hip Analysis Suite. All radiologic analyses were performed by the same independent observer (AZ) who was blinded to the materials of the femoral head and socket. The influence of several patient-related factors on polyethylene wear was assessed, including the age of the patients at the time of the index arthroplasty, activity, gender, and body mass index. The effect of socket size and inclination also was evaluated.

Clinical Evaluation

Hip functional results were rated according to the Merle d’Aubigné [20] grading system. The hip score then was classified as excellent (18 points), very good (17 points), good (16 points), fair (15 points), poor (14 points), or bad (≤ 13 points). The clinical followup was performed by the operating surgeons (JPC, MH).

Statistical Analysis

A sample size calculation was performed using femoral head penetration as the endpoint. On the basis of previous data, a penetration rate of 0.1 mm/year was assumed for the metal heads with a SD of 0.1 mm/year [22, 23]. We expected a penetration rate of 0.02 mm/year for the oxidized zirconium heads. Because four groups were compared, we used the Bonferroni correction to determine the type I error, which gave an adjusted α value of 0.0125. Therefore, power calculation, using a Mann-Whitney test, indicated that 25 patients would be necessary in each arm (α = 0.0125, β = 0.8).

The penetration data were examined for distribution using a Shapiro-Wilk test. The data were found to be not normally distributed, and thus a nonparametric Kruskal-Wallis test was used to evaluate the differences among the four groups. The influence of numerous variables on femoral head penetration was assessed using the Spearman correlation test, a Mann-Whitney, or a Kruskal-Wallis test, as appropriate. The demographic data and clinical results were compared using Fisher’s exact probability or the Kruskal-Wallis test followed when significant by pairwise comparisons using the Mann-Whitney test. Significance was determined with StatView statistical software (Version 5.0; SAS Institute, Cary, NC, USA) and was defined as a p value of < 0.0125.

Results

Femoral Head Penetration

The Kruskal-Wallis test indicated a p value < 0.001, allowing pairwise comparisons among the four groups. In the UHMWPE series, the steady-state penetration rate was lower in the oxidized zirconium group than in the metal group; the median steady-state penetration rate from 1 year onward was 0.03 mm/year (range, 0.003–0.25 mm/year) in the oxidized zirconium group versus 0.11 mm/year (range, 0.03–0.29 mm/year) in the metal group (difference of medians 0.08, p < 0.001). In the HXLPE series, likewise, the penetration rate was lower in the oxidized zirconium group; the median steady-state penetration rate from 1 year onward was 0.02 mm/year (range, −0.32 to 0.07 mm/year) in the oxidized zirconium group versus 0.05 mm/year (range, −0.39 to 0.11 mm/year) in the metal group (difference of medians 0.03, p < 0.001). Also, in the metal group, HXLPE reduced steady-state penetration when compared with the UHMWPE material; the median steady-state penetration rate from 1 year onward was 0.108 mm/year (range 0.036–0.288 mm/year) versus 0.054 mm/year (range, −0.396–1.108 mm/year) in the HXLPE group (difference of medians 0.054, p < 0.001). However, in the oxidized zirconium group, the steady-state penetration rate was not different between UHMWPE and HXLPE with the numbers available; the median steady-state penetration rate from 1 year onward was 0.036 mm/year (range, 0.0036–0.252 mm/year) in the UHMWPE group versus 0.018 mm/year (range, −0.324 to 0.072 mm/year) in the HXLPE group (differences of medians 0.018, p = 0.29). Among the different variables evaluated, with the numbers available, no relationship was found between wear and gender (p = 0.84), age at index arthroplasty (p = 0.79), or acetabular inclination (p = 0.59).

Clinical Results

There were no differences in any of the groups in terms of Merle d’Aubigné hip scores at latest followup. The median value Merle d’Aubigné hip score at the latest followup was 18 in each of the four study groups (range, 16–18) with no difference with the number available (p = 0.64). There were likewise no differences in terms of the qualitative ratings of the scores (p = 0.84); of the 43 hips in the UHMWPE series with complete followup, 29 hips were rated excellent, 12 hips as very good, one hip as good, and one hip as poor. Of the 43 hips in the HXLPE series with complete followup, 33 hips were rated excellent, seven hips as very good, two hips as good, and one hip as poor. No relationship was found between linear wear rate and the final functional hip score in either group (p = 0.33 and 0.42, respectively). No specific complication related to the use of oxidized zirconium femoral heads was recorded, and no patient underwent revision surgery.

Discussion

The low-friction torque THA has been used for over 40 years with excellent functional results and high survivorship in the long term [1, 24, 25]. Failures have mostly been related to polyethylene wear > 0.1 mm/year leading to periprosthetic osteolysis and loosening of the implants [23]. We are aware of no study evaluating alternate surface bearings with the use of 22.25-mm heads. We therefore performed a randomized controlled trial comparing the penetration rate of metal and oxidized zirconium femoral heads on UHMWPE and HXLPE. The current study shows that oxidized zirconium femoral heads reduced the steady-state penetration rate of both UHMWPE and HXLPE, the lowest penetration being observed with the oxidized zirconium on the HXLPE combination. However, the steady-state penetration rate was well below the osteolysis threshold of 0.1 mm/year in each of the four study groups apart from the metal-UHMWPE combination that provided a steady-state penetration rate of 0.108 mm/year. Likewise, the difference of medians was low, indicating that although statistically significant, the observed difference might not translate into reduced occurrence of osteolysis, loosening, and revision.

Our study has several limitations. First, the Hip Analysis Suite software dedicated to all-polyethylene sockets has lower reproducibility and repeatability with larger bias when compared with the original version for cementless sockets. However, it has been recently demonstrated that precise data also could be obtained with this version [16]. It should however be acknowledged that the detection limits of the current version of the Martell method were close to our results. Second, only a two-dimensional penetration analysis was performed in the current study, although it has a lower accuracy and detects 10% less wear than the three-dimensional technique but has a higher precision [18]. Third, we included a relatively small number of patients in each group, because two types of polyethylene sockets were used, and 14% of the initial patients were either lost or had inadequate radiographs. However, although the power of the study was set at only 80%, we were able to demonstrate differences in the steady-state penetration rate. Fourth, in the current study we used stainless steel rather that chromium-cobalt (CoCr) femoral heads, although the latter might have better tribologic properties. However, CoCr heads on stainless steel stems have a high galvanic potential, and stainless steel heads more closely mimic the Charnley approach. Fifth, we did not evaluate osteolysis, because our study protocol did not include a CT scan, which would have resulted in increased radiation exposure and additional costs. Last, our findings cannot be extrapolated to other ceramics, because the core material is highly different between oxidized zirconium and bulk ceramics.

The results of the current study are consistent with other controlled studies comparing the penetration rate of various HXLPE with nonhighly crosslinked material articulating with a metal head at followup to 10 years [3, 7, 11, 15]. In all these published studies, the penetration rate or the total penetration, according to the method of measurement, was systematically found to be lower for the HXLPE group of patients.

Concerning the evaluation of the femoral head material on polyethylene, we are aware of two randomized controlled trials comparing oxidized zirconium versus metal-on-PE in primary THAs. Contrary to the studies of Kadar et al. [12] and Morison et al. [21], we found a reduced steady-state penetration rate with oxidized zirconium femoral heads compared with metal-on-HXLPE. The steady-state penetration rate was different between oxidized zirconium and metal in the UHMWPE with the numbers available. The randomized study of Kadar et al. [12] included a total of 150 patients, and penetration of the femoral head was measured at 2 years using radiostereometric analysis. The values were not different between CoCr and oxidized zirconium femoral heads combined either with EtO UHMWPE or HXLPE. Interestingly, the femoral head penetration with the Charnley 22.25-mm heads was no different from the values in the XLPE group with CoCr or oxidized zirconium heads. However, the followup of only 2 years precluded any strong conclusions, because most of the femoral head penetration was represented by creep rather than wear. Morison et al. [21] randomized 80 patients (91 hips) in one of the following groups, all using 28-mm heads: CoCr-Eto UHMWPE (21 hips), CoCr-HXLPE (24 hips), oxidized zirconium-Eto UHMWPE (22 hips), and oxidized zirconium-HXLPE (24 hips). Femoral head penetration was measured in 87 hips using Polyware (The Logic Group, Austin, TX, USA) software after a mean followup of 7 years (range, 2-8 years). No difference was observed between the CoCr and oxidized zirconium head. It is however unclear how these authors measured wear, and the relatively high values they obtained may rather represent penetration rather than wear, including both creep and wear. Also, the metal femoral head in our study was made of stainless steel, whereas in the two other studies, it was made of CoCr. The different metal material might explain increased steady-state penetration when compared with oxidized zirconium. Garvin et al. [5] reported on 54 patients (56 hips) aged younger than 68 years who underwent primary THA using a 28-mm (40 patients), a 32-mm (15 patients), or a 36-mm (one patient) oxidized zirconium head on HXLPE. Femoral head penetration was measured with the Hip Analysis software, and the authors were able to calculate true wear values. Using the regression method, the steady-state wear was 0.004 ± 0.059 mm/year. These data are in line with our findings. Other ceramics on polyethylene including alumina and zirconia have been combined with mainly UHMWPE, but these are bulk ceramics that have specific complications, which preclude any direct comparison with oxidized zirconium that is basically a metal alloy core with an oxidized surface.

The Merle d’Aubigné scores were not different between the oxidized zirconium and metal heads. This is not surprising because decreased function is usually observed as a late complication of wear. We did not experience any specific complication related to oxidized zirconium. Indeed, major surface damage of oxidized zirconium femoral heads related to recurrent dislocation and closed reduction has been described [6]. This situation could lead to increased wear but did not happen in the current series.

We conclude from this study that femoral head penetration was reduced by use of oxidized zirconium when compared with metal-on-HXLPE. Oxidized zirconium-on-HXLPE was associated with the lowest steady-state penetration rate. However, apart from the metal-UHMWE group, all other groups had a steady-state penetration rate well below the osteolysis threshold with a low difference between groups that might not be clinically important at this point. Longer-term followup is needed to warrant whether wear reduction will generate less occurrence of osteolysis and aseptic loosening leading to revision.

References

Berry D, Harmsen WS, Cabanela ME, Morrey BF. Twenty-five-year survivorship of two thousand consecutive primary Charnley total hip replacements: factors affecting survivorship of acetabular and femoral components. J Bone Joint Surg Am. 2002;84:171–177.

Bourne RB, Barrack R,Rorabeck CH, Salehi A, Good V. Arthroplasty options for the young patient: Oxinium on cross-linked polyethylene. Clin Orthop Relat Res. 2005;441:159–167.

Bragdon CR, Doerner M, Martell J, Jarrett B, Palm H; Multicenter Study Group, Malchau H. The 2012 John Charnley Award: Clinical multicenter studies of the wear performance of highly crosslinked remelted polyethylene in THA. Clin Orthop Relat Res. 2013;471:393–402.

El Masri F, Kerboull L, Kerboull M, Courpied J, Hamadouche M. Is the so-called ‘French paradox’ a reality? Long-term survival and migration of the Charnley-Kerboull stem cemented line-to-line. J Bone Joint Surg Br. 2010;92:342–348.

Garvin KL, Hartman CW, Mangla J, Murdoch N, Martell JM. Wear analysis in THA utilizing oxidized zirconium and crosslinked polyethylene. Clin Orthop Relat Res. 2009;467:141–145.

Gibon E, Scemama C, David B, Hamadouche M. Oxinium femoral head damage generated by a metallic foreign body within the polyethylene cup following recurrent dislocation episodes. Orthop Traumatol Surg Res. 2013;99:865–869.

Glyn-Jones S, Thomas GER, Garfjeld-Roberts P, Gundle R, Taylor A, McLardy-Smith P, Murray DW. The John Charnley Award: Highly crosslinked polyethylene in total hip arthroplasty decreases long-term wear: a double-blind randomized trial. Clin Orthop Relat Res. 2015;473:432–438.

Good V, Ries M, Barrack RL, Widding K, Hunter G, Heuer D. Reduced wear with oxidized zirconium femoral heads. J Bone Joint Surg Am. 2003;85(Suppl 4):105–110.

Hamadouche M, Kerboull L, Meunier A, Courpied J, Kerboull M. Total hip arthroplasty for the treatment of ankylosed hips: a five to twenty-one-year follow-up study. J Bone Joint Surg Am. 2001;83:992–998.

Harris WH, Muratoglu OK. A review of current cross-linked polyethylenes used in total joint arthroplasty. Clin Orthop Relat Res. 2005;430:46–52.

Johanson PE, Digas G, Herberts P, Thanner J, Kärrholm J. Highly crosslinked polyethylene does not reduce aseptic loosening in cemented THA 10-year findings of a randomized study. Clin Orthop Relat Res. 2012;470:3083–3093.

Kadar T, Hallan G, Aamodt A, Indrekvam K, Badawy M, Skredderstuen A, Havelin LI, Stokke T, Haugan K, Espehaug B, Furnes O. Wear and migration of highly cross-linked and conventional cemented polyethylene cups with cobalt chrome or Oxinium femoral heads: a randomized radiostereometric study of 150 patients. J Orthop Res. 2011;29:1222–9.

Kerboull L, Hamadouche M, Courpied J, Kerboull M. Long-term results of Charnley-Kerboull hip arthroplasty in patients younger than 50 years. Clin Orthop Relat Res. 2004;418:112–118.

Kerboull M. The Charnley-Kerboull prosthesis. In: Postel M, Kerboull M, Evrard J, Courpied J, eds. Total Hip Replacement. Berlin, Germany: Springer-Verlag; 1987:13–17.

Kuzyk PR, Saccone M, Sprague S, Simunovic N, Bhandari M, Schemitsch EH. Cross-linked versus conventional polyethylene for total hip replacement: a meta-analysis of randomised controlled trials. J Bone Joint Surg Br. 2011;9:593–600.

Langlois J, Zaoui A, Scemama C, Martell JM, Bragdon CR, Hamadouche M. Validation of a computer-assisted method for measurement of radiographic wear in total hip arthroplasty using all polyethylene cemented acetabular components. J Orthop Res. 2015 Jan 6 [Epub ahead of print].

Martell JM, Berdia S. Determination of polyethylene wear in total hip replacements with use of digital radiographs. J Bone Joint Surg Am. 1997;79:1635–1641.

Martell JM, Berkson E, Berger R, Jacobs J. Comparison of two and three-dimensional computerized polyethylene wear analysis after total hip arthroplasty. J Bone Joint Surg Am. 2003;85:1111–1117.

McKellop H, Shen FW, Lu B, Campbell P, Salovey R. Development of an extremely wear-resistant ultra high molecular weight polyethylene for total hip replacements. J Orthop Res. 1999;17:157–167.

Merle d’Aubigné R. Numerical classification.of the function of the hip. Rev Chir Orthop. 1970;56:481–486.

Morison ZA, Patil S, Khan HA, Bogoch ER, Schemitsch EH, Waddell JP. A randomized controlled trial comparing Oxinium and chrome-cobalt on standard and cross-linked polyethylene. J Arthroplasty. 2014;29(Suppl):164–168.

Muratoglu OK, Bragdon CR, O’Connor DO, Jasty M, Harris WH. A novel method of cross-linking ultra-high-molecular-weight polyethylene to improve wear, reduce oxidation, and retain mechanical properties. Recipient of the 1999 HAP Paul Award. J Arthroplasty. 2001;16:149–160.

Nich C, Courpied J, Kerboull M, Postel M, Hamadouche M. Charnley-Kerboull total hip arthroplasty for osteonecrosis of the femoral head a minimal 10-year follow-up study. J Arthroplasty. 2006;21:533–540.

Warth LC, Callaghan JJ, Liu SS, Klassen AL, Goetz DD, Johnston RC. Thirty-five-year results after Charnley total hip arthroplasty in patients less than fifty years old. A concise follow-up of previous reports. J Bone Joint Surg Am. 2014;96:1814–1819.

Wroblewski BM, Fleming P, Siney P. Charnley low-frictional torque arthroplasty of the hip 20- to 30 year results. J Bone Joint Surg Br. 2005;87:1220–1221.

Author information

Authors and Affiliations

Corresponding author

Additional information

One of the authors (MH), or a member of his or her immediate family, has or may receive payments or benefits, during the study period, an amount of USD 10,000 to USD 100,000, from Smith & Nephew (Le Mans, France).

All ICMJE Conflict of Interest Forms for authors and Clinical Orthopaedics and Related Research ® editors and board members are on file with the publication and can be viewed on request.

Clinical Orthopaedics and Related Research ® neither advocates nor endorses the use of any treatment, drug, or device. Readers are encouraged to always seek additional information, including FDA-approval status, of any drug or device prior to clinical use.

Each author certifies that his or her institution approved the human protocol for this investigation, that all investigations were conducted in conformity with ethical principles of research, and that informed consent for participation in the study was obtained.

About this article

Cite this article

Zaoui, A., Hage, S.E., Langlois, J. et al. Do Oxidized Zirconium Femoral Heads Reduce Polyethylene Wear in Cemented THAs? A Blinded Randomized Clinical Trial. Clin Orthop Relat Res 473, 3822–3828 (2015). https://doi.org/10.1007/s11999-015-4414-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11999-015-4414-7