Abstract

The disadvantages of allografts to restore femoral bone defects during revision hip surgery have led to the search for alternative materials. We investigated the feasibility of using porous titanium particles and posed the following questions: (1) Is it possible to create a high-quality femoral graft of porous titanium particles in terms of graft thickness, cement thickness, and cement penetration? (2) Does this titanium particle graft layer provide initial stability when a femoral cemented stem is implanted in it? (3) What sizes of particles are released from the porous titanium particles during impaction and subsequent cyclic loading of the reconstruction? We simulated cemented revision reconstructions with titanium particles in seven composite femurs loaded for 300,000 cycles and measured stem subsidence. Particle release from the titanium particle grafts was analyzed during impaction and loading. Impacted titanium particles formed a highly interlocked graft layer. We observed limited cement penetration into the titanium particle graft. A total mean subsidence of 1.04 mm was observed after 300,000 cycles. Most particles released during impaction were in the phagocytable range (< 10 μm). There was no detectable particle release during loading. Based on the data, we believe titanium particles are a promising alternative for allografts. However, animal testing is warranted to investigate the biologic effect of small-particle release.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The aging of the population and the tendency to treat younger patients with various hip disorders have increased the incidence of primary and revision THAs in Western countries during the past 20 years [16, 24, 35]. Annually, more than 40,000 revision procedures are performed on patients in the United States alone [21]. A major problem of revision surgery is the loss of bone stock [16, 18], which compromises implantation of a new prosthesis. Morselized allografts, in combination with the bone impaction grafting technique, can restore the bone stock [14, 28]. The impacted bone restores short-term stability for the revision prosthesis and allows long-term restoration of bone stock [17, 36].

Allografts, however, have important disadvantages, such as risk of viral transmission, infection, and limited availability [8, 9, 13, 25, 33, 39]. Because of these drawbacks, various studies have been performed to identify suitable materials to replace bone grafts, such as tricalcium phosphate and hydroxyapatite [2, 5, 32]. Granules made of these materials are used as a bone graft extender, thereby reducing the amount of bone grafts necessary for bone impaction grafting. However, these materials cannot fully replace bone grafts because calcium phosphate particles can pulverize during the impaction phase when used as a stand-alone replacement for bone grafts [2, 4, 5]. Other materials thus are required to replace bone chips in revision hip surgery. Any new material that will be used to replace bone grafts should meet certain criteria. The material should be biocompatible and suitable for impaction, and the impacted mass should create a stable environment for a prosthesis. Cement penetration into the graft material should be limited because excessive cement penetration would obstruct bone ingrowth into graft material.

As an alternative material, we propose porous titanium particles, a nonresorbable replacement for the morselized cancellous bone grafts. Titanium is a biocompatible material often used in orthopaedic and dental implants [1, 22]. In addition to the biocompatibility, titanium has osteoinductive characteristics when implanted in bulk amounts in an organism [12, 40]. A disadvantage of porous titanium particles is possible release of small wear particles (< 10 μm) during impaction and cyclic loading. This can be considered a potential danger because particulate debris can induce osteolysis [20, 31, 41, 45, 47]. Contrary to the biologic response, nothing is known about the handling properties of titanium particles as an impaction grafting material and the possible stability they can provide for a prosthesis. Even though there is no experience with this material, stem stability should be comparable or better than stems implanted with morselized allograft because massive early subsidence can indicate failure of a reconstruction [11].

We therefore addressed the following questions: (1) Is it possible to create a high-quality femoral graft of porous titanium particles providing adequate graft thickness, cement thickness, and cement penetration? (2) Does this titanium particle graft layer provide initial stability when a femoral cemented stem is implanted in it? (3) What sizes of particles are released from the porous titanium particles during impaction and after subsequent loading of the impacted titanium particle layer?

Materials and Methods

We simulated seven femoral revision reconstructions with a graft of the experimental titanium particles. Before and during the 300,000 loading cycles that were applied to all revision reconstructions, stem subsidence (mm) was measured using roentgen stereophotogrammetric analysis (RSA) and particle generation (presented in volume percentages) was measured using the laser diffraction technique. After loading, the reconstructions were sectioned in the frontal plane and the cement mantle thickness, cement penetration, and titanium graft thickness were measured (mm).

We used seven large, left third-generation composite femurs (Part Number 3306, Sawbones®; Pacific Research Laboratories Inc, Malmö, Sweden) for the experiment. All models were transversely sectioned at the diaphysis 26 cm distal to the tip of the greater trochanter. Similar to the study by Barker et al. [3], we widened the medullary canal to a diameter of 18 mm (initial diameter, 16 mm) to simulate cortical thinning as seen in revision surgery. Proximally located polyurethane, representing trabecular bone, was partly removed using various broaches. As in our clinical protocol, the first step in the revision operation was to place a plug in the distal end of the medullary canal. The plug had two major purposes: to facilitate placement of a central guidewire and to limit the titanium particle graft distally.

The titanium particles were produced during the purification of titanium through titanium tetrachloride. This process creates porous commercially pure titanium with a crystalline microtexture for supplying the titanium particles. Two sizes of particles were used, referred to as either small or large particles. The small particles had a diameter in the range of 2.8 to 3.2 mm (ie, passed a 3.2-mm pore sieve but stopped by a 2.8-mm pore sieve) and the larger particles had a diameter of 3.2 to 4.0 mm (ie, passed a 4.0-mm pore sieve but stopped by a 3.2-mm pore sieve). After sieving, the titanium particles were subjected to standardized cleaning to remove potential particulates and chemical contamination (Procedure Number PS03-016; CAM Implants BV, Leiden, The Netherlands). From cross-sectional photographs (Jeol 6310 scanning electron microscope [SEM]; JEOL Ltd, Tokyo, Japan), we calculated the porosity of the titanium particles to be 83% ± 2% (mean ± standard deviation [SD]); pores were interconnected.

The graft layer, which comprised a volume of 37 mL, was carefully constructed in several layers, similar to clinical practice with allografts. Every layer was axially impacted followed by impaction in a radial fashion using tapered impactors to ensure optimal compression of the titanium particles. We performed all impaction steps with the X-change® revision instrumentation up to phantom Size 1 (Stryker Orthopaedics, Mahwah, NJ). Two different titanium particle sizes were used: 64 mL of large titanium particles (diameter, 3.2–4.0 mm) to fill larger spaces in mostly the proximal and distal areas of the Sawbones® femurs and 18 mL of the smaller titanium particles (diameter, 2.8–3.2 mm) to create the graft layer in the middle part of the reconstruction. Before impaction, the titanium particles were soaked in distilled water to improve handling.

After the complete titanium graft layer was constructed, an Exeter™ hip prosthesis (Size 1; Stryker Orthopaedics) was cemented in the Sawbones® femurs. The cement was allowed to polymerize at room temperature for at least 48 hours. Stem migration on loading was quantified with RSA; we glued six tantalum pellets to the head of the stem in addition to a lead pellet already attached to the titanium particles of the prosthesis. An Exeter™ stem centralizer was used to prevent the lead pellet from being detached from the titanium particles by the cement during insertion of the stem. Another 12 tantalum pellets were attached to the lateral and medial sides of the Sawbones® femurs.

After attachment of the tantalum pellets, we placed the Sawbones® femurs in 7° lateral tilt in a custom-made metal support. The metal support was coupled to a polysulfone filter casing (Part Number 10461000; Whatman Schleicher & Schuell, ‘s-Hertogenbosch, The Netherlands) that contained an exchangeable cellulose acetate membrane filter (Part Number 10404006; Whatman Schleicher & Schuell). The filters had a pore size of 0.45 μm, so small titanium debris could still be captured. We placed a polymethylmethacrylate reservoir that completely surrounded the Sawbones® femur on the metal support. On top of the polymethylmethacrylate reservoir was a polyethylene lid that sealed the experimental setup (Fig. 1).

The experimental setup then was filled with distilled water, submerging the entire Sawbones® femur, and placed under a servohydraulic MTS® machine (MTS Systems Corp, Eden Prairie, MN). The reconstruction was subjected to a dynamic, axial load of 20 to 3000 N for 300,000 consecutive loading cycles at 2 Hz. To analyze stem subsidence with respect to the Sawbones® femurs, we performed RSA measurements under loaded conditions (3000 N) after 0, 1000, 10,000, 50,000, 150,000, and 300,000 cycles. Displacement of the stem in the distal direction was defined as negative subsidence. Unloaded RSA measurements also were performed at the beginning (0 cycles) and at the end (300,000 cycles) of the experiment. In addition to every RSA measurement at 0, 1000, 10,000, 50,000, 150,000, and 300,000 cycles, 200 mL distilled water was forced through the cellulose acetate filter. With a syringe connected to the distal end of the filter casing, we could suck the distilled water through the cellulose acetate filter and thereby also force it to travel through the entire graft layer. A new filter was used for every 100 mL distilled water going through the reconstruction. The measurement at 0 cycles would give us an idea about the particles released by impaction; the rest of the measurements would provide more information on possible particle release resulting from dynamic loading. All samples were analyzed using a laser diffraction particle sizer (Malvern Mastersizer® 2000; Malvern Instruments Ltd, Worcestershire, UK).

Directly after completion of the impaction phase of the first reconstruction (of seven), the central guiding rod was retracted to proceed with the cementing phase. However, the remainder of the water used to soak the titanium particles would run out of the reconstruction. Because this remaining ‘soaking water’ possibly was filled with titanium particles, we decided to collect it in plastic containers in the last six reconstructions and analyze these samples using the laser diffraction technique to measure the size of possible particles. The ‘soaking water’ was centrifuged to make sure the measured titanium particles were not contaminated with polyurethane from the composite femur. In addition, we also quantified the weight of the titanium debris.

After the 300,000 loading cycles, the Sawbones® femurs were sectioned in the frontal plane and the sections scanned under a GT-12000 flatbed scanner (Epson, Amsterdam, The Netherlands). These scans then were analyzed with analySIS® AUTO 3.2 (Soft Imaging System GmbH, Münster, Germany). This software allows the user to measure distances on digital photographs or scans. In this way, we were able to measure graft thickness and cement mantle thickness at 5-mm intervals along the whole reconstruction. Cement protruding from the titanium particle graft was defined as cement penetration. This also was determined from the scans. Because cement penetration into the titanium particle graft was not seen everywhere along the titanium, we calculated this by subtracting the average cement mantle thickness from the average maximal cement thickness.

To analyze whether the cement and the titanium particle graft were evenly distributed, we determined if there were any differences in the reconstructions between the medial and lateral (1) graft layer, (2) cement mantle, and (3) cement penetration in the titanium particle graft. Therefore, we used the measurements of the scanned reconstructions and applied a Student’s t test to detect any statistical differences between the medial and lateral sides of the reconstructions. The tests were performed with Microsoft® Excel® 2007 (Microsoft Corp, Redmond, WA).

Results

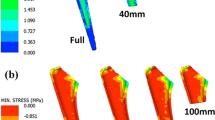

It was possible to construct a graft layer of impacted titanium particles in the femurs using the femoral bone impaction system. The porous titanium particles were heavily interlocked and formed a porous structure (Fig. 2). All specimens showed reproducible impaction of the titanium particles resulting in a firm titanium graft with an average thickness of 3.53 mm (SD, 1.43 mm) (Table 1). The bone cement had an average thickness of 2.34 mm (SD, 0.86 mm). The average cement penetration into the titanium particle graft was 0.49 mm (SD, 0.11 mm). There was a different cement thickness between the medial and lateral sides of the cement mantle. With 1.82 mm (SD, 0.76 mm), the medial cement mantle was thinner (p < 0.001) than the lateral side of the cement mantle, which was 2.89 mm (SD, 0.54 mm) (Fig. 3). Two Sawbones® femurs failed during cyclic loading. This failure was not related to the titanium particle graft or the proximomedial fissure that had occurred in one of the femurs during impaction but was attributable to damage to the distal part of the composite femur that was caused by the clamps during impaction. These two reconstructions could no longer be used for graft or cement measurements. A third reconstruction was sectioned into transverse slices for visual inspection of the reconstruction (Fig. 2).

A frontal section of one of the reconstructions shows the titanium graft layer, cement mantle, and cement penetration. The cement mantle on the medial side (left; 1.82 mm) is thinner (p < 0.001) than the cement mantle on the lateral side (right; 2.89 mm). The titanium graft is a porous structure but seems massive as an artifact of sectioning.

The reconstructions were stable. When the load was applied to the revision reconstructions for the first time, settling of the stem into the graft layer was seen. This resulted in an average initial subsidence of 0.59 mm (SD, 0.41 mm). After this initial settling, a low and reproducible time-dependent subsidence of the stem relative to the bone was observed during cyclic loading. After 300,000 loading cycles, the time-dependent stem subsidence was 0.45 mm (SD, 0.04 mm) for the five remaining stems (Fig. 4). A typical fast initial stem subsidence rate, which gradually diminished toward the end of the experiment, was observed (Fig. 4). The last subsidence measurements of the two failed reconstructions were −0.61 mm after 150,000 loading cycles (Femur 6; failure at 266,000 cycles) and −0.28 mm at 50,000 loading cycles (Femur 7; failure at 130,000 cycles). A proximomedial fissure occurred during impaction of the titanium particles in Femur 6. Despite the cerclage wire we used to repair the femur, above-average subsidence of the stem still was observed. The average total subsidence, comprising initial settling and time-dependent subsidence, after 300,000 loading cycles was 1.04 mm (SD, 0.41 mm) for the five remaining stems.

A graph shows the average time-dependent subsidence of the seven Exeter™ stems. Two femurs failed before the end of the test: one before t = 150,000 cycles and the other before t = 300,000. After the initial settling of 0.59 mm (not shown in graph), a time-dependent stem subsidence of 0.45 mm for the five remaining stems was observed after 300,000 loading cycles.

Titanium particles were released during impaction. The average amount of titanium debris collected after impaction was 55 mg (SD, 18 mg). A 0.32-volume percent of the particles had a diameter of 10.48 μm or smaller (the size of particles that can be phagocytized by cells). The bulk of the weight (> 99 volume percent) comprised particles with a diameter larger than 10.48 μm (Fig. 5). However, the majority of the particles (> 99%) had a diameter of 10.48 μm or smaller because small particles take up less volume. The filters used to collect particles released during dynamic loading contained too few particles to be analyzed by the laser diffraction method.

A graph shows the average volume percent per particle size category found in the soaking water directly after impaction of the graft in the last six reconstructions. A 0.32-volume percent of the particles had a diameter of 10.48 μm or smaller (the size of particles that can be phagocytized by cells). The bulk of the weight (> 99 volume percent) comprised particles with a diameter larger than 10.48 μm. However, the majority of the particles (> 99%) had a diameter of 10.48 μm or smaller because small particles take up less volume.

Discussion

The disadvantages of allografts, such as shortage, infection, and risks of viral transmission, have led to a search for alternative materials in bone impaction grafting [8, 9, 13, 25, 33, 39]. We therefore evaluated a new possible bone graft substitute, titanium particles. We specifically addressed the following questions: (1) Is it possible to create a high-quality femoral graft of porous titanium particles in terms of graft thickness, cement thickness, and cement penetration? (2) Does this titanium particle graft layer provide initial stability when a femoral cemented stem is implanted in it? (3) What sizes of particles are released from the porous titanium particles during impaction and after subsequent loading of the titanium particle layer?

This study has some limitations. First, because of the use of a composite femur model, morphologic variability as encountered in the operating room is absent. However, the synthetic femurs increase reproducibility and precision of the experiment. Second, the composite femur is comparable to bone of younger people [34]. We believe, by simulating cortical thinning, the bones are more comparable to (osteoporotic) bones that typically are seen in revision surgery. Third, no control revision reconstructions with morselized cancellous bone grafts were made for comparison of stem subsidence. However, the literature provided data obtained in ways similar to those in our experiment. Also, the strenuous loading protocol we used provided a safety margin when our subsidence values were compared with those from published studies. Fourth, two Sawbones® femurs of the experiment broke before the end of the testing protocol. Because the fractures originated at the location of clamping during the impaction procedure, we believe stress peaks in the synthetic bone must have damaged the bone, which eventually initiated a fatigue fracture in the femur. There was no relationship between failure of the femurs and a proximomedial fissure that was present in one of the failed reconstructions. Therefore, these fractures should be considered an experimental artifact attributable to the clamping during impaction and not linked to the titanium particle graft. Finally, the laser diffraction method has limitations. In this device, particles pass a laser beam and thereby scatter the light. This scattered light, which is typical for each size, is then caught by a sensor. The method assumes all particles to be spheres. Titanium particles, however, can have shapes ranging from spherelike to rodlike [37]. After careful SEM analyses of several filters obtained in this study, we found, although some particles were rod-shaped, most were sphere-shaped. Therefore, we believe errors in our measurements do not greatly affect the outcome of this study.

We considered the obtained characteristics of the reconstructions adequate. A highly interlocked titanium graft layer was established around the whole prosthesis (Fig. 2). The thickness of this layer was similar to the reported thickness of impacted bone chips [3, 42]. Previous reports suggested some parts of the cement mantles in revision surgery with impacted allografts were absent or less than 2 mm [26, 27]. None of the four specimens we examined showed absence of the cement mantle in any region. However, the cement mantle on the medial side (especially Gruen Zones 5 and 6) was considerably thinner than the mantle on the lateral side of the sections. The average cement penetration was very small, which is a positive finding because excessive cement penetration can hamper bone ingrowth into the titanium graft layer. The average cement penetration was only 0.49 mm, indicating the reconstruction obtains its stability by the granules and not by excessive cement penetration as reported in a study with calcium phosphate particles [4].

The distal migration of the Exeter™ stem relative to the Sawbones® femurs was in line with other in vitro studies. In two recent studies similar to our experiment, Exeter™ stems were used in combination with the impaction grafting technique [30, 44]. In one study, subsidence values of 0.44 mm and 0.13 mm were observed after 18,000 cycles for reconstructions with only bone chips and reconstructions that contained allografts and hydroxyapatite graft extenders, respectively [30]. The other study had subsidence values of 2.31 mm and 0.99 mm after 10,000 loading cycles for reconstructions with pure allografts and reconstructions with a mix of allografts and hydroxyapatite graft extenders, respectively [44]. Our average total subsidence after 10,000 and 50,000 loading cycles was 0.76 mm (SD, 0.43 mm) and 0.87 (SD, 0.43 mm), respectively. This is in line with published studies, especially when our strenuous loading regime is considered. Perhaps the most important finding is the time-dependent stem subsidence rate diminishes toward the end of the experiment, suggesting a stable situation. When we compare our findings with those of in vivo experiments, the 300,000 load cycles correspond with 3 months of normal loading for an active patient [29]. With this in mind, our results also were in line with subsidence of an Exeter™ stem in combination with morselized allografts [36, 43]. The migration we found was comparable to subsidence data from primary Exeter™ implants [15, 38].

Particle release was observed directly after impaction. Although the bulk of the volume consisted of large titanium particles (diameter > 10 μm), the majority of the particles were smaller than 10 μm (approximately 99%). Because small titanium wear particles (< 10 μm) can lead to an inflammatory reaction and osteolysis, these particles potentially are threatening for long-term behavior of the reconstruction [20, 31, 41, 45, 47]. Not enough particles were collected during cyclic loading to be measured by the laser diffraction technique. Whether this means virtually no particles were generated during cyclic loading or that our methods to collect particles were inadequate is unclear. It is possible particles were trapped in the titanium graft layer or in the cement layer and were not flushed out during the experiment. We therefore recommend long-term animal tests to establish if any particles are generated during cyclic loading of the titanium graft and if these particles have any biologic consequences. A possible concern of the use of large amounts of titanium is systemic accumulation of titanium in the body. Elevated serum levels of titanium after (excessive) wear of titanium components have been described [10, 19, 23, 46]. A relatively large amount of titanium in combination with the high surface area of the granules could lead to high serum levels if failure occurs. Third-body wear may be another possible threat to the revision reconstruction [6, 7]. Small titanium particles could be released from the graft and trapped between the head of the stem and the polyethylene cup. These particles can abrade the surface of the cup, thereby releasing osteolysis-inducing polyethylene particles. However, the access of titanium particles to the joint space can be limited by closing the graft proximally with bone cement. Additional animal tests with titanium particles should provide more insight into both phenomena.

Our data suggest titanium particles are a promising bone graft substitute from a mechanical point of view. A firm, porous layer of titanium particles can be constructed in a composite femur model. Consecutive cementing of a prosthesis in this layer results in stable reconstruction. Possible harmful titanium particles are released on impaction, but the effect of dynamic loading on particle generation is unclear. Therefore, animal tests are warranted to further investigate possible titanium particle formation and its biologic effect.

References

Arroyo JS, Garvin KL, Neff JR. Arthrodesis of the knee with a modular titanium intramedullary nail. J Bone Joint Surg Am. 1997;79:26–35.

Arts JJ, Gardeniers JW, Welten ML, Verdonschot N, Schreurs BW, Buma P. No negative effects of none impaction grafting with bone and ceramics mixtures. Clin Orthop Relat Res. 2005;438:239–247.

Barker R, Takahashi T, Toms A, Gregson P, Kuiper JH. Reconstruction of femoral defects in revision hip surgery: risk of fracture and stem migration after impaction bone grafting. J Bone Joint Surg Br. 2006;88:832–836.

Bolder SB, Verdonschot N, Schreurs BW, Buma P. Acetabular defect reconstruction with impacted morselized bone grafts or TCP/HA particles: a study on the mechanical stability of cemented cups in an artificial acetabulum model. Biomaterials. 2002;23:659–666.

Bolder SB, Verdonschot N, Schreurs BW, Buma P. The initial stability of cemented acetabular cups can be augmented by mixing morselized bone grafts with TCP/HA particles in bone impaction grafting. J Arthroplasty. 2003;18:1056–1063.

Bragdon CR, Jasty M, Muratoglu OK, Harris WH. Third-body wear testing of a highly cross-linked acetabular liner: the effect of large femoral head size in the presence of particulate poly(methyl-methacrylate) debris. J Arthroplasty. 2005;20:379–385.

Bragdon CR, Jasty M, Muratoglu OK, O’Connor DO, Harris WH. Third-body wear of highly cross-linked polyethylene in a hip simulator. J Arthroplasty. 2003;18:553–561.

Centers for Disease Control and Prevention. Hepatitis C virus transmission from an antibody-negative organ and tissue donor—United States, 2000–2002. MMWR Morb Mortal Wkly Rep. 2003;52:273–274, 276.

Conrad EU, Gretch DR, Obermeyer KR, Moogk MS, Sayers M, Wilson JJ, Strong DM. Transmission of the hepatitis-c virus by tissue transplantation. J Bone Joint Surg Am. 1995;77:214–224.

Dunstan E, Sanghrajka AP, Tilley S, Unwin P, Blunn G, Cannon SR, Briggs TW. Metal ion levels after metal-on-metal proximal femoral replacements: a 30 year follow-up. J Bone Joint Surg Br. 2005;87:628–631.

Eldridge JD, Smith EJ, Hubble MJ, Whitehouse SL, Learmonth ID. Massive early subsidence following femoral impaction grafting. J Arthroplasty. 1997;12:535–540.

Fujibayashi S, Neo M, Kim HM, Tadashi K, Nakamura T. Osteoinduction of porous bioactive titanium metal. Biomaterials. 2004;25:443–450.

Galea G, Kopman D, Graham BJ. Supply and demand of bone allograft for revision hip surgery in Scotland. J Bone Joint Surg Br. 1998;80:595–599.

Gie GA, Linder L, Ling RS, Simon JP, Slooff TJ, Timperley AJ. Impacted cancellous allografts and cement for revision total hip arthroplasty. J Bone Joint Surg Br. 1993;75:14–21.

Glyn-Jones S, Alfaro-Adrian J, Murray DW, Gill HS. The influence of surgical approach on cemented stem stability: an RSA study. Clin Orthop Relat Res. 2006;448:87–91.

Goodman SB, Oh KJ, Imrie S, Hwang K, Shegog M. Revision total hip arthroplasty in juvenile chronic arthritis: 17 revisions in 11 patients followed for 4–12 years. Acta Orthop. 2006;77:242–250.

Halliday BR, English HW, Timperley AJ, Gie GA, Ling RS. Femoral impaction grafting with cement in revision total hip replacement: evolution of the technique and results. J Bone Joint Surg Br. 2003;85:809–817.

Holt G, Murnaghan C, Reilly J, Meek RM. The biology of aseptic osteolysis. Clin Orthop Relat Res. 2007;460:240–252.

Jacobs JJ, Silverton C, Hallab NJ, Skipor AK, Patterson L, Black J, Galante JO. Metal release and excretion from cementless titanium alloy total knee replacements. Clin Orthop Relat Res. 1999;358:173–180.

Kumazawa R, Watari F, Takashi N, Tanimura Y, Uo M, Totsuka Y. Effects of Ti ions and particles on neutrophil function and morphology. Biomaterials. 2002;23:3757–3764.

Kurtz S, Mowat F, Ong K, Chan N, Lau E, Halpern M. Prevalence of primary and revision total hip and knee arthroplasty in the United States from 1990 through 2002. J Bone Joint Surg Am. 2005;87:1487–1497.

Landes CA, Ballon A. Five-year experience comparing resorbable to titanium miniplate osteosynthesis in cleft lip and palate orthognathic surgery. Cleft Palate Craniofac J. 2006;43:67–74.

Leopold SS, Berger RA, Patterson L, Skipor AK, Urban RM, Jacobs JJ. Serum titanium level for diagnosis of a failed, metal-backed patellar component. J Arthroplasty. 2000;15:938–943.

Malchau H, Herberts P, Eisler T, Garellick G, Söderman P. The Swedish total hip replacement register. J Bone Joint Surg Am. 2002;84(suppl 2):2–20.

Mankin HJ, Hornicek FJ, Raskin KA. Infection in massive bone allografts. Clin Orthop Relat Res. 2005;432:210–216.

Masterson EL, Masri BA, Duncan CP. The cement mantle in the Exeter impaction allografting technique; a cause for concern. J Arthroplasty. 1997;12:759–764.

Masterson EL, Masri BA, Duncan CP, Rosenberg A, Cabanela M, Gross M. The cement mantle in femoral impaction allografting; a comparison of three systems from four centres. J Bone Joint Surg Br. 1997;79:908–913.

Morgan HD, McCallister W, Cho MS, Casnellie MT, Leopold SS. Impaction allografting for femoral component revision: clinical update. Clin Orthop Relat Res. 2004;420:160–168.

Morlock M, Schneider E, Bluhm A, Vollmer M, Bergmann G, Müller V, Honl M. Duration and frequency of every day activities in total hip patients. J Biomech. 2001;34:873–881.

Munro NA, Downing MR, Meakin JR, Lee AJ, Ashcroft GP. A hydroxyapatite graft substitute reduces subsidence in a femoral impaction grafting model. Clin Orthop Relat Res. 2007;455:246–252.

O’Connor DT, Choi MG, Kwon SY, Sung KLP. New insight into the mechanism of hip prosthesis loosening: effect of titanium debris size on osteoblast function. J Orthop Res. 2004;22:229–236.

Oonishi H, Kadoya Y, Iwaki H, Kin N. Hydroxyapatite granules interposed at bone-cement interface in total hip replacements: histological study of retrieved specimens. J Biomed Mater Res. 2000;53:174–180.

Ornstein E, Atroshi I, Franzén H, Johnsson R, Sandquist P, Sundberg M. Early complications after one hundred and forty-four consecutive hip revisions with impacted morselized allograft bone and cement. J Bone Joint Surg Am. 2002;84:1323–1328.

Papini M, Zdero R, Schemitsch EH, Zalzal P. The biomechanics of human femurs in axial and torsional loading: comparison of finite element analysis, human cadaveric femurs, and synthetic femurs. J Biomech Eng. 2007;129:12–19.

Pedersen AB, Johnsen SP, Overgaard S, Søballe K, Sørensen HT, Lucht U. Total hip arthroplasty in Denmark: incidence of primary operations and revisions during 1996–2002 and estimated future demands. Acta Orthop. 2005;76:182–189.

Schreurs BW, Arts JJ, Verdonschot N, Buma P, Slooff TJ, Gardeniers JW. Femoral component revision with use of impaction bone-grafting and a cemented polished stem. J Bone Joint Surg Am. 2005;87:2499–2507.

Shahgaldi BF, Heatley FW, Dewar A, Corrin B. In vivo corrosion of cobalt-chromium and titanium wear particles. J Bone Joint Surg Br. 1995;77:962–966.

Stefánsdóttir A, Franzén H, Johnsson R, Ornstein E, Sundberg M. Movement pattern of the Exeter femoral stem: a radiostereometric analysis of 22 primary hip arthroplasties followed for 5 years. Acta Orthop Scand. 2004;75:408–414.

Sutherland AG, Raafat A, Yates P, Hutchison JD. Infection associated with the use of allograft bone from the North East Scotland Bone Bank. J Hosp Infect. 1997;35:215–222.

Takemoto M, Fujibayashi S, Neo M, Suzuki J, Kokubo T, Nakamura T. Mechanical properties and osteoconductivity of porous bioactive titanium. Biomaterials. 2005;26:6014–6023.

Taki N, Tatro JM, Nalepka JL, Togawa D, Goldberg VM, Rimnac CM, Greenfield EM. Polyethylene and titanium particles induce osteolysis by similar, lymphocyte-independent, mechanisms. J Orthop Res. 2005;23:376–383.

Toms AD, Barker RL, Jones RS, Kuper JH. Impaction bone-grafting in revision joint replacement surgery. J Bone Joint Surg Am. 2004;86:2050–2060.

van Biezen FC, ten Have BL, Verhaar JA. Impaction bone-grafting of severely defective femora in revision total hip surgery: 21 hips followed for 41–85 months. Acta Orthop Scand. 2000;71:135–142.

van Haaren EH, Smit TH, Phipps K, Wuisman PIJM, Blunn G, Heyligers IC. Tricalcium-phosphate and hydroxyapatite bone-graft extender for use in impaction grafting revision surgery. J Bone Joint Surg Br. 2005;87:267–271.

von Knoch M, Jewison DE, Sibonga JD, Sprecher C, Morrey BF, Loer F, Berry DJ, Scully SP. The effectiveness of polyethylene versus titanium particles in inducing osteolysis. J Orthop Res. 2004;22:237–243.

von Schroeder H, Smith DC, Gross AE, Pilliar RM, Kandel RA, Chernecky R, Jugowski SJ. Titanemia from the total knee arthroplasty: a case resulting from a failed patellar component. J Arthroplasty. 1996;11:620–625.

Warashina H, Sakano S, Kitamura S, Yamauchi KI, Yamaguchi J, Ishiguro N, Hasegawa Y. Biological reaction to alumina, zirconia, titanium, and polyethylene particles implanted onto murine calvaria. Biomaterials. 2003;24:3655–3661.

Acknowledgments

We thank Willem van de Wijdeven and Huub Peters for technical support during the experiment.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Additional information

One or more of the authors (RA, LW) have received funding from Fondel Medical, Rotterdam, The Netherlands.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Aquarius, R., Walschot, L., Buma, P. et al. In Vitro Testing of Femoral Impaction Grafting With Porous Titanium Particles: A Pilot Study. Clin Orthop Relat Res 467, 1538–1545 (2009). https://doi.org/10.1007/s11999-008-0688-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11999-008-0688-3