Abstract

Paper manufacturers are constantly looking for new methods to improve coated paper properties. Pigments are encountered in paper coatings to add new functions. For example, titanium dioxide (TiO2 ) and talc are considered among the best-known pigments used in paper coating and manufacturing due to their whiteness and other beneficial properties. Nevertheless, talc has a weak dispersion during which its particles agglomerate, and this disadvantage needs to be overcome before its application which means higher cost. Therefore, in this work, a core–shell technique is used to modify the talc surface and enhance its dispersion in order to promote its use in improving the properties of the paper. Core–shell pigments are composed of a thin shell of (nano- and micronized) titanium dioxide precipitated on talc particles. These prepared talc/TiO2 core–shell pigments were characterized using various techniques such as XRF, SEM, and TEM, and then they were incorporated in paper coatings to evaluate their effect on the different properties of the coated papers. The results showed that nano-talc/TiO2 with the obtained unique chemical and morphological structure has improved the physical, mechanical, and optical properties of the coated papers besides improving their antimicrobial activity, especially when compared to papers coated with micronized talc/TiO2.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Packaging has many different roles in industry, e.g., protection, safety, enhanced usability, attractive looks, optimal design, and specific customer requirements. Although plastics, glass, and metals are excellent materials for packaging, they are difficult to recycle and do not decompose easily in the environment, besides not being safe.

What is often perceived with packaging is its “single-use purpose”, i.e., using for one time only. There is no doubt that packing waste has become a global problem, due to the radical increase of the waste amount created by humans on an annual basis.1

Paper sheets provide an eco-friendly solution for this problem; they are produced with lower costs and can be simultaneously recycled. Cellulosic paper, a renewable, flexible, and biodegradable material, is made primarily of cellulose and derived from a variety of natural sources, and it can be widely used in communication, education, food packaging, and hygienic and industrial applications. It is formed on a machine, then begins to dry, but the surface can remain rough and porous.2 Various advanced technologies have been extensively studied and highly developed to overcome the inherent flaws of cellulosic paper and to expand its application range. Surface coating is a convenient and simple solution that can offer more commercial production advantages over the wet-end formation process and can easily improve the mechanical and optical properties of the paper.3

Coated paper is a composite structure of paper and a coating layer of a coating mixture that consists essentially of pigment, binder, additives, and water. The binder holds all these components (pigments and additives) together and fixes them on the paper substrate.

Pigments are the most abundant constituent in the coating mixture, and form the most vital part controlling the properties of the coating. These pigments may be used separately or mixed together. The vital pigment characteristics that determine the coat structure, optical properties, and coated paper performance are their shape, size, and size distribution.4,5

Progress in nanotechnology has been a milestone in developing nano-pigments for use in coatings due to their exceptional optical, electronic, photocatalytic, and biological characteristics. The small particle size and large surface area are likely to give the paper a high surface quality (extremely smooth surface) as well as good optical qualities, besides providing new functions. A variety of studies have been conducted on specific applications of nano-pigments in papermaking, utilizing the manufacturing of high-quality papers with low gas-permeability, protectability, hydrophobicity, antimicrobial properties, photocatalytic paper, electronic, and printed electronic paper. Teng et al. studied the chemical stability of self-cleaning papers using a coating containing nano-TiO2. The results obtained in this research showed that there is a potential use of nano-pigments to upgrade the durability and self-cleaning performance of the paper sheets.6 Nano-pigments have a vital concerning issue according to their passage through the paper sheet voids (mesh), making the coating mixture unstable on the surface of the paper. Thus, paper manufacturers have been seeking new economically feasible methods accompanied by a high performance to overcome this essential disadvantage. This default can be modified using core–shell pigments, due to their hybrid structure of different components and different particle sizes, hence avoiding the passage of core–shell pigments through the paper sheet voids.7,8

Core–shell-structured particles are now attracting much more research interest since they are composed of materials with different chemical compositions and particle sizes. Conclusively, they exhibit unique properties of varied materials together, especially to manipulate the surface functions to meet distinct application requirements.9 It is well known that the main properties of these core–shell pigments are manifested by the shell part. Therefore, the application of the core–shell structured particles can be a promising alternative to reduce the high cost of traditional pigments, besides offering new unique characteristics and morphological structures compared with ordinary pigments. These new materials are one of the future solutions to solve the problems of paper production challenges, with intense competition in increasing raw material and energy costs. In addition, this has been a reasonable solution for preventing the passage of the nano-particles to allocate them on the paper surface, hence providing a more stable and intense color.

Talc can be considered as an inorganic polymer based on two basic “monomer” structures—the silica tetrahedron and the magnesia octahedral—because it contains a continuous octahedral layer with joined octahedra tied on a triangular side. This unique structure makes talc a good candidate to enhance the process of paper making and to generate new paper coatings, while adding new, unique, and enhanced characteristics to the paper sheets produced for different applications.10 However, its main defect for its application in the paper industry is the agglomeration that occurs between its particles.

Micronized and nano-TiO2 particles have been employed as a highly competent pigment in paper coating for various points of interest, such as high refractive index, superior brightness, high level of whiteness, ideal hiding power, antimicrobial action, and insolubility in alkaline and acidic media.11

TiO2 has also been recorded to have antibacterial growth inhibition characters, besides its role in improving the decomposition of inorganic and organic compounds, which can be utilized in possible implementations in sanitation and sterilization. Materials coated with TiO2 are used for their efficient antibacterial properties. Nowadays, related to the shortage of TiO2 resources and its high cost, searching for replacement materials to supplant TiO2 has been of far-reaching significance.

The aim of this work can be stated as: (1) preparing a new multifunctional pigment based on an economically bulk (core) of talc with a shell of a TiO2 layer, one in micron size and another in nano-size, to evaluate the effect of these new pigments on cellulosic paper final properties, (2) studying the effect of the different particle sizes of the shells on the paper properties in terms of optical, physical, and mechanical properties and antibacterial activity, (3) improving the dispersion properties of talc via its surface modification, and (4) evaluating the effect of the new TiO2 supplant (talc/TiO2) in the paper industry.

Experimental

Materials

-

Talc ore was obtained from El-Nasr Mine, Edfo, Aswan, Egypt.

-

Titanium tetrachloride was purchased from LOBA Chemie, India, with about 99% purity.

-

The materials used for the coated paper preparation were a copolymer of Acronal S 360D (based on n-butylacrylate, styrene and acrylonitrile) and polyvinyl alcohol thickener supplied by BASF, Germany. Sodium hexametaphosphate supplied by Fine Chemicals was used as dispersing agent.

Preparation of nano-TiO2/talc core–shell pigments

The preparation was carried out in several steps:

Step 1 5 mL titanium tetrachloride was added to 100 mL hydrochloric acid with vigorous stirring, then 50 g talc was immersed in this solution and left for adequate time during slow stirring to assure complete coverage.

Step 2 the prepared solution in step 1 was poured into 1 M urea solution. Then, ammonia solution was added drop-wise to this mixture to set the pH to the neutral phase until complete precipitation of the titanium.

Step 3 filtration through a Buchner system was carried out, before the product was washed very well and calcined at 500–750°C. The calcined powder was then subjected to ball-milling for an adequate time at 300 rpm to reach the required size.

Preparation of micronized TiO2/talc core–shell pigments

An amount of 5 mL titanium tetrachloride was added to 100 mL hydrochloric acid, and then 30 g talc was added during slow stirring. Next, ammonia solution was added drop-wise to the previously formed paste to adjust the pH, until the full precipitation of TiO2. Then, the paste was filtered through a Buchner system and washed very well. The last step was calcining the paste at 500–750°C and then subjecting it to ball-milling to reach the required size.

Methods of instrumental analysis

X-ray fluorescence

The concentrations of each element in the prepared pigments were estimated using an Axios sequential WD-XRF spectrometer (PANalytical).

Scanning electron microscopy (SEM)

Scanning electron microscopy (SEM; JX 2840; JEOL, Japan) was carried out using a micro-analyzer electron probe to estimate the particle morphology.

Transmission electron microscopy (TEM)

Transmission electron microscopy (TEM; JX 1230; JEOL) was carried out with a micro-analyzer electron probe. This technique was used to confirm the formation of a core–shell structure and to correlate these structures with the results obtained from SEM.

Application of the prepared TiO2/talc core–shell pigments in paper coating

Preparation of paper coatings

The prepared pigments were dispersed in distilled water, using 0.3 part of sodium hexametaphosphate per 100 parts as a dispersing agent at a solid content of 50%. The pre-dispersed binder (15 pph) was added slowly to the pigment slurry (pph = part per 100 parts of dry pigment), and the agitator was adjusted to moderate the speed to prevent any foam formation during the addition of the binder. Finally, water was added to adjust the solid content up to 50%, and then sodium hydroxide was added to adjust the pH of the suspensions to 8.5.

Preparation of coated paper samples

A K-bar electrical semi-automatic coater (NOS k101; R&K Print Coat Instruments, UK) was used to handle the coating mixtures. A wire-wound bar was selected to create a 6-μm-thick wet film. White paper samples with a grammage of 70 g\m2 were cut using a strip cutter to overall dimensions of 200 mm × 300 mm and coated according to the standard conditions of temperature and humidity of 23 ± 1°C and 50 ± 2%.

Characterization of coated paper samples

The properties of the coated paper samples including the prepared pigments were estimated using standard tests for optical, mechanical, and physical properties. Brightness is related to the overall reflectivity, i.e., the visual efficiency of the paper. The measures were carried out on a brightness and color meter instrument (68–59-00–002; Buchel, Netherlands), according to the ISO 2470–1 (2009) standard. Opacity was also estimated using the same instrument according to ISO 2471 (2008). Paper roughness is the degree to which the surface of the paper deviates from a plane; it estimates the flow rate between the paper sample and another standard surface in contact with it. Roughness was estimated in mL/min according to the ISO 8791–2 (1990). Air porosity is the mean flow of air through the unit area under unit air pressure difference in unit time under specified conditions; it was estimated in µm/PaS according to ISO 5636–3 (1992). Both roughness and air porosity were estimated by a Bendtsen Roughness Tester (K531; Messmer Bunchel). Burst strength is the hydrostatic pressure in KPa needed to rupture paper when distorted in an approximate sphere of 1.2 inches in diameter at a controlled rate of loading. The measurements were conducted on burst tester (BT-10 TlS; Techlab Systems), according to ISO 2758–3 (2014). Tensile strength in KN/m is the resistance of paper to direct tension. It is the force needed to break a narrow strip of paper when both the length of the strip and rate loading are strictly specified. A tensile test machine (T-series H5KT; Tinius Olsen), at 1 KN was employed according to ISO 1924–2 (2008).

Antibacterial activity test for the prepared pigment

The antibacterial activity of the talc, micronized TiO2/talc, and nano-TiO2/talc on coated papers was assessed by a colony-forming unit (CFU) counting assay. According to the FDA declaration, pathogenic bacteria such Staphylococcus aureus (S. aureus) have been associated with skin- and food-transmitted diseases. It was chosen for the antimicrobial testing because it is considered as one of the most common bacteria that can be transmitted through the skin and respiratory system to simple substrates, and thus infections can be increased using paper sheets. To undergo this test of the antibacterial inhibition ratio of the coated papers, a S. aureus suspension (McFarland standard 0.5) was prepared and incubated in Mueller–Hinton broth medium. Then, 200 μL of the suspension was added to a 96-well plate containing the coated paper samples and a control sample (DMSO). The number of CFUs was determined after an incubation period of 24 h at 37°C. The antibacterial efficacy was calculated using (N/N0) × 100, where N0 and N are the average number of CFUs obtained for the control substrate and the coated papers, respectively. The bacterial colony on the plates was observed by a digital camera, and the number of colonies was counted.

Results and Discussion

Characterizations of the prepared pigments

Morphology of talc/TiO2 core–shell pigments (SEM and TEM)

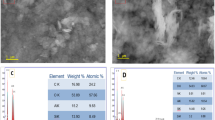

The main morphological features and particle sizes of the prepared core–shell pigments introduced by TEM and SEM techniques are shown in Figs. 1, 2. It is clear that, in the case of micronized talc/TiO2, there are large plates of the different shapes concerning both titanium and talc overlapping with each other, and with almost the same particle sizes, ranging between 0.1 and 0.2 µm. On the other hand, the nano-talc/TiO2 showed talc particles as large rectangular plates covered with tiny crowded plates of (nano-TiO2) with an average size of 10 nm.

X-ray fluorescence (XRF)

X-ray fluorescence (XRF) is a vital technique for detecting the percentage of the different element oxides in inorganic structures. The XRF results of the prepared core–shell pigments in Table 1 show that silicon and magnesium oxides are the main components of the talc. Core–shell pigments showed a decrease in the percentage of silica and magnesia due to the formation of the shell which formed a barrier. This made the detection of core elements harder, and the major detected elements were the shell materials. Additionally, in nano-talc/TiO2, the TiO2 was found with a higher percentage than in the case of the micronized talc/TiO2 , due the smaller particle sizes which occupied a larger space due to the larger surface area than the micronized titanium dioxide.

Application of the prepared pigments in paper coatings

Optical properties

According to its diverse usage, the optical properties of paper are important, especially when the paper is used for printing. Reflectance, opacity, whiteness, and light scattering are important optical properties, and it is necessary to know how the preparation and variations in the paper coating mixture can affect them. To address these effects on the optical properties and the appearance of the paper, the paper sheets were covered with micron- and nano-talc/TiO2 core–shell pigments.

Accordingly, the presence of talc/TiO2 pigments have increased the coated paper optical properties due to the high refractive index and the inherent high light-scattering coefficients of TiO2. Additionally it was clear that the presence of nano-talc/TiO2 pigments led to an increase in the brightness and whiteness to the maximum values of 99.05 and 116.95%, respectively. These advantageous properties of nano-talc/TiO2 pigments may be attributed to their smaller particle size and larger surface area than the micronized talc/TiO2 pigments, which allow them to exert higher reflectance. In addition, the opacity and light scattering exerted an increase in the incorporation of nano-talc/TiO2 in the coat, due to the tiny nano-particles of the shell which filled the narrow pores created between talc particles, thus limiting the total amount of light that could be transmitted through the paper (Fig. 3).12,13

Physical properties

Uniformity of the paper physical properties continues to be one of the most serious quality items in the paper industry. Roughness and air permeability are considered as the main physical properties of the produced paper sheets.

Roughness

Paper smoothness is known as the uniformity and flatness of the surface, which have an essential role in paper production. Rough surfaces contain higher peaks and valleys compared to smoother ones. Paper sheets coated with talc/TiO2 pigments showed that there was a low surface irregularity, which allows the toner particles to adhere to the surface more constantly, producing better images, as shown in Fig. 4a. This figure also shows that the decrease in the coated paper roughness reached 46% in the case of the nano-talc/TiO2 pigment. This increase in smoothness values can be attributed to the talc particles which often provide a denser layer than other pigments during consolidation and drying, causing shrinkage of the structure.14

Air porosity

Air porosity of the coated papers with talc and TiO2/talc core–shell pigments is illustrated in Fig. 4b. It is evident that nano-talc/TiO2 pigment exerted the lowest air porosity value, which follows the mechanism of filling the narrow pores created between the talc particles with nano-TiO2 particles; thus fewer ways are available for permeation and hence low air porosity can be achieved, which is in good agreement with the opacity results.15

Mechanical properties

The mechanical properties of the coated paper are critical in the investigation of bending and compressive deformation, because of the difficulties that a coated paper may face in a printing machine, such as runability and paper handling. The mechanical properties of coated paper are sensitive to changes in the kind and morphology of the pigment along with the binder properties, and also the degree of coverage of the pigment. As shown in Fig. 5, the talc/TiO2 pigment enhanced the coated paper's mechanical properties, due to the TiO2 being a hard and tough pigment (6–6.5 Moh) compared to the talc (1 Moh), which enables the new core–shell talc/TiO2 pigment to withstand the applied forces and enhance the hardness properties. Figure 5a demonstrates that the nano-talc/TiO2 pigment increased the tensile strength to a maximum value of 6.73 N/mm and that the degree of improvement was nearly 7%. Simultaneously, the tensile stretch was increased to 1.78% and the degree of improvement was about 7.3%, as shown in Fig. 5b. The tensile energy absorption of the coated paper also showed an increase in the presence of the nano-TiO2/talc pigment, and the degree of improvement reached about 11.2%, as shown in Fig. 5c. Generally, it can be deduced that all the obtained results are compatible with the fact that the nano-TiO2 can occupy substitutional positions in the talc matrix preventing the motion of dislocations and the migration of grain boundaries, which can cause enhancement of the strength.

Well-dispersed TiO2 is the main cause of enhanced stress transfer between the paper and the pigment. It was also found that the coated paper with nano-talc/TiO2 exhibited a higher tensile strength than paper coated with micronized talc/TiO2 pigments.

In addition, the surface area is one of the important characteristics in reinforcing pigments, showing that particles with larger surface areas can increase the properties of the paper through the stronger bonding that can occur in case of larger available contact areas. The development of this interaction improved the adhesion of the paper to the pigment and accordingly permitted better stress transfer.16,17,18

Antibacterial activity measurements

Paper can be easily contaminated by bacteria and germs in a humid environment, which can seriously reduce its service life. As mentioned above, talc/TiO2 core–shell pigments are reported to impart good antibacterial properties to the surface of the paper. Table 2 and Fig. 6 show the representative results of the CFU antibacterial tests of the prepared coated papers. The CFU assay is a quantitative method that can show the capability of bacterial cells after being incubated on surfaces. Although coated paper with talc only showed a low antibacterial inhibition of 6.3%, the inhibition effect increased and the CFU decreased significantly in the case of papers coated with the talc/TiO2 core–shell pigments, to reach 15.8% and 55.8% for the micronized and nano-talc/TiO2, respectively.

Moreover, the bacteria colony count showed lower totals in the case of papers coated with nano-talc/TiO2 , as can be seen in Fig. 6c, d. This antibacterial activity can be attributed to the generation of reactive oxygen species, e.g., O2−, OH, and HO2. These species can absorb high-energy photons under UV irradiation, or even under both natural solar irradiation and regular room light. Furthermore, it was discovered that the photo-oxidation performance is dependent on the surface area, and thus it can also be improved by the presence of nano-particles (talc/TiO2),19,20 which is the main reason that the coated papers containing nano-talc/TiO2 pigments exerted better antibacterial activity.21

Surface structure of coated paper

From the SEM images of the talc-coated paper shown in Fig. 7, it can be clearly seen that the pigment particles on the coating surface are in a disordered manner, which makes the coat loose, and thus some of the base paper fibers interweave with each other and still present an open and rough surface. Also, the appearance of some recesses and valleys can still be seen, while the distribution of coating voids was heterogeneous and the void size was relatively large.

However, in Fig. 7b, concerning paper coated with micronized talc/TiO2, the surface appears to be flat and ordered, while, for paper coated with the nano-talc/TiO2 core–shell pigment, the distribution of voids was more homogeneous and the size of the most voids was smaller (Fig. 7c). This type of void structure provided a benefit in achieving the largest light scattering, leading to the enhancement of the brightness and opacity.22

In addition, the smooth surface in the case of coatings containing talc/TiO2 contributed a higher smoothness and better final paper properties than using talc alone.

Conclusions

A new approach for applying multi-function coatings on paper sheets has been presented. The modification involved the inclusion of micronized and nano-talc/TiO2 core–shell pigments for surface paper coatings. These new structured pigments were prepared via a simple and feasible technique, core–shell. The effect of the size of the talc/TiO2 core–shell pigments was studied in terms of the coated paper properties and antibacterial activities.

From the results, coated papers with coatings containing nano-talc/TiO2 core–shell pigments exhibited better antibacterial activity against Staphylococcus aureus bacteria than papers coated with micronized talc/TiO2. Moreover, nano-talc/TiO2 core–shell pigments imparted higher mechanical, optical, and physical properties to the coated paper.

Similarly, the main disadvantage of using talc, which is agglomeration, can be solved by preparing these core–shell pigments which, due to the presence of TiO2 particles on the surface of the talc, prevent its agglomeration with each other.

References

Zhua, Y, Bousfielda, D, Gramlich, WM, “The Influence of Pigment Type and Loading on Water Vapor Barrier Properties of Paper Coatings Before and After Folding.” Prog. Org. Coat., 132 201–210 (1996)

Kaiser, K, Schmid, M, Schlummer, M, “Recycling of Polymer-Based Multilayer Packaging: A Review.” Recycling, 3 101–119 (2017)

Kumar, N, Bhardwa, NK, Chakrabarti, SK, Kumar, S, “Synthesis and Application of Calcium Sulphate Pigment for Paper Coating: Potential and Prospects.” Powder Technol., 218 40–45 (2012)

Lehtinen, E, Pigment Coating and Surface Sizing of Paper, Book 11. Finish Pulp and Paper Engineers Association and Tappi Press, Finland (2000)

Buxbaum, G, Pfaff, G, Industrial Inorganic Pigments, Chapter 1, Wiley, New York, pp. 8–17 (2005)

Teng, Y, et al. “Facile Fabrication of Superhydrophobic Paper with Durability, Chemical Stability and Self-Cleaning by Roll Coating with Modified Nano-TiO2.” Appl. Nanosci., 10 4063–4073 (2020)

Yuhong, T, “Facile Fabrication of Superhydrophobic Paper with Durability, Chemical Stability and Self-Cleaning by Roll Coating with Modified Nano-TiO2.” Appl. Nanosci., 11 4063–4073 (2020)

De Falco, G, Ciardiello, R, Commodo, M, Del Gaudio, P, Minutolo, P, Porta, A, D’Anna, A, “TiO2 Nanoparticle Coatings with Advanced Antibacterial and Hydrophilic Properties Prepared by Flame Aerosol Synthesis and Thermophoretic Deposition.” Surf. Coat. Technol., 349 830–837 (2018)

Morsy, F, El-Sherbiny, S, Samir, M, Fouad, OA, “Application of Nanostructured Titanium Dioxide Pigments in Paper Coating: A Comparison Between Prepared and Commercially Available Ones.” J. Coat. Technol. Res., 13 307–316 (2016)

Ahmed, NM, Selim, MM, Anticorrosive Performance of Titanium Dioxide‐Talc Hybrid Pigments in Alkyd Paint Formulations for Protection of Steel Structures. Anti-Corros. Methods Mater. (2010).

Ibrahim, MM, Mobarak, F, Salah El-Din, EI, Ebaid, AE, Youssef, MA, “Modified Egyptian Talc as Internal Sizing Agent for Papermaking.” Carbohyd. Polym., 25 (75) 130–134 (2019)

Hayeemasae, N, Rathnayake, WGIU, Ismail, H, “Nano-Sized TiO2-Reinforced Natural Rubber Composites Prepared by Latex Compounding Method.” J. Vinyl Addit. Technol., 23 200–209 (2017)

Khajeh, MM, “The Effect of Nano- and Micro-TiO2 Particles on Reflective Behavior of Printed Cotton/Nylon Fabrics in Vis/NIR Regions.” Color Res. Appl., 37 199–205 (2012)

El-Sherbiny, S, “Synthesis, Characterization and Application of TiO2 Nano-Powders as Special Paper Coating Pigment.” Appl. Nanosci., 4 305–313 (2014)

Ebrahimpour, KJ, “Physical Properties and Printability Characteristics of Mechanical Printing Paper with LWC.” Bio Resour., 3 3646–3656 (2013)

Saif, I, Hammood, S, Abdulhadi, HA, “Effect of Nano-TiO2 Particles on Mechanical Performance of Al-CNT Matrix Composite.” AIMS Mater. Sci., 6 1124–1134 (2019)

Amit, C, Islam, MS, “Fabrication and Characterization of TiO2-Epoxy Nano-Composite.” Mater. Sci. Eng. A, 487 574–585 (2008)

Yanjun, T, “Chitosan/Titanium Dioxide Nanocomposite Coatings: Rheological Behavior and Surface Application to Cellulosic Paper.” Carbohyd. Polym., 151 752–759 (2016)

Yong, M, “Study on the Generation Mechanism of Reactive Oxygen Species on Calcium Peroxide by Chemi Luminescence and UV-Visible Spectra.” J. Biol. Chem. Luminescence, 6 575–580 (2007)

Maximilian, H, “An Extended Spectrum Bactericidal Titanium Dioxide (TiO2) Coating for Metallic Implants: In Vitro Effectiveness Against MRSA and Mechanical Properties.” J. Mater. Sci. Mater. Med., 22 381–387 (2011)

Charinee, W, “Self-Assembly of Colloidal Lignin Nanosphere Particles Blended with Chitosan Composite Coated Bagasse Paper: An Eco-friendly Food Packaging with Antimicrobial Properties.” Colloids Surf. A Physicochem. Eng. Asp., 655 130207 (2022)

Petri, I, “Influence of Surface Properties of Coated Papers on Printed Electronics.” Ind. Eng. Chem. Res., 17 6025–6036 (2012)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest could influence the work reported in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohamed, M.G., Ahmed, N.M. & Samir, M. Sustainable coatings based on core–shell pigments to enhance antibacterial and other beneficial paper properties. J Coat Technol Res 20, 1857–1866 (2023). https://doi.org/10.1007/s11998-023-00782-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-023-00782-7