Abstract

Bioactive peptides (BPs) derived from agri-food side-streams display great potential as functional ingredients and nutraceuticals. However, BPs can be susceptible to environmental stressors and food processing conditions and typically exist as an aqueous mixture of various peptides, making their storage and use in foods very challenging. Microencapsulation offers a solution, utilizing suitable wall materials to create a protective matrix and transform them into powders for improved stability and application versatility. Here, we investigated the possibility of creating freeze-dried microencapsulated BP powders from bread waste using maltodextrin as the wall material to maintain their antifungal properties against Penicillum albocoremium, Eurotium herbariorum and Penicillium roqueforti fungi. The results were compared to those obtained from galactoglucomannans (GGM) and glucuronoxylans (GX) sourced from forest industry side-streams, aiming to explore their potential suitability as innovative materials for microencapsulating BPs. Maltodextrin microcapsules exhibited the highest inhibition rate on the tested fungi (10 − 44%), followed by GX (26 − 39%) and then GGM (9 − 14%) counterparts. Interactions between wall materials and BPs, as illustrated by FTIR analyses, were found to be the cause of variations in antifungal activities among BP microcapsules. The use of wall materials, especially wood hemicelluloses, facilitated freeze drying of BPs. However, their application in food products is restricted by the decline in the BP bioactivity resulting from the freeze drying process. For this reason, additional research on alternative drying methods is needed. The results of this study are expected to open new ways of production of stable functional ingredients from side-streams of the forest and food industries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recovering and transforming food waste and side-streams into functional products using green technologies is one of the top emerging trends in the food industry, which has the potential to be highly beneficial to economy, consumers and environment (Almuhammad et al., 2024; Helkar et al., 2016). The generation of bioactive compounds such as peptides is one of the routes explored to reutilize challenging but valuable raw materials including by-products from both animal-based and plant-based food processing such as fish skin, fruit seeds, or grain bran. In the past few decades, a wide range of food-derived bioactive peptide (BP) sequences with multiple health benefits have been identified (Chakrabarti et al., 2018; Chourasia et al., 2022; Kitts & Weiler, 2003). BPs are fragments of 3–20 amino acids that can be obtained from the protein precursors by digestive enzymes, during food processing or by in vitro hydrolysis methods, including fermentation (Daliri et al., 2017). Bioactivities of the peptides span from antimicrobial, anti-thrombotic, antihypertensive, opioid, immunomodulatory, mineral binding, antioxidative or inhibitory of aging-related enzymes. This makes them prospective functional additives and/or ingredients in food for packing and preservation (Perez Espitia et al., 2012), in pharmacy and cosmetics for treating or preventing medical conditions and life-style diseases such as obesity, diabetes type II and hypertension (Chakrabarti et al., 2018; Sánchez & Vázquez, 2017). Research on the generation and bioactivity of BPs derived from food waste and side-streams has been documented. Examples include the discovery of anticancer peptides from walnut oil extraction residues (Ma et al., 2015), antioxidant peptides extracted from tomato seeds (Mechmeche et al., 2017), antifungal peptides derived from surplus bread (Nionelli et al., 2020), antioxidant peptides originating from brewers’ spent grains (Verni et al., 2020), as well as antioxidant and antibacterial peptides isolated from bitter beans (Muhialdin et al., 2020), and antidiabetic and antioxidant peptides from quinoa seeds (Jafarpour & Hashemi, 2023).

Most BPs are water-soluble and often exist as aqueous mixtures of various peptides. As they are incorporated into food products, additional water could be added, making the food formulation more difficult, especially for low-water content food products. Additionally, the BP bioactivities can be highly sensitive to food processing conditions, environmental stressors (temperature, pH, or enzymes) and gastrointestinal conditions. Consequently, BPs could lose their functionalities during storage, fortification into foods, and passage through gastric phases. Additionally, the high degree of bitterness reduces sensory acceptability and limits their use in oral formulations (Sarabandi et al., 2020). These challenges, including isolation, purification, storage, and practical applications, must be addressed. Therefore, there is a need to obtain BPs in a more stable form to facilitate handling, storage and incorporation into various food products. The recovery of BPs in dried form, for example, through freeze drying could lead to structural changes or damage to BPs, especially as they are sensitive to oxygen, temperature and mechanical stress. This can affect their biological activity and functionality. Moreover, BPs may aggregate during the freeze drying process due to their low molecular weights and/or low glass transition temperatures, leading to the loss of bioactivity and difficulties in their recovery, collection, handling and storage, as well as reconstitution (i.e. low solubility) (Depaz et al., 2016).

Various micro and nano-carriers such as nanoliposomes (Sarabandi et al., 2019), emulsions (Rairkar et al., 2007), solid lipid nanoparticles (Ansari et al., 2016), and microgels (Zhang et al., 2016) have been developed to tackle the challenges associated with using BPs. The choice of delivery system is determined by characteristics of BPs and final applications. Stabilizing BPs is crucial for their applications as food ingredients due to their perishable nature, high reactivity in liquid-based food formulations, environmental factors, and storage, transportation and packaging issues (Olatunde et al., 2023). Microencapsulation with suitable wall materials to convert BPs to microcapsule powder form is one of the most prevalent stabilization methods. In this process, BPs are entrapped and solidified within a matrix of wall material, providing a protective environment for maintaining their structural integrity and functionality. Also, this technique allows for controlled and targeted release of the encapsulated BPs. Despite the advantages of microencapsulation, there remains a knowledge gap, regarding the preservation of BPs throughout this procedure. This challenge arises from the complex interaction between the properties of the wall material and the structure of the BPs (Aguilar-Toalá et al., 2022; Li et al., 2023), highlighting the need for further investigation to identify suitable wall materials that facilitate the retention of BPs during microencapsulation (Aghbashlo et al., 2013). Success of microencapsulation of BPs is expected to open a new way of production of functional food ingredients.

One of the crucial objectives of microencapsulating BPs is to preserve their bioactivity throughout the encapsulation process and during storage (Ngamakeue & Chitprasert, 2016). Therefore, wall materials must protect BPs from environmental factors without inducing interactions that could alter their bioactivity and reduce bioaccessibility (Aguilar-Toalá et al., 2022; Nedovic et al., 2011). One of the most commonly used wall materials for microencapsulation of various bioactive compounds, including essential oils and phenolic compounds, is maltodextrin (MD). This preference is attributed to its good film-forming ability, high solubility, low viscosity at high solids concentration, cost-effectiveness, and high thermal and freeze stability (Xiao et al., 2022). Moreover, MD imparts neutral taste and flavor and remains colorless in solutions, enabling the microcapsules to be utilized in a wide range of liquid, semi-solid, and solid food products. Despite these advantages, the use of MD as a wall material for encapsulating BPs, especially those derived from food waste/by-products, remains very limited. Recently, we have investigated a new type of wall materials, known as wood hemicelluloses, including galactoglucomannans (GGM) from softwoods (i.e. spruce) and glucuronoxylan (GX) from hardwoods (i.e. birch), to effectively encapsulate bilberry phenolic compounds (Halahlah et al., 2023c) and polyunsaturated fatty acids (Ho et al., 2023a). The use of wood hemicelluloses as wall materials offers many advantages over the commonly-used ones regarding sustainability, cost-effectiveness and ability to provide additional health benefits in the final product (Halahlah et al., 2023a). Hemicelluloses account for 25–35% of the dry wood mass (Sixta, 2006), and have been successfully recovered in large amounts from all major sources of forest industry side-streams such as sawdust, slabs, barks and chips using a safe and environmental-friendly pressurized hot water extraction (PHWE; Kilpeläinen et al., 2014). They have been tested as ingredients in yogurt and oat-based beverages (Kirjoranta et al., 2020; Valoppi et al., 2019b), and could be utilized as food ingredients/additives based on in vitro/vivo evaluation (Granato et al., 2022; Kynkäänniemi et al., 2022) although their use in food has not yet been approved by the food safety authority. In addition, wood hemicelluloses can bring additional health benefits to the final product, owing to their dietary fiber sources (Halahlah et al., 2023a) and antioxidant capacity resulting from their natural lignin derived phenolic residues (Lahtinen et al., 2019). In our previous study (Halahlah et al., 2023c), we found that the natural lignin content in wood hemicelluloses supported the formation of bilberry-based phenolic microcapsules with higher free radical-scavenging capacity (DPPH) and ferric reducing antioxidant power (FRAP) values. Specifically, the DPPH and FRAP values in the microcapsules coated with wood hemicelluloses were 100–130 and 400–500 μmol Trolox equivalent/g, respectively, which were double those in the microcapsules coated with gum Arabic (74 and 227 μmol Trolox equivalent/g, respectively). From these properties of wood hemicelluloses, it is expected that they could be effective wall materials to encapsulate BPs. However, their ability to protect bioactivities of peptides against environmental stressors and support their target delivery are still unknown and needs further investigation.

In our previous study, we showed that tailored bioprocessing of surplus bread induced the formation of BPs with antifungal effect, with the ability to delay the growth of molds commonly contaminating bakery products. The bioprocessed bread contained a significant amount of proteins (4.3 mg/mL) and bioactive peptides (8.2 mg/mL) released as a result of protein hydrolysis and fermentation. The most active antifungal fractions, having a molecular mass lower than 3 kDa, were subsequentially identified as peptides derived from native wheat proteins (Nionelli et al., 2020). However, in the above study, the antifungal BP hydrolysates were in aqueous dispersions with over 70% water, posing challenges for their storage and fortification into food products, with the potential loss of functionality during processing. In this study, we explored the feasibility of producing microencapsulated BP powders using MD as wall materials to preserve their antifungal activities during freeze drying. The expected results include the generation of food-grade BP powders exhibiting potent antifungal activities against Penicillium and Eurotium spp. and simplifying storage and incorporation into food products. The efficacy of MD as a wall material for protecting BPs has been assessed in comparison to that of wood hemicelluloses, aiming to evaluate the potential suitability of wood hemicelluloses as novel wall materials for microencapsulating BPs.

Materials and Methods

Materials and Microbial Cultivation Conditions

Spray-dried GGM and GX powders recovered by PHWE were provided by Montinutra Ltd. (Turku, Finland) and Natural Resources Institute Finland (Luke), respectively. The characteristics regarding lignin content, molar mass and carbohydrate composition of the GGM and GX powders were reported in a study by Ho et al. (2023b). MD powder with a degree of hydrolysis measured as a dextrose equivalent of 16.5–19.5 was bought from Biosynth Carbosynth (Reading, UK).

Commercial wheat bread (Ranskan Leipa, Vaasan) that consists of 47% carbohydrate, 3.6% fiber, 1.3% fat, 9.6% protein and 1.1% salt was used as substrate for BP generation. Before being used, the wheat bread was frozen at -20 °C and milled to obtain fine breadcrumbs. The enzymes used in bioprocessing were: amyloglucosidase (Grindamyl plusweet G, Danisco), alpha-amylase (Grindamyl A 140 000, fungal, Danisco) and protease (Corolase 7089, AB enzymes). Levilactobacillus brevis AM7 belonging to the University of Bari “Aldo Moro”, Italy, and available in the research collection of the Department of Food and Nutrition, University of Helsinki, Finland, was used as starter to ferment the bread hydrolysate to produce antifungal peptides (Coda et al., 2008; Nionelli et al., 2020). The strain was routinely cultivated in MRS broth (de Man, Rogosa & Sharpe broth, LABM, UK) for 24 h at 30 °C. The following molds: Penicillum albocoremium CBS 109582, Eurotium herbariorum CBS117336 (Centraslbureau voor Schimmelcutures, Utrecht, Netherlands) and Penicillium roqueforti P1 (Department of Food and Nutrition, University of Helsinki) were used to assess the antifungal activity of the bread peptides after microencapsulation. The molds were grown on potato dextrose agar (PDA, Oxoid) and incubated at 25 °C for 7 days before being used.

Preparation of Antifungal Bioactive Peptides from Bread Waste

The fermented bread hydrolysate was prepared according to the procedure described by Nionelli et al. (2020). Briefly, 0.25% of amyloglucosidase, 0.05% of alpha-amylase and 300 nKat/g (on bread protein basis) of protease were resuspended in distilled water. The enzymatic solution was then mixed with breadcrumbs at 2:1 ratio. The bread suspension was hydrolyzed by incubating at 50 °C for 24 h under continuously shaking condition (120 rpm). After that, the pH of the bread solution was adjusted to 6.5 using 1 M NaOH. Subsequentially, the bread hydrolysate was heated at 85 °C under mixing for about 20 min to inactivate the enzymes and then cooled to room temperature (~23 °C) before inoculum. Cells of L. brevis AM7 were harvested by centrifugation (10,000 rpm for 10 min) and washed with sterile phosphate buffer saline (pH 7.4, Sigma-Aldrich, Saint Louis, USA), were resuspended into 1 mL of Milli-Q water and then mixed with the bread hydrolysate, aiming to achieve the initial cell density of ca. Log 6–7 colony forming unit per gram of hydrolysate (cfu/g). Previously, it was proven that the antifungal effect of protease addition alone was very low on all the molds tested (Nionelli et al., 2020). For this reason, further fermentation with L. brevis AM7 was performed due to its proven ability to release antifungal peptides during wheat, and faba bean flour fermentation (Coda et al., 2008; Verni et al., 2023). Then, the hydrolysate was incubated at 30 °C for 24 h for BPs generation, and fermented hydrolysate was used for microencapsulation by freeze drying.

Preparation of Bioactive Peptide Microcapsules by Freeze Drying

Wall material dispersions at 25% (w/w) solid concentration were prepared by dissolving wall material powders into MilliQ water, and the dispersions were stirred overnight to facilitate the dispersion of wall materials. Wall material dispersions were then mixed with bread hydrolysates containing antifungal BPs which also had 25% (w/w) solid concentration at solid ratio of 1:1 so that the final solid concentration of the mixed dispersions was 25% (w/w). After stirring for at least 30 min, the mixed dispersions were freeze-dried (Alpha 2–4 LD plus, Martin Christ, Germany) to obtain antifungal microcapsule powders. It is noticed that BP denotes freeze-dried fermented bread hydrolysate while BP-GGM, BP-GX and BP-MD denote freeze-dried BP microcapsules coated by GGM, GX and MD, respectively.

Determination of Antifungal Activity of the Freeze-dried Microcapsules

The antifungal activity of the freeze-dried microcapsules was evaluated with the hyphal radial growth assay reported by Nionelli et al. (2020) with some modifications. First, dispersions of the above freeze-dried microencapsules were prepared by mixing them with Milli-Q water at a ratio of 1:4 under stirring for 1 h (~23 °C). Subsequentially, PDA containing 19.4% of agar and freeze-dried microcapsule dispersion were mixed at a ratio of 40:60, respectively, to reach a final volume of 16 mL, and then the mixture was poured into petri dishes. Conidia suspensions of the molds prepared as explained in Nionelli et al. (2020) were spotted (20 µL) on the petri dishes. All the petri dishes were incubated at 25 °C, and the colony diameter was measured after the mold in the control conditions (prepared as below) reached 30 − 50% of the petri dish diameter (5 days). The antifungal activity of the freeze-dried microcapsules was determined as the percentage of growth inhibition, which was calculated as follows:

where Mc is mycelial growth under control conditions, Mm is mycelial growth in the presence of microencapsulated peptides.

To take into account potential antifungal effect of the hemicelluloses, in this assay, the control conditions were represented by bread hydrolysate without BPs, prepared as explained in "Preparation of Antifungal Bioactive Peptides from Bread Waste" section but without protease addition and fermentation, coated with wall materials and freeze dried as explained in 2.3.

Physical Characterization of the Freeze-dried Antifungal Microcapsules

Physical properties of antifungal microcapsule powders including water activity, moisture content, particle size, particle surface charge, solubility, thermal properties, morphology, and structure were determined to evaluate their potential applications. The details of these analytical methods were reported in our previous studies (Halahlah et al., 2023a, c; Ho et al., 2023a). Here, we briefly reported their principle and main steps. Water activity was measured at 25 °C using water activity meter (LabMaster-AW, Novasina AG, Lachen, Switzerland). Moisture content was determined by an oven drying (Memmert 800, Schwabach, Germany) at 105 °C for 24 h as the weight of the samples was constant. Particle size was measured using a dynamic light scattering mastersizer (Mastersizer Hydro 3000 SM, Malvern Instruments Ltd., Worcestershire, UK) integrated into an Aero S dry powder disperser (Malvern Instruments Ltd., Worcestershire, UK) where air was used as a dispersion medium. The refractive index of 1.53 was employed for the calculation, and results were reported as volume-based diameter (D[4,3]), surface area-based diameter (D[3,2]) and particle size distribution curves. Particle surface charge expressed by ζ-potential values was measured by an electrophoretic light scattering instrument (Zetasizer Nano ZS series, Malvern Panalytical Ltd, Malvern, UK). The powders were dispersed into Milli-Q water at 10% solid concentrations, and the dispersion was further diluted into Milli-Q water at a volume ratio of 1:1000 to avoid multi-scattering effects. Solubility was measured by the determination of the amount of insoluble solids remaining after microcapsule powders were dispersed into Milli-Q water under a continuous stirring at 600 rpm for 30 min. The weight of insoluble solids was determined by a centrifugation of the stirred dispersion to eliminate the supernatant, followed by oven drying until constant weight. Solubility (%) was calculated as a ratio of the differences between the amount of total solids in the microcapsule powders and that of insoluble solid to the amount of total solids. Thermal properties regarding glass transition (Tg) and decomposition (Tm) temperatures were measured using a differential scanning calorimetry (DSC823e, Mettler Toledo AG, Greifensee, Switzerland) over a temperature range of 25 to 200 °C with a heating rate of 5 °C/min. Morphology was determined by a field emission scanning electron microscope (FESEM, S-4800, Hitachi, Tokyo, Japan) with an accelerating voltage of 10 kV, an energy of the incident electrons of 5 mV, and a working distance of 10 µm. To avoid particle charging, the microcapsule was coated (208HR, Cressington Scientific Instruments, Watford, UK) with gold/palladium at a thickness of 4 nm in three cycles. The structure of the microcapsules was determined by X-ray diffraction (XRD) analyses using an Empyrean Alpha 1 X-ray diffractometer (Malvern Panalytical, Worcestershire, UK) using a Cu radiation (λKα1 = 1.541 Å) with a voltage of 45 kV, a current of 40 mA and an angular range of 2θ = 5–50°.

Experimental Design and Data Analyses

The experiments were performed in two biological replicates and with two analytical replicates for each, if not stated otherwise, and results are presented as mean values (± standard deviations). A one-way analysis of variance (ANOVA) followed by post-hoc Tukey’s test were used to compare the mean values with a statistically significant difference at p-value of 0.05 using OriginPro 2020 (OriginLab Corporation, Northampton, MA, USA). For physical characterization such as morphology, thermal properties and XRD, one representative measurement was selected to illustrate in the figures due to the similarity among replications.

Results and Discussion

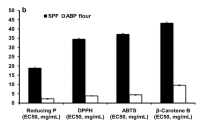

Antifungal Activity in the Freeze-dried Microcapsules

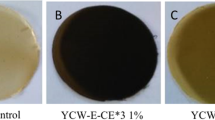

Preliminary results indicated that freeze drying of the fermented bread hydrolysate (without using coating materials) partially decreased the antifungal effect of BPs compared to our previous study, in which the hydrolysate was tested as such against mold growth (Nionelli et al., 2020), reaching 44.4% of inhibition on P. albocoremium CBS 109582 (data not shown). The inhibitory activity of the microencapsulated BP and the inhibition of the growth of P. albocoremium CBS 109582 are shown in Table 1 and Fig. 1, respectively. The incorporation ratio of the bread hydrolysate in the agar media was the same either when used alone or in combination with the coating materials. The fermented bread hydrolysate coated with MD (BP-MD) exhibited the highest antifungal activity on P. albocoremium CBS 109582 and E. herbariorum CBS 117336 (ca. 40% inhibition). BP-GX showed the highest antifungal activity on P. albocoremium CBS 109582 (ca. 26 − 39% inhibition). Lower inhibition rates were seen for fermented bread hydrolysate coated with GGM for all the fungi tested (ca. 9 − 14% inhibition). Overall, the most inhibited molds were P. albocoremium and E. herbariorum, while lower values were observed for P. roqueforti. In the previous study, the bread hydrolysate fermented by L. brevis AM7 containing BPs showed the highest growth inhibition on the three mold species used in this experiment, reaching up to 72 − 77% (Nionelli et al., 2020). Compared to that study, in which the antifungal effect of the BPs was tested without microencapsulation on fungal growth for up to 7 days, these results showed lower inhibition rates overall. Furthermore, under the conditions of this study, wood hemicelluloses did not seem to have a significant protection effect against freeze drying on the tested fungal strains. This might be due to the coating which modified the antifungal properties of the peptides. In fact, some of the features of the previously identified nine antifungal BPs (Nionelli et al., 2020) such as cationic nature, hydrophobic ratio, and structure, might have been altered during interaction with the coatings, thus reducing the inhibitory effect. It is well-known that electrostatic interactions play an important role in the formation of protein−polysaccharide complexes (Schmitt & Turgeon, 2011). In this study, pH of GGM and GX dispersions (25% solid concentration) were 3.7 and 6.9 respectively, and under these pH conditions, GGM and GX are negatively charged and can interact with the peptide’s amine groups (NH3+). Additionally, due to the presence of a high proportion of lignin in GGM (22%, w/w) and GX (24%, w/w) (Ho et al., 2023b), hydrophobic interactions between aromatic rings in bioactive peptide’s amino acids and lignin could also occur (Hu et al., 2012). All these interactions could affect the peptides conformation, leading to the loss of their bioactivity.

Example of antifungal activity of the microencapsulated bread hydrolysates as determined by hyphal radial growth rate assay on the indicator mold P. albocoremium CBS 109582. From left to the right: Galactoglucomannans (GGM) coated bread hydrolysate (Control on the top; BP-GGM the bottom); Glucuronoxylan (GX) coated bread hydrolysate (Control on the top; BP-GX the bottom the top); Maltodextrin (MD) coated bread hydrolysate (Control on the top; BP-MD the bottom)

The results emphasize the substantial impact of the chosen wall material on the antifungal effectiveness of BP microcapsules. MD emerges as a viable candidate for the production of antifungal BP microcapsules, thereby presenting an opportunity for their utilization as functional food ingredients to mitigate fungal proliferation in various food products. Nevertheless, it is crucial to optimize the microencapsulation process, with a particular emphasis on maintaining antifungal properties by preventing interactions between BPs and wall materials.

Among the coatings used, MD is most effectively retained the antifungal activity. However, due to the structure of MD, such electrostatic interactions or hydrophobic interactions are not expected between MD and bioactive peptides, and MD mainly functions as bulking/co-drying agent of peptide (not necessarily encapsulation in this case). MD may help to protect peptides from processing conditions during freeze drying (Baiocco et al., 2021). Furthermore, one of the possible reasons for a lower antifungal activity of BP-GGM and BP-GX than BP-MD microcapsules, is the aggregation tendency of the former in acidic conditions which prevent their free release of bioactive peptides (Westbye et al., 2007). Additionally, MD has shown high solubility in aqueous solutions compared to GGM and GX which could imply that MD could present permeation-enhancing effects and thus higher accessibility of bioactive peptides for fungi (Amigo & Hernández-Ledesma, 2020). It was recently shown that MD was able to increase the antibiotic and antifungal activity against Candida albicans when used as carrier of nystatin solid dispersions, due to its hyperosmotic effect (Benavent et al., 2021). A similar mechanism can be hypothesized in the case of MD microencapsulated BP in this study. However, further investigation is necessary to elucidate this phenomenon. Unlike wood hemicelluloses, a fast release of peptides from MD could promote their degradation/oxidation during storage. Therefore, exploration on the long term efficient and stable carrier for natural products as an important development for food industry needs to be made.

Physical Properties of the Freeze-dried Microcapsules

Moisture Content and Water Activity

Immediately after freeze drying, the moisture content and water activity of the microcapsule powders were determined and the results are shown in Table 2. The moisture content of BP was 9.19% (w/w), which was slightly higher than that of microcapsule powders (6.64 − 8.07%), implying that adding wall materials, especially GX to BP enabled the ease of freeze drying of BP and thus decreased its moisture content. Meanwhile, the water activity of BP was not significantly different to that of microcapsules. Moisture content and water activity are important indicators to evaluate the storage stability and shelf-life of the powders. Based on the recommended levels for water content and water activity of most dried powders which are less than 5.0% and 0.3, respectively to archive a long-term storage stability (Karaca et al., 2013; Rajabi et al., 2015), BP microcapsule powders need to be stored in a dry environment (i.e. low relative humidity) and adequate packaging conditions (i.e. airtight packaging) to inhibit microbial growth and biochemical reactions which might cause a loss of bioactivities of microencapsulated powers if they are stored for a long term.

ζ-potential

Determining ζ-potential of microcapsule powders is important to evaluate the stability of their dispersion as they are fortified into liquid or liquid-semi solid food products. Dispersions with higher absolute ζ-potential values lead to greater electrostatic repulsion between particles, which implies lower aggregation of particles and higher stability (Vallar et al., 1999). From Table 2, ζ-potential values of BP and microcapsule powders were negative. BP-GX microcapsules had the highest absolute ζ-potential (32 mV), followed by BB-GGM ones (27 mV) while BP and BP-MD microcapsules had the lowest values (13 mV). It was reported that GGM and GX wall materials had highly negative surface charges originating from uronic acids and co-extracted phenolic compounds linked to them naturally (Bhattarai et al., 2020b; Halahlah et al., 2023b). Meanwhile, MD wall materials are an uncharged water-soluble polymers (Wangsakan et al., 2004), thus the source of negative charge in BP-MD microcapsules was primarily from BP, which explains the similar ζ-potential values between BP and BP-MD. The differences in ζ-potential values among microcapsule powders could be partially explained by the differences in pH of their dispersions. The pH of mixed dispersions of BP and GX, GGM or MD before freeze drying was measured to be 4.69, 3.65 and 3.66, respectively.

According to the classification of dispersion stability based on absolute ζ-potential values (Bhattacharjee, 2016): < 10 (very unstable), 10–20 (fairly stable), 20–30 (moderately stable) and > 30 mV (highly stable), the dispersions prepared from BP-GGM and GGM-GX microcapsules are expected to have less particle aggregation, and thus are more stable over time than those prepared from BP-MD and BP. The results indicated that the use of GGM and GX as wall materials to encapsulate BP has potential to improve the stability of dispersions as BP microcapsules are intended to be mixed into liquid or liquid-semi solid food products.

Solubility

Solubility of microcapsule powders is linked to the chemical structure of the used wall material and it is an important property for food processing as it might affect the ease of manufacturing, structure of food products and cost of food production (Mahdavi et al., 2016). As shown in Table 2, the solubility of BP powders was very high (~95%), and microencapsulation of BP using GGM and GX as wall materials significantly reduced the solubility to 86 − 90% (p < 0.05) while this effect was not observed for MD (p > 0.05). The solubility of polysaccharides is related to the nature of molecules (hydrophilicity and hydrophobicity) and the formation of hydrogen bonds in water molecules and hydroxyl groups in the polysaccharides. The lower solubility of BP-GGM and BB-GX compared to BP-MD can be attributed to the natural presence of insoluble hydrophobic lignin factions in GGM and GX wall materials (Valoppi et al., 2019a), whereas MD powders exhibit complete water solubility (Wangsakan et al., 2004). Variations in the solubility of BP-GGM and BB-GX could be explained by the existence of high molar mass polysaccharides and colloidal assemblies and/or particles in sub-micron size range in GGM (Bhattarai et al., 2020a), as well as a significant amount of lignin in GX (Ho et al., 2023b).

However, the high water solubility of all microcapsule powders observed in this study can enable them to be easily and effectively fortified into various food products without changing the product appearance and structure.

Particle Size Distribution

Particle size of microcapsule powders significantly affects their physicochemical properties (porosity and bulk density) and powder flowability (Anandharamakrishnan & Padma Ishwarya, 2015). From Fig. 2a, the particle-size distribution of BP and microcapsule powders exhibited similar monomodal curves with the main peaks at around 100 μm, demonstrating good powder homogeneity in these samples. However, as compared to BP particle size distribution curves, a slight shift of the main peaks to the side of smaller particle size was observed for microencapsulated powders, indicating that microencapsulation led to a smaller size of powder particles. Additionally, from Table 2, D[4,3] and D[3,2] values of BP powders were 280 and 195 μm, respectively, which were significantly larger than those of microcapsule powders (D[4,3] and D[3,2] = 211 − 236 and 99 − 121 μm, respectively). Visual observation revealed that after freeze drying, BP powders existed as a rubbery mass and were difficult to be collected and/or ground into powders while these issues were not seen for BP microcapsule powders. The results indicate that microencapsulation of BP reduces the stickiness issue during freezing drying of BP and makes the grinding step (after freeze drying) easier to be accomplished.

Long-range Structure

The internal structure of microcapsule powders (crystalline or amorphous) greatly affects their storage stability and functional properties such as solubility, flowability and compressibility (Al-Maqtari et al., 2021). The X-ray diffraction patterns of BP and microcapsule powders (BP-GGM, BP-GX, and BP-MD) are presented in Fig. 2b. A broad peak (halo) was found for all samples which confirms that all the produced microcapsule powders were primarily glassy amorphous, which is a typical structure of most freeze-dried powders (Oyinloye & Yoon, 2020). The results also indicated that wall materials did not affect long-range structure of BP and microcapsule powders. With amorphous structure, it is expected that microcapsule powders could have low density, high water solubility, high bioactivity and high elasticity (Babu & Nangia, 2011; Hancock & Parks, 2000). However, amorphous microcapsule powders have a metastable nature and it is important to store the powders in suitable environmental conditions (relative humidity and temperature) to avoid phase transformation (e.g., caking, stickiness) (Ho et al., 2017).

Morphology

As presented in Fig. 3, both BP and microcapsule powders existed in broken lamellar structure and as flakes, which is typical morphology of freeze-dried microcapsule powders (Anwar & Kunz, 2011; Kaushik & Roos, 2007; Sousdaleff et al., 2013). The buckled shape and broken glassy interior may be due to the formation of a glassy skin in the early stage of drying in the microcapsule’s formation process (Ma et al., 2014). Previous studies explained that the low moisture diffusivity in glassy skin of polymeric materials results into internal vaporisation and periodic escape of water which results into broken structure, long semi-cylindrical particles, and wrinkled surface which is commonly observed by SEM for protein-rich formulations (Ma et al., 2014; Zhu et al., 2020). It was clearly seen from Fig. 3 that microencapsulation induced the formation of small flakes, which is comparable to the results of their particle size ("Particle Size Distribution" section). Presence of dents on the surface of particles of BP and their microcapsule could have adversely effects on the powder flowability and reconstitution properties (Kaushik & Roos, 2007).

Thermal Analysis

Due to the amorphous structure of microcapsule powders as shown in XRD results, it was important to determine Tg of microcapsule powders to determine the stability during long-term storage. Amorphous powders should be kept at temperatures lower than their Tg to avoid disrupting and collapsing of their structure (Ho et al., 2017). The DSC curves of BP powders in Fig. 4 reveal a major transition with onset temperature at 49.2 ± 2.2 °C, which could be Tg or denaturation temperature of unhydrolyzed proteins and/or BP. It is noticed that in the BP hydrolysates, along with BPs, other components remain, including starch, sugars, and unhydrolyzed proteins. In addition, protein hydrolysates contain low molecular mass peptides as a result of the enzymatic hydrolysis and typically present low Tg values, which was also suggested for meat protein hydrolysates (Kurozawa et al., 2009; Silva et al., 2012). In our previous study, the bioprocessed bread BP have 10–17 amino acid residues and mass ranging from 1083 to 1980 Da (Nionelli et al., 2020). However, for microcapsule powders another thermal event was seen at higher temperatures: 68.7 ± 1.2 °C (BP-GX), 71.9 ± 3.2 °C (BP-GGM) and 86.9 ± 1.1 °C (BP-MD), implying that microcapsule powders are more stable to phase transformation and structural collapsing during storage. Differences in Tg among microcapsule powders could be due to their differences in molar mass, molecular structure and chemical composition of wall materials. Typically, polymers with a higher molar mass, amounts of bulky and inflexible side groups, degree of cross-linking, and amounts of polar groups have a higher Tg (Roos, 2010).

DSC curves over temperature range from 25 to 200 °C (a), and those expanded in both x- and y-axes (b) to illustrate thermal events associated with glass transition temperatures and/or denaturation of freeze-dried bioactive peptides, and their microcapsule. BP: Bioactive peptides; BP-GGM, BP-GX, and BP-MD: Bioactive peptide microcapsules coated by galactoglucomannans, glucuronoxylan, and maltodextrin, respectively

Similar sharp endothermic peaks at around 170 °C were seen for all samples, which is possibly due to melting of crystalline proportions and/or decomposition of the powders. The results agree with visual observation of the samples inside pans after heating, resulting completely burned (data not shown). Therefore, microencapsulation using GGM, GX and MD did not significantly enhance the decomposition temperature of BP.

FTIR Spectra of Microcapsule Powders

The FTIR spectra of freeze-dried powders of unfermented bread hydrolysate (BH), BP and BP microcapsule powders (BP-GGM, BP-GX and BP-MD); and those of wall materials (GGM, GX and Mal), mixtures (dry mixing) of BP and wall materials (dry mixing BP-GGM, dry mixing BP-GX and dry mixing BP-MD) are reported in Fig. S1 (Supplementary materials). The FTIR spectra of BP exhibit the characteristics of protein spectra including the peaks at ∼1450–1240 cm−1 (C–N stretch and N–H bend in amide III), the peaks at ∼1700 (C=O stretch in amide I) and 1550 cm−1 and (N–H bend and C–N stretch in amide II) (Nooshkam & Madadlou, 2016). Furthermore, C−H stretch from carboxylic group (∼2900 cm−1) and CH3 and C−H bend (∼1410 cm−1), and C−O stretch (∼1020 cm−1) can also appear on FTIR spectra of BP (Karrar et al., 2021). The FTIR spectra of GGM and GX were quite similar as both of them display O−H stretch (∼3278 cm−1), CH2– and CH3– stretch (∼2930–2868 cm−1), a peak at ∼1725 cm−1 representing for acetyl groups, a peak at ∼ 1510 cm−1 due to lignin bonded to hemicelluloses, peaks at ∼1300–1000 cm−1 caused by C single bond O stretching from the carbohydrates (C−O−C) and the hydroxyl groups (C−O−H) (Ho et al., 2023a). Meanwhile, MD has shown similar peaks to GGM and GX at around ∼3300 cm−1 (O−H stretch), and ∼1300–1000 cm−1 (by C single bond O stretching), however, the peak at around 1700 cm−1 was due to asymmetrical and symmetrical stretching –COO– for acetyl groups which was not observed for MD.

FTIR analysis was also performed to identify if BP were generated during fermentation process using the vibrational pattern of various functional groups present. From Fig. S1, comparing FTIR spectra of BP and BH revealed that after fermentation, some bands shifted to lower wavelengths for BP along with reduction in the intensities such as the bands around 3300 cm−1 (O−H stretch), 1600–1700 cm−1 (amin I) and 750–1200 cm−1 fingerprint regions (carbohydrate). These variations indicate that fermentation was responsible for changes in these functional groups of proteins/polypeptides in the bread hydrolysate, such as proteolysis events that lead to the generation of BP and further starch depolymerization (Toor et al., 2021).

As BP and wall materials were physically mixed without freeze drying (dry mixing BP-GGM, dry mixing BP-GX and dry mixing BP-MD), their FTIR spectra was easily distinguished from those of GGM, GX and MD alone which indicated that no interactions took place. For example, peaks specified for BP (∼1300 and 1700 cm−1) were clearly identified on the FTIR spectra of all physically mixed samples. However, after freeze-dried microencapsulation, the differences in the spectra between the wall materials and microencapsulated BP powders were not as highly visible compared to physically mixed BP with wall materials due to overlapped chemical bonds as a result of microencapsulation (Yasar et al., 2020). Moreover, visible changes were observed near 1300, 1700 cm−1 and 3300 cm−1 in the microcapsule powders (BP-GGM, BP-GX and BP-MD) in comparison to the individual initial materials (BP and wall materials). Such variations, absence and/or appearance of characteristic absorption bands, can provide supportive evidence for microencapsulation formation and/or interactions between BP and GGM, GX and MD (Bratu et al., 2004). These shifts could indicate possible interactions between wall materials and BP (Kalušević et al., 2017). The possible interactions between functional groups of BP and wall materials, which requires further investigation to be identified.

Conclusion and Future Perspectives

This study illustrates the different behaviors of the bread derived BPs, in terms of antifungal properties, when freeze-dried with and without the use of wall materials. The freeze drying process was supported by the incorporation of the investigated wall materials, whereas it did not improve the preservation of the BP bioactivity. Notably, among the investigated wall materials, MD microcapsules showed the highest antifungal activity, especially against P. albocoremium and E. herbariorum, with approximately 43% inhibition rate, emphasizing their potential for use as food ingredients. Regarding wood hemicelluloses, especially GX, demonstrated an inhibitory rate of 26 − 39% on the investigated fungi, highlighting the potential of wood hemicelluloses as wall materials for microencapsulation of BPs. However, the bioactivity of the microencapsulated BP was never superior to BP freeze-dried alone. The interactions between wall materials and BPs, confirmed by FTIR, affected the antifungal activity of the microcapsule powders on specific fungi, possibly reducing their inhibitory effect. The use of wood hemicelluloses (i.e. GGM and GX) deriving from forest industries to protect BPs originating from food waste can be seen as an innovative strategy to obtain stable functional ingredients for food, and beyond. Further studies are required to purify BPs and their microencapsulation, as well as identify the precise interactions between wall materials and BPs, allowing optimization of the process to preserve their functionality. Additionally, it is crucial to determine the properties of BP microcapsules that are vital for their application in foods, such as the release properties of BPs from the microcapsules and their storage stability. Moreover, alternative microencapsulation techniques, such as spray drying, which offer numerous advantages over freeze drying in terms of process speed, scalability, cost-effectiveness, and process control, warrant further investigation.

Data Availability

Research data are not shared.

References

Aghbashlo, M., Mobli, H., Madadlou, A., & Rafiee, S. (2013). Influence of wall material and inlet drying air temperature on the microencapsulation of fish oil by spray drying. Food and Bioprocess Technology, 6, 1561–1569.

Aguilar-Toalá, J., Quintanar-Guerrero, D., Liceaga, A., & Zambrano-Zaragoza, M. (2022). Encapsulation of bioactive peptides: A strategy to improve the stability, protect the nutraceutical bioactivity and support their food applications. RSC Advances, 12, 6449–6458.

Al-Maqtari, Q. A., Mohammed, J. K., Mahdi, A. A., Al-Ansi, W., Zhang, M., Al-Adeeb, A., Wei, M., Phyo, H. M., & Yao, W. (2021). Physicochemical properties, microstructure, and storage stability of Pulicaria jaubertii extract microencapsulated with different protein biopolymers and gum arabic as wall materials. International Journal of Biological Macromolecules, 187, 939–954.

Almuhammad, M., Kölling, R., & Einfalt, D. (2024). Comparative assessment of ethanol production from six typical German waste baked products. Food and Bioprocess Technology, 1–12. https://doi.org/10.1007/s11947-023-03304-w

Amigo, L., & Hernández-Ledesma, B. (2020). Current evidence on the bioavailability of food bioactive peptides. Molecules, 25(19), 4479.

Anandharamakrishnan, C., & Padma Ishwarya, S. (2015). Spray drying techniques for food ingredient encapsulation. John Wiley & Sons.

Ansari, M. J., Anwer, M. K., Jamil, S., Al-Shdefat, R., Ali, B. E., Ahmad, M. M., & Ansari, M. N. (2016). Enhanced oral bioavailability of insulin-loaded solid lipid nanoparticles: Pharmacokinetic bioavailability of insulin-loaded solid lipid nanoparticles in diabetic rats. Drug Delivery, 23, 1972–1979.

Anwar, S. H., & Kunz, B. (2011). The influence of drying methods on the stabilization of fish oil microcapsules: Comparison of spray granulation, spray drying, and freeze drying. Journal of Food Engineering, 105, 367–378.

Babu, N. J., & Nangia, A. (2011). Solubility advantage of amorphous drugs and pharmaceutical cocrystals. Crystal Growth & Design, 11, 2662–2679.

Baiocco, D., Preece, J. A., & Zhang, Z. (2021). Microcapsules with a fungal chitosan-gum Arabic-maltodextrin shell to encapsulate health-beneficial peppermint oil. Food Hydrocolloids for Health, 1, 100016.

Benavent, C., Torrado-Salmerón, C., & Torrado-Santiago, S. (2021). Development of a solid dispersion of nystatin with maltodextrin as a carrier agent: Improvements in antifungal efficacy against Candida spp. biofilm infections. Pharmaceuticals, 14(5), 397.

Bhattacharjee, S. (2016). DLS and zeta potential–what they are and what they are not? Journal of Controlled Release, 235, 337–351.

Bhattarai, M., Sulaeva, I., Pitkänen, L., Kontro, I., Tenkanen, M., Potthast, A., & Mikkonen, K. S. (2020a). Colloidal features of softwood galactoglucomannans-rich extract. Carbohydrate Polymers, 241, 116368.

Bhattarai, M., Valoppi, F., Hirvonen, S.-P., Hietala, S., Kilpeläinen, P., Aseyev, V., & Mikkonen, K. S. (2020b). Time-dependent self-association of spruce galactoglucomannans depends on pH and mechanical shearing. Food Hydrocolloids, 102, 105607.

Bratu, I., Veiga, F., Fernandes, C., Hernanz, A., & Gavira, J. (2004). Infrared spectroscopic study of triacetyl-β-cyclodextrin and its inclusion complex with nicardipine. Spectroscopy, 18, 459–467.

Chakrabarti, S., Guha, S., & Majumder, K. (2018). Food-derived bioactive peptides in human health: Challenges and opportunities. Nutrients, 10, 1738.

Chourasia, R., Phukon, L. C., Abedin, M. M., Sahoo, D., & Rai, A. K. (2022). Production and characterization of bioactive peptides in novel functional soybean chhurpi produced using Lactobacillus delbrueckii WS4. Food Chemistry, 387, 132889.

Coda, R., Rizzello, C. G., Nigro, F., De Angelis, M., Arnault, P., & Gobbetti, M. (2008). Long-term fungal inhibitory activity of water-soluble extracts of Phaseolus vulgaris cv. Pinto and sourdough lactic acid bacteria during bread storage. Applied and Environmental Microbiology, 74, 7391–7398.

Daliri, E.B.-M., Oh, D. H., & Lee, B. H. (2017). Bioactive peptides. Foods, 6, 32.

Depaz, R. A., Pansare, S., & Patel, S. M. (2016). Freeze-drying above the glass transition temperature in amorphous protein formulations while maintaining product quality and improving process efficiency. Journal of Pharmaceutical Sciences, 105(1), 40–49.

Granato, D., Reshamwala, D., Korpinen, R., Azevedo, L., do Carmo, M. A. V., Cruz, T. M., Marques, M. B., Wen, M., Zhang, L., & Marjomäki, V. (2022). From the forest to the plate–hemicelluloses, galactoglucomannan, glucuronoxylan, and phenolic-rich extracts from unconventional sources as functional food ingredients. Food Chemistry, 381, 132284.

Halahlah, A., Piironen, V., Mikkonen, K. S., & Ho, T. M. (2023a). Polysaccharides as wall materials in spray-dried microencapsulation of bioactive compounds: Physicochemical properties and characterization. Critical Reviews in Food Science and Nutrition, 63(24), 6983–7015.

Halahlah, A., Piironen, V., Mikkonen, K. S., & Ho, T. M. (2023b). Wood hemicelluloses as innovative wall materials for spray-dried microencapsulation of berry juice: Part 1—effect of homogenization techniques on their feed solution properties. Food and Bioprocess Technology, 16, 909–929.

Halahlah, A., Räikkönen, H., Piironen, V., Valoppi, F., Mikkonen, K. S., & Ho, T. M. (2023c). Wood hemicelluloses as sustainable wall materials to protect bioactive compounds during spray drying of bilberries. Powder Technology, 415, 118148.

Hancock, B. C., & Parks, M. (2000). What is the true solubility advantage for amorphous pharmaceuticals? Pharmaceutical Research, 17, 397–404.

Helkar, P. B., Sahoo, A. K., & Patil, N. (2016). Review: Food industry by-products used as a functional food ingredients. International Journal of Waste Resources, 6, 1–6.

Ho, T. M., Lehtonen, M., Räikkönen, H., Kilpeläinen, P. O., & Mikkonen, K. S. (2023a). Wood hemicelluloses as effective wall materials for spray-dried microcapsulation of polyunsaturated fatty acid-rich oils. Food Research International, 164, 112333.

Ho, T. M., Abik, F., Hietala, S., Isaza Ferro, E., Pitkänen, L., Juhl, D. W., ... & Mikkonen, K. S. (2023b). Wood lignocellulosic stabilizers: effect of their characteristics on stability and rheological properties of emulsions. Cellulose, 30(2), 753-773.

Ho, T. M., Truong, T., & Bhandari, B. R. (2017). Methods to characterize the structure of food powders–a review. Bioscience, Biotechnology, and Biochemistry, 81, 651–671.

Hu, F., Jung, S., & Ragauskas, A. (2012). Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresource technology, 117, 7–12.

Jafarpour, D., & Hashemi, S. M. B. (2023). Pure and Co-Fermentation of Quinoa Seeds by Limosilactobacillus fermentum and Lacticaseibacillus rhamnosus: Bioactive Content. Antidiabetic and Antioxidant Activities. Fermentation, 9, 80.

Kalušević, A., Lević, S., Čalija, B., Pantić, M., Belović, M., Pavlović, V., Bugarski, B., Milić, J., Žilić, S., & Nedović, V. (2017). Microencapsulation of anthocyanin-rich black soybean coat extract by spray drying using maltodextrin, gum Arabic and skimmed milk powder. Journal of Microencapsulation, 34, 475–487.

Karaca, A. C., Low, N., & Nickerson, M. (2013). Encapsulation of flaxseed oil using a benchtop spray dryer for legume protein–maltodextrin microcapsule preparation. Journal of Agricultural and Food Chemistry, 61, 5148–5155.

Karrar, E., Mahdi, A. A., Sheth, S., Ahmed, I. A. M., Manzoor, M. F., Wei, W., & Wang, X. (2021). Effect of maltodextrin combination with gum arabic and whey protein isolate on the microencapsulation of gurum seed oil using a spray-drying method. International Journal of Biological Macromolecules, 171, 208–216.

Kaushik, V., & Roos, Y. H. (2007). Limonene encapsulation in freeze-drying of gum Arabic–sucrose–gelatin systems. LWT-Food Science and Technology, 40, 1381–1391.

Kilpeläinen, P., Hautala, S., Byman, O., Tanner, L., Korpinen, R., Lillandt, M. K., Pranovich, A., Kitunen, V., Willför, S., & Ilvesniemi, H. (2014). Pressurized hot water flow-through extraction system scale up from the laboratory to the pilot scale. Green Chemistry, 16, 3186–3194.

Kirjoranta, S., Knaapila, A., Kilpeläinen, P., & Mikkonen, K. S. (2020). Sensory profile of hemicellulose-rich wood extracts in yogurt models. Cellulose, 27, 7607–7620.

Kitts, D. D., & Weiler, K. (2003). Bioactive proteins and peptides from food sources. Applications of bioprocesses used in isolation and recovery. Current Pharmaceutical Design, 9, 1309–1323.

Kurozawa, L. E., Park, K. J., & Hubinger, M. D. (2009). Effect of maltodextrin and gum arabic on water sorption and glass transition temperature of spray dried chicken meat hydrolysate protein. Journal of Food Engineering, 91, 287–296.

Kynkäänniemi, E., Lahtinen, M. H., Jian, C., Salonen, A., Hatanpää, T., Mikkonen, K. S., & Pajari, A.-M. (2022). Gut microbiota can utilize prebiotic birch glucuronoxylan in production of short-chain fatty acids in rats. Food & Function, 13, 3746–3759.

Lahtinen, M. H., Valoppi, F., Juntti, V., Heikkinen, S., Kilpeläinen, P. O., Maina, N. H., & Mikkonen, K. S. (2019). Lignin-rich PHWE hemicellulose extracts responsible for extended emulsion stabilization. Frontiers in Chemistry, 7, 871.

Li, M., Guo, Q., Lin, Y., Bao, H., & Miao, S. (2023). Recent Progress in Microencapsulation of Active Peptides—Wall Material, Preparation, and Application: A Review. Foods, 12, 896.

Ma, J.-J., Mao, X.-Y., Wang, Q., Yang, S., Zhang, D., Chen, S.-W., & Li, Y.-H. (2014). Effect of spray drying and freeze drying on the immunomodulatory activity, bitter taste and hygroscopicity of hydrolysate derived from whey protein concentrate. LWT-Food Science and Technology, 56, 296–302.

Ma, S., Huang, D., Zhai, M., Yang, L., Peng, S., Chen, C., Feng, X., Weng, Q., Zhang, B., & Xu, M. (2015). Isolation of a novel bio-peptide from walnut residual protein inducing apoptosis and autophagy on cancer cells. BMC Complementary and Alternative Medicine, 15, 1–14.

Mahdavi, S. A., Jafari, S. M., Assadpoor, E., & Dehnad, D. (2016). Microencapsulation optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. International Journal of Biological Macromolecules, 85, 379–385.

Mechmeche, M., Kachouri, F., Ksontini, H., & Hamdi, M. (2017). Production of bioactive peptides from tomato seed isolate by Lactobacillus plantarum fermentation and enhancement of antioxidant activity. Food Biotechnology, 31, 94–113.

Muhialdin, B. J., Rani, N. F. A., & Hussin, A. S. M. (2020). Identification of antioxidant and antibacterial activities for the bioactive peptides generated from bitter beans (Parkia speciosa) via boiling and fermentation processes. Lwt, 131, 109776.

Nedovic, V., Kalusevic, A., Manojlovic, V., Levic, S., & Bugarski, B. (2011). An overview of encapsulation technologies for food applications. Procedia Food Science, 1, 1806–1815.

Ngamakeue, N., & Chitprasert, P. (2016). Encapsulation of holy basil essential oil in gelatin: Effects of palmitic acid in carboxymethyl cellulose emulsion coating on antioxidant and antimicrobial activities. Food and Bioprocess Technology, 9, 1735–1745.

Nionelli, L., Wang, Y., Pontonio, E., Immonen, M., Rizzello, C., Maina, H., Katina, K., & Coda, R. (2020). Antifungal effect of bioprocessed surplus bread as ingredient for bread-making: Identification of active compounds and impact on shelf-life. Food Control, 118, 107437.

Nooshkam, M., & Madadlou, A. (2016). Maillard conjugation of lactulose with potentially bioactive peptides. Food Chemistry, 192, 831–836.

Olatunde, O. O., Owolabi, I. O., Fadairo, O. S., Ghosal, A., Coker, O. J., Soladoye, O., & P& Bandara, N. (2023). Enzymatic modification of plant proteins for improved functional and bioactive properties. Food and Bioprocess Technology, 16(6), 1216–1234.

Oyinloye, T. M., & Yoon, W. B. (2020). Effect of freeze-drying on quality and grinding process of food produce: A review. Processes, 8, 354.

Perez Espitia, P. J., de Fátima Ferreira Soares, N., dos Reis Coimbra, J. S., de Andrade, N. J., Souza Cruz, R., & Alves Medeiros, E. A. (2012). Bioactive peptides: Synthesis, properties, and applications in the packaging and preservation of food. Comprehensive Reviews in Food Science and Food Safety, 11, 187–204.

Rairkar, M. E., Hayes, D. G., & Harris, J. M. (2007). Solubilization of enzymes in water-in-oil microemulsions and their rapid and efficient release through use of a pH-degradable surfactant. Biotechnology Letters, 29, 767–771.

Rajabi, H., Ghorbani, M., Jafari, S. M., Sadeghi Mahoonak, A., & Rajabzadeh, G. (2015). Retention of saffron bioactive components by spray drying encapsulation using maltodextrin, gum Arabic and gelatin as wall materials. Food Hydrocolloids, 51, 327–337.

Roos, Y. H. (2010). Glass transition temperature and its relevance in food processing. Annual Review of Food Science and Technology, 1, 469–496.

Sánchez, A., & Vázquez, A. (2017). Bioactive peptides: A review. Food Quality and Safety, 1, 29–46.

Sarabandi, K., Gharehbeglou, P., & Jafari, S. M. (2020). Spray-drying encapsulation of protein hydrolysates and bioactive peptides: Opportunities and challenges. Drying Technology, 38, 577–595.

Sarabandi, K., Jafari, S. M., Mohammadi, M., Akbarbaglu, Z., Pezeshki, A., & Heshmati, M. K. (2019). Production of reconstitutable nanoliposomes loaded with flaxseed protein hydrolysates: Stability and characterization. Food Hydrocolloids, 96, 442–450.

Schmitt, C., & Turgeon, S. L. (2011). Protein/polysaccharide complexes and coacervates in food systems. Advances in Colloid and Interface Science, 167(1–2), 63–70.

Silva, V. M., Kurozawa, L. E., Park, K. J., & Hubinger, M. D. (2012). Water sorption and glass transition temperature of spray-dried mussel meat protein hydrolysate. Drying Technology, 30, 175–184.

Sixta, H. (2006). Handbook of Pulp. Wiley-VCH Verlag Gmbh & Co.

Sousdaleff, M., Baesso, M. L., Neto, A. M., Nogueira, A. C., Marcolino, V. A., & Matioli, G. (2013). Microencapsulation by freeze-drying of potassium norbixinate and curcumin with maltodextrin: Stability, solubility, and food application. Journal of Agricultural and Food Chemistry, 61, 955–965.

Toor, B. S., Kaur, A., Sahota, P. P., & Kaur, J. (2021). Antioxidant Potential, antinutrients, mineral composition and FTIR spectra of legumes fermented with Rhizopus oligosporus. Food Technology and Biotechnology, 59, 530–542.

Vallar, S., Houivet, D., El Fallah, J., Kervadec, D., & Haussonne, J.-M. (1999). Oxide slurries stability and powders dispersion: Optimization with zeta potential and rheological measurements. Journal of the European Ceramic Society, 19, 1017–1021.

Valoppi, F., Lahtinen, M. H., Bhattarai, M., Kirjoranta, S. J., Juntti, V. K., Peltonen, L. J., Kilpeläinen, P. O., & Mikkonen, K. S. (2019a). Centrifugal fractionation of softwood extracts improves the biorefinery workflow and yields functional emulsifiers. Green Chemistry, 21, 4691–4705.

Valoppi, F., Maina, N., Allén, M., Miglioli, R., Kilpeläinen, P. O., & Mikkonen, K. S. (2019b). Spruce galactoglucomannan-stabilized emulsions as essential fatty acid delivery systems for functionalized drinkable yogurt and oat-based beverage. European Food Research and Technology, 245, 1387–1398.

Verni, M., Pontonio, E., Krona, A., Jacob, S., Pinto, D., Rinaldi, F., Verardo, V., Díaz-de-Cerio, E., Coda, R., & Rizzello, C. G. (2020). Bioprocessing of brewers’ spent grain enhances its antioxidant activity: Characterization of phenolic compounds and bioactive peptides. Frontiers in Microbiology, 11, 1831.

Verni, M., Wang, Y., Clement, H., Koirala, P., Rizzello, C. G., & Coda, R. (2023). Antifungal peptides from faba bean flour fermented by Levilactobacillus brevis AM7 improve the shelf-life of composite faba-wheat bread. International Journal of Food Microbiology, 407, 110403.

Wangsakan, A., Chinachoti, P., & McClements, D. J. (2004). Effect of surfactant type on surfactant− maltodextrin interactions: Isothermal titration calorimetry, surface tensiometry, and ultrasonic velocimetry study. Langmuir, 20, 3913–3919.

Westbye, P., Köhnke, T., Glasser, W., & Gatenholm, P. (2007). The influence of lignin on the self-assembly behaviour of xylan rich fractions from birch (Betula pendula). Cellulose, 14, 603–613.

Xiao, Z., Xia, J., Zhao, Q., Niu, Y., & Zhao, D. (2022). Maltodextrin as wall material for microcapsules: A review. Carbohydrate polymers, 298, 120113.

Yasar, S., Tosun, R., & Sonmez, Z. (2020). Fungal fermentation inducing improved nutritional qualities associated with altered secondary protein structure of soybean meal determined by FTIR spectroscopy. Measurement, 161, 107895.

Zhang, Z., Chen, F., Zhang, R., Deng, Z., & McClements, D. J. (2016). Encapsulation of pancreatic lipase in hydrogel beads with self-regulating internal pH microenvironments: Retention of lipase activity after exposure to gastric conditions. Journal of Agricultural and Food Chemistry, 64, 9616–9623.

Zhu, P., Wang, M., Du, X., Chen, Z., Liu, C., & Zhao, H. (2020). Morphological and physicochemical properties of rice starch dry heated with whey protein isolate. Food Hydrocolloids, 109, 106091.

Acknowledgements

Authors acknowledge the proof-of-concept grant from Faculty of Agriculture and Forestry (University of Helsinki) for the funding; Montinutra company and Natural Resources Institute Finland (Luke) for providing GGM and GX powders, respectively; Dr. Thao Le (Auckland University of Technology, New Zealand) for fruitful discussion; and Mr. Troy Faithfull for his editing and proofreading. Abedalghani Halahlah and Thao M. Ho thank the Finnish Natural Resources Research Foundation (No: 20210017). Thao M. Ho also acknowledge the Academy of Finland (No: 346839).

Funding

Open Access funding provided by University of Helsinki (including Helsinki University Central Hospital). Proof-of-concept grant from Faculty of Agriculture and Forestry (University of Helsinki).

Author information

Authors and Affiliations

Contributions

Thao M. Ho and Rossana Coda designed the experiments. Daniele Santangelo, Abedalghani Halahlah and Idowu O. Adesanya conducted the experiments to collect the data. Kirsi S. Mikkonen helped with experimental plan and analytical methods, and revised the manuscript. All authors interpreted the results. Abedalghani Halahlah, Daniele Santangelo and Idowu O. Adesanya drafted and revised the manuscript. Thao M. Ho and Rossana Coda as corresponding authors supervised the experiment and corrected the manuscript. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Santangelo, D., Halahlah, A., Adesanya, I.O. et al. Protective Effects of Polysaccharides on Antifungal Activity of Bread Waste-derived Bioactive Peptides During Freeze Drying. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03443-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03443-8