Abstract

Edible insect powder is a new ingredient that can be used to create innovative functional and nutritional properties in food products. However, adding insect powder to bakery goods could impact the dough’s technological and sensory attributes. This study aims to investigate possible alterations in dough enriched with insect powder and examine the texture of salty snacks produced using a 3D food printer. The doughs were prepared using varying quantities of two types of edible insect powders. The stiff flow properties showed a pseudoplastic behaviour that fit well with a power-law equation. Viscosity and pseudoplasticity increased in proportion to insect powder concentration, with the strongest effect observed for L. migratoria. The linear viscoelastic behaviour exhibited G′ values exceeding G″ values, and both moduli increased with insect concentration. A. migratoria displayed a greater elastic contribution (lower tan δ) compared to A. diaperinus, which correlates with the lower printability of A. migratoria. The texture of the snacks prepared with A. diaperinus demonstrated a rise in the breaking force as the insect concentration increased and exhibited a corresponding texture profile to the control and the 4.6% sample. Moreover, the addition of A. diaperinus heightened the crispiness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Food and Agriculture Organization (FAO) of the United Nations reports that, based on estimates, the current global population of 7 billion is expected to increase to 9.85 billion by 2050 (Van Huis et al., 2013). Therefore, food demand is predicted to increase dramatically amid already strained agricultural land. Therefore, finding alternative protein and fat sources for feed and food can alleviate pressure on overused sources, including livestock. In recent times, insects have emerged as a viable alternative to conventional sources of fat and protein owing to their nutritional value and sustainable nature (Hall et al., 2017). Consumable insects, rich in fats, proteins, and micronutrients, are an excellent nutrition source and can be used as a highly nutritious ingredient (Rumpold & Schülter, 2013). Various insect powders have been used, for example, to fortify bakery products (Khatun et al., 2021) or to improve the nutritional quality of extruded snacks (Gomes et al., 2023). Several studies have shown a negative linear correlation between the quantity of insect powder (Acheta domesticus, Nauphoeta cinerea) and the technological parameters (Kathun et al., 2021; Osimani et al., 2018; de Oliveira et al., 2017).

3D food printing is a developing technology for direct manufacturing that involves the layer-by-layer deposition of materials to produce a 3D structure (Sundarsingh, et al., 2023; Seung Yun Lee et al., 2023). In this process, the rheological characteristics of the printed materials influence the outcomes of the printing. The properties of food that affect viscosity, consistency, and elasticity play a crucial role in 3D printing to achieve the desired structure (Dankar et al., 2018; Kim et al., 2018; Liu et al., 2017; Nachal et al., 2019). Specifically, the viscosity of the food should be low enough to ensure smooth extrusion through the 3D printer, but then increase immediately after the extrusion process to maintain the printed product's shape. Additives are commonly used in 3D printing to improve the printing properties of food (Azam et al., 2018; Guo et al., 2019). Incorporating olive oil into the dough for printing renders it smoother and more liquid due to the plasticising and lubricating effect of the fat in the ingredients (Liu et al., 2019). Similar observations have been made with the use of egg yolk, which facilitates the printing of the dough. Chen et al. (2019) demonstrated that the printing ability of soybean protein isolate is improved through the incorporation of xanthan gum, which is related to its shear-thinning characteristics. The viscosity of the starch printing system is increased by adding guar gum, improving its stability during heating and stirring. In this sense, Cai et al. (2023) explained the importance of food hydrocolloids in 3D printing of purple sweet potato puree and their effect on physical properties, microstructure, and printing performance. They concluded that of all the hydrocolloids studied, guar gum had significantly the highest print stability. Several studies have been attempting to combine insect powders of their extracts with 3D printing technology. Soares and Forkes (2014) studied the possibility of using 3D dimensionally extruded insect paste filament as a method of creating foodstuffs and Severini et al. (2018) studied 3D printing technology to produce snacks formulated with wheat flour enriched with ground yellow mealworm larvae.

In summary, there are studies where insects are used as an alternative source of protein for the development of new products and studies where 3D printing technology is used for food development, where the importance of the rheological properties of the food to achieve a suitable texture is highlighted. As far as we know, no previous research has investigated the rheological and textural properties of insect-enriched snacks made with 3D printing technology. The objective of the present work was to examine the rheological impacts of enriching chickpea dough with diverse concentrations of Alphitobius diaperinus and Locusta migratoria powders and to investigate the textural behaviour of adding A. diaperinus into 3D-printed snacks.

Materials and Methods

Dough Preparation

The dough ingredients were chickpea flour (46.3%, La Finestra Sul Cielo S.A., Madrid, Spain), water (39.4%), extra virgin olive oil (11.6%, Hacienda Ortigosa S.L., Navarra, Spain), curry powder (1.8%, Westmill Foods, London, UK), and salt (0.9%, Sal Costa, S.L.U., Barcelona, Spain) (Garcia et al., 2021). Different amounts of A. diaperinus or L. migratoria (Kreca Ento-Food BV, Ermelo, The Netherlands) were added ranging from 0% (control) to 13.9% (enriched samples), replacing part of the chickpea flour fraction (0, 4.6%, 9.3%, and 13.9%). All ingredients were weighed (50.0 g of total dough mass) and mixed with a hand blender (Bluesky BHB170-16) for 2 min. The particle size of milled insect powder was 310 µm (span 2.2), 967 µm (span 1.1), and for A. diaperinus and L. migratoria, respectively.

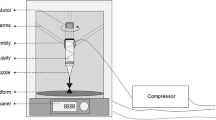

3D Printing and Baking Process

A Focus 3D Food Printer (byFlow, Eindhoven, Netherlands) was used to print the doughs following the process used by García-Gutiérrez et al. (2021). A 1.6 mm nozzle was used at a speed of 30 mm/s and each formulation was made in triplicate. The 3D-printed snacks were baked at 180 °C for 12 min using the ventilation mode of a vapour oven (3HV469X/02 model, Balay, Pamplona, Spain). Nutritional composition of doughs and A. diaperinus 3D-printed snacks is shown in supplementary Tables S1 and S2, respectively.

Rheological Measurements

Rheological measurements were made with a controlled stress rheomether (AR-G2, TA Instruments, Crawley, England) equipped with a Peltier heating system set at 20 °C. A 40 mm diameter plate-plate geometry with a serrated surface and a gap of 1 mm was used. The samples equilibrated for 10 min between plates prior to measurements. Silicon oil was applied to the sample’s outer edges to prevent drying.

Flow Properties

Flow-stepped tests were conducted over a log distribution from 0.5 to 50 s−1, with 10 data points per decade and 10 s of equilibration time.

Linear Viscoelastic Measurements

Stress sweeps ranging from 0.01 to 200 Pa were conducted to ascertain the linear viscoelastic region. Both G′ and G″ were monitored during the application of shear stress. When within the linear viscoelastic region, G′ and G″ remain unaffected by the applied stress or strain. A series of frequency sweeps (10 to 0.01 Hz) were then performed in this linear viscoelastic region at a stress wave amplitude that was well within acceptable limits. The stress wave amplitude has been set at 0.6 Pa in the doughs that did not contain insect powder. However, it was increased to 1 Pa in the doughs with 4.6%, 9.3%, and 13.9% insect powder concentrations. The values of G′, G″ and the loss tangent = G″/G′ were recorded.

Texture Profile Analysis

Texture measurements (breaking strength and penetration tests) were performed with a TA-XT.plus Texture Analyser equipped with Texture Exponent software (version 2.0.7.0.; Stable Microsystems, Godalming, UK). The tests were conducted at room temperature (20 ± 1 °C) 24 h after preparation. Three 3D-printed snacks per formulation were used for measurement to ensure reproducibility, and two repetitions of each sample were evaluated on different days.

Breaking Strength Three-Point Bending Test

Snacks were broken with the three-point bending probe (A/3 PB) (Fig. 1a). The experimental conditions support 70 mm apart, a 10-mm probe travel distance, a trigger force of 0.05 N, and a test speed of 1 mm/s. The breaking force (N) was measured.

Penetration Test

The penetration test was conducted with the upper Volodkevich Bite Jaw (VB) (Fig. 1b), penetrating the snack to 1.5 mm at a test speed of 1 mm/s and a trigger force of 0.05 N. The area under the penetration curve (N.s), which is related to hardness, and the number of force peaks as an index of crispness, were also measured.

Statistical Analysis

The raw data obtained were statistically analysed using a one-way analysis of variance (ANOVA) to evaluate the effects of the different percentages of insect powders on the rheological and textural properties of dough and snacks. To analyse the significant differences between the different samples, Fisher’s test was used (significance at p < 0.05). Statistical analyses were performed using the XLSTAT software (2019.2.2, Addinsoft, Barcelona, Spain).

Results and Discussion

Flow Curves

Because 3D printing technology is related to the flow of the material, it is considered important to study the rheological properties of the products to be printed (Qiu et al., 2022). For proper 3D printing, the viscosity of the food must be low enough to be extruded through a small nozzle but high enough to form proper layers when printing without causing deformation of the food (Godoi, Prakasj, and Bhandari, 2016). Therefore, the flow properties of food materials should be shear thinning (Gholamipour-Shirazi et al., 2020; Liu & Zhang, 2019; Prakash et al., 2019; Sun et al., 2020).

The effect of adding A. diaperinus and L. migratoria powders to the flow properties is shown in Fig. 2. A decrease in viscosity was detected when an increase in the shear rate was applied, showing a pseudoplastic behaviour for all the doughs tested. The increase in the amount of insect powder added to the chickpea dough also produced an increase in their viscosity in all the shear rate ranges studied (0.5 to 50 s−1). Furthermore, the differences were more evident at lower shear rates due to the higher pseudoplasticity behaviour found when adding a higher amount of insect powder (13.9%). The existing differences at lower shear rates became smaller at higher shear rates due to the pseudoplastic behaviour and to a higher degree of peudoplasticity at higher amount of insect powder. Higher pseudoplasticity implies higher slope of the log/log viscosity versus shear rate curve, so the differences found at lower shear rate become lower at higher shear rate.

To better understand the differences between samples, the viscosity versus shear rate data were well adjusted to a power-law Eq. (1):

where η1 is the viscosity at 1 s−1 and n is the power-law index, which represents the degree of pseudoplasticity of the sample. The parameter n is related to the slope of the viscosity versus shear rate curve. Values of n = 1 represent Newtonian behaviour (viscosity does not depend on the shear rate). The higher the difference of n from 1, the higher the pseudoplasticity (Schramm, 2004). Lower n values represent a higher decrease of viscosity with the increase in shear rate, implying higher pseudoplasticity and an increase in structural complexity, which is favourable in the context of their application for 3D printing. The mean values of η1 and n are presented in Table 1.

A difference in flow behaviour was observed between the dough enriched with A. diaperinus and L. migratoria powders. In both cases, the inclusion of insect powder raised viscosity values and the degree of pseudoplasticity (values of n closer to 0); however, the impact on pseudoplasticity was more noticeable in the dough enriched with L. migratoria, with n values lower than those of A. diaperinus (Table 1). The rise in viscosity and pseudoplasticity are acknowledged positive factors for printability. In the case of grasshopper dough, the greater heterogeneity of the powder, caused by retained pieces of exoskeleton, as compared to buffalo powder, could explain the inability to print this dough, even at lower concentrations. González et al. (2019) also found an increase in dough consistency when insect powder was added to wheat flour, which resulted in a slight increase in dough development time and stability was obtained when Acheta domestica or Hermetia illucens was added compared to the control.

Viscoelastic Properties

Solid-like viscoelastic behaviour is necessary for extrusion-type 3D printing because liquid-like food cannot be shaped in an extrusion-type 3D printer (Pulatsu et al., 2020; Su et al., 2019). The values of the elastic moduli (G′) and the viscous moduli (G″) versus frequency are shown in Fig. 3. The mechanical strength and self-supporting properties of the inks have been linked to the values of G′ and G″, as reported by Chen et al. (2022). The results revealed a predominance of the solid/elastic component (G′) over the liquid/viscous component (G″), which is suitable for 3D printing. The viscoelastic behaviour can be classified as typical of soft gels, with values of G′ always higher than G″ and softly dependent on frequency. In the dough made with 13.9% L. migratoria, viscoelastic properties could not be measured at frequency values < 0.5 Hz due to its heterogeneity, thus is not represented in Fig. 3b.

In Table 2, the mean values of G′, G″, and tan δ (G″/G′) at 1 Hz are shown. Enrichment with both types of insect powders increased the viscoelastic parameters, the increase higher for L. migratoria dough. For 13.9% A. diaperinus, G′ values increase 5.6 times compared to the control, from 4016 Pa (control) to 22,586 Pa (13.9% A. diaperinus); whereas for 13.9% L. migratoria, G′ values increased 19.24 times (from 4016 Pa for the control to 77,304 Pa for 13.9% for L. migratoria). Therefore, the incorporation of L. migratoria powders has more effect on the viscoelastic properties of the dough than on the flow properties. For both types of insect powder, the increase in the amounts in the dough increase the values G′ and G″. The tan δ values (G″/G′) in all frequency sweeps studied were less than 1, indicating the predominance of G′ over G”. This illustrates the prevalence of the elastic component. In the L. migratoria doughs, the tan δ values were lower than in the A. diaperinus at all concentrations, indicating a higher predominance of the elastic component in those samples. At all concentrations, A. diaperinus tan δ values indicate the lowest contribution of elasticity than L. migratoria doughs, even at the lowest L. migratoria concentration (4.6%). The differences in viscoelasticity (relation amongst the viscous and elastic component) between the two types of insects objectively explain the observed differences in printability. Although a predominance of elastic versus the viscous moduli is required for an appropriate printability, a limitation in the value of G′ and tan δ was found. Thus, the greatest elasticity of L. migratoria dough at all the concentrations, together with the lowest values of tan δ, did not allow for correct printability. Values of G′ alone could not explain the differences in printability; for example, at the smallest L. migratoria amount (4.6%) added to the dough was not printable, whereas its G′ values were lower than G′ values for the A. diaperinus dough at 13.9%. Therefore, the best parameter to evaluate the printability in the doughs studied was tan δ, with a limit value level of 0.2, below which the dough would be too elastic to be printed. Regarding the limit values of G, their maximum level will depend on the values of tan δ. Therefore, G′ values alone were not suitable to explain the differences in printability, but tan δ was. The interpretation of these results should also consider the negative contribution of L. migratoria powder heterogeneity to printability at all concentrations studied.

Texture

The textural profiles of the 3D-printed baked snacks prepared with the A. diaperinus doughs are shown in Figs. 4 and 5. Each curve is a representative profile of each sample. Figure 4 represents curve profiles of the bending test that measure the force required to break a snack in half. Figure 5 shows the profiles of the penetration test which imitate the force required to bite the snack. In the bending test, the force curves of the snacks with 4.6% insect powder added were like those of the control snack, whereas the other snacks with a higher amount of A. diaperinus had a lower hardness compared to the control sample. However, in the penetration test, all curve profiles were similar, although the curves of snacks prepared using dough enriched with A. diaperinus powder showed a more jagged appearance with several fracture events typical of crispy food compared to control snacks (Chen et al., 2005).

The textural parameters (Table 3) were calculated from the texture profiles to provide a better analysis of these textural differences. It was observed in the texture profiles of the bending test that there were no significant differences in breaking force between the control sample and the 4.6% insect powder added. However, higher concentrations of insect powder led to lower breaking force. In the penetration test, the snacks prepared with insect powder had a more crispy behaviour than the control sample (greater number of force peaks), but slightly significant differences in the hardness were found in the penetration test. In both tests, no significant differences in hardness were found between snacks prepared with insect powder. Therefore, insect powder increased crispness in this type of snack.

Different texture results were obtained for snacks acquired through the addition of insect powder. Ogunlakin et al. (2018) studied the quality of wheat biscuit fortified with edible termites (Macrotermes nigeriensis) and found that the break strength of the biscuit was reduced with an increase in the level of termite flour inclusion, although the insect partial substitute for wheat in biscuit production up to 20% does not affect the biscuit quality. Biró et al. (2020) assessed the hardness of oat biscuits enriched with cricket powder using the three-point rig test. Their findings indicate that the addition of cricket powder up to 15% did not significantly impact the texture of the samples, although a slight increase in hardness was observed with higher levels of cricket concentration. Severini et al. (2018) concluded that there was no discernible effect on hardness with different insect enrichments in their study on 3D-printed snacks enhanced with edible insects. Although hardness increased with the level of insect enrichment at higher temperatures (220 °C), the behaviour of hardness as a function of baking temperature was not linear, with a decrease in hardness at intermediate baking temperatures (180–185 °C).

Conclusions

In this study, the effect of A. diaperinus and L. migratoria on the flow and linear viscoelastic properties of a salty snack formula was studied and related to printability properties. L. migratoria showed a greater increase in viscosity and pseudoplasticity than L. diaperinus. In both types of insect powder, the increases in concentration increase viscosity and pseudoplasticity. The linear viscoelastic properties showed a predominance of the elastic modulus (G′) versus the viscous modulus (G″) in all doughs, with the highest elastic contribution shown by L. migratoria. Although a predominance of elastic versus the viscous moduli is required for appropriate printability, the highest elasticity (lowest tan δ) of L. migratoria made it unsuitable for printing. A tan δ of 0.2 was set as the limit value, below which the dough would be too elastic to be printed.

Salty snacks with a texture profile similar as the control (no insect) were found with 4.6% L. migratoria incorporation. A higher concentration of L. migratoria resulted in increased crispiness. Incorporating L. migratoria up to a concentration of 13.9% demonstrated optimal dough rheological properties for printing and yielded optimal texture for the 3D-printed salty snacks.

Data Availability

Data will be made available on request.

References

Azam, R. S. M., Zhang, M., Bhandari, B., & Yang, C. H. (2018). Effect of different gums on features of 3D printed object based on vitamin-D enriched orange concentrate. Food Biophysics, 13, 250–262. https://doi.org/10.1007/s11483-018-9531-x

Biró, B., Sipos, M. A., Kovács, A., Badak-Kerti, K., Pásztor-Huszár, K., & Gere, A. (2020). Cricket-enriched oat biscuit: Technological analysis and sensory evaluation. Foods, 9, 1561. https://doi.org/10.3390/foods9111561

Cai, L., Feng, L., Nie, M., Li, D., Zheng, T., & Min Zhang, M. (2023). Effect of different hydrocolloids on the rheological, microstructural, and 3D printing characteristics of purple sweet potato puree. Food and Bioprocess Technology, 2023(16), 2622–2634.

Chen, H., Xie, F. W., Chen, L., & Zheng, B. (2019). Effect of rheological properties of potato, rice and corn starches on their hot-extrusion 3D printing behaviors. Journal of Food Engineering, 244, 150–158. https://doi.org/10.1016/j.jfoodeng.2018.09.011

Chen, J., Karlsson, C., & Povey, M. (2005). Acoustic envelope detector for crispness assessment of biscuits. Journal of Texture Studies, 36, 139–156. https://doi.org/10.1111/j.1745-4603.2005.00008.x

Chen, Y. Y., Zhang, M., Sun, Y. N., & Phuhongsung, P. (2022). Improving 3D/4D printing characteristics of natural food gels by novel additives: A review. Food Hydrocoll, 123, 107160. https://doi.org/10.1016/j.foodhyd.2021.107160

Dankar, I., Haddarah, A., Omar, F. E. L., Sepulcre, F., & Pujola, M. (2018). 3D printing technology: The new era for food customization and elaboration. Trends in Food Science & Technology, 75, 231–242. https://doi.org/10.1016/j.tifs.2018.03.018

De Oliveira, L. M., Da Silva Lucas, A. J., Lopes Cadaval, C., & Sallas Mellado, M. (2017). Bread enriched with flour from cinereous cockroach (Nauphoeta cinerea). Innovative Food Science and Emerging Technologies, 44, 30–35. https://doi.org/10.1016/j.ifset.2017.08.015

García-Gutiérrez, N., Mellado-Carretero, J., Bengoa, C., Salvador, A., Sanz, T., Wang, J., Ferrando, M., Güell, C., & de Lamo-Castellví, S. (2021). ATR-FTIR Spectroscopy combined with multivariate analysis successfully discriminates raw doughs and baked 3D-printed snacks enriched with edible insect powder. Foods, 10, 1806. https://doi.org/10.3390/foods10081806

Gholamipour-Shirazi, A., Kamlow, M.-A.T., Norton, I., & Mills, T. (2020). How to formulate for structure and texture via medium of additive manufacturing—A review. Foods, 9, 497. https://doi.org/10.3390/foods9040497

Godoi, F. C., Prakash, S., & Bhandari, B. R. (2016). 3D printing technologies applied for food design: Status and prospects. Journal of Food Engineering, 179, 44–54. https://doi.org/10.1016/j.jfoodeng.2016.01.025

Gomes, K. S., Berwian, G. F., Batistella, V. M. C., et al. (2023). Nutritional and technological aspects of the production of proteic extruded snacks added of novel raw materials. Food and Bioprocess Technology, 16, 247–267.

González, C. M., Garzón, R., & Rosell, C. M. (2019). Insects as ingredients for bakery goods. A comparison study of H. illucens, A. domestica and T. molitor flours. Innovative Food Science and Emerging Technologies, 51, 205–210. https://doi.org/10.1016/j.ifset.2018.03.021

Guo, C., Zhang, M., & Bhandari, B. (2019). Model building and slicing in food 3D printing processes: A review. comprehensive reviews in food science and food safety, 18, 1052–1069. https://doi.org/10.1111/1541-4337.12443

Hall, F. G., Jones, O. G., O’Haire, M. E., & Liceaga, A. M. (2017). Functional properties of tropical banded cricket (Gryllodes sigillatus) protein hydrolysates. Food Chemistry, 224, 414–422. https://doi.org/10.1016/j.foodchem.2016.11.138

Van Huis, A., Van Itterbeeck, J., Klunder, H., Mertens, E., Halloran, A., Muir, G., Vantomme, P. (2013). Edible insects: Future prospects for food and feed security; Food and Agriculture Organization of the United Nations: Rome, ISBN 978–92–5–107595–1.

Khatun, H., Van Der Borght, M., Akhtaruzzaman, M., & Claes, J. (2021). Rheological characterization of Chapatti (Roti) enriched with flour or paste of house crickets (Acheta domesticus). Foods, 2021(10), 2750. https://doi.org/10.3390/foods10112750

Kim, H. W., Bae, H., & Park, H. J. (2018). Reprint of: Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. Journal of Food Engineering, 220, 28–37. https://doi.org/10.1016/j.jfoodeng.2017.10.023

Liu, Z., Zhang, M., Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., (2019). 3D food printing technologies and factors affecting printing precision. In Fundamentals of 3D Food Printing and Applications Academic Press Cambridge 19–40.

Liu, Y., Liang, X., Ahmed, S., & Lan, W. (2019). Properties of 3D printed dough and optimization of printing parameters. Innovative Food Science and Emerging Technologies, 54, 8–19. https://doi.org/10.1016/j.ifset.2019.03.008

Liu, Z. B., Zhang, M., Bhandari, B., & Wang, Y. C. (2017). 3D printing: Printing precision and application in food sector. Trends in Food Science & Technology, 69, 83–94. https://doi.org/10.1016/j.tifs.2017.08.018

Nachal, N., Moses, J. A., Karthik, P., & Anandharamakrishnan, C. (2019). Applications of 3D printing in food processing. Food Engineering Reviews, 11, 123–141. https://doi.org/10.1007/s12393-019-09199-8

Ogunlakin, G. O., Oni, V. T., & Olaniyan, S. A. (2018). Quality evaluation of biscuit fortified with edible termite (Macrotermes nigeriensis). Asian Journal Biotechnology, 4, 1–7. https://doi.org/10.9734/AJB2T/2018/43659

Osimani, A., Milanović, V., Cardinali, F., Roncolini, A., Garofalo, C., Clementi, F., Pasquini, M., Mozzon, M., Foligni, R., Raffaelli, N., Zamporlini, F., & Aquilanti, L. (2018). Bread enriched with cricket powder (Acheta domesticus): A technological, microbiological and nutritional evaluation. Innovative Food Science and Emerging Technologies, 48, 150–163. https://doi.org/10.1016/j.ifset.2018.06.007

Prakash, S., Bhandari, B. R., Godoi, F. C., Zhang, M., Godoi, F. C., Bhandari, B. R., Prakash, S., Zhang, M., (2019). Future outlook of 3D food printing. In Fundamentals of 3D Food Printing and Applications Academic Press Cambridge, 373–381.

Pulatsu, E., Su, J.-W., Lin, J., & Lin, M. (2020). Factors affecting 3D printing and post-processing capacity of cookie dough. Innovative Food Science and Emerging Technologies, 61, 102316. https://doi.org/10.1016/j.ifset.2020.102316

Qiu, R., Wang, K., Tian, H., Liu, X., Liu, G., Hu, Z., & Zhao, L. (2022). Analysis on the printability and rheological characteristics of bigel inks: Potential in 3D food printing. Food Hydrocolloids, 129, 107675. https://doi.org/10.1016/j.foodhyd.2022.107675

Rumpold, B. A., & Schlüter, O. K. (2013). Potential and challenges of insects as an innovative source for food and feed production. Innovative Food Science and Emerging Technologies, 17, 1–11. https://doi.org/10.1016/j.ifset.2012.11.005

Schramm, G. 2004. A Practical Approach to Rheology and Rheometry. Thermo Electron (Karlsruhe) GmbH, Germany.

Severini, C., Azzollini, D., Albenzio, M., & Deross, A. (2018). On printability, quality and nutritional properties of 3D printed cereal based snacks enriched with edible insects. Food Research International, 106, 666–676. https://doi.org/10.1016/j.foodres.2018.01.034

Soares, S., & Forkes, A. (2014). Insects Au gratin-an investigation into the experiences of developing a 3D printer that uses insect protein-based flour as a building medium for the production of sustainable food." In DS 78: Proceedings of the 16th International conference on Engineering and Product Design Education (E&PDE14), Design Education and Human Technology Relations, University of Twente, The Netherlands, 426–431.

Seung, Yun Lee,, Da Young, Lee., Jae Won, Jeong., Jae Hyeon, Kim., Seung Hyeon, Yun., Seon‑Tea, Joo., Inho, Choi., Jung Seok, Choi., Gap‑Don, Kim., Sun Jin, Hur. (2023). Studies on meat alternatives with a focus on structuring technologies. Food and Bioprocess Technology 16:1389–1412.

Su, J. W., Gao, W., Trinh, K., Kenderes, S. M., Tekin Pulatsu, E., Zhang, C., & Lin, J. (2019). 4D printing of polyurethane paint-based composites. International Journal of Smart and Nano Materials, 10, 237–248. https://doi.org/10.1080/19475411.2019.1618409

Sun, J., Zhou, W., Yan, L., Huang, D., & Lin, L. (2020). Extrusion-based food printing for digitalized food design and nutrition control. Journal of Food Engineering, 220, 1–11. https://doi.org/10.1016/j.jfoodeng.2017.02.028

Sundarsingh, A., Zhang, M., Mujumdar, A.S., & Li, J. (2023). Review. research progress in printing formulation for 3D printing of healthy future foods. Food and Bioprocess Technology https://doi.org/10.1007/s11947-023-03265-0.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This research was funded by Ministerio de Economía i Competitividad (CTQ 2014–54520-P), Ministerio de Ciencia e Innovación (PGC2018-097095-B-I00), and Agencia Estatal de Investigación, Fondo Social Europeo (FSE) and Iniciativa de Empleo Juvenil (PEJ2018-004192-A). In addition, this study forms part of the AGROALNEXT programme (grant AGROALNEXT/2022/031) and was supported by MCIN (Spain) with funding from European Union NextGenerationEU (PRTR-C17.I1) and by Generalitat Valenciana (Spain). IATA-CSIC is a Centre of Excellence Severo Ochoa (CEX2021-001189-S funded by MCIN/AEI/ https://doi.org/10.13039/501100011033).

Author information

Authors and Affiliations

Contributions

Nerea García-Gutiérrez conducted the experiments. Ana Salvador and Teresa Sanz designed the investigation, formal analysis, writing—review and editing. Montse Ferrando, Carme Güell, and Carmen Mendez conducted some experiments, and Silvia de Lamo Castellvi made the conceptualization, supervision, review and editing.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

García-Gutiérrez, N., Salvador, A., Sanz, T. et al. Rheological and Textural Characterisation of Chickpea Dough and Baked 3D-Printed Snacks Enriched with Alphitobius diaperinus and Locusta migratoria Powders. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03437-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03437-6