Abstract

Ripening is an irreversible phenomenon involving several physiological, biochemical and organoleptic changes that affect the nutritional value, colour, texture and taste of fruit. Amongst the physical non-destructive technologies, Delayed Luminescence (DL) has been reported able to provide valid information on the functional status of living biological systems, reflecting changes in quality parameters following the occurrence of certain metabolic processes. In this study, we followed up and analysed the variations in the colour and DL signals emitted by tomato fruit as a function of their ripening degree. Four lots of tomato fruit, similar to each other for cultivar and geographical origin, were considered. Tomatoes were harvested at various maturity stages and stored in the dark at room temperature. The changes in DL emission trends were monitored at different times after harvesting for a period of about 20 days and correlated with the a*/b* colour ratio, which is normally used as an indicator of fruit ripeness degree. Results highlighted that the emission intensities, as well as the parameters by fitting DL decay curves, were strongly dependent on harvest maturity, varying significantly even as fruit ripeness progressed after their harvesting. Significant differences were also found between DL signals emitted by field-ripened tomatoes at the beginning of storage and those emitted by postharvest-ripened tomatoes at the end of the storage period. Delayed Luminescence may be used as a fast, reliable and sensitive tool for evaluating, more generally, the sensorial quality of fruit during postharvest storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tomato (Solanum lycopersicum L.) is one of the most worldwide cultivated vegetable crops intended both for fresh consumption and industrial processing. Italy is the largest European tomato-producing country, reaching a global cultivated land and an estimated production of 97,610 ha and 6.1 Mt, respectively (FAOSTAT, 2022). Cultivation is practiced both in open field and in greenhouse environments, depending on the geographic area and the season.

Tomato is particularly appreciated in the Mediterranean diet for the high presence of minerals, vitamins and phenolic compounds, constituting good health protection against cancer and cardiovascular diseases (Dumas et al., 2003; Martí et al., 2016). Recent studies have shown that the chemical and microbiological composition of tomato berries, on which the safety and quality parameters depend, is related to their territory of origin and, in particular, to climatic conditions, soil characteristics and farming practices, such as fertilizer and pesticide application (Demir et al., 2010; Mauromicale et al., 2011; Panebianco et al., 2022a, 2022b, 2023a; Santos & Olivares, 2021). In addition to environmental conditions, other factors can affect tomato chemical composition, such as the ripening stage, storage conditions and the genotype (Gautier et al., 2008; George et al., 2004; Giovanelli et al., 1999).

During ripening, sugars, carotenoids (lycopene and β-carotene) and phenolic compound concentration increase, whereas titratable acidity and chlorophyll content decrease (Gautier et al., 2008). Sugars and organic acids represent the main water-soluble substances in tomato berries and their ratio affects the taste and organoleptic properties of the fruit, together with volatile compounds (Kaur et al., 2006); carotenoids, instead, play an important role in fruit colouring (Gonzali & Perata, 2021). The tomato is a typical climacteric fruit and, consequently, it ripens also after harvest. However, during postharvest storage, some undesirable metabolic processes lead to quality deterioration (loss of flavour and water, reduction of nutritional value, softening of texture and decomposition of tissues); this phenomenon is proportional to storage time (Dong et al., 2023). So, the external features, including colour, are not always strictly related to internal quality, whilst, on the contrary, consumer selection of vegetables is mostly based on their appearance. The possibility of having tools able to give a global and rapid evaluation of quality is significant.

Currently, changes in tomato fruit quality during the ripening process can be successfully revelated by using traditional methods, such as chromatography and mass spectrometry (Carrillo-López & Yahia, 2014; Dong et al., 2023; Hu et al., 2019; Tang et al., 2020). However, these methods require complicated procedures for sample preparation, processing and analysis and they can be performed on a restricted number of samples, often reducing their representativeness. Consequently, as an alternative, various optical methods, such as Raman and VIS–NIR spectroscopy, have been investigated for a rapid, accurate and non-destructive assessment of tomato quality and maturity (Akpolat et al., 2020; Borba et al., 2021; de Brito et al., 2022; Li et al., 2022; Trebolazabala et al., 2017).

Within the non-destructive optical techniques, Delayed Luminescence (DL) has attracted particular interest in the last decades. It consists of the prolonged (up to the seconds range) ultra-weak emission of optical photons by a sample following its exposure to light. The properties of DL emissions, as well as the decay trend, are influenced by the excitation conditions (excitation energy and duration) and molecular structures characterizing the analysed matrix (Stolz et al., 2019). Experimental studies have shown that Delayed Luminescence is particularly suitable in assessing the functional state of a living biological system, as it highlights structural and/or functional changes in cells induced by certain metabolic processes (Goltsev et al., 2009; Kang et al., 2008). For these characteristics, it has been applied to discriminate between normal and tumour cells, to determine seed germination performances and to reveal the activation of apoptotic pathways induced by chemical agents (Costanzo et al., 2008; Grasso et al., 2016, 2018; Lanzanò et al., 2009; Scordino et al., 2014). On tomato fruit, significant changes in DL decay trends related to the colour of fruit and their respiration were reported (Triglia et al., 1998). In addition, DL has been also successfully used for assessing food safety (Chen et al., 2005) and for discriminating herbal medicine products with respect to growing environments, processing, properties and age of the herbs (Jia et al., 2020; Sun et al., 2016, 2018, 2019). Moreover, the feasibility of applying Delayed Luminescence to evaluate some tomato fruit quality parameters has been already demonstrated in our recent publication, where we have highlighted differences in DL emissions related to the total soluble solid content present in tomato juice (Panebianco et al., 2023b). Such feasibility study was conducted on tomatoes not submitted to storage and harvested at full ripeness stage (skin with intense red colour).

In the present work, the experimental approach validated in Panebianco et al. (2023b) was used to reveal postharvest quality changes in cherry tomatoes harvested at different ripening stages. This work is part of a multidisciplinary scientific framework aimed at determining the postharvest quality of cherry tomato fruit using non-destructive techniques in support of the traditional analysis methods. Colorimetric and DL measurements were performed on tomato fruit originating from a restricted geographical area of south-eastern Sicily, in Ragusa province (Italy), specialised in the intensive cultivation of tomato under greenhouse environment. The changes in colour and DL emission trends were monitored at different times after harvesting and compared. As a result, DL data, unlike colorimetric data, made it possible to distinguish postharvest from field-ripened fruit. This knowledge, in addition, could provide important information related to metabolic processes occurring in fruit during postharvest ripening. Interestingly, such results come from a single measure on each fruit and did not require preprocessing of combined data from tomato’s different regions, as in the case of other techniques (de Brito et al., 2022; Li et al., 2022), showing the possibility that DL measurements become a more rapid quality evaluation tool, that could help in the improvement of fruit quality control.

Materials and Methods

Samples

For this study, four different lots were used, each consisting of cherry tomato fruit cv. Creativo harvested at different ripening stages. Lots were collected from four different tomato greenhouses located in the Ragusa province (south-east of Sicily, Italy) at Marina di Ragusa (Lot 1), Santa Croce Camerina (Lot 2) and Ispica (Lots 3 and 4) municipalities. Tomatoes were kindly provided by greenhouses’ owners. Tomato plants were grown during the spring of 2022 in unheated glasshouses assembled by using plastic films and watered by drip irrigation, following standard cultural practices.

At harvest time, within each greenhouse, 2–3 kg of undamaged tomato fruit were randomly removed with their bunches from six different sampling points, equidistant from each other, and pooled in a single lot. Then, tomatoes were transferred to the laboratory and divided into four groups or classes according to external fruit coloration, as follows: class A (fully red skin), class B (fully orange or light red skin), class C (orange-green skin) and class D (green skin) (Fig. 1). Finally, they were stored at room temperature (20 °C ± 2 °C and 65% RH) and in dark conditions throughout the period of experiments.

Cherry tomato fruit selected for the chromatic and DL measurements. For each lot, tomatoes have been divided into four different classes based on their maturation stage as follows: class A (fully red skin), class B (fully orange or light red skin), class C (orange-green skin) and class D (green skin). The picture represents tomato fruit at different ripening stages, 3 days after harvesting

Experimental measurements were performed on 16 fruit groups, each consisting of fruit with a similar degree of ripening (4 classes for 4 lots). For each fruit group, we selected 20 tomatoes (resulting in a total of 320 tomatoes that constituted the whole experimental set) and we determined chromatic and DL parameters at four different monitoring times from harvest (T1, T2, T3 and T4). In detail, chromatic measurements were performed on days 3, 11, 14 and 17, whilst DL measurements on days 6, 10, 13 and 17 after harvesting. As tomatoes belonging to the class A were very ripe, measurements were carried out up to the time T3 (beyond this time, fruit presented remarkable wrinkles of tissues). At the end of the storage period, the total soluble solid (TSS) content was also determined on tomato fruits.

Chromatic Measurements

Fruit chromaticity was measured through the CIE (Commission Internationale de l’Eclairage) L*, a* and b* system using a portable colorimeter model PCE-XXM 30 (PCE-Deutschland GmbH, Meschede, Germany) with a repeatability of ΔE*ab ≤ 0.1. The light source inside the colorimeter consisted of a LED lamp with a wavelength of 400–700 mm. As previously reported, for each class, chromatic measurements were carried out on 20 fruits, by placing the measuring area of the instrument (8 mm in size) against two different points of each fruit, except for the chromatic measurements at time T1. In this case, for each lot and each class, a set of 15 fruit, different from the 20 berries used for DL measurements, was selected, as it was used to detect some of chemical parameters reported in Panebianco et al. (2023b), resulting in the destruction of the analysed matrices. Therefore, in summary, on each lot we carried out 120 chromatic measurements, spread over 60 tomatoes (30 measures for each class) at time T1, and 160 chromatic measurements, spread over 80 tomatoes (40 measures for each class) at the following times.

During measurements, CIE L*, a* and b* chromatic values were determined. In the CIELab system, L* parameter measures the amount of light reflected that ranges from 100 (white) to 0 (black), whereas a* and b* values are chromaticity coordinates indicating a colour’s position along the green (− a*)-red (+ a*) axis and the blue (− b*)-yellow (+ b*) axis (Backhaus et al., 1998).

From L*, a* and b* values we calculated the a*/b* colour ratio, which is considered a good indicator of the degree of fruit ripeness (Gormley & Egan, 1978), and the colour difference ΔE* between different fruit, defined as

which can be used both to test the uniformity of the fruit colour inside the class of a lot and to quantify colour differences between different classes.

Measurements were repeated four times during the storage of fruit, according to the monitoring times indicated in the previous paragraph. In this way, it was possible to follow over time the colour changes linked to the ripening process undergone by tomatoes during their storage.

Delayed Luminescence Measurements

The experimental setup was designed to measure the ultraweak flow of photons emitted by tomato samples as their ripening degree and storage duration vary. DL measurements were carried out on the same fruit used for the chromatic measurements, except at the time T1 (see the “Chromatic Measurements” section), performing one measurement on each fruit (20 measures per class of ripeness, for a total of 80 measurements per lot). As for the colorimetric parameters, DL decay curves associated with each fruit were evaluated at four different monitoring times (T1, T2, T3, T4), following the timesheet reported in the “Samples” section.

The instrumental apparatus employed to measure the delayed light emission was provided by Meluna Research (Wageningen, The Netherlands) and described in Sun et al. (2019) and in Panebianco et al. (2023b). The light source consisted of a white tungsten halogen lamp, characterised by an emission spectrum ranging from 350 to 950 nm (20 W, model 284–2812, Philips, Germany). Measurement consisted of illuminating the sample, placed inside a dark chamber with a diameter of 10 cm, for a time of 10 s and counting the number of photons reemitted from the sample after the light source had been switched off. The light reemitted from each sample was detected by a photomultiplier tube (PMT, model 9558QB; Electron Tubes Enterprises Ltd., Ruislip, UK), having a cathode end with a sensitive range at 300–800 nm. The PMT, working in a single-photon counting mode, was cooled to − 25 °C to decrease its thermal noise. The DL signal was amplified by a fast spectroscopy preamplifier (model 9301 ORTEC, Oak Ridge, TN) connected to the PMT, whereas the number of released optical photons was counted by means of a photon counting card (model C9744; Hamamatsu, Iwata, Japan) installed into a personal computer. For each fruit, DL trends were obtained by recording the number of counts in non-overlapping time bins of 100 ms for a total period of 30 s, resulting in a total of 300 data points.

Total Soluble Solid Content Determination

Due to their destructive nature, chemical measurements to determine the TSS content were performed at the end of the monitoring period, which is immediately after performing colorimetric and DL measurements at monitoring time T4. Fruits were crushed by using a commercial juice extractor and TSS, expressed as °Brix, was read directly by applying two drops of the juice, at room temperature, on an optical portable refractometer with a °Brix detection range of 0 to 80% (refractometer model 103, Bormac S.r.l., Carpi, Modena, Italy). As for chromatic and DL measurements, TSS content was determined on a total of 16 different fruit groups, consisting of 20 fruits each with a similar degree of ripening (4 classes for 4 lots). Within each fruit group, measurements were carried out on four replicates, each consisting of the juice of five tomato fruits.

Data Processing and Statistical Analysis

To evaluate the effects of ripeness degree and harvest time (fixed factors) on chromatic parameters, experimental chromatic data (CIE L*, a* and b* values, a*/b* colour ratio and average < ΔE*˃ parameter) were subjected to two-way analysis of variance (ANOVA; Minitab Statistical Software, version 19) and compared by means of Fisher’s least significant difference (LSD) test at 5% level of significance. Similarly, significant differences in experimental first points I1 of DL curves and in TSS content were assessed through one-way ANOVA, applying a significance level (p-value) of α = 0.05. Statistical analysis was performed separately for each lot. Chromatic data from each fruit were also plotted in bubble charts (XLSTAT package, 2023), which allowed us to better represent the colour gradient evolution from green to red occurring in tomatoes during the storage period.

As it concerns Delayed Luminescence measurements, we compared the trends of delayed light emitted by the different tomato samples as a function of storage time (T1, T2, T3, T4) and fruit ripening stage (classes A, B, C, D). For this purpose, to facilitate comparison, for each lot and at each storage time, we obtained four single average DL trends that could best represent the four ripeness classes within a lot, as described below. Each class consisted of 20 tomato fruit, with a similar degree of ripening. Starting from the single DL decay I(t), we normalised such decay to its photon rate at t = 0.1 s (I1, the first point of the experimental decay curve), by evaluating In(t) = I(t)/I1. Thus, every average decay curve has been built by computing, at each time instant, the mean value of the corresponding 20 normalised DL rates In(t) at that instant.

The average DL decay curve, representative of each ripeness class at a fixed storage time of a lot, was fit to the following hyperbolic function:

This function was firstly introduced by E. Becquerel in 1867 and it is reported in literature suitable for describing the relaxation of many complex systems, including biological systems (Austin et al., 1975; Frauenfelder et al., 1999; Palazzo et al., 2002; Popp & Yan, 2002; Scordino et al., 1996).

Fit parameters I0, t0 and m were evaluated according to the non-linear least-squares procedure described in Scordino et al. (1996). This fast-fitting procedure has been validated in our previous study that showed negligible differences between the average of the DL parameters obtained by fitting the single DL decay trends from the berries of a group and the DL parameters obtained by fitting the average normalised decay trends representative of the group (Panebianco et al., 2023b).

Results and Discussion

Chromatic Measurements

Fruit were selected by visual inspection. So, to test the colour uniformity inside each group, the average value of colour difference ΔE* amongst fruit of the same ripeness class was calculated from L*, a* and b* components, as well as reported in the “Materials and Methods” section.

At time T1, the fruit colour was quite uniform for the class A (lower ΔE* values), whilst a greater dispersion was observed within the classes C and D, especially for fruit belonging to lots 3 and 4 (Table 1).

These differences persisted during fruit storage, in the subsequent monitoring times. By considering all the times, the average values ranged between 1.90 and 4.25 for the class A, 2.69–5.32 for the class B, 3.36–7.67 for the class C and 4.57–11.12 for the class D.

Chromatic parameters (CIE L*, a* and b* values, a*/b* colour ratio and ΔE* values) of all four lots were significantly affected both by single factors (“Time after harvesting” and degree of “Ripeness at harvesting”) and by their interaction (p-value ≤ 0.05), as reported in Table S1 (Supplementary Information). The comparison of F-values highlighted that the effects of "Ripeness at harvesting" factor on chromatic parameters were always considerably higher than those exerted by "Time after harvesting" factor (the larger the F-value for a particular factor, the greater the effect on the observations under study).

As expected, for each lot and ripeness class, significant differences occurred in fruit chromatic characteristics determined at the beginning and at the end of the storage period. The a*/b* colour ratio was highest in ripe fruit (class A) and lowest in unripe green fruit (class D), for which it assumed negative values during the first days of storage (Fig. 2). The highest values were recovered for the tomatoes belonging to lots 1 and 2 (0.92–0.81, class A), whereas the lowest values for the tomatoes of lot 3 (− 0.58–0.03, class D). The a*/b* values increased with ripening and with days after harvesting; the rate of increase was most evident on unripe fruit belonging to classes B, C and D.

Tomato colour changes during the ripening process: average values of the a*/b* colour ratio as a function of time after harvesting and fruit ripening stage at harvest. Values in the bars represent the mean of 30 measures ± standard error (two measurements per 15 fruit) at time 1 and the mean of 40 measures ± standard error (two measurements per 20 fruit) at the other times. For each lot, values within each class followed by the same letter are not significantly different according to Fisher’s least significance difference test (α = 0.05)

Our results are in accordance with the previous studies (Arias et al., 2000; Giovanelli et al., 1999; Gormley & Egan, 1978), who reported that it is possible to estimate the degree of ripeness of the tomato fruit by determining the a*/b* colour ratio inside the CIE L* a* b* colour space.

Similarly, the CIE L*, a* and b* components affecting the colour of tomato samples varied significantly during storage, with temporal trends heavily dependent on the ripeness class. This could not be otherwise since the a*/b* colour ratio is a parameter deriving from them.

It has been reported that the colorimetric parameters and the a*/b* colour ratio are closely related to the carotenoid content of the fruit (Bui et al., 2010, and references therein; Kim et al., 2019; Goisser et al., 2020). As it is well known, the colour of the tomato berry is the result of a combination of different pigments, the ratio of which changes during ripening. In the pericarp of the unripe fruit, chloroplasts and chlorophyll (which is responsible for the green colour of the fruit) prevail, whilst with the onset of ripening, called “veraison”, the pigmentation of the berry is determined by carotenoids and, more precisely, by the quantitative ratio between β-carotene and lycopene, which progressively take the place of chlorophyll following the conversion of chloroplasts into chromoplasts (Gonzali & Perata, 2021; Kaur et al., 2006). Lycopene, whose presence determines the red colour of berries, is the main carotenoid present in ripe fruit, and its content peaks in the last ripening period (Carrillo-López & Yahia, 2014; Kim et al., 2019; Trebolazabala et al., 2017). The content of chlorophyll, β-carotene and lycopene, which differs as ripening progresses, determines the colour shade of the berry, which gradually assumes different positions along the L*, a* and b* axes in the CIELab colour space system, turning from green to yellow, orange and finally red.

During tomato ripening, L* values progressively decreased as tomato skin colours became darker and duller due to the increase of pigments responsible for colour shifts from yellow-green to red (Table S2, Supplementary Information). In this respect, it can be noted that the lightness values remained almost stable or slightly decreased in the ripe fruit having a completely red skin (class A) and in the unripe ones with a still completely green skin (class D, lots 3 and 4), whereas they strongly decreased when tomatoes started to redden. A similar behaviour was observed for the a* component: little or no significant changes were observed at the end of the storage period when fruit reached the latest ripening stage (skin with intense red colour, classes A–C), whilst a strong increase was observed when the tomatoes, harvested in the early stages of ripening, gradually began to ripen (classes C and D) (Table S3, Supplementary Information). In particular, during the ripening process, the a* parameter turned from being negative (green colour) to positive (red colour) as a result of chlorophyll degradation and lycopene synthesis, as previously demonstrated by some researchers (Arias et. al, 2000; López-Camelo & Gómez, 2004). Contrary to the L* and a* parameters, the b* values changed slowly during the storage period. Their values were always positive and decreased over time, with the exception of the tomatoes belonging to class D (Table S4, Supplementary Information). As concerning this parameter, different trends were described in the literature. For example, Goisser et al. (2020) reported an increase of b* values when fruit turned from green to pink, followed by a slow decrease when tomatoes reached the full ripeness stage at harvest time and during storage. On the opposite, Kim et al. (2019) observed a slow decrease of b* values when fruit ripening progressed from the breaker stage to the deep red one. In other studies, b* parameter changed very little during the ripening process, reaching the higher value at the pink-light red stage (Arias et al., 2000; López-Camelo & Gómez, 2004) or at the breaker and turning stages (Brandt et al., 2006).

The relationships between L*, a* and b* chromatic coordinates at each monitoring time, as well as the evolution of fruit colour during the whole storage period, were more clearly highlighted by means of bubble charts. The bubble’s size was used to represent the amount of light reflected by fruit (the larger the size, the greater the L* parameter), whereas the a* and b* variables were plotted along the x and y axes, like every two-dimensional chart. The bubble plots are reported in Fig. 3 for lot 1 and in Figs. S1, S2 and S3 (Supplementary Information) for the other lots.

Comparison of bubble charts of chromatic coordinates obtained for the first lot of fruit harvested at different ripening stages (see legends: classes A, B, C, D). Different frames refer to different monitoring times after harvesting (time 1, time 2, time 3, time 4). Solid lines represent the 95% confidence ellipses for each group. The graphs were obtained using XLSTAT package (https://www.xlstat.com/en, 2023)

At the beginning of the storage period, the CIE L*, a* and b* parameters were able to discriminate tomatoes based on their degree of ripening. At time T1, there were four well-defined clusters, which occupy different zones of the plot (Fig. 3A). Tomatoes with a high degree of ripeness at harvest (deep or light red skin colour, classes A and B) were located in the right quadrant (a* values > 0), whilst the most unripe ones, harvested at the first or second stage of ripening (completely green or yellow-green skin colour, classes D and C), were located around the y-axis and in the left quadrant (a* values < 0), respectively.

As time elapsed and the ripening process was completed, the distances amongst the groups gradually shortened to such an extent that by the end of the storage period some groups were no longer distinguishable from each other from a colorimetric point of view. In particular, at times T3 and T4, the groups representing classes A, B and C overlapped each other, due to uneven colour variations amongst the groups (Fig. 3 C and D). As a matter of fact, as mentioned above, the coordinates L*, a* and b* changed faster on unripe tomatoes as the colour of the skin changed from yellow-green to red (classes B and C) and slower on fully ripe tomatoes (class A). The tomatoes in class D, on the other hand, always remained quite distinct from the other groups, never reaching the degree of ripeness possessed by fruit ripened on the plant under natural conditions (Fig. 3D). Similar results were obtained by comparing the datasets of the lots 2, 3 and 4 (Figs. S1, S2 and S3, Supplementary Information).

Delayed Luminescence Measurements

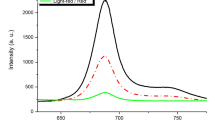

Similarly to chromatic parameters, also DL trends were different on varying ripeness classes at harvest and storage time, as reported in Fig. 4 for lot 1. In this figure, DL intensity is reported as \(\langle {I}_{n}\left(t\right)\rangle \langle {I}_{1}\rangle\), that is the normalised averaged trend (described in the “Data Processing and Statistical Analysis” section) times the average value of the first point intensity for the class at that monitoring time.

Comparison of DL decay curves obtained for lot 1, split into four classes according to tomato ripening stages (see legends: classes A, B, C, D). Different frames refer to different monitoring times after harvesting (time 1, time 2, time 3, time 4). DL measurements have been performed on 20 fruits per class of ripeness (80 measurements per lot). In the graphs, for each monitoring time and class under study, the average normalised decay trend was reported. Standard errors are within marker size. Solid lines represent the theoretical trend according to Becquerel’s formula (Eq. 1). Data are plotted on a log–log scale. Fit parameters are reported in Table S5 (Supplementary Information)

The greatest difference was observed in the total number of photons emitted during the acquisition time after the flash lamp was switched off and, consequently, in the total area delimited by the curves.

In detail, it was observed that the intensity of the DL signal was inversely proportional to the degree of ripeness, as tomatoes harvested at the full-ripeness stage (class A) emitted light signals less intense than tomatoes harvested at the first-ripeness stage (class D) (Fig. 4A–D).

We hypothesise that these differences can be correlated to the quantitative ratio of pigments present in tomato skin (chlorophylls and carotenoids), whose content varies as ripeness progresses. As a matter of fact, DL technique arises from the property of certain molecules (fluorophores) to absorb amounts of energy in the visible region, later returned in the form of photons of lower energy. The DL phenomenon is similar to the fluorescence process observable in samples excited via light, differing from it in the excited state decay time length.

The absorption of light by chlorophyll and carotenoids is due to the presence of conjugated carbon–carbon double bonds, above which the electrons form an electron cloud belonging to this system as a whole rather than to a single atom (Schoefs, 2002). As a result of the light absorption by fruit, it was observed that chlorophyll and chlorophyll-related molecules can de-excite by emitting high-intensity fluorescence signals, in the contrast of carotenoids, characterised by fluorescence signals with a much weaker intensity (Schoefs, 2002). The different behaviour shown by pigments following their excitation by light can be extended to the case of Delayed Luminescence, in view of the strong similarity with the fluorescence phenomenon, and it would explain the different DL signals obtained in this study, which were of lower intensity in red-coloured ripe fruit (class A) and of higher intensity in green-coloured immature fruit (class D). On the other hand, DL phenomenon has largely been observed in biological samples with high photosynthetic activity, such as green plants, leaves, chloroplasts, algae and photosynthetic bacteria (Jiang et al., 2023; Wang et al., 2004, 2007, and references therein). For this reason, as previously said, DL can be used as an important index to evaluate biological activity (cell division and death, photosynthesis, etc.) in the living systems and to reveal structural and/or functional changes induced by certain metabolic processes (Goltsev et al., 2009; Kang et al., 2008). The technique is also extremely sensitive to slight changes induced by external agents, such as physiological stresses, agricultural practices and technological processes, that affect plant photosynthesis, chloroplast content and, more generally, molecular structure (Chuenwarin et al., 2016, and references therein; Sun et al., 2016, 2018; Stolz et al., 2019; Jiang et al., 2023).

The differences found between the kinetics of the DL curves for classes B, C and D at the first monitoring time (time T1; Fig. 4A) became increasingly smaller as the storage process (and, consequently, the ripening of fruit) progressed and were no longer appreciable at the last day monitored (time T4; Fig. 4D). On the opposite, the decay curve associated with class A (red line) was more distant from the other curves (orange, yellow and green lines), remaining always clearly distinguishable even when the storage time varied.

As suggested for the colorimetric measurements, we believe that this is due to the fact that the curves associated with the four classes shifted towards lower values unevenly, as monitoring time progressed. In detail, the shift of the curves towards lower values compared to the initial position (DL trend at time T1) was of greater magnitude for class D and of lesser magnitude for class A, as shown in Fig. 5 for lot 1.

Changes in DL decay curves obtained for lot 1, split into four monitoring times (see legends: time 1, time 2, time 3, time 4). Different frames refer to different classes according to tomato ripening stages (classes A, B, C, D). At each monitoring time, DL measurements have been performed on 20 fruits per class of ripeness (80 measurements per lot). In the graphs, for each monitoring time and class under study, the average normalised decay trend was reported. Standard errors are within marker size. Solid lines represent the theoretical trend according to Becquerel’s formula (Eq. 1). Data are plotted on a log–log scale. Fit parameters are reported in the Table S5 (Supplementary Information). The pictures represent tomato fruit at different ripening stages as they looked at the first monitoring time T1 and the last one T4, showing their colour changes

Once again, these differences could be related to the different pigment ratio present in the analysed tissues. It must be also considered that the number of ripening phases monitored over time using the DL technique was different for the various classes, as the bioluminescence observations covered the entire ripening process in the case of unripe harvested tomatoes (fruit colour change from green to red) and, in contrast, only the terminal phase in the case of ripe harvested fruit (fully red fruit that become progressively overripe). This resulted in a greater decrease in light signals for immature and postharvest-ripened harvested fruit, whose skin colour changed from green to red as a result of chlorophyll degradation and lycopene synthesis, and in a lower decrease for fruit harvested at the fully ripe stage, characterised already at time T1 by a high amount of lycopene and the absence of chlorophyll. The different trends could be also associated with the different content of sugar and organic acids present in tomato pulp, whose concentrations vary during the ripening process (Gautier et al., 2008).

Similar trends were also found for the other lots (Figs. S4, S5 and S6, Supplementary Information). At lot 3, the decay curves associated with classes B, C and D remained distinct even at the end of the storage period, suggesting a delay in the ripening process compared to the other lots.

In addition to the observed changes in the kinetics of the DL curves, significant differences also occurred in the experimental first point I1 and in its average value \(\langle {I}_{1}\rangle\) as the monitoring time and degree of ripening varied, as well as in the parameters I0, t0 and m obtained by fitting the average decay trends normalised \(\langle {I}_{n}\left(t\right)\rangle\) to Eq. 1. The values of I0, t0 and m are reported in the Table S5 (Supplementary Information), along with the experimental \(\langle {I}_{1}\rangle\) average values.

Figure 6 shows, for each lot, the \(\langle {I}_{1}\rangle\) values as a function of the corresponding a*/b* colour ratio evaluated on varying the fruit ripening degree at harvest and the monitoring time after harvesting. According to the results previously highlighted in Figs. 4 and 5, there was an unequivocal relation between the fruit ripening process and the intensity of the DL signals recorded in correspondence of each class under study. As observed before, the average intensity values at the first point of experimental DL curves are negatively correlated to the degree of ripeness of the fruit (the riper the fruit, the lower the corresponding intensity value \(\langle {I}_{1}\rangle\)). The results were reproducible in all four analysed lots (Fig. 6).

Intensity of DL signals at first point (I1 at t = 0.1 s) as a function of a*/b* colour ratio, at different times after harvesting. Markers represent the I1 average values obtained, for each time and class of ripeness, from the single fruit DL trends. I1 and a*/b* average values were reported at the four different monitoring times (T1, T2, T3, T4). Bars denote the standard errors, whereas grey dotted line refers to the weighted linear fit of experimental data detected for the classes B, C and D (fit parameters are reported in Table S6, Supplementary Information)

It is interesting to note that the markers corresponding to the four classes examined occupied different positions in the graphs reported in Fig. 6, which were quite distinct from each other: fruit harvested unripe and becoming ripe under non-natural postharvest conditions (green markers) were located in the upper left-hand corner, fruit with intermediate ripening (yellow and orange markers) in the middle and fruit harvested from the plant at the fully ripe stage (red markers) in the lower right-hand corner. In addition, although a linear correlation between DL intensities and colorimetric data can be found considering only the fruits not fully ripe at harvest (classes B, C and D), as shown in Fig. 6 by the dashed lines, the fully ripe fruit belonging to class A differed more markedly from the other groups. More precisely, the \(\langle {I}_{1}\rangle\) values of tomatoes that were harvested at not fully ripe stage (as for instance class B, time T4) remain higher than the ones measured for class A tomatoes when they approach the a*/b* values of tomatoes harvested at fully ripe stage (class A, time T1), as highlighted by the linear trend shown in Fig. 6. Fit parameters of such linear trend for the different lots are reported in Table S6 (Supplementary Information).

These results highlight significantly different changes in the physical–chemical structure of tomatoes depending on whether the ripening process takes place under natural conditions (on the plant) or under postharvest conditions (confined environment). The correlations found between the DL signals and the a*/b* colour ratio, taking into account also the results obtained in a previous study (Panebianco et al., 2023b), suggest that DL technique can be successfully used not only to assess ripening degree in fruit and vegetables that lose chlorophyll as they ripen, like colorimetric techniques, but it represents a viable alternative to traditional chemical techniques, presenting the advantage of determining the internal quality of the fruit reliably, quickly and without damaging or destroying the biological analysed matrices. As a matter of fact, chemical analysis performed after the end of the monitoring period showed, for each lot, differences in the solid soluble content (TSS) in tomatoes of the different classes (Table 2), the most significant difference being between class A and class B even if their colorimetric parameters (a*/b* colour ratio) were quite similar.

It is worth noting that TSS content, mainly represented by the sugar and organic acid content dissolved in the tomato juice, significantly affects the taste and so the sensorial quality of the fruit. These findings, obtained by measuring the single DL decay of a large number of fruits, reinforce the ones that were previously reported by Triglia et al. (1998), obtained by using a reduced number of tomatoes, which have highlighted significant changes in the total DL emissions as a function of harvest maturity.

The considerations made for Fig. 6, namely the possibility of distinguishing postharvest-ripened tomatoes from field-ripened ones, are also confirmed by the analysis of the parameters characterising DL decay trends according to Eq. 1. In this regard, Fig. 7 shows the I0 parameter as a function of the corresponding m parameter obtained from the decay curves associated with class A at the first monitoring time (time T1) and class B at the last monitoring time (time T4). As shown in Fig. 7, the data for the two classes were distributed in different areas of the diagram, with class B (at time T4) being characterised by higher I0 and m values than those found for class A (at time T1).

Relation between the intercept (I0) and slope (m) values obtained, for each lot, by fitting to Eq. (1) the decay trends characterizing the class A at the first monitoring time (time 1) and the class B at the last monitoring time (time 4). Solid lines represent the 50% confidence ellipses for each group. The graph was obtained by using XLSTAT package (https://www.xlstat.com/en, 2023)

Some authors have demonstrated that ripening conditions affect the content of ascorbic acid, polyphenols and carotenoids, whose values were much higher in postharvest-ripened than in field-ripened tomatoes (Giovanelli et al., 1999). The different level of optical photons emitted could also reflect possible deterioration of plant tissues (present in fruit analysed at time T4 and still absent in those analysed at time T1), which occurs naturally when fruit pass from the ripening phase to the over-ripening phase.

As a matter of fact, after the optimal ripening state, the fruit quality deterioration increases, following the occurrence of certain undesirable metabolic processes, such as loss of flavour and water, changes in organic acids and softening of texture due to hydrolysis of pectin, hemicellulose and cellulose in cell walls (Dong et al., 2023; Prasanna et al., 2007). Although at present the obtained results do not allow for a detailed discussion on specific metabolic pathways involved, the determination of which would require a spectral analysis of the emitted photons like the one reported in Baran et al. (2013), our results again suggest that the DL technique is a good indicator of the functional state of a living biological system, revealing significant structural changes related to fruit quality and degree of ripeness.

Conclusions

Comparison between data obtained at the beginning and at the end of storage as a function of harvest maturity revealed significant differences both in the fruit colour and in the total number of photons emitted by the fruit themselves. DL measurement consistency was verified by analysing four tomato lots of the same cultivar, similar to each other for degree of ripeness and geographical origin. Measurements always appeared reproducible, confirming the high reliability of the DL technique.

DL emissions were strongly dependent on tomato harvest ripeness, changing in a negative linear relationship to the a*/b* colour ratio determined for some classes of ripeness. Significant differences were also found between DL signals emitted by field-ripened tomatoes at the beginning of storage and those emitted by postharvest-ripened tomatoes at the end of the storage period, although the a*/b* colour ratio was quite similar.

These results suggest a high sensitivity of the DL technique towards structural changes undergone by living biological systems following the occurrence of metabolic processes, including the ripening process, confirming the findings achieved in our previous feasibility study. This property makes DL particularly suitable to determine relevant quality features affecting flavour, nutritional value and commerciality of vegetal crops close to harvest and throughout the storage period.

Further investigation by using spectral analysis of DL emission could give more insights into the relationship between DL signals and the metabolic process involved. Currently, the technique offers the advantage of discriminating vegetable crops that can apparently present the same degree of ripeness, similar in skin colour but different in relation to other qualitative parameters (e.g. sugar content, tissue consistency) not detectable through the classic colorimetric techniques.

Therefore, as a simple, rapid and non-destructive measurement tool, the DL technique has great potential to be developed in the agrifood sector to assess fruit quality and maturity degree, supporting or replacing the traditional analytical methods.

Data Availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information file. Should any raw data files be needed in another format, they are available from the corresponding author upon reasonable request.

References

Akpolat, H., Barineau, M., Jackson, K. A., Akpolat, M. Z., Francis, D. M., Chen, Y. J., & Rodriguez-Saona, L. E. (2020). High-throughput phenotyping approach for screening major carotenoids of tomato by handheld Raman spectroscopy using chemometric methods. Sensors, 20(13), 3723. https://doi.org/10.3390/s20133723

Arias, R., Lee, T. C., Logendra, L., & Janes, H. (2000). Correlation of lycopene measured by HPLC with the L*, a*, b* color readings of a hydroponic tomato and the relationship of maturity with color and lycopene content. Journal of Agricultural and Food Chemistry, 48(5), 1697–1702. https://doi.org/10.1021/jf990974e

Austin, R. H., Beeson, K. W., Eisenstein, L., Frauenfelder, H., & Gunsalus, I. C. (1975). Dynamics of ligand binding to myoglobin. Biochemistry, 14(24), 5355–5373. https://doi.org/10.1021/bi00695a021

Backhaus, W. G. K., Kliegl, R., Werner, J. S. (1998). Color vision: Perspectives from different disciplines. Walter de Gruyter, Berlin-New York. ISBN 3110161001.

Baran, I., Ionescu, D., Privitera, S., Scordino, A., Mocanu, M. M., Musumeci, F., Grasso, R., Gulino, M., Iftime, A., Tofolean, I. T., Garaiman, A., Goicea, A., Irimia, R., Dimancea, A., & Ganea, C. (2013). Mitochondrial respiratory complex I probed by delayed luminescence spectroscopy. Journal of Biomedical Optics, 18(12), 127006. https://doi.org/10.1117/1.JBO.18.12.127006

Borba, K. R., Aykas, D. P., Milani, M. I., Colnago, L. A., Ferreira, M. D., & Rodriguez-Saona, L. E. (2021). Portable near infrared spectroscopy as a tool for fresh tomato quality control analysis in the field. Applied Sciences, 11(7), 3209. https://doi.org/10.3390/app11073209

Brandt, S., Pék, Z., Barna, É., Lugasi, A., & Helyes, L. (2006). Lycopene content and colour of ripening tomatoes as affected by environmental conditions. Journal of the Science of Food and Agriculture, 86(4), 568–572. https://doi.org/10.1002/jsfa.2390

Bui, H. T., Makhlouf, J., & Ratti, C. (2010). Postharvest ripening characterization of greenhouse tomatoes. International Journal of Food Properties, 13(4), 830–846. https://doi.org/10.1080/10942910902895234

Carrillo-López, A., & Yahia, E. M. (2014). Changes in color-related compounds in tomato fruit exocarp and mesocarp during ripening using HPLC-APcI+-mass spectrometry. Journal of Food Science and Technology, 51, 2720–2726. https://doi.org/10.1007/s13197-012-0782-0

Chen, W., Xing, D., & Chen, W. (2005). Rapid detection of Aspergillus flavus contamination in peanut with novel delayed luminescence spectra. Photochemistry and Photobiology, 81(6), 1361–1365. https://doi.org/10.1562/2005-05-23-RC-538

Chuenwarin, P., Shimazaki, A., Shimizu, M., Kobayashi, Y., Katsumata, M., & Kobayashi, H. (2016). Non-destructive evaluation of photosynthesis by delayed luminescence in Arabidopsis in Petri dishes. Bioscience, Biotechnology and Biochemistry, 80(3), 452–460. https://doi.org/10.1080/09168451.2015.1101332

Costanzo, E., Gulino, M., Lanzanò, L., Musumeci, F., Scordino, A., Tudisco, S., & Sui, L. (2008). Single seed viability checked by delayed luminescence. European Biophysics Journal, 37, 235–238. https://doi.org/10.1007/s00249-007-0221-8

de Brito, A. A., Campos, F., dos Reis Nascimento, A., Damiani, C., da Silva, F. A., de Almeida Teixeira, G. H., & Júnior, L. C. C. (2022). Non-destructive determination of color, titratable acidity, and dry matter in intact tomatoes using a portable Vis-NIR spectrometer. Journal of Food Composition and Analysis, 107, 104288. https://doi.org/10.1016/j.jfca.2021.104288

Demir, K., Sahin, O., Kadioglu, Y. K., Pilbeam, D. J., & Gunes, A. (2010). Essential and non-essential element composition of tomato plants fertilized with poultry manure. Scientia Horticulturae, 127(1), 16–22. https://doi.org/10.1016/j.scienta.2010.08.009

Dong, M., Xin, R., Li, Z. Y., Li, Y. L., Huang, X. H., Dong, X. P., Zhu, B. W., & Qin, L. (2023). Simultaneously quantification of organic acids metabolites by HPLC mass spectrometry to reveal the postharvest quality change in cherry tomato. Journal of Food Composition and Analysis, 117, 105105. https://doi.org/10.1016/j.jfca.2022.105105

Dumas, Y., Dadomo, M., Di Lucca, G., & Grolier, P. (2003). Effects of environmental factors and agricultural techniques on antioxidant content of tomatoes. Journal of the Science of Food and Agriculture, 83, 369–382. https://doi.org/10.1002/jsfa.1370

FAOSTAT (2022). Food and Agriculture Organization of the United Nations. Food and agricultural data referring to crops and livestock products. Available online: https://www.fao.org/faostat/en/#data/QCL

Frauenfelder, H., Wolynes, P. G., & Austin, R. H. (1999). Biological physics. Reviews of Modern Physics, 71(2), S419–S430. https://doi.org/10.1103/RevModPhys.71.S419

Gautier, H., Diakou-Verdin, V., Bénard, C., Reich, M., Buret, M., Bourgaud, F., Poëssel, J. L., Caris-Veyrat, C., & Génard, M. (2008). How does tomato quality (sugar, acid, and nutritional quality) vary with ripening stage, temperature, and irradiance? Journal of Agricultural and Food Chemistry, 56(4), 1241–1250. https://doi.org/10.1021/jf072196t

George, B., Kaur, C., Khurdiya, D. S., & Kapoor, H. C. (2004). Antioxidants in tomato (Lycopersium esculentum) as a function of genotype. Food Chemistry, 84(1), 45–51. https://doi.org/10.1016/S0308-8146(03)00165-1

Giovanelli, G., Lavelli, V., Peri, C., & Nobili, S. (1999). Variation in antioxidant components of tomato during vine and post-harvest ripening. Journal of the Science of Food and Agriculture, 79(12), 1583–1588. https://doi.org/10.1002/(SICI)1097-0010(199909)79:12%3c1583::AID-JSFA405%3e3.0.CO;2-J

Goisser, S., Wittmann, S., Fernandes, M., Mempel, H., & Ulrichs, C. (2020). Comparison of colorimeter and different portable food-scanners for non-destructive prediction of lycopene content in tomato fruit. Postharvest Biology and Technology, 167, 111232. https://doi.org/10.1016/j.postharvbio.2020.111232

Goltsev, V., Zaharieva, I., Chernev, P., & Strasser, R. J. (2009). Delayed fluorescence in photosynthesis. Photosynthesis Research, 101(2–3), 217–232. https://doi.org/10.1007/s11120-009-9451-1

Gonzali, S., & Perata, P. (2021). Fruit colour and novel mechanisms of genetic regulation of pigment production in tomato fruits. Horticulturae, 7(8), 259. https://doi.org/10.3390/horticulturae7080259

Gormley, R., & Egan, S. (1978). Firmness and colour of the fruit of some tomato cultivars from various sources during storage. Journal of the Science of Food and Agriculture, 29(6), 534–538. https://doi.org/10.1002/jsfa.2740290607

Grasso, R., Abe, T., Cirrone, G. A. P., Cuttone, G., Gulino, M., Musumeci, F., Romano, F., Ryuto, H., & Scordino, A. (2016). Effects of ion irradiation on seedlings growth monitored by ultraweak Delayed Luminescence. PLoS ONE, 11(12), e0167998. https://doi.org/10.1371/journal.pone.0167998

Grasso, R., Gulino, M., Giuffrida, F., Agnello, M., Musumeci, F., & Scordino, A. (2018). Non-destructive evaluation of watermelon seeds germination by using Delayed Luminescence. Journal of Photochemistry and Photobiology B: Biology, 187, 126–130. https://doi.org/10.1016/j.jphotobiol.2018.08.012

Hu, B., Sun, D. W., Pu, H., & Wei, Q. (2019). Recent advances in detecting and regulating ethylene concentrations for shelf-life extension and maturity control of fruit: A review. Trends in Food Science and Technology, 91, 66–82. https://doi.org/10.1016/j.tifs.2019.06.010

Jia, Y., Sun, M., Shi, Y., Zhu, Z., van Wijk, E., van Wijk, R., van Andel, T., & Wang, M. (2020). A comparative study of aged and contemporary Chinese herbal materials by using delayed luminescence technique. Chinese Medicine, 15, 6. https://doi.org/10.1186/s13020-020-0287-0

Jiang, M., Li, C., Tang, B. Q., Gao, P., Wang, J., Yang, Y., Zhang, X., & Liu, Y. (2023). Study on the characteristic curve of laser-induced delayed luminescence in leaves of Scindapsus. Journal of Optics, 52(2), 908–914. https://doi.org/10.1007/s12596-021-00743-6

Kang, J., Kim, T., Jeong, D., & Lee, H. (2008). Effect of dehydration stress on delayed luminescence in plant leaves. Journal of the Korean Physical Society, 52, 132–136. https://doi.org/10.3938/jkps.52.132

Kaur, D., Sharma, R., Wani, A. A., Gill, B. S., & Sogi, D. S. (2006). Physicochemical changes in seven tomato (Lycopersicon esculentum) cultivars during ripening. International Journal of Food Properties, 9(4), 747–757. https://doi.org/10.1080/10942910600575716

Kim, D. S., Choi, J. H., Kim, S., & Lim, J. H. (2019). Prediction of carotenoid content in tomato fruit using a fluorescence screening method. Postharvest Biology and Technology, 156, 110917. https://doi.org/10.1016/j.postharvbio.2019.05.018

Lanzanò, L., Sui, L., Costanzo, E., Gulino, M., Scordino, A., Tudisco, S., & Musumeci, F. (2009). Time-resolved spectral measurements of delayed luminescence from a single soybean seed: Effects of thermal damage and correlation with germination performance. Luminescence, 24, 409–415. https://doi.org/10.1002/bio.1127

Li, L., Lu, L. M., Zhao, X. H., Hu, D. Y., Tang, T. Y., & Tang, Y. L. (2022). Nondestructive detection of tomato quality based on multiregion combination model. Journal of Food Process Engineering, 45(9), e14100. https://doi.org/10.1111/jfpe.14100

López-Camelo, A. F., & Gómez, P. A. (2004). Comparison of color indexes for tomato ripening. Horticultura Brasileira, 22, 534–537. https://doi.org/10.1590/S0102-05362004000300006

Martí, R., Roselló, S., & Cebolla-Cornejo, J. (2016). Tomato as a source of carotenoids and polyphenols targeted to cancer prevention. Cancers, 8(6), 58. https://doi.org/10.3390/cancers8060058

Mauromicale, G., Longo, A. M. G., & Monaco, A. L. (2011). The effect of organic supplementation of solarized soil on the quality of tomato fruit. Scientia Horticulturae, 129(2), 189–196. https://doi.org/10.1016/j.scienta.2011.03.024

Palazzo, G., Mallardi, A., Hochkoeppler, A., Cordone, L., & Venturosi, G. (2002). Electron transfer kinetics in photosynthetic reaction centers embedded in trehalose glasses: Trapping of conformational substates at room temperature. Biophysical Journal, 82(2), 558–568. https://doi.org/10.1016/S0006-3495(02)75421-0

Panebianco, S., Lombardo, M. F., Anzalone, A., Musumarra, A., Pellegriti, M. G., Catara, V., & Cirvilleri, G. (2022a). Epiphytic and endophytic microorganisms associated to different cultivar of tomato fruits in greenhouse environment and characterization of beneficial bacterial strains for the control of post-harvest tomato pathogens. International Journal of Food Microbiology, 379, 109861. https://doi.org/10.1016/j.ijfoodmicro.2022.109861

Panebianco, S., Mazzoleni, P., Barone, G., Musumarra, A., Pellegriti, M. G., Pulvirenti, A., Scordino, A., & Cirvilleri, G. (2022b). Feasibility study of tomato fruit characterization by fast XRF analysis for quality assessment and food traceability. Food Chemistry, 383, 132364. https://doi.org/10.1016/j.foodchem.2022.132364

Panebianco, S., Pellegriti, M. G., Finocchiaro, C., Musumarra, A., Barone, G., Caggiani, M. C., Cirvilleri, G., Lanzafame, G., Pulvirenti, A., Scordino, A., & Mazzoleni, P. (2023a). XRF analysis searching for fingerprint elemental profile in south-eastern Sicily tomatoes. Scientific Reports, 13, 13739. https://doi.org/10.1038/s41598-023-40124-6

Panebianco, S., van Wijk, E., Yan, Y., Cirvilleri, G., Continella, A., Modica, G., Musumarra, A., Pellegriti, M. G., & Scordino, A. (2023b). Applications of Delayed Luminescence for tomato fruit quality assessment across varied Sicilian cultivation zones. PLoS ONE, 18(6), e0286383. https://doi.org/10.1371/journal.pone.0286383

Popp, F. A., & Yan, Y. (2002). Delayed luminescence of biological systems in terms of coherent states. Physics Letters A, 293(1–2), 93–97. https://doi.org/10.1016/S0375-9601(01)00831-3

Prasanna, V., Prabha, T. N., & Tharanathan, R. N. (2007). Fruit ripening phenomena — An overview. Critical Reviews in Food Science and Nutrition, 47(1), 1–19. https://doi.org/10.1080/10408390600976841

Santos, L. F., & Olivares, F. L. (2021). Plant microbiome structure and benefits for sustainable agriculture. Current Plant Biology, 26, 100198. https://doi.org/10.1016/j.cpb.2021.100198

Schoefs, B. (2002). Chlorophyll and carotenoid analysis in food products. Properties of the pigments and methods of analysis. Trends in Food Science and Technology, 13(11), 361–371. https://doi.org/10.1016/S0924-2244(02)00182-6

Scordino, A., Baran, I., Gulino, M., Ganea, C., Grasso, R., Niggli, J. H., & Musumeci, F. (2014). Ultraweak delayed luminescence in cancer research: A review of the results by the ARETUSA equipment. Journal of Photochemistry and Photobiology B: Biology, 139, 76–84. https://doi.org/10.1016/j.jphotobiol.2014.03.027

Scordino, A., Triglia, A., Musumeci, F., Grasso, F., & Rajfur, Z. (1996). Influence of the presence of atrazine in water on the in-vivo delayed luminescence of Acetabularia acetabulum. Journal of Photochemistry and Photobiology B: Biology, 32(1–2), 11–17. https://doi.org/10.1016/1011-1344(95)07213-6

Stolz, P., Wohlers, J., & Mende, G. (2019). Measuring delayed luminescence by FES to evaluate special quality aspects of food samples—An overview. Open Agriculture, 4(1), 410–417. https://doi.org/10.1515/opag-2019-0039

Sun, M., Chang, W. T., van Wijk, E., He, M., van Wijk, R., & Wang, M. (2018). Application of delayed luminescence method on measuring of the processing of Chinese herbal materials. Chinese Medicine, 13(1), 43. https://doi.org/10.1186/s13020-018-0202-0

Sun, M., Li, L., Wang, M., van Wijk, E., He, M., van Wijk, R., Koval, S., Hankemeier, T., van der Greef, J., & Wei, S. (2016). Effects of growth altitude on chemical constituents and delayed luminescence properties in medicinal rhubarb. Journal of Photochemistry and Photobiology B: Biology, 162, 24–33. https://doi.org/10.1016/j.jphotobiol.2016.06.018

Sun, M., Wang, S., Jing, Y., Li, L., He, M., Jia, Y., van Wijk, E., Wang, Y., Wang, Z., & Wang, M. (2019). Application of delayed luminescence measurements for the identification of herbal materials: A step toward rapid quality control. Chinese Medicine, 14(1), 47. https://doi.org/10.1186/s13020-019-0269-2

Tang, H., Zhang, X., Gong, B., Yan, Y., & Shi, Q. (2020). Proteomics and metabolomics analysis of tomato fruit at different maturity stages and under salt treatment. Food Chemistry, 311, 126009. https://doi.org/10.1016/j.foodchem.2019.126009

Trebolazabala, J., Maguregui, M., Morillas, H., de Diego, A., & Madariaga, J. M. (2017). Portable Raman spectroscopy for an in-situ monitoring the ripening of tomato (Solanum lycopersicum) fruits. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 180, 138–143. https://doi.org/10.1016/j.saa.2017.03.024

Triglia, A., La Malfa, G., Musumeci, F., Leonardi, C., & Scordino, A. (1998). Delayed luminescence as an indicator of tomato fruit quality. Journal of Food Science, 63(3), 512–515. https://doi.org/10.1111/j.1365-2621.1998.tb15775.x

Wang, C., Xing, D., & Chen, Q. (2004). A novel method for measuring photosynthesis using delayed fluorescence of chloroplast. Biosensors and Bioelectronics, 20, 454–459. https://doi.org/10.1016/j.bios.2004.03.031

Wang, J., Xing, D., Zhang, L., & Jia, L. (2007). A new principle photosynthesis capacity biosensor based on quantitative measurement of delayed fluorescence in vivo. Biosensors and Bioelectronics, 22, 2861–2868. https://doi.org/10.1016/j.bios.2006.12.007

Funding

Open access funding provided by Università degli Studi di Catania within the CRUI-CARE Agreement. This work was supported by the University of Catania (PIA.CE.RI. 2020–2022. Linea 2: Research Projects “NaTI4Smart” and “MEDIT ECO) and by the Italian Ministry of University and Research (PON on Research and Innovation 2014–2020, Project POFACS “ARS01_00640”).

Author information

Authors and Affiliations

Contributions

S.P.: Conceptualization, Formal analysis, Investigation, Methodology, Resources, Validation, Visualization, Writing - original draft, Writing - review & editing; E.W.: Methodology, Resources, Supervision, Validation, Writing - review & editing; Y.Y.: Investigation, Methodology, Resources, Validation, Writing - review & editing; G.C.: Conceptualization, Funding Acquisition, Methodology, Project administration, Resources, Writing - review & editing; A.M.: Conceptualization, Methodology, Project administration, Resources, Supervision, Writing - review & editing; M.G.P.: Conceptualization, Formal analysis, Methodology, Resources, Validation, Writing - review & editing; A.S.: Conceptualization, Formal analysis, Funding Acquisition, Methodology, Resources, Supervision, Validation, Visualization, Writing - original draft, Writing - review & editing

Corresponding author

Ethics declarations

Competing Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Panebianco, S., Van Wijk, E., Yan, Y. et al. Delayed Luminescence in Monitoring the Postharvest Ripening of Tomato Fruit and Classifying According to Their Maturity Stage at Harvest. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03429-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03429-6