Abstract

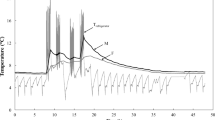

Globally, regulations focus on the energy use of cold chain units and not on their food preservation performance. Our hypothesis is that this reflects a lack of practical/science-based assessment protocols which is addressed in this work. About 3 million time–temperature values for fish fillets stored in the bottom drawer independently set at 0.0 °C and a peer-reviewed predictive model were used to assess the microbial preservation performance of a residential refrigerator operating at 5.0 °C. The temperature effect on the exponential growth rate of Pseudomonas spp. on fish fillets was used to generate a refrigerator preservation indicator (RPI) with values < 1, ~ 1, and > 1 describing excellent, acceptable, or poor microbial preservation performance, respectively. Experimental effects evaluated were refrigerator technology (single/variable speed compressor, SS/VS), ambient temperature (21.1/32.2 °C, LT/HT), refrigerator load (22.5/39 kg, RL/HL), and emulation of door openings during meal preparation. Deterministic RPI estimations for the VS compressor ranged from 1.28 to 1.71, while those for SS ranged from 1.13 to 1.24. Probabilistic estimations yielded confidence intervals also exceeding the desirable 1.0 value. Mean comparisons through Tukey’s HSD identified p-values < 0.05 for all main effects; nonetheless, compressor technology was the most influential factor since the compressor × ambient temperature interaction was significant for both compressors and the compressor × food load interaction was significant for VS compressors. It is concluded that users of cold chain units would benefit from regulations covering energy use and preservation performance with the latter assessed by RPI determinations.

Similar content being viewed by others

Data Availability

The authors declare that the data is available upon requests submitted to the correspondence author.

Abbreviations

- HL:

-

High load (39.0 kg)

- RL:

-

Regular load (22.5 kg)

- HT:

-

High ambient temperature (32.2 °C)

- LT:

-

Low ambient temperature (21.1 °C)

- T min (°C):

-

Square root model constant associated with a theoretical minimum growth temperature

- b :

-

Square root model constant, its value depends on the time units used and whether microbial counts are expressed as decimal or natural logarithm values

- T (t):

-

Fish fillets center temperature as a function of time

- T i (°C):

-

Average fish fillet center temperature during time interval \({\Delta t}_{i}\) (h)

- T rec (°C):

-

Recommended temperature for refrigerated product handling (1.0 °C for fish fillets)

- CFU/g:

-

Colony-forming unit/g

- μ max (T i) (ln CFU/g h):

-

Exponential growth rate at Ti during time interval \({\Delta t}_{i}\), h

- API (log CFU/g) \({\equiv \Delta logN}_{test}\)):

-

Absolute preservation indicator defined as the estimated microbial counts increase during the test time

- RPI :

-

Refrigerator preservation indicator (RPI) defined as the ratio of the API for test temperatures divided by the API at constant Trec. RPI values < 1, ~1, and >1 correspond to excellent, acceptable, or poor refrigerated preservation performance, respectively.

- TTE:

-

Time-temperature equivalent (Rosset et al., 2004)

References

Abbas, K. A., Saleh, A. M., Mohamed, A., & Lasekan, O. (2009). The relationship between water activity and fish spoilage during cold storage: A review. Journal of Food, Agriculture & Environment, 7, 86–90.

Akkermans, S., Nimmegeers, P., & van Impe, J. F. (2018). A tutorial on uncertainty propagation techniques for predictive microbiology models: A critical analysis of state-of-the-art techniques. International Journal of Food Microbiology, 282, 1–8.

Almonacid-Merino, S. F., & Torres, J. A. (2010). Uncertainty of microbial shelf-life estimations for refrigerated foods due to the experimental variability of the model parameters. Journal of Food Process Engineering, 33(S1), 66–84.

Andritsos, N. D., Stasinou, V., Tserolas, D., & Giaouris, E. (2021). Temperature distribution and hygienic status of domestic refrigerators in Lemnos island. Greece Food Control, 127(108121), 1–7.

ANSI. (2008). AHAM HRF-1–2008: Energy and internal volume of refrigerating appliances. American National Standards Institute & Association of Home Appliance Manufacturers, Chicago, IL.

Carpentier, B., Lagendijk, E., Chassaing, D., Rosset, P., Morelli, E., & Noël, V. (2012). Factors impacting microbial load of food refrigeration equipment. Food Control, 25(1), 254–259.

Cheng, J.-H., & Sun, D.-W. (2015). Rapid quantification analysis and visualization of Escherichia coli loads in grass carp fish flesh by hyperspectral imaging method. Food and Bioprocess Technology, 8(5), 951–959.

Chotyakul, N., Pérez-Lamela, C., & Torres, J. A. (2012). Effect of model parameter variability on the uncertainty of refrigerated microbial shelf-life estimates. Journal of Food Process Engineering, 35(6), 829–839.

da Silva Robazza, W., Tiago Teleken, J., Cazonatto Galvão, A., Miorelli, S., & Ortigosa Stolf, D. (2017). Application of a model based on the central limit theorem to predict growth of Pseudomonas spp. In fish meat. Food and Bioprocess Technology, 10, 1685–1694.

de la Cruz Quiroz, R., Fagotti, F., Welti Chanes, J., & Torres, J. A. (2021). Food preservation performance of residential refrigerators: Pasteurized milk and ground beef as animal food models. Food Engineering Reviews, 13(1), 104–114.

de la Cruz-Quiroz, R., Rodriguez-Martinez, V., Velazquez, G., Perez, G. M., Fagotti, F., Welti-Chanes, J., & Torres, J. A. (2020). Residential refrigerator performance based on microbial indicators of ground beef preservation assessed using predictive microbiology tools. Food and Bioprocess Technology, 13(12), 2172–2185.

Derens-Bertheau, E., Osswald, V., Laguerre, O., & Alvarez, G. (2015). Cold chain of chilled food in France. International Journal of Refrigeration, 52, 161–167.

Elsayed, A. O., & Kayed, T. S. (2020). Dynamic performance analysis of inverter-driven split air conditioner. International Journal of Refrigeration, 118, 443–452.

Ekren, O., Celik, S., Noble, B., & Krauss, R. (2013). Performance evaluation of a variable speed DC compressor. International Journal of Refrigeration, 36(3), 745–757.

FAO. (2022). Food loss and waste in fish value chains. FAO. Available at https://www.fao.org/flw-in-fish-value-chains/en/. Accessed December 27 2022

FDA. (2020). Fish and fishery products hazards and controls guidance. 4th edn. U.S. Food and Drug Administration. https://doi.org/10.1039/9781847558398-00136

Gao, T., Tian, Y., Zhu, Z., & Sun, D.-W. (2020). Modelling, responses and applications of time-temperature indicators (TTIs) in monitoring fresh food quality. Trends in Food Science & Technology, 99, 311–322.

Garcia Cortes, A., Martinez-Martinez, E., Fernandez Villanueva, G., Torres-Valdez, A. Y., Fagotti, F., Garcia Garcia, R. R., de la Cruz, Q. R., & Torres, J. A. (2022). Absolute preservation indicator for the assessment of refrigeration performance based on dynamic temperature measurements and predictive microbiology. Food Control, 136(108891), 1–9.

Getahun, S., Ambaw, A., Delele, M., Meyer, C. J., & Opara, U. L. (2017). Analysis of airflow and heat transfer inside fruit packed refrigerated shipping container: Part I - Model development and validation. Journal of Food Engineering, 203, 58–68.

Ghaly, A. E., Dave. D., Budge, S., & Brooks, M. S. (2010). Fish spoilage mechanisms and preservation techniques: Review. American Journal of Applied Sciences, 7(7), 859–877.

Gram, L., & Dalgaard, P. (2002). Fish spoilage bacteria – problems and solutions. Current Opinion in Biotechnology, 13(3), 262–266.

Guillier, L. (2016). Predictive microbiology models and operational readiness. Procedia Food Science, 7, 133–136.

Günlü, A., & Koyun, E. (2013). Effects of vacuum packaging and wrapping with chitosan-based edible film on the extension of the shelf life of sea bass (Dicentrarchus labrax) fillets in cold storage (4 C). Food and Bioprocess Technology, 6(7), 1713–1719.

Gunders, D. (2012). Wasted: How America is losing up to 40 percent of Its food from farm to fork to landfill. In: NRDC Issue Paper, vol IP:12–06-B. p. 26. Natural Resources Defense Council, New York, NY.

Hoaglin, D. C., Iglewicz, B., & Tukey, J. W. (1986). Performance of some resistant rules for outlier labeling. Journal of the American Statistical Association, 8(396), 991–999.

Huss, H. H., Ababouch, L., & Gram, L. (2003). Assessment and management of seafood safety and quality, vol 444. FAO Fisheries Technical Paper. Food and Agriculture Organization, Rome, Italy.

IIF-IIR. (2020). The role of refrigeration in worldwide nutrition, 6th Informatory note on refrigeration and food. International Institute of Refrigeration. Available at https://iifiir.org/en/fridoc/the-role-of-refrigeration-in-worldwide-nutrition-2020-142029. Accessed Sep 7 2022.

James, C., Onarinde, B. A., & James, S. J. (2017). The use and performance of household refrigerators: A review. Comprehensive Reviews in Food Science and Food Safety, 16(1), 160–179.

Jamróz, E., Kulawik. P., Guzik, P., & Duda, I. (2019). The verification of intelligent properties of furcellaran films with plant extracts on the stored fresh Atlantic mackerel during storage at 2 °C. Food Hydrocolloids. 97.

Jedermann, R., Nicometo, M., Uysal, I., & Lang, W. (2014). Reducing food losses by intelligent food logistics. Philosophical Transactions of the Royal Society, A Mathematical, Physical and Engineering Sciences, 372(2017), 20130302.

Jovanovic, J., Djekic, I., Smigic, N., Tomic, N., & Rajkovic, A. (2022). Temperature profile and hygiene in household refrigerators in Belgrade, Serbia and their relation to consumers food safety knowledge and characteristics of the refrigerators. Food Control, 136(108813), 1–8.

Kayansayan, N., Alptekin, E., & Ezan, M. A. (2017). Thermal analysis of airflow inside a refrigerated container. International Journal of Refrigeration, 84, 76–91.

Koseki, S., Koyama, K., & Abe, H. (2021). Recent advances in predictive microbiology: Theory and application of conversion from population dynamics to individual cell heterogeneity during inactivation process. Current Opinion in Food Science, 39, 60–67.

Koutsoumanis, K. (2001). Predictive modeling of the shelf life of fish under nonisothermal conditions. Applied and Environmental Microbiology, 67(4), 1821–1829.

Koutsoumanis, K., & Nychas, G. J. (2000). Application of a systematic experimental procedure to develop a microbial model for rapid fish shelf life predictions. International Journal of Food Microbiology, 60(2–3), 171–184.

Laguerre, O., Derens, E., & Palagos, B. (2002). Study of domestic refrigerator temperature and analysis of factors affecting temperature: A French survey. International Journal of Refrigeration, 25, 653–659.

Li, B., Guo, J., Xia, J., Wei, X., Shen, H., Cao, Y., Lu, H., & Lü, E. (2020). Temperature distribution in insulated temperature-controlled container by numerical simulation. Energies, 13(18): 4765.

Martínez-Martínez, E., de la Cruz, Q. R., Fagotti, F., & Torres, J. A. (2021). Methodology for the food preservation assessment of residential refrigerators: Compressor and consumer practices effects on absolute and relative preservation indicators. International Journal of Refrigeration, 127, 260–271.

Martínez-Martínez, E., de la Cruz-Quiroz, R., González-de la Garza, D., García-Cortés, A., Fernandez Villanueva, G., Fagotti, F., & Torres, J. A. (2023). Novel refrigerated preservation performance indicator based on predictive microbiology and product time-temperature data, an essential tool to reach zero food waste. CyTA - Journal of Food, 21(1), 64–71.

McCuttac, A. (2021). Liebherr explains the best way to store fish and keep it fresh. Available at https://blog.liebherr.com/appliances/my/best-way-store-fish/. Accessed June 25 2021.

Miranda, J. M., Trigo, M., Barros-Velázquez, J., & Aubourg, S. P. (2018). Quality enhancement of chilled lean fish by previous active dipping in Bifurcaria bifurcata alga extract. Food and Bioprocess Technology, 11(9), 1662–1673.

Morelli, E., Noel, V., Rosset, P., & Poumeyrol, G. (2012). Performance and conditions of use of refrigerated display cabinets among producer/vendors of foodstuffs. Food Control, 26(2), 363–368.

Ndraha, N., Vlajic, J., Chang, C-C., & Hsiao, H-I. (2020). Challenges with food waste management in the food cold chains. In: Kosseva MR & Webb C (eds) Food Industry Wastes. 2nd. p. 467–483. Academic Press.

NOM-022-ENER/SCFI-2014. (2014). Eficiencia energética y requisitos de seguridad al usuario para aparatos de refrigeración comercial autocontenidos. Límites, métodos de prueba y etiquetado. In: Energía Sd (ed). p. Gobierno de México, Ciudad de México, México.

Nunes, M. C. N., Emond, J. P., Rauth, M., Dea, S., & Chau, K. V. (2009). Environmental conditions encountered during typical consumer retail display affect fruit and vegetable quality and waste. Postharvest Biology and Technology, 51(2), 232–241.

Petricorena, Z. C. (2015). Chemical composition of fish and fishery products. In P. C. K. Cheung & B. M. Mehta (Eds.), Handbook of Food Chemistry (Vol. 1, pp. 403–435). Springer-Verlag.

Piedrahita-Velásquez, C. A., Ciro-Velásquez, H. J., & Gómez-Botero, M. A. (2014). Identification and digital control of a household refrigeration system with a variable speed compressor. International Journal of Refrigeration., 48, 178–187.

Powell, C. D., López, S., & France, J. (2020). New insights into modelling bacterial growth with reference to the fish pathogen Flavobacterium psychrophilum. Animals, 10(3), 435.

Qureshi, T. Q., & Tassou, S. A. (1996). Variable-speed capacity control in refrigeration systems. Applied Thermal Engineering, 16(2), 103–113.

Ratkowsky, D. A., Olley, J., McMeekin, T. A., & Ball, A. (1982). Relationship between temperature and growth rate of bacterial cultures. Journal of Bacteriology, 149(1), 1–5.

Reguillo-Granados, L., Pérez, F., & Valero, A. (2018). Food quality management systems in the dairy industry: A case study on the application of predictive microbiology in the microbial quality of milk. In: Koca N (ed) Technological Approaches for Novel Applications in Dairy Processing. p. Intech Open, London, UK.

Rodriguez-Martinez, V., Velazquez, G., Massa-Barrera, S., Welti Chanes, J., Fagotti, F., & Torres, J. A. (2019). Estimation of safety and quality losses of foods stored in residential refrigerators. Food Engineering Reviews, 11, 184–199.

Rodriguez-Martinez, V., Velazquez, G., Rodriguez Altaif, Rd. J., Fagotti, F., Welti-Chanes, J., & Torres, J. A. (2020). Deterministic and probabilistic predictive microbiology-based indicator of the listeriosis and microbial spoilage risk of pasteurized milk stored in residential refrigerators. LWT - Food Science and Technology, 117(108650), 1–12.

Rosset, P., Cornu, M., Noël, V., Morelli, E., & Poumeyrol, G. (2004). Time–temperature profiles of chilled ready-to-eat foods in school catering and probabilistic analysis of Listeria monocytogenes growth. International Journal of Food Microbiology, 96(1), 49–59.

Sakai, K., Lee, J. H., Kocharunchitt, C., Ross, T., Jenson, I., Koyama, K., & Koseki, S. (2020). Development of a Maillard reaction–based time-temperature integrator/indicator (TTI) for visual monitoring of chilled beef during long-term storage and distribution. Food and Bioprocess Technology, 13(12), 2094–2103.

Santos, J., Lisboa, F., Pestana, N., Casal, S., Alves, M. R., & Oliveira, M. B. P. P. (2013). Shelf Life assessment of modified atmosphere packaged turbot (Psetta maxima) fillets: Evaluation of Microbial, physical and chemical quality parameters. Food and Bioprocess Technology, 6(10), 2630–2639.

Senturk, T., & Alpas, H. (2013). Effect of high hydrostatic pressure treatment (HHPT) on quality and shelf life of Atlantic mackerel (Scomber scombrus). Food and Bioprocess Technology, 6(9), 2306–2318.

Serment-Moreno, V., Deng, K., Wu, X., Su, Y.-C., Fuentes, C., Torres, J. A., & Welti-Chanes, J. (2015). Monte Carlo analysis of the product handling and high-pressure treatment effects on the Vibrio vulnificus risk to raw oysters consumers. Journal of Food Engineering, 144(1), 86–92.

Shokri, S., Ehsani, A., & Jasour, M. S. (2015). Efficacy of lactoperoxidase system-whey protein coating on shelf-life extension of rainbow trout fillets during cold storage (4 °C). Food and Bioprocess Technology, 8(1), 54–62.

Smale, N., East, A., Eddy, A., & Kang, S. P. (2007). Modeling meat temperatures during off-power events in refrigerated shipping containers. In: 22nd International Institute of Refrigeration (IIR) International Congress of Refrigeration. p., Beijing, China.

Stejskal, N., Miranda, J. M., Martucci, J. F., Ruseckaite, R. A., Barros-Velázquez, J., & Aubourg, S. P. (2020). Quality enhancement of refrigerated hake muscle by active packaging with a protein concentrate from Spirulina platensis. Food and Bioprocess Technology, 13(7), 1110–1118.

Sterniša, M., Bucar, F., Kunert, O., & Smole Možina, S. (2020). Targeting fish spoilers Pseudomonas and Shewanella with oregano and nettle extracts. International Journal of Food Microbiology,328, 108664

Teixeira, B., Marques, A., Mendes, R., Gonçalves, A., Fidalgo, L., Oliveira, M., Saraiva, J. A., & Nunes, M. L. (2014). Effects of high-pressure processing on the quality of sea bass (Dicentrarchus labrax) fillets during refrigerated storage. Food and Bioprocess Technology, 7(5), 1333–1343.

Tsironi, T., Lougovois, V., Simou, V. N., Mexi, A., Koussissis, S., Tsakali, E., Papatheodorou, S. A., Stefanou, V., van Impe, J., & Houhoula, D. (2019). Next generation sequencing (NGS) for the determination of fish flesh microbiota. Journal of Food Research, 8(4), 101–110.

Tsironi, T., Maltezou, I., Tsevdou, M., Katsaros, G., & Taoukis, P. (2015). High-pressure cold pasteurization of gilthead seabream fillets: Selection of process conditions and validation of shelf life extension. Food and Bioprocess Technology, 8(3), 681–690.

Tsujihashi, M., Tanaka, S., Koayama, K., & Koseki, S. (2022). Application of time–temperature indicator/integrator based on the Maillard reaction to frozen food distribution. Food and Bioprocess Technology, 15(6), 1343–1358.

USDA FSIS. (2012). Introduction to the microbiology of food processing. United States Department of Agriculture (USDA), Food Safety and Inspection Service (FSIS).

Wu, S., Zhang, M., Yu, Q., Mujumdar, A. S., & Yang, C. (2023). Fresh Food quality deterioration detection and labeling: A review of recent research and application in supply chain. Food and Bioprocess Technology.

Zhuang, S., Hong, H., Zhang, L., & Luo, Y. (2021). Spoilage-related microbiota in fish and crustaceans during storage: Research progress and future trends. Comprehensive Reviews in Food Science and Food Safety, 20(1), 252–288.

Funding

Author Enrique Martinez Martinez acknowledges the support from CONACyT – Mexico for his stipend scholarship (CVU No. 1106274) and Tecnologico de Monterrey for his doctoral program tuition waiver. Author J. Antonio Torres acknowledges the support from Tecnologico de Monterrey (Research chair funds GEE 1A01001 and CDB081) and from Embraco Mexico S de RL de CV.

Author information

Authors and Affiliations

Contributions

Authors Enrique Martinez Martinez and Andres Garcia Cortes worked on the data analysis and preparation of a first draft. Author Enrique Martinez Martinez updated the data analysis, reprocessed the experimental data, implemented new statistical analysis, and prepared multiple revisions of the first draft. Author Reynaldo de la Cruz Quiroz participated in the conceptual project design, data acquisition and manuscript revisions. Author Jose Guadalupe Rios Alejandro participated in statistical analysis. Author Fabian Fagotti participated in the conceptual project design and in the interpretation of experimental findings from a cold chain manufacturer point of view. Finally, author J. Antonio Torres identified the research need, proposed and designed all experiments, provided overall project supervision, allocated resources, approved the methods and the analysis of the experimental data collected, revised all manuscript drafts, and edited and approved the final version here submitted and which has been shared with all coauthors.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Time-temperature data converted into an effective microbial preservation performance indicator

• Indicator affected by the compressor technology, ambient temperature and food load

• Compressor speed control should consider energy use AND food preservation performance

• To improve preservation performance door openings length/frequency must be lowered

• To improve preservation performance temperature recovery time must be shortened

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Martínez Martínez, E., Cortés, A.G., de la Cruz Quiroz, R. et al. Microbial Preservation Performance of Cold Storage Units Assessed by Modeling of Time–Temperature Data. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03344-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03344-w