Abstract

In this study, our objective was to show the effects of pH and calcium on the techno functional properties of four pulse flours (chickpea, lentil, red lentil, and white bean) and the rheological properties of their pastes and gels. Five conditions were considered: a natural condition and four modifications (pH 3 and pH 5; with or without calcium addition). All measured properties varied with the type, condition, and the interaction among them. All flours exhibited high foaming capacity (44.3 − 78.8%) and emulsifying capacity (46.6 − 49.9%). The white bean flour showed a high water holding capacity (1.6 – 2.0 g/g), and the red lentil, lentil, and chickpea formed strong gels and high viscosity pastes. For the four pulses, the water holding capacity and foaming capacity of the flours and the viscosity of the pastes were improved by decreasing the pH (at 3 or 5) plus the addition of calcium. The hardness, elasticity, and resistance of gels obtained from pulse flours (except for white bean) were high when using natural conditions. Lowering pH resulted in a reduction of these parameters.

Highlights

The properties of the flours were affected by pH and Ca differently depending on the pulse.

The water holding capacity and foaming properties of pulse flours are improved by lowering pH and adding calcium.

The viscosity of pulse flour pastes is improved by lowering the pH to 5 and 3.

The strengths and elasticity of the pulse gels were reduced when the pH was decreased and calcium was added except for white beans.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, the interest in plant-based products as a source of protein in the diet has been growing because of institutional recommendations and the willingness of some consumers to reduce animal-based products. Different motivations are behind the shift toward more plant-based products in human diets, such as sustainability, reducing the environmental footprint, animal welfare, and health (Pais et al., 2022; Tárrega et al., 2020; Singh & Sit., 2022). Soy and wheat are the leading plant-based proteins, but more recently the pea protein has also gained relevance due to the allergenicity of soy and wheat (Sun-Waterhouse et al., 2014). Research has been mostly conducted on these sources, and the knowledge of formulation and processing factors affecting gelling, emulsifying, or foaming properties has been key to develop new plant-based alternatives or analogs (Manassero et al., 2018; Lu et al., 2020; Aluko et al., 2009; Luo & Koksel, 2020; Peng et al., 2020). However, the low variability and lack of appealing textures and flavors are still the main barriers for consumers (Alcorta et al., 2021). Using more diverse plant-based ingredients has been proposed as a strategy to enhance the quality of alternative products. Other pulses with a high production volume worldwide, such as beans, chickpeas, and lentils (30.4, 17.2, and 7.2 millions of tons per year, respectively), are now being considered as alternative sources of protein (Bravo-nez & Gómez, 2021). Chickpeas, beans, and lentils contain 20–30% protein (Shevkani et al., 2019), although this can vary among genotypes, germination, environmental conditions, and fertilizer use (Shevkani et al., 2019). Protein concentrates and isolates of these pulses provided interesting technological functionalities, such as foaming, emulsifying, and gelling capacity (Boye et al., 2010; Joshi et al., 2014; Karaca et al., 2011; Sosa et al., 2020). These properties vary depending on the pH and ionic strength, because they affect protein solubility, surface charge, and hydrophobicity. These effects are complex as they depend on the type and state of the protein (Manassero et al., 2018; Shevkani et al., 2019). The production of concentrates and isolates includes extraction and separation processes that make them expensive and/or less sustainable ingredients. The most used method is alkaline extraction combined with isoelectric precipitation, but harsh chemicals that can affect functional properties and make this process non-environmentally friendly (Mondor et al., 2022). Flours are less processed ingredients, obtained by milling whole or split pulses. They still have a relatively high content of proteins but also contain starch that can provide additional properties under heating conditions.

Most research and industry applications of pulse flours focus on the enrichment of bakery products, snacks, baby foods, and sport foods (Escobedo & Mojica, 2021; Maia et al., 2021; Motta & Zhang, 2019; Patrascu et al., 2017; Rachwa-Rosiak et al., 2015). However, pulse flours appear to be a good alternative base ingredient for new products, designing the product structure around the knowledge of base ingredient’s functional properties and how they can be modulated by processing and formulation conditions. Therefore, the objectives of this work are to study and compare the impact of pH and calcium conditions on the techno functional properties of different pulse flours (chickpea, lentil red lentil, and white bean) and on the rheological properties of their pastes and gels to facilitate their application in the development of sustainable products with high protein content.

Materials and Methods

Materials

Four types of pulse flour (chickpea, lentil, red lentil, and white bean) provided by Dacsa Group (Valencia, Spain) were used. All were whole grain flours except red lentil flour that came from dehulled lentils. The composition of the flours was determined in a previous study (Badia-Olmos et al., 2023). The properties of the raw flours, pastes, and gels of pulses were determined under different conditions: pH 3 ± 0.2 with and without added calcium, pH 5 ± 0.2 with and without added calcium, and compared to the natural conditions pH (6.3–7.1) and without calcium. The pH was adjusted using a 10% citric acid solution (Sensus, Valencia, Spain) with mineral water (Cortes, Spain). Calcium chloride 2-hydrate (CaCl2.2H2O) (PanReac, Barcelona, Spain) was added to the flour at 0.025 g Ca/g flour.

Water Holding Capacity

Three grams of flour were mixed with 30 mL of water. The solution was stirred in a vortex for 30 s, allowed to stand for 2 h at room temperature, and centrifuged using Centrifuge Sorvall RCS-B at 388 x g for 10 min at 20 °C. The supernatant was decanted and the tubes with sediment were weighed. Water holding capacity was calculated as g of water retained per g of flour (Aziah and Komathi, 2009). The experiment was repeated twice.

Emulsifying Capacity

One gram of flour, 20 mL of water, and 20 mL of sunflower oil were homogenized using an Ultraturrax (IKA T18 basic, Ultraturrax, Germany) at 9500 rpm for 1 min. The mixture was centrifuged at 3490 x g for 30 min at 20 °C (Centrifuge Sorvall Rcs-B) and then at 3000 x g for 5 min at 20 °C (Centrifuge 5810 R Eppendorf). Emulsifying Capacity (%) was calculated as the volume of the emulsified layer/total volume after centrifugation in the centrifuge tube. The experiment was repeated twice.

Foaming Properties

One gram of flour was mixed with 50 mL of water. The solution was homogenized using an Ultraturrax (IKA T18 basic, Ultraturrax) at 13,500 rpm for 2 min and then transferred to a graduated cylinder using a spoon to recover all the foam. The foam volume was measured immediately to calculate the foaming capacity (increase in volume percentage due to foam) and after 30 min to calculate foaming stability. The experiment was repeated twice.

Pasting Behavior

Pasting behavior of the flours was determined using 7.5% flour in water. A starch paste cell adapted to a controlled stress rheometer (ARG2, TA Instruments, Cheshire, UK) with a Peltier concentric cylinder system to control the temperature was used. The mixture was placed in the cylindrical container and the viscosity values were recorded during the heating process, as the sample was stirred constantly at 160 rpm. The temperature was set at 50 °C for 1 min, then increased to 90 °C during 2.83 min, it was maintained at 90 °C for 5 min, and finally decreased to 50 °C. The experiment was repeated twice.

Viscoelastic Properties of Pastes

The pastes obtained in Sect. 2.5 were stored overnight at 4°C. Viscoelastic properties were measured using a controlled stress rheometer (RheoStress 1, Haake, Germany) equipped with a parallel plate geometry (60 mm diameter, 1 mm gap). The linear viscoelastic region of each sample was determined using preliminary stress sweep tests at 1 Hz and 20°C. Then, frequency sweep tests of 10 to 0.01 Hz were run at 20°C. The values of the storage modulus (G’), loss modulus (G’’), and loss angle tangent (tan δ), as a function of frequency, were registered. The experiment was repeated twice.

Texture Measurement of Gels

The gels were prepared with a kitchen robot (Thermomix, Vorwerk, Spain) in 500 g batches and using 15% flour in water. First, the mixture was homogenized at 1100 rpm for 2 min without applying temperature. Then it was heated for 20 min at 90 °C with stirring at 1100 rpm. Subsequently, the water evaporated during heating was recovered and the mixture was cooled for 5 min with gentle stirring at 100 rpm until it reached 65 °C. Finally, the paste was transferred to two glass containers (height = 37 mm, diameter = 65 mm), covered with plastic film and stored at 4 °C for 24 h. All textural measurements were made at 20 °C using a texture analyzer (TA/XT Plus, Stable Micro Systems Ltd., Surrey, UK).

Resistance to Penetration

Using a 10 mm diameter cylindrical probe, the force was registered when the sample gel in the cylindrical container (height = 37 mm, diameter = 65 mm) was penetrated to 5 mm at 1 mm/s. The maximum force value was obtained as a measure of the resistance to penetration. For each pulse and condition, two cylinders of two batches were measured.

Textural Profile Analysis

Texture Profile Analysis (TPA) was performed on gel cylinders (17 × 22 mm) using a 75-mm diameter flat aluminum disk (SMS P/75), and compressed twice (10%) at 1 mm/s. From the force-time curves, hardness (maximum force of the first compression) and springiness (distance ratio of the first to the second compression) were obtained. For each pulse and condition, eight cylinders were measured from two batches.

Compression up to Rupture of Gels

Gel cylinders (17 × 22 mm) were compressed at 1 mm/s up to 50% of their original height with a 75-mm diameter flat aluminum disk (SMS P/75). For each pulse and condition, eight cylinders were measured from two batches. The force and distance at rupture were obtained from the force-time curves to calculate the Young Modulus (E) (N/mm2) using formula 1:

where F is the rupture force, h0 and A0 are the original height and the surface of the sample.\(\varDelta h\) is the distance at rupture (Bayarri et al., 2002).

Data Analysis

Analysis of Variance (ANOVA) of two factors (pulse and condition) with interaction was applied to each parameter studied. The Tukey test (α = 0.05) was used to calculate the significance of the differences among conditions for each pulse type. To summarize the differences among the type and conditions, principal component analysis (PCA) was applied to all parameters, including the properties of flours and its pastes and gels, considering the four pulse flours at the five conditions. All the analysis was conducted using XLSTAT 2021.4.1 software (Addinsoft, New York, USA).

Results and Discussion

Properties of Pulse Flours at Different Conditions of pH and Calcium

ANOVA results showed that for all the flour properties (water holding, emulsifying, and foaming), values varied significantly (α = 0.05) depending on the effects of pulse type, the condition (pH and Ca) and its interaction.

Water Holding Capacity

Table 1 presents the mean values of the water holding capacity of the four pulse flours under different conditions. The water holding capacity that corresponds to the amount of water retained per gram of flour ranged from 0.8 to 2.0 g/g. In natural conditions, the water holding capacity was the highest for white bean flour and the lowest for red lentil. Changes in water holding capacity with pH and added calcium depended on the flour. All flours showed higher water holding capacity at pH 3 than in natural condition, but in the presence of calcium, the increase was lower or values did not changed as it was the case of lentil and white bean flours. Furthermore, decreasing the pH to 5 increased the water holding capacity for red lentil and white bean flour only, and if calcium was not added. The water holding capacity of flours depend on the polysaccharides and proteins capable of adsorbing water, but also on the size of particles (Ettoumi, 2015; Pedrosa et al., 2020). Du et al. (2014) observed a high water holding capacity for legumes, explained mainly by the polysaccharide content. Berggren (2018) showed that it was mainly correlated with fiber content, although also modulated by other factors such as proteins, starch, and particle size. Similarly, in this study, the differences in water holding capacity among flour pulses are mainly explained by differences in fiber content (white bean (33.5%) > lentil (16.4%) > chickpea (14.0%) > red lentil (9.8%)). However, the effects of pH and calcium on the water holding capacity according to the literature seem more related to proteins and its solubility affected by pH and ionic strength (Patrascu et al., 2017). At a pH further away from the isoelectric point, the solubility is improved, preventing their aggregation and increasing the water holding capacity (Kumitch et al., 2020). Sreerama et al. (2012) described an isoelectric region between 4 and 6 for chickpea, cowpea, and horse gram legume flours, showing the solubility of proteins is higher at pH 2–3. This explains the higher water holding capacity observed at pH 3 for all flours. The presence of Ca however decreased water holding capacity probably due to the competition between the cations and protein for the water molecules, which enhances the protein-protein interactions and reduces its solubility.

Emulsifying Capacity

Emulsifying capacity, measured as the amount of emulsion (% volume), varied greatly, with values ranging from 2.9 to 49.7%. All flours had a high emulsifying capacity under natural condition, being the highest for chickpea (49.9%) and the lowest for red lentil (46.6%). The emulsifying capacity of the four pulse flours decreased dramatically with a reduction in pH, but the effect was much higher at pH 5 than at pH 3. Emulsifying properties are usually attributed to proteins; however, in this case, the emulsion properties varied little between pulse flours. According to Pedrosa et al. (2020), emulsifying capacity depends highly on the protein content, especially the ratio of soluble proteins legumin/vecilin, and other factors such as the presence of carbohydrates. Polysaccharides, due to their hydrophilic character, often exhibit little surface activity at the oil–water interface and cannot act as emulsifiers. However, polysaccharides complexed with proteins can adsorb strongly at the oil–water interface and contribute to the formation and stabilization of emulsions. The electrostatic nature of these complexes make emulsions stabilized by protein-polysaccharide coacervates sensitive to pH and ionic strength. Once the film is formed, the droplets can assume a negative or positive charge depending on whether the pH of the emulsion is above or below the protein’s isoelectric point. The high electrostatic repulsion between oil droplets leads to greater emulsion stability, whereas under pH conditions close to the protein’s isoelectric point droplet, flocculation/aggregation dominates, leading to coalescence and instability. At pH 3 and 5, the emulsifying capacity was enhanced by the presence of calcium which can be attributed to the electrostatic repulsion between oil droplet due to the ionic strength which stabilize the emulsion (Osemwota et al., 2021, Shevkani et al., 2019).

Foaming Capacity

The foaming capacity, corresponding to the increase in volume (%) due to foam formation, varied within the range of 44.3–78.8%. Foam stability (volume remaining after 30 min) ranged from 20.8 to 58.8% (Table 1). Lentil and red lentil flour produced more foam, and it was more stable over time than white bean and chickpea flours. The effect of conditions significantly (α = 0.05) affected both foaming parameters, but differences were more relevant in foaming stability. The effect of decreasing the pH depended on the presence of calcium. The foaming capacity and stability increased at pH 3 and increased further with added calcium. However, they decreased at pH 5 (without calcium), but when calcium was added, the values were similar or higher than under natural condition. For chickpeas, the variation in foaming capacity among conditions followed a different pattern, as it was higher under natural condition and slightly decreased at pH 3 and 5. Proteins are especially relevant to foaming properties, as they are responsible for the formed interfacial film, which incorporate air bubbles in suspension and reduce the rate of coalescence (Aluko et al., 2009; Osemwota et al., 2021). Differences in foaming capacity and stability among flours under natural conditions are explained by the higher protein content in lentil and red lentil flours (24.0% and 25.9% respectively). Regarding changes with pH, the higher amount of foaming and stability observed at pH 3 and the lower values observed at pH 5 can be explained by the change in protein solubility. Proteins from pulses (bean, pea, and chickpea) showed higher foaming properties in the acidic condition (pH < 4) but lower values at a pH around the isoelectric point (4–6) (Shevkani et al., 2019). Calcium also played a relevant role in the foaming properties of pulses, and regardless of pH, calcium addition increased foaming properties. Previous studies showed improvement in the foaming properties of pulse flour with increased ionic strength (Farooq and Boye, 2011), and of pulse proteins with the addition of calcium and magnesium (Ahmed et al., 2012), attributed to an increase in the solubility of proteins. However, other mechanisms such as calcium ion bridges forming between the carboxylic groups of proteins have been proposed that strengthen the interfacial film and thus improve the stability of foams (Miquelim et al., 2010).

Pasting Behavior of Pulses Flours at Different Conditions of pH and Calcium

The paste behavior curves of the pulse flour dispersions under different pH and calcium conditions are shown in Fig. 1. In all cases, the viscosity of the flours remains constant during heating until the swelling point temperature when the viscosity suddenly increases due to gelatinization of starch. It reached a maximum value at 90 °C that remained almost constant when at 90 °C. Then, the viscosity values continuously increased during the cooling down period. It is noticeable that in these flours there is no decrease in viscosity during the heating period at 90 °C, indicating that starch in these flours is resistant to heating and shearing (Du et al., 2014). Li et al. (2014) reported that starch from legumes is resistant to swelling and repture and display high pasting temperature.

Pasting temperature values ranged from 68.4 to 80.4 °C, maximum viscosity during heating; ranged between 84.0 and 268.0 mPa.s, and the viscosity at the end of the process ranged between 125.5 and 296.4 mPa.s (Table 2). ANOVA showed these three parameters varied significantly (α = 0.05) with the pulse type and the conditions (pH and calcium) and its interaction. In the natural condition, chickpea showed the highest viscosity values and lowest pasting temperature. The white bean showed the lowest viscosity values and the highest pasting temperature. The effect of pH and calcium on pasting parameters was similar for all flours except for white bean. Decreasing pH resulted in a decrease in pasting temperature and an increase in viscosity during the heating and cooling of chickpea, lentil, and red lentil flours; furthermore, these effects were higher at pH 5, whereas they were higher at pH 3 for white bean flour. For lentil, red lentil, and chickpea flours, the effects of pH were lower when calcium was added, but higher for white bean flours.

Pasting behavior of flours is mainly determined by starch, but other components, such as proteins, fibers, and lipids, should be considered (Adebowale & Adebowale, 2007). In previous studies, the viscosity values of heated starch dispersions decreased with decreasing pH, which was attributed to the deterioration of the amorphous region of starch granules due to high acidity (Bravo-n et al., 2019; Joshi et al., 2014). Other studies indicate that acid modification changes the physicochemical properties of starch without destroying its granule structure and results in higher gelatinization temperature (Shi & Seib, 1992), higher solubility, gel strength, and lower viscosity (Kim & Ahn, 1996). However, here, the effect of pH on the viscosity profile was different and more complex depending on the pulse flour. For white bean flour, viscosity increased when the pH decreased. For lentil and red lentil flour, viscosity values were higher at pH 5 than under natural conditions and pH 3, indicating a possible effect of protein on the pasting behavior of starch. Natural and pH 3 conditions are far from the isoelectric point of proteins (4–6) which increases protein solubility and then decrease the availability of water for starch gelatinization. Consequently, the process of starch gelatinization may be delayed, resulting in a higher pasting temperature and lower viscosity. Likewise, the decrease in viscosity with calcium can be explained by the availability of water. Torres et al. (2014) reported that the presence of salts lowers water activity, delaying and limiting starch gelatinization.

Rheological Properties of Pulse Pastes Under Different pH and Calcium Conditions

All flour pastes (Fig. 2) showed a similar viscoelastic response typical of gel materials, with G’ values higher than G’’ and slightly dependent on frequency. Values of G’, G’’, tan δ at a frequency of 1 Hz were used to compare viscoelastic properties (Table 3). ANOVA showed that viscoelastic parameters varied significantly (α = 0.05) with the pulse type and the conditions (pH and calcium), and their interaction. Under natural condition, chickpea paste had the highest values of G’ and G’’, white bean paste had the lowest values of G’ and G’’, and the highest tan δ. For chickpea, lentil and red lentil pastes, the values of G’ and G’’ significantly (α = 0.05) increased when decreasing pH to 5 with and without calcium, but when decreasing pH to 3, the increase in G’ and G’’ was lower or not significant compared to the natural condition. For white bean paste, decreasing pH with or without calcium, increased G’ and G’’ and lowered tan δ, this effect was higher at pH 3 with calcium.

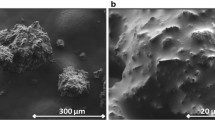

Mechanical spectra of pulse flour pastes obtained under different pH and Ca conditions. For each flour, the pastes with extreme behaviors are presented. Paste under natural conditions (○), paste at pH 5 without calcium (Δ), paste at pH 3 without calcium (□), paste at pH 3 with calcium (◊). G’ (filled symbols) and G’’ (open symbols)

The variation in the rheological behavior of pastes depends highly on starch content (Farooq & Boye, 2011; Pang et al., 2020). During cooling, starches change their structure, become more ordered, and form a network. In our study, the results varied depending on the type of pulse. Chickpea, lentil, and red lentil pastes had higher G’ and G’’ and lower tan δ reflecting a typical gel structure. However, white bean paste had higher values when lowering pH. Motta & Zhang (2019) suggested that other non-starch components of bean flours, like proteins, could affect their rheological behavior, as they can form a matrix when heated. In acidic conditions, Kaur & Singh (1999) reported that changes in wheat paste are attributed to changes on the proteins. Furthermore, the increase in the storage modulus of starch gels with the content of protein at pH 5 was related to increased aggregation and denaturation during thermal treatment (Van Kleef, 1986; Shim & Mulvaney, 2001; Xu et al., 2015). At pH close to their isoelectric point, proteins aggregate and result in network formation due to their low solubility (Manassero et al., 2018). This could explain the higher values of G’ and G’’ of lentil, red lentil, and chickpea pastes obtained at pH 5 with a gel form. The different behavior of the white bean paste that showed an increase in the storage and loss modulus at pH 3 could be explained by the effect of the type of proteins and other components of each pulse on their viscoelastic properties.

Mechanical Properties of Pulse Gels at Different Conditions of pH and Calcium

The four pulses at a concentration of 15% (w/w) formed gels, and the values of the maximum force at penetration, hardness, and springiness were obtained (Table 4). ANOVA showed that they varied significantly (α = 0.05) with pulse type and conditions (pH and calcium) and its interaction. Important variations among gels were observed for the maximum force at penetration (1.30–4.64 N) and hardness (0.50–2.25 N). Under natural conditions, red lentil gel showed the highest values of both parameters, whereas white bean gel showed the lowest. Both the maximum force at penetration and the hardness values changed with pH and calcium, except for the white bean gel that did not show significant differences between the gels prepared under different conditions. For the other three pulses, decreasing pH and adding calcium resulted in less hard and less resistant gels. Both parameters were lower at pH 3 than at pH 5 except for chickpea, which showed little differences between gels prepared at pH 5 and pH 3. The springiness values of the pulse flour gels were high (> 0.65) except for white beans that showed poor ability to recover shape. The springiness slightly changed with the conditions. Young modulus was lower for white bean gel and higher for red lentil (Fig. 3). For lentil and red lentil gels, Young’s modulus decreased when decreasing the pH to 3 and for chickpea gel, it decreased with calcium addition. The mechanical properties depend on the structure, swollen starch granules and proteins in the continuous phase that can form a network. In the literature, the effect of lowering the pH in starch gels is different between papers, but in most cases, the reduction in pH resulted in stiffer gels. In corn starch, the addition of citric acid hydrolyzed amylose and amylopectin that resulted in a higher retrogradation and gel strength at pH 3 and pH 5 than under natural conditions (Jiménez et al., 2016). Another explanation could be the effect of pH on the gelation of protein. Renkema et al. (2002) studied the influence of pH and ionic strength on gel formation and gel properties of soy protein isolates (SPI) in relation to denaturation and protein aggregation/precipitation. The results showed that the stiffness of the gel increased with the decrease in pH due to a different gelation mechanism. At pH 3.8, the proteins aggregate to a greater extent, resulting in coarser gels with low stiffness, whereas at pH 7.6 the proteins were less aggregated, resulting in more fine-strand gels. Moreover, (Salinas et al., 2012) studied the effect of calcium addition on the rheological properties of wheat flour which resulted in a stiffer dough. The authors attributed this behaviour to the development of three-dimensional network due to the bridges formed among the negatively charged proteins enhanced by calcium presence.

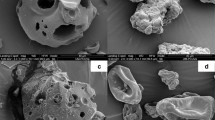

Mean values of Young Modulus E (N/mm2) obtained from compression at rupture test of pulse flour gels under different conditions (pH and calcium). For each flour, the letters on the top of the bars indicate significant differences (α = 0.05) between the mean values according to the Tukey test. N.S: no significant difference

PCA was used to summarize changes in the properties of pulses under different conditions. Figure 4 shows the first plot of the two components that explained the 67.63% of the total variance. The first component was positively correlated with the hardness, elasticity, and the stiffness of the gels and viscosity and viscoelastic parameters (G ‘and G’) of pastes and negatively correlated with the water holding capacity and pasting temperature. The second component was positively correlated with the emulsifying capacity and negatively correlated with the foaming capacity and stability. The flours and conditions that can be used for favoring certain properties can be easily obtained from this plot. Hard, stiff, and elastic gels can be obtained from red lentil and chickpea flours, whereas white bean gels are soft and more plastic. High viscosity pastes with high values of viscoelastic moduli are obtained from red lentil, chickpea, and lentil flours at pH 5, whereas low-viscosity pastes are obtained from white bean flour, which also provided more water holding capacity. The four pulses provide maximum emulsifying capacity under natural conditions.

Conclusions

The four pulse flours (chickpea, lentil, red lentil and white bean) exhibit different techno functional properties that also varied with the conditions of pH and ionic strength, providing a wide range of possibilities to modulate the structure and texture of new or alternative plant-based products. The four pulse flours are good emulsifiers at natural conditions, which is a desirable feature in the development of different food categories such as baby foods, bakery products and soups. When heated in water, pulse flours can form viscous pastes or gels depending on the concentration (10% and 15%, respectively). Chickpea flour provides higher viscosity in pastes and the red lentil the stiffer gel. These findings make them suitable choice for bakery and snack foods, soups, cheese analogues and cold-set product in terms of texture properties. The water holding capacity, foaming capacity and viscosity can be improved by decreasing the pH. However, the emulsifying capacity and gel hardness and stiffness are not improved, but decrease at low pH (especially at 3). This should be taken into consideration when designing the texture of new food products based on pulse flours.

Data Availability

The datasets generated are available from the corresponding author on reasonable request.

References

Adebowale, Y. A., & Adebowale, K. A. (2007). Evaluation of the Gelation characteristics of Mucuna Bean Flour and Protein isolate. Electronic Journal of Environmental, Agricultural and Food Chemistry, 6(2007), 2243–2262.

Ahmed, I. A. M., Eltayeb, M. M., & Faridullah, F. (2012). Effect of Sodium Chloride Concentration on the Functional properties of selected legumes flour. African Journal of Food Agriculture Nutrition and Development, 12(October 2012), 6. https://doi.org/10.18697/ajfand.54.11130.

Alcorta, A., Porta, A., Tárrega, A., Alvarez, M. D., & Vaquero, M. P. (2021). Foods for Plant-Based Diets: Challenges and Innovations. Foods, 10(2), 293. https://doi.org/10.3390/foods10020293.

Aluko, R. E., Mofolasayo, O. A., & Watts, B. M. (2009). Emulsifying and foaming properties of commercial yellow pea (Pisum sativum L.) seed flours. Journal of Agricultural and food Chemistry, 57(20), 9793–9800. https://doi.org/10.1021/jf902199x.

Aziah, A. A. N., & Komathi, C. A. (2009). Physicochemical and functional properties of peeled and unpeeled pumpkin flour. Journal of Food Science, 74(7), S328–S333. https://doi.org/10.1111/j.1750-3841.2009.01298.x.

Badia-Olmos, C., Laguna, L., C., Haros., & Tárrega, A. (2023). Techno-functional and rheological properties of alternative plant-based flours. Foods, 12(7). https://doi.org/10.3390/foods12071411.

Bayarri, S., Costell, E., & Dura, L. (2002). Influence of low sucrose concentrations on the compression resistance of gellan gum gels. Journal of Fod Hydrocolloids, 16(6), 593–597. https://doi.org/10.1016/S0268-005X(02)00021-8.

Berggren, S. (2018). Water holding capacity and viscosity of ingredients from oats: the effect of b-glucan and starch content, particle size, pH and temperature (Dissertation). http://urn.kb.se/resolve?urn=urn:nbn:se:lnu:diva-70544.

botanical origins. Journal of food Science, 85(12), 4130–4140. https://doi.org/10.1111/1750-3841.15501.

Boye, J. I., Aksay, S., Roufik, S., Ribéreau, S., Mondor, M., Farnworth, E., & Rajamohamed, S. H. (2010). Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Research International, 43(2), 537–546. https://doi.org/10.1016/j.foodres.2009.07.021.

Bravo-núñez, Á., & Gómez, M. (2021). Enrichment of cakes and cookies with pulse flours. A review. Food Reviews International, 1–19. https://doi.org/10.1080/87559129.2021.1983591.

Bravo-Núñez, Á., Garzón, R., Rosell, C. M., & Gómez, M. (2019). Evaluation of Starch-Protein interactions as a function of pH. Food (Basel Switzerland), 8(5), 155. https://doi.org/10.3390/foods8050155.

Du, S., Jiang, H., Yu, X., & Jane, J. (2014). Physicochemical and functional properties of whole legume flour. LWT - Food Science and Technology, 55(1), 308–313. https://doi.org/10.1016/j.lwt.2013.06.001.

Escobedo, A., & Mojica, L. (2021). Pulse-based snacks as functional foods. Processing challenges and biological potential. Comprehensive Reviews In Food Science And Food Safety, (2021 20). 4678– 4702. https://doi.org/10.1111/1541-4337.12809.

Ettoumi, L. Y., & Chibane, M. (2015). Some physicochemical and functional properties of pea, chickpea and lentil whole flours. International Food Research Journal, 22(3), 987–996.

Farooq, Z., & Boye, J. I. (2011). Novel food and industrial applications of pulse flours and fractions. Pulse Foods (1st ed.). Elsevier Ltd. https://doi.org/10.1016/B978-0-12-382018-1.00011-3.

Jiménez, M. J., Tárrega, A., Fuentes, R., Canet, W., & Álvarez, M. D. (2016). Consumer perceptions, descriptive profile, and mechanical properties of a novel product with chickpea flour: Effect of ingredients. Food Science and Technology, International22(6), 547–562. https://doi.org/10.1177/1082013216639452.

Joshi, M., Aldred, P., Panozzo, J. F., Kasapis, S., & Adhikari, B. (2014). Food Hydrocolloids Rheological and microstructural characteristics of lentil starch lentil protein composite pastes and gels. Food Hydrocolloids, 35, 226–237. https://doi.org/10.1016/j.foodhyd.2013.05.016.

Karaca, A. C., Low, N., & Nickerson, M. (2011). Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Research International, 44(9), 2742–2750. https://doi.org/10.1016/j.foodres.2011.06.012.

Kaur, K., & Singh, N. (1999). Effect of acetic acid and CMC on rheological and baking properties of flour. Journal of Food Quality, 22(3), 317–327. https://doi.org/10.1111/j.1745-4557.1999.tb00560.x.

Kim, R., & Ahn, S. (1996). Gelling properties of Acid-Modified Red Bean Starch gels. Applied Biological Chemistry, 39, 49–53.

Kumitch, H. M., Stone, A. K., Korber, D. R., Tanaka, T., & Nickerson, M. T. (2020). Effect of fermentation time on the physicochemical and functional properties of pea protein-enriched flour fermented by Aspergillus oryzae and Aspergillus niger. Cereal Chemistry. 2020; 97: 416– 428. https://doi.org/10.1002/cche.10257.

Li, W., Xiao, X., Guo, S., Ouyang, S., Luo, Q., Zheng, J., & Zhang, G. (2014). Proximate composition of triangular pea, White Pea, spotted Colored pea, and small white kidney Bean and their Starch Properties. Food and Bioprocess Technology, 7(4), 1078–1087. https://doi.org/10.1007/s11947-013-1128-2.

Lu, Z. X., He, J. F., Zhang, Y. C., & Bing, D. J. (2020). Composition, physicochemical properties of pea protein and its application in functional foods. Critical Reviews in Food Science and Nutrition, 60(15), 2593–2605. https://doi.org/10.1080/10408398.2019.1651248.

Luo, S., & Koksel, F. (2020). Physical and technofunctional properties of yellow pea flour and bread crumb mixtures processed with low moisture extrusion cooking. Journal of Food Science, 85, 2688–2698. https://doi.org/10.1111/1750-3841.15385.

Maia, L. C., Maria, R., Nano, W., Oliveira, F. S., De, Barros, C. O., Elizabeth, K., & Miranda, D. S. (2021). Evaluation of the nutritional quality of cereal bars made with pulse flours using desirability functions. Food Society and Technology International, 1–10. https://doi.org/10.1177/1082013220983080.

Manassero, C. A., Beaumal, V., Vaudagna, S. R., Speroni, F., & Anton, M. (2018). Calcium addition, pH and high hydrostatic pressure effects on soybean protein isolates—part 2: Emulsifying Properties. Food and Bioprocess Technology, 11(11), 2079–2093. https://doi.org/10.1007/s11947-018-2164-8.

Miquelim, J. N., Lannes, S. C. S., & Mezzenga, R. (2010). pH influence on the stability of foams with protein-polysaccharide complexes at their interfaces. Food Hydrocolloids, 24(4), 398–405. https://doi.org/10.1016/j.foodhyd.2009.11.006.

Mondor, M., & Hernández-Álvarez, A. J. (2022). Processing technologies to produce plant protein concentrates and isolates. In A. Manickavasagan, L. T. Lim, & A. Ali (Eds.), Plant Protein Foods. Springer. https://doi.org/10.1007/978-3-030-91206-2_3.

Motta, H., & Zhang, Y. (2019). Physicochemical properties and rheological behavior of flours and starches from four bean varieties for gluten-free pasta formulation. Journal of Agriculture and Food Research, 1(149), 100001. https://doi.org/10.1016/j.jafr.2019.100001.

Osemwota, E. C., Alashi, A. M., & Aluko, R. E. (2021). Comparative study of the Structural and Functional properties of membrane-isolated and isoelectric pH precipitated Green Lentil seed protein isolates. Membranes, 11(9), 694, 1–24. https://doi.org/10.3390/membranes11090694.

Pais, D. F., Marques, A. C., & Fuinhas, J. A. (2022). The cost of healthier and more sustainable food choices: Do plant-based consumers spend more on food? Agricultural and food Economics, 10(1), 18. https://doi.org/10.1186/s40100-022-00224-9.

Pang, Z., Cao, J., Li, H., Chen, C., & Liu, X. (2020). Rheology and tribology properties of cereal and legume flour paste from different.

Patrascu, L., Vasilean, I., Banu, I., & Aprodu, I. (2017). Functional properties of pulse flours and their opportunities in spreadable food products. Quality Assurance & Safety of Crops and Food, 9(1), 67–78. https://doi.org/10.3920/QAS2015.0770.

Pedrosa, M. M., Varela, A., Domínguez-Timón, F., Tovar, C. A., Moreno, H. M., Borderías, A. J., & Díaz, M. T. (2020). Comparison of Bioactive compounds Content and Techno-Functional properties of pea and Bean flours and their protein isolates. Plant Foods for Human Nutrition, 75(4), 642–650. https://doi.org/10.1007/s11130-020-00866-4.

Peng, Y., Putu, D., Pradnya, A., Kyriakopoulou, K., Goot, A. J., & Van Der (2020). Effect of calcium hydroxide and fractionation process on the functional properties of soy protein concentrate. Innovative Food Science and Emerging Technologies, 66(August), 102501. https://doi.org/10.1016/j.ifset.2020.102501.

Rachwa-Rosiak, D., Nebesny, E., & Budryn, G. (2015). Chickpeas—composition, nutritional value, health benefits, application to bread and snacks: A review. Critical Reviews in food Science and Nutrition, 55(8), 1137–1145.

Renkema, J. M., Gruppen, H., & van Vliet, T. (2002). Influence of pH and ionic strength on heat-induced formation and rheological properties of soy protein gels in relation to denaturation and their protein compositions. Journal of Agricultural and food Chemistry, 50(21), 6064–6071. https://doi.org/10.1080/10408398.2012.687418.

Salinas, M. V., Zuleta, A., Ronayne, P., & Puppo, M. C. (2012). Wheat flour enriched with calcium and inulin: A study of hydration and Rheological properties of Dough. Food and Bioprocess Technology, 5(8), 3129–3141. https://doi.org/10.1007/s11947-011-0691-7.

Shevkani, K., Singh, N., Chen, Y., & Kaur, A. (2019). Pulse proteins: Secondary structure, functionality and applications. Journal of Food Science and Technology, 56(6), 2787–2798. https://doi.org/10.1007/s13197-019-03723-8.

Shi, Y., & Seib, P. A. (1992). The structure of four waxy starches related to gelatinization and retrogradation. Carbohydrate Research. 227, 131–145, https://doi.org/10.1016/0008-6215(92)85066-9.

Shim, J., & Mulvaney, S. J. (2001). Effect of heating temperature, pH, concentration and starch/whey protein ratio on the viscoelastic properties of corn starch/whey protein mixed gels. Journal of Science of Food and Agriculture, 81, 706. https://doi.org/10.1002/jsfa.869.

Singh, A., & Sit, N. (2022). Meat analogues: Types, methods of production and their effect on attributes of developed meat analogues. Food and Bioprocess Technology, 2664–2682. https://doi.org/10.1007/s11947-022-02859-4.

Sosa, E. F., Thompson, C., & Chaves, M. G. (2020). Legume seeds treated by high hydrostatic pressure: Effect on Functional properties of Flours. Food and Bioprocess Technology, 13, 323–340. https://doi.org/10.1007/s11947-019-02386-9.

Sreerama, Y. N., Sashikala, V. B., Pratape, V. M., & Singh, V. (2012). Nutrients and antinutrients in cowpea and horse gram flours in comparison to chickpea flour: Evaluation of their flour functionality. Food Chemistry, 131(2), 462–468. https://doi.org/10.1016/j.foodchem.2011.09.008.

Sun-Waterhouse, D., Zhao, M., & Waterhouse, G. I. N. (2014). Protein modification during ingredient Preparation and Food Processing: Approaches to Improve Food Processability and Nutrition. Food and Bioprocess Technology, 7(7), 1853–1893. https://doi.org/10.1007/s11947-014-1326-6.

Tárrega, A., Rizo, A., Murciano, A., Laguna, L., & Fiszman, S. (2020). Current research in Food Science are mixed meat and vegetable protein products good alternatives for reducing meat consumption? A case study with burgers. Current Research in Food Science, 3, 30–40. https://doi.org/10.1016/j.crfs.2020.02.003.

Torres, M. D., Raymundo, A., & Sousa, I. (2014). Influence of Na+, K+ and Ca2+ on mechanical and structural properties of gels from chestnut and rice flours. Carbohydrate Polymers, 102, 30–37. https://doi.org/10.1016/j.carbpol.2013.11.018.

Van Kleef, F. S. (1986). Thermally induced protein gelation: Gelation and rheological characterization of highly concentrated ovalbumin and soybean protein gels. Biopolymers, 25(1), 31–59. https://doi.org/10.1002/bip.360250105.

Xu, J., Carson, B., & Kim, S. (2015). The pH dependence on the rheology of wheat protein isolate suspensions. Polymer Sciences, 1(1), 1–7. https://doi.org/10.21767/2471-9935.100005.

Acknowledgements

The authors are grateful to the Dacsa group (Valencia, Spain) for providing pulse flours used in this study. Thanks to Spanish government MCIN/AEI to the Center of Excellence Accreditation Severo Ochoa (CEX2021-001189-S/ MCIN/AEI / https://doi.org/10.13039/501100011033). The authors also acknowledge the Algerian government for the scholarship offered to Djemaa Moussaoui giving an opportunity to perform this study.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. The research leading to these results received funding from MCIN/ AEI/https://doi.org/10.13039/501100011033, project PID2019 107723RB-C21.

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature.

Author information

Authors and Affiliations

Contributions

Djemaa Moussaoui and Amparo Tarrega designed the study and wrote the manuscript; Djemaa Moussaoui and Celia Badia-Olmos carried out experimental work. Djemaa Moussaoui, Carolina Chaya and Arantxa Rizo performed data analysis, Carolina Chaya and Arantxa Rizo revised the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

Authors declare to not have conflict of interest when publishing this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moussaoui, D., Chaya, C., Badia-Olmos, C. et al. Effect of pH and Calcium on the Techno Functional Properties of Different Pulse Flours, Pastes, and Gels. Food Bioprocess Technol 17, 2292–2303 (2024). https://doi.org/10.1007/s11947-023-03264-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03264-1