Abstract

Animal-based foods have a large impact on the environment; for this reason, plant-based meat analogous are now in the spotlight. Although protein concentrates/isolates from soy are the most used raw materials for meat analogues, some concerns about allergenicity, loss of biodiversity, and low sustainability of their production rise from their uses. In this context, high protein fractions obtained by air classification of pulse flours are here proposed as substitutes of protein concentrates. Thus, this work is aimed at understanding the aptitude of high protein fraction from pulses to be transformed into meat analogous through high moisture extrusion process. Differences in functional and rheological properties among high protein fractions resulted in different high moisture extrusion properties and thus products with different appearance. Specifically, the foaming capacity of high protein fraction from red lentil resulted in expansion at the end of the extruder creating a heterogeneous structure, whereas the high lipid content of high protein fraction from chickpea can account for the unsuitability of this raw material to high moisture extrusion. On the contrary, high protein fraction from both fava bean and yellow pea presented a fibrous structure. However, the structure and textual properties of the final products need to be further investigated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The term “meat analogue” describes food products that are made of protein sources other than animal ones and reproduce meat with respect to taste, texture, and appearance. Both nutritional and environmental reasons drove the interest in meat analogues (Andreani et al., 2023; Thavamani et al., 2020). High consumption of meat is indeed linked to an increased risk of several health diseases like cardiovascular disease and type 2 diabetes (Richi et al., 2015). Moreover, meat products are less sustainable than plant ones (Gerber et al., 2013).

Various technologies have been proposed to develop meat analogues, including extrusion, shear cell, high temperature induced shearing with Couette Cell technology, 3D printing, wet spinning, and electrospinning. The potential and challenges of these techniques have been the objective of several reviews (Lee et al., 2023; Singh & Sit, 2022; Boukid, 2021). Among them, extrusion is one of the most applied technologies to produce meat analogues. It is a cost-effective process able to produce-due to both thermal and mechanical stresses-a desirable fibrous structure that can mimic meat functionality. Extrusion can be performed at a low (< 40%) or high (> 40%) moisture level. In the first case, the immediate expansion of the product is due to the rapid evaporation of water at the end of the extruder. The obtained intermediate product (called texturized vegetable proteins or TVP) needs to be rehydrated to obtain a fibrous and spongy structure. In the high moisture extrusion process, raw materials are hydrated (> 40% moisture content), subjected to thermomechanical stresses and then forced through a cooling die (Wittek et al., 2021). Due to the shear, thermal stress, pressure, and final cooling, proteins are denatured, realigned, and cross-linked (Zahari et al., 2020), inducing a fibrous structure.

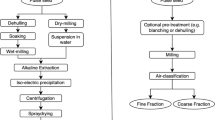

The most used raw materials in high moisture extrusion are protein isolated from soy, pea, wheat, and rice (Bakhsh et al., 2022). More recently, the effect of extrusion on the functional characteristics of TVP from hempseed was studied (Rajendra et al., 2023). In this study, we decided to investigate the potentiality of other botanical sources (i.e., faba bean, chickpea, and red lentil). However, the use of protein isolates/concentrates has some limitations, mostly due to functionality loss during their production that involves the use of large amount of water, energy, and solvents (Grandison et al., 1996). In this context, dry separation processes have been proposed to separate plant proteins while maintaining their functionality (Schutyser et al., 2015). Among them, air classification allows to separate flour into particles differing in size and density and thus in chemical composition: a fine fraction rich in proteins (also called high protein fraction) and a coarse one in carbohydrates. The composition of the air classified fractions can be controlled by setting the classifier wheel speed and the air flow through the classifier wheel. Classifier wheel speed and air flow are inversely proportional to the cut point, which is the size where a particle has an equal chance to end up in the fine or in the coarse fraction: the lower the cut point, the smaller the average diameter of the particles in the fine fraction, which in turn increases the protein content of the fine fraction (Funke et al., 2022).

Although the functional and nutritional features of air-classified fractions from limited number of pulses have been investigated (do Carmoet al., 2020; Martinez et al., 2016), studies about the use of high protein fractions obtained by air classification to produce meat analogues are scarce and limited to a pea-oat mixture processed through a low-moisture extrusion-cooking process (De Angelis et al., 2020). Thus, this study exploring the potential use of high protein fractions rather than protein isolates in meat analogues produced by high moisture extrusion.

Taking into consideration the interest in meat-analogue production and the actual knowledge gap in the state of the art (i.e., lack of information about the relation between the characteristics of high protein fractions and their application in high moisture extrusion), the aim of this short note was to rapidly communicate the aptitude of high protein fractions – that were obtained by the air classification of various type of pulses-to be processed into meat analogues. To the best of our knowledge, this is the first time that high protein fractions from chickpea, red lentil, yellow pea, and fava beans are compared for their functional, pasting, and mixing properties in relation to their extrusion properties for the production of meat analogues.

Materials and Methods

High Protein Enriched Fractions and Their Properties

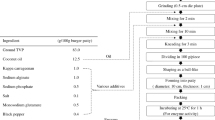

Commercial high protein fractions obtained applying air classification to red lentil, yellow pea, fava bean, and chickpea were provided by Müller’s Mühle GmbH (Gelsenkirchen, Germany). Protein (AACC 46-19.01), fiber (AACC 32-10.01), lipid (AACC 30-10.01), and carbohydrate (by difference) content are reported in Table 1.

Water absorption capacity and oil absorption capacity were evaluated as reported by Bresciani et al. (2022a), whereas foaming capacity and foaming stability were assessed as reported by Yadav et al. (2012).

The pasting properties were evaluated using the ViscoQuick (Brabender GmbH & Co. KG, Duisburg, Germany), by dispersing 25 g of sample in 75 ml of distilled water scaling both sample and water weight on a 14% flour moisture basis. Slurries were subjected to the following temperature profile: heating from 50 °C up to 92 °C, holding at 92 °C for 10 min and cooling from 95 °C to 50 °C with a heating/cooling rate of 3 °C/min.

The mixing properties were measured by using the Farinograph-TS® (Brabender GmbH & Co. KG, Duisburg, Germany) equipped with a 300-g mixing bowl at a constant hydration level (i.e., 50% on dry matter as reported by Bresciani et al. (2022b).

High Moisture Extrusion

High moisture extrusion was carried out using a twin-screw extruder TwinLab-F20/40 (Brabender GmbH & Co. KG, Duisburg, Germany) equipped with a modular cooling die. The following parameters were adopted: throughput, 2 kg/h; feed moisture, 50%; melt temperature, 115 °C; and screw speed, 1000 rpm. As discussed below, these conditions were not suitable for high protein fraction from chickpea and red lentil. Thus, for these two raw materials, a textured vegetable protein (TVP) process was carried out using a twin-screw extruder TwinLab-F20/40 (Brabender GmbH & Co. KG, Duisburg, Germany) equipped with a round die head and adopting the following conditions: throughput, 2 kg/h; feed moisture, 30%; melt temperature, 130 °C; and screw speed: 750 rpm.

Statistics

The pasting and mixing properties were carried out in triplicate, and one representative curve for each sample was reported. Functional properties (i.e., water absorption capacity, oil absorption capacity, foaming capacity, and foaming stability) were carried out in triplicate, and the results were expressed as mean ± standard deviation. Analysis of variance (one-way ANOVA) was assessed by Statgraphics Plus 5.1 (StatPoint Inc., Warrenton, USA) using the samples as factors. The significant differences (p < 0.05) were determined by using Tukey’s Honestly Significant Difference (HSD) test. Data from functional properties, as well as final viscosity and maximum consistency, were processed by principal component analysis (PCA) by using Unscramble software.

Results and Discussion

In the first part of the study, some functional properties, including hydration, foaming, pasting, and mixing properties, of the raw materials were evaluated. Particularly, the features of fractions enriched in protein that were obtained by air classification of chickpea, red lentil, faba bean, and yellow pea were compared and for the first time related to the extrusion properties through extrusion at high moisture level.

Functional Properties

High protein fraction from red lentil exhibited significantly higher water absorption capacity than the value found in high protein fraction from chickpea (Table 1). This suggests that in high protein fraction from chickpea, there is a lower availability of polar sites interacting with water. Differences between the fractions from red lentil and chickpea can be explained by their different chemical composition, having the fraction from red lentil a higher protein content and a lower lipid and carbohydrate content than chickpea fraction (Table 1). Although other components than protein content (e.g., fiber and starch) impact on water absorption capacity (Du et al., 2014), no relation between chemical composition (Table 1) and water absorption capacity was found for this set of samples, suggesting that the botanical source, type of proteins, and their functionality could prevail on chemical composition. Indeed, functional properties of food proteins depend on various factors, including amino acid composition, protein structure and conformation (which are determined by the botanical origin), and the interactions that occur between proteins and other food components (e.g., fats, carbohydrates, and phenolics) (Boye et al., 2010).

Recently, De Angelis et al. (2021) investigated the effect of air classification on the chemical composition and functional properties of high-protein fractions obtained by the air classification of pulses. The authors found that water absorption capacity of protein rich fractions followed the order: red lentils > yellow and green pea > chickpea, which is partially in agreement with our results (Table 2). Both the variety used and the air-classifier settings certainly impact on the chemical composition (e.g., protein, fiber) and functional properties of the fractions.

As regard oil absorption capacity, high protein fraction from chickpea showed the highest value that was significantly different from that found in yellow pea (Table 2), suggesting higher hydrophobicity/non-polar amino acid side chains. The highest oil absorption capacity of high protein fractions from chickpea is in agreement with its high lipid content (Table 1).

As regard foaming capacity, high protein fraction from red lentil and faba bean showed the highest and lowest foaming capacity and foaming stability (Table 2), which represent the ability to form a foam and the ability to maintain it stable, respectively. Such indices generally depend on the interfacial film formed by proteins, which maintains the air bubbles in suspension and slows down the rate of coalescence. The high foaming capacity of sample from red lentil could suggest high surface activities of soluble proteins in the water phases (Sosa et al., 2020). The low foaming stability of fraction from faba bean compared to the other samples is in agreement with previous studies that were recently reviewed by Boukid and Castellari (2022).

The functional properties of pulse proteins have been discussed in various reviews, including those of Boye et al. (2010) and Foschia et al. (2017). Even considering the same botanical species, variations in the results from different studies could be due to differences in the protein purity/content of the samples studied as well as the specific conditions used for the foaming tests (Boye et al., 2010).

Pasting Properties

The ability to form a gel under heating and cooling conditions is another techno-functional property to consider since it is related to the capability of proteins to form a three-dimensional network. The study of pasting properties, generally, gives information regarding the ability of starch to form a gel upon thermal treatments. Regarding high protein fractions, protein denaturation, aggregation, and gelation also play a decisive role in pasting properties. Indeed, in this study, the change in viscosity upon heating and cooling was mainly due to protein fractions, because of the low starch content in the samples, and the sample:water ratio used during the test. Indeed, although high protein fraction from chickpea and from yellow pea exhibited different carbohydrate content (Table 1), their pasting profile was similar (Fig. 1A). At the same time, the pasting profile of high protein fractions seemed not to be affected by the protein content: The lowest pasting profile was shown by the fraction from faba beans which was characterized by the highest protein content. Such results suggest that protein type and properties might account for the differences among the samples, with the sample from red lentil showing the greatest gelling capacity.

Pasting profiles are in line with functional properties (Table 2): high protein fraction from red lentil showed the highest viscosity and foaming capacity, while the fraction from faba bean showed the lowest viscosity and foaming capacity. The greater tendency of sample from red lentil to absorb water could have an effect in creating a more consistent paste, and its greater foaming capacity could result in greater viscosity. In contrast, high protein fraction from faba bean showed the lowest foaming capacity and consequently lower viscosity during the test. In this case, low carbohydrate content (i.e., starch) might account for the low viscosity. Finally, the fraction from yellow pea showed a decrease in viscosity during the holding phase at high temperature suggesting lower stability to both thermal and mechanical stress (considering that the sample was kept under stirring during all the analysis). The pasting properties profiles of the other samples did not show this loss of viscosity; on the other hand, their viscosity continued to increase during the holding period at 92 °C, suggesting that the protein modification were not completed.

Mixing Properties

Even though pulse proteins are not able to aggregate into a network like gluten, they are able to create a cohesive mass with measurable consistency (Fig. 1B). The rheological behavior of high protein fractions showed a trend related to the amount of protein: the sample from chickpea (with 37% proteins) shows the lowest dough consistency, while the consistency of the fraction from red lentil (51% proteins), from yellow pea (52% proteins), and from faba bean (58% proteins) increased proportionally with the increase in protein content. The lack of studies on the mixing properties of air-classified fractions from pulses makes the discussion of the results difficult.

Principal Component Analysis

Exploratory multivariate analysis via PCA was used to explore the data further and provide additional discriminatory power. The PCA in Fig. 2A shows the distribution of the high protein fractions according to the indices described above. The first two principal components provided a good summary of the data, accounting for about 84% of the total variance (PC 1 = 46%; PC 2 = 38%). Moreover, the loading plot (Fig. 2B) distinguishes the variables affecting sample distributions, which are those more distant from the origin of the plot. Specifically, the sample in quadrant I (i.e., high protein fraction from chickpea) was separated by all the other samples for its high lipid, carbohydrate content, and oil absorption capacity. Sample in quadrant III (i.e., high protein fraction from red lentil) was characterized by high water absorption capacity and foaming capacity. Finally, samples in quadrant IV (i.e., high protein fraction from yellow pea and from faba bean) were separated from all the other samples for their high protein content and high maximum consistency during mixing (variables in quadrant IV in Fig. 2B) and by low carbohydrate content, foaming stability, and final viscosity after heating and cooling (variables in quadrant II in Fig. 2B).

Extrusion Properties

With regard to the high moisture extrusion process, high protein fractions from pulses showed different behaviors that led to the formation of products having different characteristics, especially regarding the formation of a fibrous structure capable of reproducing the functionality of meat (Fig. 3).

As for the high protein fraction from chickpea and from red lentil, it was not possible to obtain through high moisture extrusion a product characterized by a structure capable of reproducing meat: both raw materials did not show the ability to aggregate during the process (data not shown). The reason why the high protein fraction from chickpea did not perform adequately during the process could be due to the high amount of lipids (Table 1). Lipids, in fact, could act as a lubricant by decreasing the specific mechanical energy and therefore the mechanical stress during the process, leading to the inefficiency of the process. Similar results were found by De la Peña and Manthey (2017), who observed that the addition of flaxseed flour seeds during the extrusion process reduced the SME and thus the quality of the extruded product (i.e., pasta).

In the case of high protein fraction from red lentil as well, it was not possible to obtain a product through high moisture extrusion likely due to high foaming capacity (Table 2). It is likely that the presence of air (i.e., mixing was not carried out under vacuum) inside the dough made the process inhomogeneous because thermal and mechanical stress were not equally imparted to the dough during extrusion. Besides showing bubbles, the product from high protein fraction from red lentil tended to expand rather than creating a compact and fibrous structure. Therefore, the suitability of high protein fraction from chickpea and from red lentil during a TVP process was investigated. The purpose of this process is to create an expanded, honeycomb structure that should be later processed to produce meat analogues. No successful results were obtained in the case of high protein fraction from chickpea, suggesting that further investigations for optimizing the processing conditions are needed. On the other hand, in the case of high protein fraction from red lentil, it was possible to obtain an extruded product characterized by good expansion, as shown in Fig. 3.

The extrusion of high protein fraction from both yellow pea and faba bean led to good results for the production of extrudates through high moisture extrusion; in fact, the obtained products showed a meat-like structure (Fig. 3). These two raw materials were the ones that showed the highest farinographic consistency, suggesting that greater consistency is positively related to greater mechanical shear and consequently to greater efficiency of the extrusion process.

Conclusions

The use of high protein fractions from pulses seems to be a viable sustainable alternative to the use concentrated/isolated proteins. Functional, pasting, and mixing tests seem to be able to provide information on the behavior of these raw materials during the extrusion process. Specifically, high farinographic consistency is linked to product with desirable characteristics, whereas the worst results were obtained from samples showing the highest viscosity (pasting properties) and foaming capacity. Since the high lipid content in high protein fraction from chickpea negatively affected the extrusion properties, further studies will consider the use of defatted chickpeas to reduce the negative impact they have, as well as the use of blends in order to combine the functional properties of various fractions to obtain the best aptitude for high moisture extrusion. This short note provides useful information to understand the characteristics of high protein fractions from pulses that mainly affect their extrusion performance. Being the first study on the extrusion at high moisture level of fractions from the air classification of chickpea, red lentil, faba bean, and yellow pea for the production of meat analogues, further studies are needed to gather more information on the relation between this new ingredient (i.e., high protein fraction from air classification), processing conditions, and product quality, in terms of texture, sensory acceptability, and nutritional value.

Data Availability

All data generated or analyzed during this study are included in this published article and comply with research standards.

References

Andreani, G., Sogari, G., Marti, A., Froldi, F., Dagevos, H., & Martini, D. (2023). Plant-based meat alternatives: Technological, nutritional, environmental, market, and social challenges and opportunities. Nutrients, 15(2), 452.

Bakhsh, A., Lee, E. Y., Ncho, C. M., Kim, C. J., Son, Y. M., Hwang, Y. H., & Joo, S. T. (2022). Quality characteristics of meat analogs through the incorporation of textured vegetable protein: A systematic review. Foods, 11(9), 1242.

Boukid, F. (2021). Plant-based meat analogues: From niche to mainstream. European Food Research and Technology, 247(2), 297–308.

Boukid, F., & Castellari, M. (2022). How can processing technologies boost the application of faba bean (Vicia faba L.) proteins in food production? eFood, 3(3), e18.

Boye, J., Zare, F., & Pletch, A. (2010). Pulse proteins: Processing, characterization, functional properties and applications in food and feed. Food Research International, 43(2), 414–431.

Bresciani, A., Cardone, G., Jucker, C., Savoldelli, S., & Marti, A. (2022a). Technological performance of cricket powder (Acheta domesticus L.) in wheat-based formulations. Insects, 13(6), 546.

Bresciani, A., Annor, G. A., Gardella, M., & Marti, A. (2022b). Use of the farinograph for gluten-free grains. In J. E. Bock & C. Don (Eds.), The Farinograph Handbook (pp. 111–126). Woodhead Publishing.

De Angelis, D., Kaleda, A., Pasqualone, A., Vaikma, H., Tamm, M., Tammik, M. L., Squeo, G., & Summo, C. (2020). Physicochemical and sensorial evaluation of meat analogues produced from dry-fractionated pea and oat proteins. Foods, 9(12), 1754.

De Angelis, D., Pasqualone, A., Allegretta, I., Porfido, C., Terzano, R., Squeo, G., & Summo, C. (2021). Antinutritional factors, mineral composition and functional properties of dry fractionated flours as influenced by the type of pulse. Heliyon, 7(2).

de la Peña, E., & Manthey, F. A. (2017). Effect of formulation and dough hydration level on extrusion, physical and cooked qualities of nontraditional spaghetti. Journal of Food Processing Engineering, 40(1), e12301.

do Carmo, C. S., Silventoinen, P., Nordgård, C. T., Poudroux, C., Dessev, T., Zobel, H., Holtekjølen, A., K., Draget, K. I., Holopainen-Mantila, U., Knutsen, S. H., & Sahlstrøm, S. (2020). Is dehulling of peas and fava beans necessary prior to dry fractionation for the production of protein-and starch-rich fractions? Impact on physical properties, chemical composition and techno-functional properties. Journal of Food Engineering, 278, 109937.

Du, S. K., Jiang, H., Yu, X., & Jane, J. L. (2014). Physicochemical and functional properties of whole legume flour. LWT-Food Science and Technology, 55(1), 308–313.

Foschia, M., Horstmann, S. W., Arendt, E. K., & Zannini, E. (2017). Legumes as functional ingredients in gluten-free bakery and pasta products. Annual Review of Food Science and Technology, 8, 75–96.

Funke, M., Boom, R., & Weiss, J. (2022). Dry fractionation of lentils by air classification - Composition, interfacial properties and behavior in concentrated O/W emulsions. LWT-Food Science & Technology, 154, 112718.

Gerber, P., Steinfeld, H., Henderson, B., Mottet, A., Opio, C., Dijkman, J., Falcucci, A., & Tempio, G. (2013). Tackling climate change through livestock—A global assessment of emissions and mitigation opportunities. FAO.

Grandison, A. S., Grandison, A. S., & Lewis, M. J. (1996). Separation processes in the food and biotechnology industries: Principles and applications. Woodhead Publishing.

Lee, S. Y., Lee, D. Y., Jeong, J. W., Kim, J. H., Yun, S. H., Joo, S. T., Choi, I., Choi, J.S., Kim, G.D, & Hur, S. J. (2023). Studies on meat alternatives with a focus on structuring technologies. Food and Bioprocess Technology, 1–24.

Martinez, M., Stone, A. K., Yovchev, A. G., Peter, R., Vandenberg, A., & Nickerson, M. T. (2016). Effect of genotype and environment on the surface characteristics and functionality of air-classified fava bean protein concentrates. European Food Research and Technology, 242(11), 1903–1911.

Rajendra, A., Ying, D., Warner, R. D., Ha, M., & Fang, Z. (2023). Effect of extrusion on the functional, textural and colour characteristics of texturized hempseed protein. Food and Bioprocess Technology, 16(1), 98–110.

Richi, E. B., Baumer, B., Conrad, B., Darioli, R., Schmid, A., & Keller, U. (2015). Health risks associated with meat consumption: A review of epidemiological studies. International Journal for Vitamin and Nutrition Research, 85(1–2), 70–78.

Schutyser, M. A. I., Pelgrom, P. J. M., Van der Goot, A. J., & Boom, R. M. (2015). Dry fractionation for sustainable production of functional legume protein concentrates. Trends in Food Science and Technology, 45(2), 327–335.

Singh, A., & Sit, N. (2022). Meat analogues: Types, methods of production and their effect on attributes of developed meat analogues. Food and Bioprocess Technology, 15(12), 2664–2682.

Sosa, E. F., Thompson, C., Chaves, M. G., Acevedo, B. A., & Avanza, M. V. (2020). Legume seeds treated by high hydrostatic pressure: Effect on functional properties of flours. Food and Bioprocess Technology, 13(2), 323–340.

Thavamani, A., Sferra, T. J., & Sankararaman, S. (2020). Meet the meat alternatives: The value of alternative protein sources. Current Nutrition Reports, 9, 346–355.

Wittek, P., Ellwanger, F., Karbstein, H. P., & Emin, M. A. (2021). Morphology development and flow characteristics during high moisture extrusion of a plant-based meat analogue. Foods, 10(8), 1753.

Yadav, R. B., Yadav, B. S., & Dhull, N. (2012). Effect of incorporation of plantain and chickpea flours on the quality characteristics of biscuits. Journal of Food Science and Technology, 49(2), 207–213.

Zahari, I., Ferawati, F., Helstad, A., Ahlström, C., Östbring, K., Rayner, M., & Purhagen, J. K. (2020). Development of high-moisture meat analogues with hemp and soy protein using extrusion cooking. Foods, 9(6), 772.

Acknowledgements

The authors would like to thank Müller’s Mühle GmbH (Gelsenkirchen, Germany) for kindly providing the raw materials. This study is part of the project “Research and innovation network on food and nutrition Sustainability, Safety and Security (ONFoods),” funded under the National Recovery and Resilience Plan (NRRP) and Mission 4 Component 2 Investment 1.3 -Call for tender No. 341 of 15/03/2022 of Italian Ministry of University and Research funded by the European Union – Next Generation EU.

Funding

Open access funding provided by Università degli Studi di Milano within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Andrea Bresciani: methodology, formal analysis, investigation, data curation, writing—original draft preparation, visualization. Giulia Chiodaroli: formal analysis. Michael Landers: methodology. Jens Müller: methodology. Jessica Wiertz: conceptualization, resources, project administration. Alessandra Marti: conceptualization, resources, writing—review and editing, supervision, project administration.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bresciani, A., Chiodaroli, G., Landers, M. et al. A Short Communication on Functional, Rheological, and Extrusion Properties of High Protein Fractions from Pulses Obtained by Air Classification. Food Bioprocess Technol 17, 1539–1545 (2024). https://doi.org/10.1007/s11947-023-03220-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03220-z