Abstract

Aureobasidium pullulans NCYC 4012 was used to produce gluconic acid (GA) and fructo-oligosaccharides (FOS) from sugarcane molasses (ScM). For the first time, three types of bioreactors operating at different conditions of oxygenation—a stirred tank reactor (STR) operating under atmospheric pressure varying stirring rate, a pressurized STR under increased air pressure up to 4 bar of air, and an airlift reactor under atmospheric pressure varying aeration rate—were employed for GA and FOS biosynthesis by A. pullulans. The highest oxygenation conditions favored GA production in the three bioreactors, whereas the synthesis of FOS was not favored by high oxygen availability. GA yields close to 1 g·g−1 (grams of GA produced per grams of glucose consumed) were achieved in bioreactors under atmospheric pressure, and the highest titer of GA of 75 g·L−1 was obtained in the airlift bioreactor. In this last, the highest concentration of total FOS of 65 g·L−1 and yield of FOS of 0.58 g·g−1 were obtained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Aureobasidium pullulans is a black yeast-like fungus of considerable biotechnological importance owing to the large spectrum of extracellular enzymatic activities (e.g., xylanase, cellulase, esterase, α-amylase, glucose oxidase, transfructosylating enzymes), which enable the utilization of many substrate sources (glucose, sucrose, fructose, xylose, xylan, starch, inulin, cellulose, etc.) and the production of several metabolites (e.g., pullulan, organic acids, melanin, fructo-oligosaccharides (FOS), siderophore, Aureobasidin A, isomaltose) (Mishra et al., 2022; Wang et al., 2022).

The ability of some A. pullulans strains to produce gluconic acid (GA) from pure glucose has already been reported (Anastassiadis et al., 2008; Fernandes et al., 2021; Ma et al., 2018), although the GA synthesis from unrefined by-products has yet to be explored. Gluconic acid is an acid sugar belonging to the aldonic acid family, which has a GRAS status and is considered a bio-based additive for food, beverages, chemicals, pharmaceuticals, textiles, agricultural, and medicinal products (Ma et al., 2022). Recently, the prebiotic effect of GA was also described (Wojciechowska et al., 2020; Ząbek et al., 2020). These multifunctional applications are driving the global market of GA and its derivatives (e.g., gluconolactones and gluconates). Its industrial consumption will exceed 1.2 × 105 tons by 2024 (Ma et al., 2022) and is expected to reach a value of USD 1.8 billion in 2028 (Reports and Data, 2021). The microbial production of GA by A. pullulans occurs through a dehydrogenation reaction catalyzed by the enzyme glucose oxidase (GOx), which is mainly located in the cell wall and uses molecular oxygen as the electron acceptor (Ma et al., 2018). Half a mole of oxygen is consumed in the direct bioconversion of one mole of glucose to one mole of GA, making oxygen one of the principal substrates for GA production (Klein et al., 2002). Therefore, this GOx-catalyzed oxidation reaction of glucose is an extremely oxygen-consuming process and highly dependent on dissolved oxygen concentration (DOC). The importance of using high levels of DOC in A. pullulans cultures to improve GA productivity in pure glucose medium has been demonstrated, such as the use of highly aerated cultures obtained by increased agitation rate or total air pressure up to 4 bar (Fernandes et al., 2021).

Currently, pure glucose is gradually being replaced by agro-industrial by-products for GA microbial production to achieve high titers with a more economical and environmentally friendly bioprocess. Several alternative carbohydrate sources have been studied for the biosynthesis of GA, mainly by Aspergillus niger or Gluconobacter oxydans, such as banana must and corn starch (Alsaheb et al., 2022), concentrated cellulosic hydrolysate (Dai et al., 2022), sugarcane (Alsaheb et al., 2022) and beet molasses (Kelleci et al., 2023), sugarcane juice (Pal et al., 2019), corn stover hydrolysate (Zhou et al., 2019), and breadfruit hydrolysate (Ajala et al., 2016). Nevertheless, the production of GA by A. pullulans from low-cost and renewables substrates has never been attempted. Moreover, the potential advantages of using yeast like A. pullulans instead of filamentous fungi such as A. niger have already been described (Anastassiadis et al., 2008; Fernandes et al., 2021). In this context, this study intends to evaluate the potential of using sugarcane molasses as a cheap carbon source for GA synthesis. Sugarcane molasses (ScM) is a by-product obtained in the processing of sugarcane during the production of crystallized sugar. Approximately 0.5 tons of ScM are produced from 1 ton of sugarcane, estimating that about 5 million tons per year are obtained worldwide (Jo et al., 2021). ScM is a sugar-rich syrup containing a surplus of 43% sugars (mainly sucrose, followed by glucose and fructose), non-sugar compounds, polyphenols, several minerals, minute amounts of vitamins, and proteins (Jamir et al., 2021; Palmonari et al., 2020). Due to its exceptional composition, ScM is widely used as an ingredient in baking and animal feed (Jamir et al., 2021), but it is also a promising feedstock for microbial processes. The low price of ScM (around USD 150/ton)—20 to 30 times cheaper than glucose (Alsaheb et al., 2022; Chuenpraphai & Jaturapiree, 2019)—enables the utilization of ScM as an inexpensive source of glucose for GA production by A. pullulans.

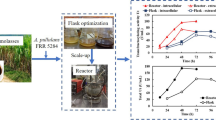

The main goal of this work was to evaluate the effect of different bioreactor types and oxygenation conditions on the production of GA by A. pullulans from low-cost ScM as a raw material. For that, (i) an STR operating at atmospheric pressure, (ii) a pressurized STR, and (iii) an airlift bioreactor were employed for the A. pullulans batch cultivations. Notably, no reports were found in the literature regarding the comparison of these types of bioreactors in the production of GA.

It should be highlighted that simultaneously with GA, fructo-oligosaccharides (FOS) production from ScM was also investigated. Aureobasidium pullulans secretes transfructosylating enzymes (e.g., β-D-fructofuranosidase (FFase) and fructosyltransferase (FTase)), which convert sucrose into FOS (Khatun et al., 2021a). FOS are carbohydrates resistant to the hard conditions of gastrointestinal digestion, reaching the colon almost intact for subsequent selective metabolization by probiotic bacteria. Therefore, FOS are considered prebiotics (Nobre et al., 2022; Roupar et al., 2022). The increased awareness of the health-beneficial effects of prebiotics by consumers is driving their global market. The prebiotic market is expected to grow from USD 6.3 billion in 2022 to USD 10.9 billion by 2027, with a CAGR of 11.7% during the forecast period (Markets & Markets, 2021). FOS synthesis by A. pullulans from ScM was already described (Khatun et al., 2020; Shin et al., 2004), but the simultaneous production of GA and FOS in this sucrose-rich substrate was never reported. Thus, the impact of bioreactor typology and oxygenation conditions on FOS biosynthesis was also assessed. The biotransformation of low-value ScM into high-value GA and FOS reduces the surplus of this by-product, increasing the sugarcane industry’s revenue and reducing the global costs of both metabolites’ production, introducing this novel process in the biorefinery concept.

Materials and Methods

Microorganism

The yeast-like fungus Aureobasidium pullulans NCYC 4012, isolated from the shell of unknown beetle species (Norwich, Norfolk, UK), was obtained from the National Collection of Yeast Cultures (UK).

Aureobasidium pullulans NCYC 4012 cells were pre-grown in Erlenmeyer flasks filled with a YPD medium (10 g∙L−1 yeast extract, 10 g∙L−1 peptone, and 20 g∙L−1 glucose) for 4 days at 28 °C and 200 rpm in an orbital shaker. The culture was stored at − 80 °C with 30% (v/v) pure glycerol (cryo-stock) until be used in pre-inoculum preparation for the batch production of GA. Pre-inoculum cultures were prepared in Erlenmeyer flasks by inoculating one cryo-stock in YPD medium and incubated for 4 days at 28 °C and 200 rpm. Cells were harvested by centrifugation (10,000 rpm, 5 min) and resuspended in the medium production at an initial cell density of 0.5 g·L−1.

Characterization of Sugarcane Molasses

Sugarcane molasses (ScM 1 and ScM 2, collected at 2 different times), kindly supplied by a sugar refinery company located in the North region of Portugal, was sterilized at 115 °C for 30 min (to avoid sugars caramelization) and stored at − 20 °C until use. The total content of sugars from the molasses ranged from 600 g·L−1 to 670 g·L−1, with sucrose (71–88%) being the main sugar in both molasses (Table 1).

Bioreactor Batch Experiments

Aureobasidium pullulans cells, pre-grown for 4 days in YPD medium, were centrifuged (10,000 rpm, 5 min) and resuspended (at an initial cell density of 0.5 g·L−1) in the ScM-based medium (diluted ScM with distilled water to attain 110 g·L−1 ± 10 g·L−1 of glucose + sucrose and 3.5 g·L−1 CaCO3, pH 6.5). The culture medium was sterilized at 115 °C for 30 min (0.69 bar of relative pressure).

STR at Atmospheric Pressure: Effect of Agitation Rate

A 2-L lab-scale STR (BIOLAB, B. Braun, Germany) filled with 1 L of ScM1-based medium, at 28 °C and a specific air flow rate of 1 vvm (1 L·min−1) at atmospheric pressure, was used to evaluate the effect of agitation rate (400 rpm and 600 rpm) for 96 h. The medium pH was measured with a probe (405-DPAS-SC-K8S/325, Metler Toledo, Urdorf, Switzerland) and kept at 6.5 ± 0.5 by the automatic addition of NaOH 3 M or H3PO4 21% (v/v). Dissolved oxygen concentration (DOC) in the culture medium was measured with a polarographic oxygen probe (InPro6820/12/320 T-type, Metler Toledo) and the respective meter (type 170). STR is a glass cylinder of 0.11 m diameter (total area 0.0095 m2; ratio H/D is 2) equipped with an impeller with two Rushton turbines with 6 vertical blades (0.056 m diameter). The distance between the turbines is 0.064 m, the ratio turbine diameter/vessel diameter is 0.51, and the vessel has no baffle plates.

Pressurized STR: Effect of Total Air Pressure

A stainless steel STR (PARR 4563, Parr Instruments, USA) with a total capacity of 600 mL was used to evaluate the effect of total air pressure (1 bar and 4 bar). These experiments were performed for 96 h with 400 mL of ScM1-based medium at 400 rpm, 28 °C, 1 vvm (standard conditions of temperature and pressure), and a pH of 6.5, which was adjusted after all samplings with NaOH 2 M. Total internal pressure was established by manipulating the inlet air pressure and the regulatory valve in the exit gas line, and it was monitored by a pressure transducer (PARR 4842, PARR Instruments, USA). Stainless steel STR is a cylinder of 0.063 m diameter (total area 0.00312 m2; ratio H/D is 3) equipped with an impeller with two turbines of four pitched blades (0.035 m diameter). The distance between the turbines is 0.08 m, the ratio turbine diameter/vessel diameter is 0.56, and the vessel has no baffle plates.

Airlift Bioreactor: Effect of Aeration Rate

A 5-L lab-scale airlift bioreactor was used to evaluate the effect of aeration rate (1 vvm–3.5 L·min−1 and 2 vvm–7 L·min−1). The batch experiments were performed with 3.5 L of ScM2-based medium at 28 °C for 168 h, and the medium pH was measured with a probe (InPro 3253i/SG/325, Metler Toledo) and kept at 6.5 ± 0.5 by the automatic addition of NaOH 3 M. The airlift bioreactor has 0.7 m of inside diameter and is constructed in glass. The riser tube has an inside diameter of 0.032 m and 0.37 m of height. Air was fed at the bottom of the bioreactor by a five holes sparger and used as the gas stream in the gas–liquid contactor. Dissolved oxygen concentration in the culture medium was measured with an optical oxygen probe (InPro6860i/12/320/mA Ex, Metler Toledo, Urdorf, Switzerland) and the respective meter (Solaris Biotechnology SRL, Italy).

Estimation of Oxygen Transfer Rate (OTR)

The estimation of kLa values in the STR operating at atmospheric pressure and airlift bioreactor was performed in blank assays (water) at 28 °C by the static gassing-out technique, as described in Ferreira et al. (2016).

In the pressurized bioreactor, OTR was estimated in blank assays (water) by the sulfite oxidation method, at 28 °C, 1 vvm of air flow rate, 400 rpm of agitation, and two values of total air pressure (1 bar and 4 bar), as described by Lopes et al. (2013).

Analytical Methods

Culture samples were collected twice daily for cellular concentration, pH, sugars, GA, and FOS concentration analysis. Cellular concentration was quantified by cell counting in an optical microscope (Leica DM 750, Wetzlar, Germany) and converted to cell dry weight (g·L−1) using a conversion factor. Culture samples were centrifuged at 9000 rpm for 10 min, and the supernatant was stored at − 20 °C. Before HPLC analysis, the supernatants were filtered using a 0.22 µm acetate cellulose syringe filter. GA and sugars (ScM and samples) were measured by HPLC, using an Aminex HPX-87H column (300 mm × 7.8 mm, 8 µm particle size) at 25 °C and coupled with a UV detector (λ = 210 nm). Sulfuric acid 0.1 M was used as the mobile phase at 0.5 mL·min−1 flow rate. The FOS concentration was quantified by HPLC equipped with a RI detector (working at 30 °C), an Asahipak NH2P-50G 4A, 4.6 mm × 10 mm (Shodex) pre-column, and an Asahipak NH2P-50 4E column, 4.6 × 250 mm, 5 µm particle size (Shodex). A mixture of acetonitrile (HPLC Grade) in pure water (70:30, v/v), containing 0.04% ammonium hydroxide in water, was used as a mobile phase at a flow rate of 1 mL·min−1 (Roupar et al., 2022). Total phenols were quantified by the Folin–Ciocalteu protocol (Commission Regulation (EEC) No. 2676/90), using gallic acid as standard. The total nitrogen was measured spectrophotometrically using the kit LCK 338 (Hach-Lange GmbH, Berlin, Germany).

Statistical Analysis

The statistical analysis was carried out using the IBM SPSS Statistics 27 software. One-way ANOVA, coupled with Tukey’s post hoc test, was used to determine significant differences (p < 0.05).

Results and Discussion

Gluconic Acid Production

STR at Atmospheric Pressure: Effect of Agitation Rate

GA is obtained by the direct oxidation of glucose, and this reaction has a high oxygen demand (Dubey et al., 2017). High-cell density cultures and the use of complex by-products from the food industry (e.g., molasses) as substrates can be a challenge due to the viscosity increase of the medium, particularly in GA microbial production. The oxygen transfer rate (OTR) from the gaseous phase to the culture medium is highly affected by the volumetric oxygen transfer coefficient (kLa) that decreases with medium viscosity (Lopes et al., 2014). One strategy to enhance the kLa in STR bioreactors, and consequently the OTR, is by increasing the agitation rate, which was already proven to have a positive effect on GA production from pure glucose by A. pullulans NCYC 4012. In the lab-scale STR bioreactor used in this study, a 2.4-fold improvement of OTR was attained by increasing the agitation rate from 400 to 600 rpm (Table 2).

Though the complex composition of ScM and the presence of phenolic compounds (Table 1), no inhibitory effects on A. pullulans growth were observed, and the biomass yields are in the range of others obtained with pure glucose by the same strain (Fernandes et al., 2021), and with pretreated ScM (Srikanth et al., 2014) and beet molasses (Roukas & Liakopoulou-kyriakides, 1999) by other strains of A. pullulans, and by a mutant strain of A. pullulans (Feng et al., 2018). The increase in oxygen transfer had no relevant effect on biomass concentration (Fig. 1a), and the biomass yield was similar for both experimental conditions (Table 2). By contrast, the maximum GA concentration (Fig. 1b) was enhanced approximately 25% by increasing the agitation rate from 400 to 600 rpm. At this condition, DOC in the medium dropped to near zero after 24 h of cultivation (corresponding to the exponential growth phase), increasing gradually to 60% of saturation until the end of the process. In the experiments carried out at the lowest agitation rate, DOC also fell to zero after 24 h but remained below 6% of saturation until the end (Fig. 1a). This oxygen-limiting condition can explain the differences observed in GA and sugar profile between the two experiments after 32 h of the process (Fig. 1b). At the highest agitation rate, 31 g·L−1 of GA was produced between 32 and 96 h, whereas only 16 g·L−1 was obtained in the experiments conducted at 400 rpm. The consumption of glucose and sucrose was also faster at 600 rpm, being completely consumed after 56 h of cultivation. By contrast, at 400 rpm, 96 h were needed for a total consumption of sugars. These findings demonstrate the great importance of high DOC since the bioconversion of glucose to GA by A. pullulans is an oxidative process. The agitation rate not affected fructose assimilation, and approximately 30 g·L−1 was consumed in both conditions (data not shown).

Profiles of a biomass (red square, blue square) and dissolved oxygen concentration (% of saturation), b GA (red triangle, blue triangle) and glucose + sucrose (red diamond, blue diamond) obtained in batch cultures of A. pullulans NCYC 4012 carried out in an STR operating at atmospheric pressure, 1 vvm of aeration rate and 400 rpm (red symbols; red line) or 600 rpm (blue symbols; blue line) of agitation. The error bars represent the standard deviation of two independent replicates

The requirement of high oxygen supply conditions for GA production by A. pullulans species from pure glucose was previously reported. A threefold enhancement of GA productivity was attained by increasing the kLa at expenses of high agitation and aeration rates (Fernandes et al., 2021). In A. pullulans DSM 7085 batch and continuous cultures, the increase of aeration or agitation rates was not enough to meet the oxygen requirements for GA synthesis, and cultures needed to be aerated with pure oxygen (Anastassiadis & Rehm, 2006; Anastassiadis et al., 2003, 2008). The significance of oxygenation conditions in STR bioreactors was also observed in A. niger cultures producing GA from unrefined and hydrolysate by-products. The production of GA from molasses was accompanied by a rapid decrease in DOC after 3 h of cultivation (Alsaheb et al., 2022). The increase of oxygen supply by raising aeration and agitation rates positively affected GA production from pretreated corn stover (Zhang et al., 2016) and breadfruit hydrolysate (Ajala et al., 2016). By contrast, in Cryptococcus podzolicus batch cultures, a considerable decrease in GA concentration was obtained by increasing the agitation rate to 930 rpm (Qian et al., 2019).

Pressurized STR: Effect of Total Air Pressure

In addition to kLa, OTR is also controlled by the driven force for mass transfer (C*–CL). The saturation concentration of oxygen from the air in the culture medium (C*) is affected by the oxygen partial pressure and can be enhanced by raising the total air pressure (Lopes et al., 2013). It was reported the use of increased air pressure as a way of improving OTR in microbial cultures, as well as the potential of this strategy to enhance biomass and metabolite production (Lopes et al., 2014). Previous studies demonstrated the applicability of pressurized air conditions as an effective approach to oxygen supply to A. pullulans cultures producing GA (Fernandes et al., 2021) and pullulan (Dufresne et al., 1990). Moreover, cells growing in pure glucose induced an antioxidant response (enzyme superoxide dismutase) to cope with oxidative stress imposed by high oxygen concentration at 4 bar (Fernandes et al., 2021). In this study, the feasibility of using pressurized air conditions for GA production from ScM was evaluated in an STR operating at 1 bar and 4 bar of total air pressure.

The twofold improvement of OTR obtained by increasing the total air pressure from 1 to 4 bar led to a twofold enhancement of biomass yield and final biomass concentration (Fig. 2a). Similarly, GA production was considerably increased at 4 bar compared to the experiments carried out at 1 bar in the same bioreactor (Fig. 2b). In this condition, 18 g·L−1 of unconsumed glucose and sucrose remained in the culture medium, whereas at 4 bar, these sugars were consumed after 56 h of cultivation (Fig. 2b). The increase in total air pressure did not affect fructose assimilation, and approximately 34 g·L−1 was consumed during the cultivation time (data not shown). The enhancement of GA synthesis by A. pullulans NCYC 4012 under pressurized air conditions was also demonstrated from pure glucose (Fernandes et al., 2021), but 60% more GA was obtained using ScM as substrate (this work). On the other hand, and regardless of the air pressure tested, biomass concentration in the ScM-based medium was lower than the value achieved from pure glucose, suggesting that glucose of molasses was preferably used towards GA production. The production of A. pullulans 2552 cell mass and the exopolysaccharide pullulan from sucrose was enhanced by using pressurized air conditions up to 6.5 bar (Dufresne et al., 1990). The use of high oxygen concentrations in inlet air in cultures of A. pullulans (Anastassiadis & Rehm, 2006; Anastassiadis et al., 2003, 2008) and A. niger (Tian et al., 2018) enhanced GA synthesis from pure glucose, reducing the production of intermediates and by-products of the tricarboxylic acid cycle and Embden–Meyerhof–Parnas pathway. The high oxygen demand of glucose oxidation to GA by Gluconobacter oxydans was surpassed by carrying out the experiments in a sealed STR with a compressed pure oxygen supply (inlet pressure of 0.2–0.5 bar). This condition provided sufficient oxygen supply to the bacterium culture, improving GA synthesis from dilute acid pretreated corn stover (Dai et al., 2022). Zhou et al., 2018 also concluded that a compressed pure oxygen supply, using the same system described above, enhanced GA production from concentrated corncob enzymatic hydrolysate owing to the improvement of OTR by raising the partial pressure of oxygen. Although the promising results, using pure oxygen at an industrial scale is costly and requires special handling.

Profiles of a biomass (red square, blue square), b GA (red triangle, blue triangle) and glucose + sucrose (red diamond, blue diamond) obtained in batch cultures of A. pullulans NCYC 4012 carried out in a pressurized STR at 1 vvm of aeration rate and 1 bar (red symbols) or 4 bar (blue symbols) of total air pressure. The error bars represent the standard deviation of two independent replicates

Airlift Bioreactor: Effect of Aeration Rate

In airlift bioreactors (a column containing the riser—section for the gas–liquid up flow—and the downcomer—section for the gas–liquid down flow), the mixing of culture medium and gases is provided only by the air. Due to their design, this type of bioreactor is usually associated with high mass transfer rates. Generally, the increase in aeration rates leads to high gas hold-up (εg), enhancing the kLa and, consequently, the OTR (Li et al., 2022). Some advantages are recognized to airlift bioreactors, namely simple design, low shear force (preserving cells’ integrity), low energy requirement, and good mixing (Rosa et al., 2019).

Airlift bioreactors were already used with A. pullulans cultures to produce some metabolites, such as esterase (Meneses et al., 2021), pullulan (Özcan et al., 2014; Roukas & Mantzouridou, 2001), and fructosyltransferase (Šedová et al., 2014a, b). However, GA production by A. pullulans strains in this bioreactor type was never attempted. Even the synthesis of GA by the model species A. niger in airlift bioreactors was poorly explored, and the substrate used was pure glucose (Klein et al., 2002; Znad et al., 2004a). Thus, the behavior of A. pullulans NCYC 4012 in the GA biosynthesis from ScM was studied at 1 vvm and 2 vvm.

Increasing the aeration rate doubled the OTR value (Table 2), but this enhancement was insufficient to maintain DOC at high levels (Fig. 3a). In both experiments, DOC sharply decreased in the first 16 h of cultivation, reaching values very close to zero, corresponding to the exponential growth phase (Fig. 3a) and faster consumption of sugars (Fig. 3b). At 1 vvm, complete depletion of oxygen was observed until the end of the experiments and, notwithstanding the constant aeration at the same rate, oxygen provided was promptly consumed by A. pullulans for metabolic activities and for GA biosynthesis—half a mole of oxygen is required to convert 1 mol of glucose to 1 mol of GA (Ma et al., 2018). This O2-limiting condition had a remarkable negative effect on sugar consumption and GA production (Fig. 3b), which were consumed and produced at sluggish rates. From 24 h until the end of the cultivation, only 16 g·L−1 of glucose and sucrose were consumed, remaining 34 g·L−1 of unconsumed sugars in the culture medium. In this period, 12 g·L−1 of GA was synthesized. At 2 vvm, DOC stabilized below 15% of saturation between 24 and 144 h, starting to increase on the last day. Glucose and sucrose were consumed within 168 h of cultivation, and GA synthesis occurred until the end with a higher production rate than at 1 vvm. A threefold improvement in maximum GA concentration was attained by increasing the aeration rate from 1 to 2 vvm. In the airlift bioreactor, fructose assimilation decreased with aeration rate, and 33 g·L−1 and 45 g·L−1 of fructose were consumed at 2 vvm and 1 vvm, respectively.

Profiles of a biomass (red square, blue square) and dissolved oxygen concentration (% of saturation), b GA (red triangle, blue triangle) and glucose + sucrose (red diamond, blue diamond) obtained in batch cultures of A. pullulans NCYC 4012 carried out in an airlift at 1vvm (red symbols; red line) or 2 vvm (blue symbols; blue line) of aeration rate. The error bars represent the standard deviation of two independent replicates

No significant effect on the biomass profile and the final concentration was found by varying the aeration rate, being the stationary phase obtained after 48 h of cultivation for both conditions (Fig. 3a). As A. pullulans is not a strictly aerobic yeast (Roukas & Mantzouridou, 2001), some authors state that high OTR and DOC do not improve microbial growth. However, the effect of oxygenation conditions on A. pullulans growth is not consensual and seems to depend on strain, culture medium, operational conditions, and type of bioreactor. In an airlift bioreactor, the aeration rate (1–4 vvm) affected the cell mass of A. pullulans URM 7059 growing in crude glycerol, and the highest biomass was obtained at 3 vvm (Meneses et al., 2021). Using sucrose as substrate, the increase of the aeration rate over 1 vvm and 2 vvm resulted in a decrease in the growth of A. pullulans DSM-2404 (Özcan et al., 2014) and P56 (Roukas & Mantzouridou, 2001) strains, respectively, and a morphological shift from yeast-like cells to mycelial forms was observed. The production of A. niger CCM 8004 biomass enhanced with the increase of aeration rate up to 4.3 vvm, but above this value, the effect of aeration on fungus growth was insignificant (Znad et al., 2004b). In the current work, the increase of OTR in STR operating at atmospheric pressure and in the airlift bioreactor had no significant effect on biomass proliferation, but in pressurized STR, the improvement of oxygen solubility owing to the rise of total air pressure led to a twofold enhancement of biomass concentration. Furthermore, the amount of cell mass in the airlift was 2.5 and 3.2 times lower than that obtained, respectively, in pressurized STR at 4 bar and STR at 600 rpm and atmospheric pressure. Probably, the aeration rates used in the airlift were not enough to promote an efficient medium circulation, hindering the mixture and the access of cells to the nutrients. Moreover, and tough have been reported the non-strict aerobic feature of A. pullulans (Roukas & Mantzouridou, 2001), the DOC below 15% may have contributed to the slow biomass proliferation. This oxygen limitation was even more pronounced in the experiments carried out at 1 vvm, in which DOC sharply decreased to zero in the first 10 h of cultivation, remaining in this value until the end (Fig. 3a). The low biomass production in this bioreactor can be the reason for the slower bioconversion of glucose to GA compared to the other two bioreactors.

Some works in the literature report the positive effect of high aeration rates on GA production by free (Klein et al., 2002; Znad et al., 2004a) or immobilized (Sankpal & Kulkarni, 2002) mycelia of A. niger from pure glucose in airlift bioreactors. However, when the aeration rates exceed 4.3 vvm, the productivity of GA slows down mainly due to the following: (a) high shear stress caused by high aeration leads to cellular damage, reducing the capability of A. niger to produce GA; and (b) high respiration rates that can lead to a reduction in glucose availability for GA synthesis (Znad et al., 2004b). At a low aeration rate (1 vvm), DOC in A. pullulans URM 7059 cultures dropped to zero in the first 12 h, whereas at 4 vvm, oxygen did not reach limiting levels, and higher esterase production was obtained (Meneses et al., 2021). The batch production of polysaccharides by A. pullulans DSM-2404 (Özcan et al., 2014) and P56 (Roukas & Mantzouridou, 2001) strains from sucrose in an airlift bioreactor was strongly affected by the aeration rate. The maximum polysaccharide production was obtained in cultures growing at 3 vvm, whereas the highest pullulan content was attained at 2 vvm. The decrease in pullulan proportion at aeration rates over 2 vvm was attributed to the morphological changes in A. pullulan cells (Özcan et al., 2014; Roukas & Mantzouridou, 2001).

The potential of producing GA by A. pullulans NCYC 4012 using ScM as a low-cost substrate was evaluated in three types of bioreactors: STR operating at atmospheric pressure, STR operating at increased air pressure (4 bar), and airlift bioreactor. Regardless of bioreactor typology, highly aerated cultures favored the conversion of glucose to GA. Both final GA concentration and GA yield (Table 2) were considerably enhanced by increasing the OTR in each bioreactor, proving the importance of high DOC on GA synthesis by A. pullulans. The highest GA production was obtained in STR (600 rpm) and airlift (2 vvm) bioreactors, whereas the maximum biomass yield was attained in STR bioreactors (operating at atmospheric pressure and 600 rpm or operating at 4 bar). However, the GA productivity obtained in the airlift bioreactor was twofold lower than that attained in the STR (600 rpm). It should be noticed that the maximum GA yields reached in this work are higher than others found in the literature for A. pullulans cultures growing in pure glucose and carried out with high agitation rates or at 4 bar of total air pressure (Fernandes et al., 2021) or using oxygen-enriched air (Anastassiadis & Rehm, 2006; Anastassiadis et al., 2003, 2008).

FOS Production

Aureobasidium pullulans is a known producer of FTase enzymes, which are involved in the biotransformation of sucrose into FOS. A large amount of sucrose was quantified in both ScM1 and ScM2 (Table 1). Thus, the potential for FOS production in these media is high. On the other hand, although substantial levels of glucose were quantified in the ScM media, more glucose will be generated as a by-product during the transfructosylation of sucrose by the FTase enzyme, which may be used to produce GA. Glucose has an inhibitory effect on FTase activity, resulting in low FOS production yields (Nobre et al., 2018). Nevertheless, the aerated conditions favored the conversion of glucose into GA. Therefore, the presence of oxygen may enhance FOS synthesis as glucose will progressively be removed from the medium avoiding transfructosylation inhibition. In this context, the production of FOS during the GA production process was investigated.

FOS production by A. pullulans NCYC 4012 using ScM in the three bioreactors is detailed in Table 3, namely in (i) STR, (ii) pressurized STR, and (iii) airlift, at increasing aerated conditions, delivered either by modification of (i) the agitation rate, (ii) the air pressure, or (iii) the aeration rate, respectively.

FOS production was first evaluated in the bioprocess conducted in the STR bioreactor at atmospheric pressure and two agitation rates. FOS were mainly produced in the first 24 h, with the sucrose concentration decreasing sharply (Fig. 4a). Around 87 to 93% of the initial sucrose content was consumed or bio-converted after 24 h of cultivation, being the maximum FOS yield also achieved at this period (around 30 g·L−1 of FOS). Increasing agitation rate showed no significant effect on the total amount of FOS produced, although the yield of FOS had decreased 1.2-fold.

Profiles of a total FOS (red triangle) and sucrose (blue triangle), b 1-kestose (GF2) (red circle), nystose (GF3) (blue circle), and 1F-fructofuranosylnystose (GF4) (green circle) obtained in A. pullulans NCYC 4012 batch cultures carried out in an STR operating at atmospheric pressure, with 1 vvm of aeration rate (400 rpm, solid line; 600 rpm, dashed line). The error bars represent the standard deviation of two independent replicates

Despite a similar maximal FOS synthesis, the production profile of each FOS was slightly different (Fig. 4b). A faster 1-kestose (GF2) synthesis was observed at 600 rpm. The higher agitation rate slightly enhanced the enzymatic reaction rate, which resulted in a 1.3-fold improvement of GF2 synthesis at 8 h of cultivation. The nystose (GF3) production did not change significantly between the tested conditions, while 1F-fructofuranosylnystose (GF4) was synthesized at the same rate, but its hydrolysis after peak production was slower under the lowest agitation rate.

These findings suggest that increasing the agitation rate, and consequently the DOC, only enhances the enzyme’s reaction rate. Accordingly, Liang et al. (2021) observed only a slight improvement in the FOS biosynthesis in batch cultures of A. pullulans ipe-3 when the agitation rate was increased from 400 to 600 rpm. The authors reported an increase of FOS concentration from 116.6 g·L‒1 ± 5.8 g·L‒1 to 123.2 g·L‒1 ± 6.2 g·L‒1, however, without statistical significance (p ≥ 0.05). At agitation conditions above 600 rpm, a decrease in the FOS production was observed. The maximum FOS production yield of 0.62 g·g−1 ± 0.03 g·g−1 was obtained at 600 rpm. The same authors also reported that A. pullulans ipe-3 FTase enzyme activity increased 2.6-fold when the agitation rate raised from 400 to 600 rpm (Liang et al., 2021). Therefore, the higher GF2 synthesis verified in the current work at the first 8 h of cultivation at 600 rpm may be possibly related to the enhancement of the FTase activity under these conditions.

Figure 5 illustrates the FOS production in a pressurized STR under 1 bar and 4 bar of total air pressure. FOS synthesis was considerably lower at 4 bar as compared to the experiments carried out at 1 bar (Fig. 5a). Regardless of the air pressure tested, maximal FOS biosynthesis was attained after 24 h of cultivation. At 1 bar, 79% sucrose depletion was attained, and 51.8 g·L−1 ± 1.2 g·L−1 of FOS were synthesized. On the other hand, the increase of total air pressure to 4 bar led to a 1.7 times lower FOS biosynthesis (30.90 g·L−1 ± 1.10 g·L−1). As compared to the experiments operating at 1 bar, GF2, and GF4 production was halved at 4 bar (Fig. 5b), and GF3 production decreased around 26%. Consequently, the yield of FOS also decreased about 1.6-fold. Increasing the total air pressure from 1 to 4 bar in the pressurized bioreactor did not benefit the biosynthesis of FOS by A. pullulans from ScM. On the other hand, the production of GA and the biomass content was enhanced (Fig. 2). The phenomena may be explained by a shift in A. pullulans NCYC 4012 metabolic pathways towards growth and GA production instead of FOS production. Similar results were reported in batch culture using A. pullulans ipe-3, in which an increase in the bioreactor partial pressure from 0 bar to 0.8 bar decreased FOS synthesis from 123.2 to 110.4 g·L−1 (Liang et al., 2021). Also, the authors noted that FTase activity was significantly reduced with increasing pressure, whereas biomass production was maximized.

Profiles of a total FOS (red triangle) and sucrose (blue triangle), b 1-kestose (GF2) (red circle), nystose (GF3) (blue circle), and 1F-fructofuranosylnystose (GF4) (green circle) obtained in A. pullulans NCYC 4012 batch cultures carried out in a pressurized STR working at 1 vvm of aeration rate, 400 rpm, and 1 bar (solid line) or 4 bar (dashed line). The error bars represent the standard deviation of two independent replicates

In the airlift bioreactor, the increase of the OTR in the ScM-medium by applying different aeration rates had no major effects on FOS biosynthesis. FOS production profiles were similar, achieving a maximum concentration of 63.5 g·L‒1 ± 1.8 g·L‒1 (1 vvm) and 64.8 g·L‒1 ± 2.7 g·L‒1 (2 vvm) at 24 h of cultivation (Fig. 6a). At this point, approximately 87% of the initial sucrose was assimilated. The most notable difference was related to the production of GF4. The low aeration rate promoted an earlier GF4 synthesis. The biosynthesis of GF4 only started after 24 h fermentation at 2 vvm, while for 1 vvm, it started after 8 h (Fig. 6b). GF2 and GF3 production appeared to be slightly faster in the first 8 h at 1 vvm of aeration. Similarly, Liang et al. (2021) found no significative differences in the FOS biosynthesis when using aeration rates of 0.9 L·min−1 and 1.8 L·min−1. Further increase in the aeration rate to 2.7 L·min−1 led to a 1.4-fold decrease in FOS production. FTase-specific activity per cell mass has been reported to be positively influenced by conditions that avoid biomass propagation, such as low oxygen transfer rates and high sucrose concentrations (Šedová et al., 2014a, b), which may explain the results.

Profiles of a total FOS (red triangle) and sucrose (blue triangle), b 1-kestose (GF2) (red circle), nystose (GF3) (blue circle), and 1F-fructofuranosylnystose (GF4) (green circle) obtained in A. pullulans NCYC 4012 batch cultures carried out in an airlift bioreactor operating at an aeration rate of 1 vvm (solid line) and 2 vvm (dashed line). The error bars represent the standard deviation of two independent replicates

A. pullulans NCYC 4012 was capable of synthesizing FOS independently on the reactor typology and oxygenation conditions. Comparing the FOS production from ScM in the three types of bioreactors evaluated, it was observed that highly aerated conditions, delivered either by increasing the agitation rate, the total air pressure, or by the aeration rate, were either unfavorable for FOS synthesis or not relevant. Both total FOS and FOS yield were considerably reduced by increasing the OTR in the STR and the pressurized STR bioreactor, whereas no statistical difference (p ≥ 0.05) between conditions was found in the airlift bioreactor. FOS purity remained similar regardless of the OTR. Nonetheless, A. pullulans NCYC 4012 strain proved to efficiently produce FOS from ScM. The best production, yield, and purity were obtained when the experiments were performed in the airlift-type bioreactor. Compared to the pressurized reactor and the STR operating at atmospheric pressure, approximately 1.2- and 2.1-fold improvement in FOS synthesis was observed. The highest FOS productivity was obtained when the airlift operated at the lowest aeration rate, i.e., 1 vvm. Nevertheless, the productivity at 2 vvm of aeration increased twofold comparatively to that obtained in the other two bioreactors. As OTR in this bioreactor was lower than in the other two bioreactors, biomass propagation was negatively affected, but FTase activity and FOS synthesis were improved. The airlift bioreactor also allowed the highest synthesis of all individual FOS. Therefore, the airlift bioreactor was demonstrated to be the best choice to produce FOS from ScM (Table 3). This bioreactor allowed to obtain higher FOS yield (0.58 g·g−1 ± 0.0 g·g−1) and productivity (2.64 g·L‒1 h−1 ± 0.19 g·L‒1 h−1).

FOS production profiles herein obtained were similar to the ones obtained by other authors, despite the difference in the operational conditions (Nobre et al., 2022). For example, in a work conducted with pure sucrose, A. pullulans CCY 27–1-94 strain yielded 0.59 g·g−1 ± 0.05 g·g−1 FOS after 25 h of cultivation in an STR bioreactor operating at 32 °C, pH 5.5, and 150 rpm of agitation. Productivity of 4.9 g·L−1 h−1 ± 0.2 g·L‒1 h−1 and a purity of 53.5% (w/w) ± 1.9% (w/w) were also attained (Castro et al., 2019). In another study, cultivations performed at similar conditions (32 °C, pH 5.5, 385 rpm) led to a production yield of 0.63 g·g−1 ± 0.03 g·g−1 FOS, a purity of 54.0% (w/w) ± 1.6% (w/w), and a productivity of 4.8 g·L‒1 h−1 ± 1.4 g·L‒1 h−1 after 20 h (Nobre et al., 2016). From sugarcane molasses, A. pullulans FRR 5284 strain produced FOS in an STR bioreactor, with a yield of 0.59 g·g−1 FOS after 9 h at 28 °C and 180 rpm of agitation (Khatun et al., 2021a). When using washed A. pullulans FRR 5284 cells at 55 °C, pH 5.5, and a stirring speed of 100 rpm, the yield increased to 0.61 g·g−1 after 6 h (Khatun et al., 2021b). Another study reported the production of 0.46 g·g−1 FOS from molasses by A. pullulans inactive cells at 55 °C and pH 5.5 after 24 h (Shin et al., 2004). Although FTase has been produced in an airlift bioreactor (Šedová et al., 2014a, b), no study was found in this type of bioreactor to produce FOS.

Conclusions

For the first time, the simultaneous synthesis of GA and FOS by the yeast-like fungus A. pullulans from sugarcane molasses, a sucrose-rich by-product from the sugar refinery, was described. These findings enable the reduction of production costs of both added-value products while increasing the revenue of the sugarcane industry.

Regardless of bioreactor typology, highly aerated cultures favored GA synthesis and sugars consumption. The highest titers of GA were attained in the STR operating at atmospheric pressure (600 rpm) and in the airlift (2 vvm). By contrast, total FOS production was not improved by the increase in the OTR, since oxygen favors biomass production instead of FTase and FOS. This is advantageous for the industrial production of FOS since it represents important saving costs with power consumption and aeration. Nonetheless, the highest FOS concentration, productivity, and purity were obtained in the airlift bioreactor, which is very interesting since it was the first time that FOS production was performed in a bioreactor with pneumatic agitation. In general, the values of OTR obtained in the airlift were lower than in the other bioreactors, which had a negative effect on biomass propagation but a strong positive effect on FOS synthesis.

Data Availability

No data was used for the research described in the article.

References

Ajala, E. O., Ajala, M. A., Ogunniyi, D. S., & Sunmonu, M. O. (2016). Kinetics of gluconic acid production and cell growth in a batch bioreactor by Aspergillus niger using breadfruit hydrolysate. Journal of Food Process Engineering, 40(3). https://doi.org/10.1111/jfpe.12461

Alsaheb, R. A. A., Abdullah, J. K., & Lafi, A. S. H. A. (2022). Systematic comparison of gluconic acid optimization produced by Aspergillus using raw bioresources cultivation medium. Journal of Engineering Science and Technology, 17(1), 673–688.

Anastassiadis, S., Aivasidis, A., & Wandrey, C. (2003). Continuous gluconic acid production by isolated yeast-like mould strains of Aureobasidium pullulans. Applied Microbiology and Biotechnology, 61(2), 110–117. https://doi.org/10.1007/s00253-002-1180-8

Anastassiadis, S., Kamzolova, S. V, Morgunov, I. G., & Rehm, H. (2008). The effect of iron on gluconic acid production by Aureobasidium pullulans. The Open Biotechnology Journal, 2, 195–201. https://doi.org/10.2174/1874070700802010195

Anastassiadis, S., & Rehm, H. J. (2006). Continuous gluconic acid production by the yeast-like Aureobasidium pullulans in a cascading operation of two bioreactors. Applied Microbiology and Biotechnology, 73(3), 541–548. https://doi.org/10.1007/s00253-006-0499-y

Castro, C. C., Nobre, C., De Weireld, G., & Hantson, A. L. (2019). Microbial co-culturing strategies for fructo-oligosaccharide production. New Biotechnology, 51, 1–7. https://doi.org/10.1016/j.nbt.2019.01.009

Chuenpraphai, B., & Jaturapiree, P. (July,2019). Gluconic acid production from sugar cane molasses by Aspergillus neoniger DK026 at The 1st Thailand biorefinery Conference, “The future of biorefinery for Thailand 4.0” Suranaree, University of Technology, Nakhon Ratchasima, Thailand,pp 1–5.

Dai, L., Lian, Z., Zhang, R., Nawaz, A., ul Haq, I., Zhou, X., & Xu, Y. (2022). Multi-strategy in production of high titer gluconic acid by the fermentation of concentrated cellulosic hydrolysate with Gluconobacter oxydans. Industrial Crops and Products, 189, 115748. https://doi.org/10.1016/j.indcrop.2022.115748

Dubey, M. K., Zehra, A., Aamir, M., Meena, M., Ahirwal, L., Singh, S., Shukla, S., Upadhyay, R. S., Bueno-Mari, R., & Bajpai, V. K. (2017). Improvement strategies, cost effective production, and potential applications of fungal glucose oxidase (GOD): Current updates. Frontiers in Microbiology, 8, 1–22. https://doi.org/10.3389/fmicb.2017.01032

Dufresne, R., Thibault, J., Leduy, A., & Lencki, R. (1990). The effects of pressure on the growth of Aureobasidium pullulans and the synthesis of pullulan. Applied Microbiology and Biotechnology, 32, 526–532. https://doi.org/10.1007/BF00173722

Feng, J., Yang, J., Yang, W., Chen, J., Jiang, M., & Zou, X. (2018). Metabolome- and genome-scale model analyses for engineering of Aureobasidium pullulans to enhance polymalic acid and malic acid production from sugarcane molasses. Biotechnology for Biofuels, 11(1), 1–13. https://doi.org/10.1186/s13068-018-1099-7

Fernandes, S., Belo, I., & Lopes, M. (2021). Highly aerated cultures boost gluconic acid production by the yeast-like fungus Aureobasidium pullulans. Biochemical Engineering Journal, 175, 108133. https://doi.org/10.1016/j.bej.2021.108133

Ferreira, P., Lopes, M., Mota, M., & Belo, I. (2016). Oxygen mass transfer impact on citric acid production by Yarrowia lipolytica from crude glycerol. Biochemical Engineering Journal, 110, 35–42. https://doi.org/10.1016/j.bej.2016.02.001

Jamir, L., Kumar, V., Kaur, J., Kumar, S., & Singh, H. (2021). Composition, valorization and therapeutical potential of molasses: A critical review. Environmental Technology Reviews, 10(1), 131–142. https://doi.org/10.1080/21622515.2021.1892203

Jo, S. Y., Sohn, Y. J., Park, S. Y., Son, J., Yoo, J. I., Baritugo, K. A., David, Y., Kang, K. H., Kim, H., Choi, J., & il, Rhie, M. N., Kim, H. T., Joo, J. C., & Park, S. J. (2021). Biosynthesis of polyhydroxyalkanoates from sugarcane molasses by recombinant Ralstonia eutropha strains. Korean Journal of Chemical Engineering, 38(7), 1452–1459. https://doi.org/10.1007/s11814-021-0783-7

Kelleci, K., Altundoğan, H. S., & Tanyıldızı, M. Ş. (2023). Valorization of beet-processing sugar factory by-products for in-situ gluconic acid production by using Aspergillus niger. Fermentation. Sugar Tech, 25(2), 410–421. https://doi.org/10.1007/s12355-022-01206-3

Khatun, M. S., Harrison, M. D., Speight, R. E., O’Hara, I. M., & Zhang, Z. (2020). Efficient production of fructo-oligosaccharides from sucrose and molasses by a novel Aureobasidium pullulan strain. Biochemical Engineering Journal, 163, 107747. https://doi.org/10.1016/j.bej.2020.107747

Khatun, M. S., Hassanpour, M., Mussatto, S. I., Harrison, M. D., Speight, R. E., O’Hara, I. M., & Zhang, Z. (2021b). Transformation of sugarcane molasses into fructooligosaccharides with enhanced prebiotic activity using whole-cell biocatalysts from Aureobasidium pullulans FRR 5284 and an invertase-deficient Saccharomyces cerevisiae 1403–7A. Bioresources and Bioprocessing, 8(1). https://doi.org/10.1186/s40643-021-00438-7

Khatun, M. S., Hassanpour, M., Harrison, M. D., Speight, R. E., O’Hara, I. M., & Zhang, Z. (2021a). Highly efficient production of transfructosylating enzymes using low-cost sugarcane molasses by A. pullulans FRR 5284. Bioresources and Bioprocessing, 8(1). https://doi.org/10.1186/s40643-021-00399-x

Klein, J., Rosenberg, M., Markoš, J., Dolgoš, O., Krošlák, M., & Krištofíková, L. (2002). Biotransformation of glucose to gluconic acid by Aspergillus niger - Study of mass transfer in an airlift bioreactor. Biochemical Engineering Journal, 10(3), 197–205. https://doi.org/10.1016/S1369-703X(01)00181-4

Li, L., Xu, X., Wang, W., Lau, R., & Wang, C. (2022). Bioresource Technology Hydrodynamics and mass transfer of concentric-tube internal loop airlift reactors : A review. Bioresource Technology, 359, 127451. https://doi.org/10.1016/j.biortech.2022.127451

Liang, X., Li, C., Cao, W., Cao, W., Shen, F., & Wan, Y. (2021). Fermentative production of fructo-oligosaccharides using Aureobasidium pullulans: Effect of dissolved oxygen concentration and fermentation mode. Molecules, 26(13). https://doi.org/10.3390/molecules26133867

Lopes, M., Belo, I., & Mota, M. (2014). Over-pressurized bioreactors: Application to microbial cell cultures. Biotechnology Progress, 30(4), 767–775. https://doi.org/10.1002/btpr.1917

Lopes, M., Mota, M., & Belo, I. (2013). Oxygen mass transfer rate in a pressurized lab-scale stirred bioreactor. Chemical Engineering and Technology, 36(10), 1779–1784. https://doi.org/10.1002/ceat.201300082

Ma, Y., Chi, Z., Li, Y.-F., Jiang, H., Liu, G.-L., Hu, Z., & Chi, Z.-M. (2018). Cloning, deletion, and overexpression of a glucose oxidase gene in Aureobasidium sp . P6 for Ca 2+ -gluconic acid overproduction. Annals of Microbiology, 68(5), 871–879. https://doi.org/10.1007/s13213-018-1393-4

Ma, Y., Li, B., Zhang, X., Wang, C., & Chen, W. (2022). Production of gluconic acid and its derivatives by microbial fermentation: Process improvement based on integrated routes. Frontiers in Bioengineering and Biotechnology, 10, 1–12. https://doi.org/10.3389/fbioe.2022.864787

Markets and Markets. (2021). Prebiotic ingredients market with Covid-19 impact by type (oligosaccharides, inulin, & polydextrose), application (food & beverage, dietary supplements, & animal feed), source, brand, functionality, bacterial activity and region – global forecast to 2027. Retrieved February 28, 2023, from https://www.marketsandmarkets.com/Market-Reports/prebiotics-ingredients-market-219677001.html.

Meneses, D. P., Paixão, L. M. N., Fonteles, T. V., Gudiña, E. J., Rodrigues, L. R., Fernandes, F. A. N., & Rodrigues, S. (2021). Esterase production by Aureobasidium pullulans URM 7059 in stirred tank and airlift bioreactors using residual biodiesel glycerol as substrate. Biochemical Engineering Journal, 168. https://doi.org/10.1016/j.bej.2021.107954

Mishra, B., Mohanta, Y. K., Varjani, S., Mandal, S. K., Lakshmayya, N. S. V., Chaturvedi, P., Awasthi, M. K., Zhang, Z., Sindhu, R., Binod, P., Singhania, R. R., & Kumar, V. (2022). A critical review on valorization of food processing wastes and by-products for pullulan production. Journal of Food Science and Technology. https://doi.org/10.1007/s13197-022-05490-5

Nobre, C., Castro, C. C., Hantson, A. L., Teixeira, J. A., De Weireld, G., & Rodrigues, L. R. (2016). Strategies for the production of high-content fructo-oligosaccharides through the removal of small saccharides by co-culture or successive fermentation with yeast. Carbohydrate Polymers, 136, 274–281. https://doi.org/10.1016/j.carbpol.2015.08.088

Nobre, C., Gonçalves, D. A., Teixeira, J. A., & Rodrigues, L. R. (2018). One-step co-culture fermentation strategy to produce high-content fructo-oligosaccharides. Carbohydrate Polymers, 201, 31–38. https://doi.org/10.1016/j.carbpol.2018.08.051

Nobre, C., Simões, L. S., Gonçalves, D. A., Berni, P., & Teixeira, J. A. (2022). Fructooligosaccharides production and the health benefits of prebiotics. In A. Rai, S. Singh, A. Pandey, C. Larroche, & C. Soccol (Eds.), Current developments in biotechnology and bioengineering: technologies for production of nutraceuticals and functional food products (pp. 109–138). Elsevier. https://doi.org/10.1016/B978-0-12-823506-5.00002-3

Özcan, E., Sargin, S., & Göksungur, Y. (2014). Comparison of pullulan production performances of air-lift and bubble column bioreactors and optimization of process parameters in air-lift bioreactor. Biochemical Engineering Journal, 92, 9–15. https://doi.org/10.1016/j.bej.2014.05.017

Pal, P., Kumar, R., & Banerjee, S. (2019). Purification and concentration of gluconic acid from an integrated fermentation and membrane process using response surface optimized conditions. Frontiers of Chemical Science Engineering, 13(1), 152–163. https://doi.org/10.1007/s11705-018-1721-z

Palmonari, A., Cavallini, D., Sniffen, C. J., Fernandes, L., Holder, P., Fagioli, L., Fusaro, I., Biagi, G., Formigoni, A., & Mammi, L. (2020). Short communication: Characterization of molasses chemical composition. Journal of Dairy Science, 103(7), 6244–6249. https://doi.org/10.3168/jds.2019-17644

Qian, X., Gorte, O., Chen, L., Zhang, W., Dong, W., Ma, J., Jiang, M., Xin, F., & Ochsenreither, K. (2019). Co-production of single cell oil and gluconic acid using oleaginous Cryptococcus podzolicus DSM 27192. Biotechnology for Biofuels, 12(1), 1–9. https://doi.org/10.1186/s13068-019-1469-9

Reports and Data. (2021). Gluconic acid mark. Size to reach USD 1.8 Billion 2028. Retrieved February 21, 2023, from https://www.reportsanddata.com/press-release/global-gluconic-acid-market.

Rosa, E. A. R., Bianchini, L. F., da Silva Ramos, R. C. P., Arantes, A. B., da Silva, R. F., & Glassey, J. (2019). Hydrodynamics of split-rectangle-internal loop airlift bioreactor with variations in riser and downcomer cross-sectional areas based on the golden ratio. Journal of Chemical Technology and Biotechnology, 94(4), 1323–1329. https://doi.org/10.1002/jctb.5890

Roukas, T., & Liakopoulou-kyriakides, M. (1999). Production of pullulan from beet molasses by Aureobasidium pullulans in a stirred tank fermentor. Journal of Food Engineering, 40, 89–94. https://doi.org/10.1016/S0260-8774(99)00043-6

Roukas, T., & Mantzouridou, F. (2001). Effect of the aeration rate on pullulan production and fermentation broth rheological properties in an airlift reactor. Journal of Chemical Technology & Biotechnology, 376, 371–376. https://doi.org/10.1002/jctb.391

Roupar, D., Coelho, M. C., Gonçalves, D. A., Silva, S. P., Coelho, E., Silva, S., Coimbra, M. A., Pintado, M., Teixeira, J. A., & Nobre, C. (2022). Evaluation of microbial‐fructo‐oligosaccharides metabolism by human gut microbiota fermentation as compared to commercial inulin‐derived oligosaccharides. Foods, 11(7). https://doi.org/10.3390/foods11070954

Sankpal, N. V., & Kulkarni, B. D. (2002). Optimization of fermentation conditions for gluconic acid production using Aspergillus niger immobilized on cellulose microfibrils. Process Biochemistry, 37, 1343–1350. https://doi.org/10.1016/S0032-9592(01)00335-1

Šedová, M., Illeová, V., Antošová, M., Annus, J., & Polakovič, M. (2014a). Production of fructosyltransferase in mechanically stirred and air-lift bioreactors. Chemical Papers, 1–10. https://doi.org/10.2478/s11696-014-0563-5

Šedová, M., Illeová, V., Antošová, M., Annus, J., & Polakovič, M. (2014b). Production of fructosyltransferase in mechanically stirred and air-lift bioreactors. Chemical Papers, 68(12), 1639–1648. https://doi.org/10.2478/s11696-014-0563-5

Shin, H. T., Baig, S. Y., Lee, S. W., Suh, D. S., Kwon, S. T., Lim, Y. B., & Lee, J. H. (2004). Production of fructo-oligosaccharides from molasses by Aureobasidium pullulans cells. Bioresource Technology, 93, 59–62. https://doi.org/10.1016/j.biortech.2003.10.008

Srikanth, S., Swathi, M., Tejaswini, M., Sharmila, G., Muthukumaran, C., Jaganathan, M. K., & Tamilarasan, K. (2014). Biocatalysis and Agricultural Biotechnology Statistical optimization of molasses based exopolysaccharide and biomass production by Aureobasidium pullulans MTCC 2195. Biocatalysis and Agricultural Biotechnology, 3, 7–12. https://doi.org/10.1016/j.bcab.2013.11.011

Tian, X., Shen, Y., Zhuang, Y., Zhao, W., Hang, H., & Chu, J. (2018). Kinetic analysis of sodium gluconate production by Aspergillus niger with different inlet oxygen concentrations. Bioprocess and Biosystems Engineering, 41(11), 1697–1706. https://doi.org/10.1007/s00449-018-1993-1

Wang, P., Jia, S. L., Liu, G. L., Chi, Z., & Chi, Z. M. (2022). Aureobasidium spp. and their applications in biotechnology. Process Biochemistry, 116, 72–83. https://doi.org/10.1016/j.procbio.2022.03.006

Wojciechowska, A., Klewicki, R., & Klewicka, E. (2020). The potential of new bionic acids as prebiotics and antimicrobials. Lwt, 125, 109246. https://doi.org/10.1016/j.lwt.2020.109246

Ząbek, K., Szkopek, D., Michalczuk, M., & Konieczka, P. (2020). Dietary phytogenic combination with hops and a mixture of a free butyrate acidifier and gluconic acid maintaining the health status of the gut and performance in chickens. Animals, 10, 1–12. https://doi.org/10.3390/ani10081335

Zhang, H., Zhang, J., & Bao, J. (2016). High titer gluconic acid fermentation by Aspergillus niger from dry dilute acid pretreated corn stover without detoxification. Bioresource Technology, 203, 211–219. https://doi.org/10.1016/j.biortech.2015.12.042

Zhou, P., Yao, R., Zhang, H., & Bao, J. (2019). Unique glucose oxidation catalysis of Gluconobacter oxydans constitutes an efficient cellulosic gluconic acid fermentation free of inhibitory compounds disturbance. Biotechnology and Bioengineering, 116(9), 2191–2199. https://doi.org/10.1002/bit.27020

Zhou, X., Zhou, X., Liu, G., Xu, Y., & Balan, V. (2018). Integrated production of gluconic acid and xylonic acid using dilute acid pretreated corn stover by two-stage fermentation. Biochemical Engineering Journal, 137, 18–22. https://doi.org/10.1016/j.bej.2018.05.005

Znad, H., Báleš, V., Markoš, J., & Kawase, Y. (2004a). Modeling and simulation of airlift bioreactors. Biochemical Engineering Journal, 21, 73–81. https://doi.org/10.1016/j.bej.2004.05.005

Znad, H., Markoš, J., & Baleš, V. (2004b). Production of gluconic acid from glucose by Aspergillus niger: Growth and non-growth conditions. Process Biochemistry, 39(11), 1341–1345. https://doi.org/10.1016/S0032-9592(03)00270-X

Funding

Open access funding provided by FCT|FCCN (b-on). This study was supported by the Portuguese Foundation for Science and Technology (FCT) under the scope of the strategic funding of UIDB/04469/2020 unit and by LABBELS – Associate Laboratory in Biotechnology, Bioengineering and Microelectromechanical Systems, LA/P/0029/2020. Sílvia Fernandes, Daniela A. Gonçalves, and Clarisse Nobre acknowledge the FCT for the Ph.D. Grant SFRH/BD/129475/2017 and 2022.11590.BD, and for the Assistant Research contract 2021.01234.CEECIN, respectively.

Author information

Authors and Affiliations

Contributions

Sílvia Fernandes: investigation, methodology, formal analysis, writing—original draft; Bruna Dias: investigation, methodology; Daniela A. Gonçalves: methodology, writing—original draft; Clarisse Nobre: supervision, writing—review and editing. Isabel Belo: conceptualization, supervision, validation, writing—review and editing; Marlene Lopes: conceptualization, supervision, validation, writing—original draft, writing—review and editing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fernandes, S., Dias, B., Gonçalves, D.A. et al. Co-production of Gluconic Acid and Fructo-oligosaccharides by Aureobasidium pullulans from Sugarcane Molasses: Effect of Oxygen Transfer Rate in Stirred Tank and Airlift Bioreactors. Food Bioprocess Technol 17, 1321–1334 (2024). https://doi.org/10.1007/s11947-023-03201-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03201-2