Abstract

The increasing commercialization of fresh date fruits (Confitera cv) in Spain is generating important amounts of co-products which currently are discarded as waste with the corresponding environmental problem and economic losses. The aim of this work was to valorize them, in an integral way, applying non-polluting procedures (grinding, soaking, filtering, or drying) allowing their reincorporation in the food chain in function on both nutritional and technological properties. Different intermediate and stable products with high added value have been obtained: (1) Date pastes with 50% moisture content and the same amount of sugars and dietary fiber (20% approx.), good source of K, Ca, and Mg, with low Na/K ratio,whose technological properties give them a great potential to provide desirable texture properties in some foods; (2) date waters rich in sugars and minerals with potential application as natural sweeteners or as source of carbon for the microbiota in fermented foods; (3) date flours with low moisture and high TDF content (58–66%), rich in minerals, and whose technological properties allow them to be used as carrier of oils (i.e., with healthy lipid profile) or as an emulsion stabilizer in the development of new foods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the world, over 9 million tons of date fruits are annually produced (FAO, 2023) and about 30% are discarded or wasted due to low-grade classification (size, color, insects or natural damages, etc.) for their commercialization. These co-products could be subjected to several treatments for converting them, through low environmental impact procedure, into raw materials with added value for food applications (Echegaray et al., 2021; Muñoz-Tebar et al., 2023), returning to the food chain and thus contributing to the circular economy as well as fulfilling with the Sustainable Development Goals (FAO, 2018).

The growing interest in the valorization of agro-industrial co-products has led to the search for efficient treatments that also environmentally friendly. In this sense, several pretreatments and treatment processes (chemical, physical, and biological) have been applied to agro-industrial co-products depending on the original matrix and the amount of value-added compounds that they contain (Ahmed et al., 2021; Almaraz-Sánchez et al., 2022). For example, dietary fiber concentrates are the most reported value-added compounds extracted from fruit and vegetable co-products (Bchir et al., 2014; Borchani et al., 2012; García-Amezquita et al., 2018). However, in all these cases, the process used focuses on obtaining a single value-added product with a very specific characteristic (high dietary fiber content), undervaluing other compounds of high food value that are discarded during processing.

Date fruits have a valuable content of nutritional components (sugars, dietary fiber, certain essential vitamins, and minerals) and bioactive compounds (polyphenolic compounds, anthocyanins, sterols, and carotenoids) which can be recovered by applying the adequate process, transforming their co-products into new products, or extracting the compounds of interest (Echegaray et al., 2021; Muñoz-Tebar et al., 2023). This composition is highly related to the cultivar, growing place and conditions, and ripening stage of date fruits (Amira et al., 2012; Fernández-López et al., 2022; Hussain et al., 2020). Through their ripening stages (hababuk, kimri, khalal, rutab, and tamar), date fruits undergo relevant variations not only in their composition but also in the color, texture, and taste (Al-Qarni & Bazzi, 2020; Eid et al., 2013). Therefore, the application of a process (by using simple and environmentally friendly operations) that allows the valorization of date co-products in an integral way, obtaining different value-added products which, due to their specific characteristics, could be applied as functional ingredients in the food industry, would represent a great advance in the reduction of food waste in line with the UN’s sustainable development goals, and would contribute to the circular economy as well.

Confitera is an autochthonous cultivar of date palm from the southeast of Spain (Elche palm grove, UNESCO World Heritage Site) that is been promoting in this area as an alternative to other cultivars worldwide and widely distributed (Medjoul, Deglet Noir, Hayani, etc.). Confitera is a cultivar well adapted to the specific edaphoclimatic conditions in European oasis among that contributes to maintain local cultivars, Ilicitan ecosystems, and plant diversity (Martín-Sánchez et al., 2014; Pérez-Álvarez et al., 2023). Confitera dates are harvested (October–April) at the three last ripening stages: khalal (firm skin and hard texture, bright yellow color, with high sugar content but also strong tannins that can be overpowered), rutab (at this stage fresh dates are at their best, the hard skin begins to soften at the tip and turn to brown color, advancing while the fruit continue to ripen until a combination of sweet juiciness with a slightly crunchy texture is reached), and tamar (fully ripe dates, easy to peel, dark brown color, very sweet, and full of aromas and flavors) (Pérez-Álvarez et al., 2023).

The aim of this work was to valorize Confitera date co-products (at different ripening stages) applying efficient and green processes in order to obtain value-added products suitable for food applications. In addition, the whole characterization of all the value-added products obtained along with its processing has been assessed in view of selecting, for each product, the most suitable food application.

Materials and Methods

Raw Materials (Date Fruit Co-products)

Date fruits (Confitera cv.) from Elche palm grove (Alicante, Spain) at different ripening stages (khalal, rutab, and tamar) and with no commercial value (below standard sizes, with minor physical damage due to bruises or insects) were provided by the Catedra Palmeral d’Elx (UMH, Alicante, Spain).

Date Fruit Co-product Processing

Date fruit coproducts were processed applying only physical treatments such as milling, soaking, pressing, and drying (Fig. 1). Date co-products were separated in three batches depending on the ripening stage (khalal, rutab, and tamar) and then they were independently processed. Date seeds were manually separated, and the rest (date pulp and peel) was ground using a cutter 1094-Homogeneizer (Tekator, Höganäs, Sweden) to obtain date paste. This date paste was soaked with distilled water 3 times. For the first two soakings, the proportion of water added was 1:1 (paste:water), while in the third soaking it was necessary to increase the proportion of water to 1:2. After every soaking, the corresponding date waters were separated from the date paste by pressing, using cotton filter clothes. Then, the solid part was distributed on trays and dried in an oven with forced ventilation at 60 °C for 24 h. The dried date paste was milling and sieved to obtain the date flour with a particular size > 0.52 mm.

From the initial raw material (date co-products at each of the 3 ripening stages) five value-added products were obtained (date paste, 3 date waters, and date flour). So, 15 value-added products were obtained in total: KHDP, date paste at khalal stage; RTDP, date paste at rutab stage; TMDP, date paste at tamar stage; KHDW1, date water at khalal stage from soaking 1; RTDW1, date water at rutab stage from soaking 1; TMDW1, date water at tamar stage from soaking 1; KHDW2, date water at khalal stage from soaking 2; RTDW2, date water at rutab stage from soaking 2; TMDW2, date water at tamar stage from soaking 2; KHDW3, date water at khalal stage from soaking 3; RTDW3, date water at rutab stage from soaking 3; TMDW3, date water at tamar stage from soaking 3; KHDF, date flour at khalal stage; RTDF, date flour at rutab stage; TMDF, date flour at tamar stage.

Date Paste Analysis

The date pastes obtained from the processing of date coproducts at each ripening stages (KHDP, RTDP, and TMDP) were subjected to the following analysis.

Proximate Composition

Total moisture content (AOAC 925.45), protein (AOAC 981.10), fat (AOAC 991.36), ash (AOAC 923.03), and dietary fiber (AOAC 985.29) of date paste were assessed (in triplicate) following AOAC methods (AOAC, 2006). Total sugar content was calculated by difference, subtracting the sum of the other components (moisture, protein, fat, ash, and dietary fiber) from the total (100%).

Sugar and Organic Acid Profile

For the extraction of sugars and organic acids from date paste samples, 2 g of each date paste was mixed with 50 mL of ultrapure water and stirred at room temperature for 24 h. Then, these solutions were homogenized at 20,000 rpm for 2 min (Ultra-Turrax T25 BASIC, IKA-Werke GmbH & Co. KG, Staufen, Germany) and heated at 80 °C for 1 h, under constant stirring. After their centrifugation (6500 × g for 10 min at 4 °C) the supernatant was filtered through a 0.45-µm filter.

Organic acids and sugars were quantified by HPLC analysis (Hewlett-Packard 1100 series model, Woldbronn, Germany) following the procedure described by Lucas-González et al. (2018). The samples (20 µL) were injected in a Supelco column (Supelcogel TM C-610H column 300 mm × 78 mm) using as elution buffer ortho-phosphoric acid in water (0.1% v/v) with an isocratic flow rate of 0.5 mL/min. For organic acid determination, the absorbance was measured at 210 nm using a diode-array detector (DAD G-1315A), while sugar determination was carried out by means of a refractive index detector (RID G1362A). Peaks were identified by comparison with retention time of the standards (organic acids, monosaccharides, and oligosaccharides from Supelco, Sigma-Aldrich, St. Louis, MO, USA), and quantified by regression formula obtained with the standards.

Mineral Content

The mineral content was determined using inductively coupled plasma–mass spectrometry (ICP-MS) Shimadzu MS-2030 (Shimadzu, Kioto, Japan). The standard compounds were diluted and utilized to calibrate the ICP-MS for mineral analysis in date samples. ICP-MS operated with the follow conditions: nebulizer gas flow, 0.91 L/min; radio frequency 1200 W lens voltage 1.6 V; cool gas 12.0 L/min; auxiliary gas 0.70 L/min.

Physicochemical Properties

The pH was determined in a suspension with water (blending 1 g sample with 9 mL deionized water for 2 min) by using a pH-meter GLP21 (Crison Barcelona, Spain). The color of date pastes was measured using a CM-700 Minolta spectro-photocolorimeter (Minolta, Osaka, Japan) in CIELAB mode selecting the illuminant D65 and an observation angle 10°. CIELAB coordinates [lightness (L*), red/green (a*), and yellow/blue (b*)] were obtained and the psychophysical magnitudes chroma [C* = (a*2 + b*2)1/2] and hue (H* = arctg b*/a*) were calculated from them.

Technofunctional Properties

The water-holding capacity (WHC), oil-holding capacity (OHC), and swelling capacity (SWC) of date pastes were evaluated according procedure described by López-Marcos et al. (2015). For WHC and OHC, 10 mL of ultrapure water or 5 g of sunflower oil, respectively, was added into centrifuge tubes with date paste (500 mg). Then, the tubes were stored at 25 °C for 18 h and centrifuged (1200 g, 20 min at 25 °C) (Nahita Model 2652, Alicante, Spain). After discarding the supernatant, the pellet was weighed and the results were expressed as the weight of water held (WHC) or oil held (OHC) by 1 g of date paste. For the SWC, 200 mg of date paste was weighed in a 10-mL graduated tube (0.1 mL graduations) and the volume occupied by the date fruit sample was noted. After that, 5 mL of ultrapure water was added, stirring the tubes to eliminate entrapped air bubbles and keeping at room temperature for 24 h to allow the sample to settle. The volume (mL) occupied by the hydrated sample was measured, and SC was expressed as mL per gram of date paste.

Microbiological Analysis

Total aerobic bacterial, molds, and yeast and enterobacteria of paste at the 3 ripening stages were analyzed. Ten grams of date paste was homogenized with 90 mL of sterile 0.1% (w/v) peptone water in a masticator during 60 s. Decimal dilutions were prepared and 1 mL was seeded in duplicate in Petrifilm plates (3M, Madrid, Spain). For total aerobic bacterial counts, samples were seeded on aerobic count plates and incubated at 37 °C for 48 h. For enterobacteria, paste samples were seeded on Enterobacteriaceae count plates and incubated at 37 °C for 24 h. Finally, molds and yeasts were counted on rapid yeast and mold count plates after incubation at 25 °C for 72 h. Plates ranging from 30 to 300 colony-forming units (CFU) were manually counted and the results were expressed as logarithm CFU/g paste.

Date Water Analysis

Each of the date waters obtained from the processing of date coproducts at each ripening stages by 3 consecutives soaking and pressing (KHDW1, RTDW1, TMDW1, KHDW2, RTDW2, TMDW2, KHDW3, RTDW3, and TMDW3) was subjected to the following analysis.

Total Soluble Solids

Total soluble solids (TSS) were determined using a digital refractometer Milwaukee MA 871 (Milwaukee electronics, Milwaukee, WI, USA) and expressed as °Brix.

Sugar and Organic Acid Content

The methodology used was the same as described for date pastes.

Mineral Content

The methodology used was the same as described for date pastes.

Date Flour Analysis

The date flours obtained from the processing of date coproducts at each of the three ripening stages (KHDF, RTDF, and TMDF) were subjected to the same analysis than reported for date pastes.

Statistical Analysis

Data from this paper were analyzed using SPSS software (IBM SPSS Statistics version 26). One-way analysis of variance ANOVA was applied using a confidence level of 95% and Tukey test was carried out to determine any significant difference (p < 0.05) between the 3 ripening stages of Confitera dates (khalal, rutab, and tamar). All data in this paper are means ± standard deviations of greater than or equal to three separate experiments.

Results and Discussions

Date Pastes

The results of the proximate composition of date pastes are shown in Table 1. Since they are obtained from fresh dates, the predominant fraction in the three date pastes was moisture followed by total carbohydrates (sugars and dietary fiber) with small amounts of fat, ash, and protein. Regarding differences in proximate composition due to the ripening stage, only moisture, TDF, and sugar content showed significant differences (p < 0.05). Moisture and TDF content of date pastes decreased, and sugar content increased (p < 0.05) as the ripening stage progressed, which has been widely documented (Al-Qarni & Bazzi, 2020; Fernández-López et al., 2022). The gradual enzymatic breakdown of long carbohydrates, identified as TDF, produces more soluble compounds (sugars) responsible for the sweetness and softness of ripe dates that can explain the changes in the proportion of TDF and sugars (Al-Farsi & Lee, 2008; Echegaray et al., 2021). The decrease in moisture through ripening is due to the transpiration and drying caused by environmental heat and moisture. All these values are within the range reported for fresh dates from different cultivars (Al-Farsi & Lee, 2008) although relevant differences depending on cultivar, growth conditions, and origin have been reported.

Mineral composition of date pastes affected by the ripening stage is shown in Table 1. There is not a clear trend between mineral content and ripening stage because there are some minerals whose content was not affected (p > 0.05) by the ripening stage (Mg, Mn, and Zn), while some of them increased (K, Fe, Ca, and Cu) and Na decreased (p < 0.05). Overall, the most abundant mineral in the three date pastes was K, followed (in decreasing order) by Ca and Mg (Ca in RTDP and TMDP and Mg in KHDP), Na, Fe, Cu, Mn, and Zn. Therefore, date pastes can be considered good sources of macroelements but poor in microelements, in accordance with what has been previously reported for fresh dates (Bouhlali et al., 2017; Salomón-Torres et al., 2019). For their potential application in food processing, it is very interesting to highlight the low Na:K ratio which is in line with the official recommendations aimed at reducing the sodium content of foods as a way to decrease the incidence of cardiovascular diseases among the population (WHO, 2020).

Date pastes are characterized by their high sugar content being glucose and fructose (reducing sugars) the major ones (Table 1). The amount and type of sugar change according to variety and ripening stage (Al-Qarni & Bazzi, 2020). The absence of sucrose in some cultivars has been explained by the environmental and genetic factors that may affect the qualitative and quantitative compositions of the sugar fraction by altering the activity of the enzymes involved in the synthesis and breakdown processes (Rastegar et al., 2012). The content of both reducing sugars in date pastes increased with the ripening stage of the dates (p < 0.05) reaching the highest content in TMDP, being glucose content higher than fructose (p < 0.05) in all the samples. Consequently, glucose to fructose ratios were > 1. These results are comparable with those published previously on different date varieties (Hamad et al., 2015). The content of reducing sugars depends on the cultivar and is closely related to texture and color (Ghnimi et al., 2018). Reducing sugars makes dates softer and would be responsible for the color changes of the pastes if subjected to thermal treatments due to their participation as substrates of the Maillard or caramelization reactions (Ghnimi et al., 2018).

Regarding organic acid content (Table 1), it could be said that total acidity (the sum of the content of each of the organic acids present in the sample) decreased during ripening (p < 0.05), but with significant changes in the predominance of specific organic acids, as has been previously reported (Famiani et al., 2015; Ghnimi et al., 2018). Tartaric, malic, and succinic acids were predominant in KHDP and TMDP (p < 0.05), while tartaric acid was not detected in RTDP. The content of specific organic acids depends on the cultivar, growth conditions, and ripening stage (Famiani et al., 2015; Martín-Sánchez et al., 2014; Sánchez-Zapata et al., 2011). The five organic acids identified in date pastes have been detected in date fruits of different cultivars and origins (Hamad et al., 2015). In the case of date pastes, the content of organic acids is very important due to their effect on pH reduction, their role as natural preservatives, and for their effect on date paste taste (acidity).

Physicochemical properties of date pastes are shown in Table 2. Date paste from dates at khalal stage (KHDP; the least ripe) showed the lowest pH values (p < 0.05) which could be related to its highest acidity (lower organic acids content, Table 1). Regarding color properties, lightness decreased through ripening, obtaining the highest L* values in date pastes at khalal stage (KHDP) and the lowest (p < 0.05) at tamar (TMDP). So, it could be said that TMDP is darker than RTDP and KHDP. Several authors have reported a close relationship between the moisture of food and its lightness: the greater the amount of surface water, the greater the light reflection and therefore the greater the lightness (Vera Zambrano et al., 2019). In this case the values of L* in date pastes are in agreement with their moisture content (Table 1). The behavior of the rest of color properties (a*, b*, C*, and H*) was the same: KHDP and RTDP showed the highest values (without differences between them) and TMDP the lowest (p < 0.05). Color is one of the most affected aspects by the fruit ripening process, and in the case of date fruits, these changes are more evident, being used for their classification into the different ripening stages (khalal, rutab, and tamar). Changes in a* and b* coordinates have been related to the chlorophyll degradation, the carotenes and anthocyanin content (from orange-yellow to red pigments), and also to some non-enzymatic browning reactions (mainly Maillard reaction) due to their high reducing sugar contents (Al-Qarni & Bazzi, 2020). As the date ripening stage progresses, the color saturation (C*) of the date pastes decreased obtaining the lowest C* values (p < 0.05) in TMDP. H* values of date pastes evolved from yellowish-orange (KHDP) to orange (RTDP and TMDP) as fruit ripening progresses.

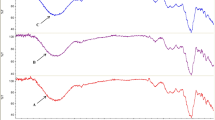

In the potential use of date pastes as ingredients for the development and innovation of functional foods, it is fundamental to know not only the technological behavior they would have when incorporated into a food matrix but also their physiological effect during the gut transit (for example, absorbing water contributing to stool bulking) (Sahni & Shere, 2017; Viuda-Martos et al., 2010). Therefore, properties such as water and oil holding capacity and swelling capacity (techno-functional properties) give interesting industrial information that would allow to optimize both formulation and food processes in view to achieve desirable results. Figure 2 shows the techno-functional properties of date pastes as affected by the ripening stage of date fruits. Regarding hydration properties (WHC and SWC), their behavior was different depending on the ripening stage; WHC decreased as the ripening progresses while SWC increased (p < 0.05). WHC is mainly related to the chemical and physical structures of the polysaccharides, which can hold water by absorption and adsorption phenomena, and to the sugar content because of their hygroscopic properties. Date pastes exhibited a WHC ranging from 0.91 to 1.5 g water/g paste (TMDP and KHDP, respectively) and these values agree with those reported by other authors for date pastes of different cultivars and ripening stages (Martín-Sánchez et al., 2014; Sánchez-Zapata et al., 2011). As expected, SWC was higher than WHC because WHC only measures the ability to retain water after applying an external force (centrifugation), while SWC measures the ability to absorb water when the sample is in contact with a constantly moist surface (López-Marcos et al., 2015). Based on these hydration properties, date pastes could provide desirable texture properties in some foods. On the other hand, there is not a clear relation between OHC and the ripening stage because the lowest values (p < 0.05) were obtained in RTDP and the highest in KHDP and TMDP (without significant differences between them). In any case, OHC values ranged from 0.44 to 1.03 g oil/g paste, which is in accordance with OHC values reported for other date pastes (Martín-Sánchez et al., 2014; Sánchez-Zapata et al., 2011). In this case, it could be said that date pastes do not have good capacity to bind oily components and this could mean that they can be potentially used for decreasing the greasy sensation in some fatty foods or to decrease oil retention during food frying.

Techno-functional properties (WHC, water holding capacity; OHC, oil holding capacity; SWC, swelling capacity) of date pastes from dates at different ripening stages (kahlal, rutab, and tamar). For the same parameter, (a,b) different letters indicate significant differences between samples (p < 0.05)

From a microbiological point, aerobic bacteria and enterobacteria were detected in all the samples, molds in KHDP and TMDP, and yeasts only in KHDP (Table 3). Regarding the ripening stage, there is not a clear trend in the microbiological quality. The European Union legislation regarding microbiological criteria for foods (Reglament CE 2073/2005), and particularly for fresh fruits minimally processed, does not include limits for this type of microorganism related to shelf-life decrease, only for pathogens (Salmonella spp, and Listeria monocytogenes). However, the maximum allowed value for ready-to-eat foods is 105 CFU/g, as highlighted in the guidelines for microbiological quality (Gilbert et al., 2000). Counts > 106 CFU/g (108 CFU/g in some cases) would induce some visible modifications related to deterioration (Costa et al., 2019). On the present data, all date pastes showed microbial counts (for all microbial groups evaluated) lower than 104 CFU/g, meaning that they were stable during the study, in terms of refrigeration (4 °C). These microbiological counts are within the range of those reported by Nayik et al. (2013) and Ogodo et al. (2016) for fruit samples.

Date Waters

Date waters were obtained after soaking the date pastes in distilled water and the separation of solids by filtering. Each date paste was subjected to 3 consecutive soakings, and the date water obtained after each soaking was separately analyzed. Figure 3 shows the TSS of all the date waters obtained after each consecutive soaking of date pastes at different ripening stages. As can be expected, TSS decreased (p < 0.05) with the number of soaks: the highest TSS content was obtained in date waters after the first soak and the lowest after the third one, regardless of the ripening stage. The high content of soluble sugars in date pastes easily passes into the water during the soaking stage; thus, the higher the sugar content of the original paste, the greater the flow (Zhou et al., 2015). This could explain the higher TSS content found in the date waters from the first soaking in comparison with the second and third ones. Regarding the ripening stage, it could be said that the riper, the higher the TSS content in date water, although not in all cases these differences were statistically significant. RTDW1 and TMDW1 showed the highest TSS values (18.3–19.5°Brix) which are very close to the TSS content reported for date juice freshly prepared (20°Brix) (Kulkarni et al., 2010).

Total soluble solids (°Brix) of date waters obtained after each of the three consecutives soaking of date pastes at different ripening stages (kahlal, rutab, and tamar). For the same sample, (a–c) different letters indicate significant differences between soaking (p < 0.05); for the same soaking, (x–z) different letters indicate significant differences between samples

Mineral content of date waters is presented in Table 4. As expected, there is a coincidence between the majority of minerals in the date pastes (Table 1) and those in the date waters (K, Mg, and Ca). The higher the concentration in the original date paste, the higher the extraction with water. These three minerals have been reported as the main minerals in several fruit juices (lemon, orange, grape, mango, pineapple, watermelon, etc.) (Ichado & Ayeni, 2020; Oladipo et al., 2022). It should be noted that K was the only mineral that exceeds the amount of 1 g/L in some date waters, specifically in date water from the first soaking (KHDW1, RTDW1, and TMDW1). The content of all minerals decreased significantly (p < 0.05) with the number of soakings, except for Fe in KHDW (p > 0.05), supporting the fact that the major extraction of minerals occurs during the first soaking. Based on this fact, it could be said that date waters might be considered a good source of minerals.

Sugars along with organic acids are the main soluble components of ripe fruits being easily extracted with water. During the soaking of date pastes, great amount of sugars was extracted with the water (Table 5). The amount of extracted sugars was the highest in the first soak progressively decreasing in the following soaks (p < 0.05), which agree with TSS results (Fig. 3). The highest sugar contents correspond to waters from the ripest pastes (p < 0.05). The average values of sugars (glucose + fructose) extracted after the 3 soakings of the pastes in increasing order of ripening were: 35.0 g/100 mL in KHDW, 45.9 g/100 mL in RTDW, and 51.7 g/100 mL in TMDP. No clear pattern was observed regarding the higher or lower extraction of glucose vs. fructose in relation to the ripening stage or the number of soakings. Glucose and fructose were detected as the main sugars in citrus water (from coproducts of juice industries) in amounts of 200 g/L and 125 g/L, respectively (Viuda-Martos et al., 2010), and in quince water in amounts of 6.0 g/kg and 14.2 g/kg, respectively (Trigueros et al., 2011). Overall, the results showed that date waters are and excellent source of natural sugars with potential application as carbon source for microbial flora (i.e., in fermented foods) or as a sweetener for the food industry.

With regard to the organic acids the main ones extracted were oxalic, malic, succinic, and citric acids (Table 5). Tartaric acid was not detected in TMDW (at any soaking) or in KHDW in the second and third soaking. For each date water, the amount of acids decreased progressively with soaking (p < 0.05). The maximum total acidity corresponded to TMDW1 (0.55 g/100 mL) and the minimum to RTDW3 (0.14 g/100 mL). Trigueros et al. (2011) and Viuda-Martos et al. (2010) reported that waters from citrus and quince were able to extract a great part of organic acids from fruit pastes. These authors reported a total acidity of 0.43 g/100 g in quince water and 0.52 g/100 mL in citrus water.

Date Flour

Proximate composition of the three date flours is shown in Table 6. The main components in all flours were TDF (58–66%) and sugars (19–26%) following the same trend observed in pastes affected by the ripening stage: KHDF and RTDF showed the lowest TDF content but the highest sugar content, in opposition to TMDF (the ripest) that showed the lowest sugar content but the highest TDF content (p < 0.05). The higher extraction of sugars in the date waters of the ripest pastes (TMDP) could be contributing to this pattern. Moisture (4.6–7.3%), protein (6.8–7.4%), and ash content (1.3–1.9%) were not affected by the ripening stage. Flours showed a low fat content (< 1.2%) with slight differences between samples. Several authors have reported extraction processes to obtain dietary fiber concentrates with higher TDF content (> 90%) and lower sugar content (< 1%) than our flours but applying hot water and a greater number of washes or soaks (i.e., 7 times) (Borchani et al., 2010; Hasnaoui et al., 2012) than those used in the present study, resulting in higher water and energy consumption. In this case, the purpose was not to obtain a sugar-free flour or powder but an intermediate and stable ingredient with potential suitability to be used in the development of new foods.

Regarding mineral content (Table 6) it could be said that in general, date flours followed the same pattern as the one observed in date pastes (K and Mg as the main minerals and Zn and Mn the minorities) (Table 1) but with different concentrations, depending on their initial content and on the greater or lesser extraction with date waters. For instance, although potassium continues to be the major mineral, being the most extracted in the date water (Table 4), its concentration in the flour is lower than in the pastes. Like what has been previously stated for date pastes, flour can also be considered a good source of macroelements but poor in microelements. Higher amounts of Fe, Cu, Zn, and Mg have been reported in wheat flour, rice flour, hemp flour, corn flour, barley flour, rye flour, and oat flour (Leśniewicz et al., 2009; Rusu et al., 2021; Tian et al., 2022).

Sugar and organic acid profile of date flours is shown in Table 6. All date flours showed higher fructose than glucose content (p < 0.05), in contrast to pastes (Table 1), which could be explained by the higher extraction of glucose than fructose in date waters (Table 5). All flours presented lower organic acid content than the corresponding pastes (which was expected due to their extraction in date waters) but with different proportions of each organic acid. Oxalic and malic acids were detected in the three flours, with malic acid being the major one (p < 0.05). Tartaric acid was not detected in KHDF, and succinic and citric acids were not detected in TMDF. TMDF showed the lowest total acidity (0.26 g/100 g), followed by RTDF (0.72 g/100 g) and KHDF (0.74 g/100 g) representing reductions between 65 and 82% of the total acidity of the corresponding pastes.

Physicochemical properties (pH and color properties) of date flours affected by the ripening stage of the original dates are shown in Table 7. All flours were mildly acidic with pH ranging from 6.22 (TMDF) to 6.36 (KHDF). Slightly lower pH through ripening progress could be related to a higher extraction of organic acids (toward the date water through the soaking process) from the corresponding date paste. The pH values of date flours were higher than the corresponding pH of date pastes (Table 2), which may indicate that the soluble organic acids of the date pastes were mostly extracted in the date water. Majzoobi et al. (2019) reported that the soluble organic acids of date fruits were mostly extracted in the juice resulting in higher pH values of the date press cake than the ones of date juice. Regarding color parameters, it could be said that the three date flours differ only in terms of lightness and hue, because although significant differences (p < 0.05) were detected for all the color parameters evaluated, the variations between samples for the a* and b* coordinates and the saturation (C*) were less than 1 unit and therefore without practical meaning. Date flour lost lightness as the ripening stage advances, with KHDF being the lightest and TMDF the darkest. In this case, the development of darker color could possibly be attributed to non-enzymatic browning (Maillard and caramelization reactions) (Hasan et al., 2022) induced by heat treatment during flours processing (Fig. 1) which would be more probable at higher sugar content (corresponding with the ripest stages). This effect could also be responsible for the decrease of hue values toward yellow-orange hues.

Hydration properties of date flours (WHC and SWC) (Fig. 4) decreased through the ripening process reaching the highest values for KHDFDF and the lowest (p < 0.05) for RTDF and TMDF (without differences between them). These flours due to their powder structure have the ability to hold water depending on the moisture gradient between the powder and the surrounding. Date flour with the lowest moisture content (KHDF, Table 6) and therefore with the highest moisture gradient when it is in contact with water, it was expected to show the highest water absorption and the highest WHC and SWC values. Similar behavior has already been reported for dehydrated fruits and food powders (Ferrari et al., 2012; Hasan et al., 2022). For the same reason, WHC and SWC of date flours are higher than those of the corresponding date pastes (Fig. 2). All the date flours showed similar OHC (p > 0.05) with a mean value of 1.37 g oil/g flour (Fig. 4) which allow them to be used as carrier of oils (i.e., with healthy lipid profile) or as an emulsion stabilizer in the development of functional foods.

Techno-functional properties (WHC, water holding capacity; OHC, oil holding capacity; SWC, swelling capacity) of date flours from dates at different ripening stages (kahlal, rutab, and tamar). For the same parameter, (a, b) different letters indicate significant differences between samples (p < 0.05)

The microbiological quality of date flours was significantly improved in comparison with the corresponding date flours. Total aerobic bacteria were not detected in any flour. Yeasts were only detected in RTDF (0.30 log CFU/g), and molds in RTDF (0.39 log CFU/g) and KHDF (0.45 log CFU/g), without differences between them (p > 0.05). Counts lower than 0.7 log CFU/g were obtained for Enterobacteriaceae, without differences between samples (p > 0.05). These differences could be due to the different sensitivities to heating and drying processes of the different analyzed microorganisms (Alp & Bulantekin, 2021).

Given the special characteristics of the different intermediate food products with high added value obtained from the valorization of date co-products (pastes, waters, and flours), in order to ensure their food safety, preservation methods in line with these characteristics should be applied. For example, date pastes and waters, due to their high moisture and sugar content, should be kept frozen/refrigerated, while date flours, due to their high hygroscopicity, could be kept vacuum packed and/or refrigerated. In any case, studies should be carried out to determine their shelf life under specific storage conditions. In addition, for their application as ingredients in foods, processing conditions should be optimized to ensure food safety.

In view of the results obtained, further research should be directed toward the optimization of the processes for their addition in different food matrices. For example, date pastes could be integrated into meat and dairy products as well as into bakery and pastry products; the first date waters could be useful for the development of syrups, liquid caramel, etc.; date waters 2 for the development of fresh fruit drinks or as an ingredient in the development of fermented meat products; and date waters 3 would have potential application in bakery, confectionery, reconstitution for the dairy industry, among others; lastly, date flours could be used bakery, pastry, and meat products.

Conclusions

The valorization of the co-products generated from the commercialization of fresh dates (Confitera cv.) applying simple and environmentally friendly technologies is a technologically viable strategy. Their application has resulted in three types of high added-value products (date pastes, date waters, and date flours) with different appearance, physicochemical properties, and composition, giving them great versatility for their incorporation in different food matrices, depending on both the technological objective to be achieved and the characteristics aimed in the new product developed. This research contributes to the reduction of agro-industrial waste, to the sustainability of fresh date production in Spain, to economic and social development in this specific area, and therefore to the circular economy.

Data Availability

Data are available on request from the corresponding author.

References

Ahmed, O. S., Sedraoui, S., Zhou, B., Reversat, G., Rocher, A., Bultel-Poncé, V., et al. (2021). Phytoprostanes from date palm fruit and byproducts: Five different varieties grown in two different locations as potential sources. Journal of Agricultural and Food Chemistry, 69(46), 13754–13761. https://doi.org/10.1021/acs.jafc.1c03364

Al-Farsi, M. A., & Lee, C. Y. (2008). Nutritional and functional properties of dates: A review. Critical Reviews in Food Science and Nutrition, 48(10), 877–887. https://doi.org/10.1080/10408390701724264

Almaraz-Sánchez, I., Amaro-Reyes, A., Acosta-Gallegos, J. A., & Mendoza-Sánchez, M. (2022). Processing agroindustry by-products for obtaining value-added products and reducing environmental impact. Journal of Chemistry, 2022, 1–13. https://doi.org/10.1155/2022/3656932

Alp, D., & Bulantekin, Ö. (2021). The microbiological quality of various foods dried by applying different drying methods: A review. European Food Research and Technology, 247, 1333–1343. https://doi.org/10.1007/s00217-021-03731-z

Al-Qarni, S. S. M., & Bazzi, M. D. (2020). Date fruit ripening with degradation of chlorophylls, carotenes, and other pigments. International Journal of Fruit Science, 20(S2), S827–S839. https://doi.org/10.1080/15538362.2020.1770151

Amira, E. A., Behija, S. E., Beligh, M., Lamia, L., Manel, I., Mohamed, H., & Lotfi, A. (2012). Effects of the ripening stage on phenolic profile, phytochemical composition and antioxidant activity of date palm fruit. Journal of Agricultural and Food Chemistry, 60(44), 10896–10902. https://doi.org/10.1021/jf302602v

AOAC. (2006). Official methods of analysis. 18th Edition, Association of Official Analytical Chemists, Gaithersburgs, MD. AOAC (2006) Official Methods of Analysis. 18th Edition, Association of Official Analytical Chemists, Gaithersburgs, MD.

Bchir, B., Rabetafika, H. N., Paquot, M., & Blecker, C. (2014). Effect of pear, apple and date fibres from cooked fruit by-products on dough performance and bread quality. Food and Bioprocess Technology, 7, 1114–1127. https://doi.org/10.1007/s11947-013-1148-y

Borchani, C., Besbes, S., Blecker, C., Masmoudi, M., Baati, R., & Attia, H. (2010). Chemical properties of 11 date cultivars and their corresponding fiber extracts. African Journal of Biotechnology, 9(26), 4096–4105. http://www.academicjournals.org/AJB

Borchani, C., Besbes, S., Masmoudi, M., Bouaziz, M. A., Blecker, C., & Attia, H. (2012). Influence of oven-drying temperature on physicochemical and functional properties of date fibre concentrates. Food and Bioprocess Technology, 5, 1541–1551. https://doi.org/10.1007/s11947-011-0549-z

Bouhlali, E. dine T., Ramchoun, M., Alem, C., Ghafoor, K., Ennassir, J., & Zegzouti, Y. F. (2017). Functional composition and antioxidant activities of eight Moroccan date fruit varieties (Phoenix dactylifera L.). Journal of the Saudi Society of Agricultural Sciences, 16(3), 257–264. https://doi.org/10.1016/j.jssas.2015.08.005

de Costa, E., A., de Sousa, P. H. M., Siqueira, A. C. P., de Figueiredo, E. A. T., Gouveia, S. T., de Figueiredo, R. W., et al. (2019). Fruit pastes with organic honey texturized with gellan gum: Bioacessibility of antioxidant activity and sensory analysis fruit pastes with gellan and organic honey. Food Science and Technology, 39(3), 667–676. https://doi.org/10.1590/fst.05518

Echegaray, N., Gullón, B., Pateiro, M., Amarowicz, R., Misihairabgwi, J. M., & Lorenzo, J. M. (2021). Date fruit and its by-products as promising source of bioactive components: A review. Food Reviews International, 39(3), 1411–1432. https://doi.org/10.1080/87559129.2021.1934003

Eid, N. M. S., Al-Awadi, B., Vauzour, D., Oruna-Concha, M. J., & Spencer, J. P. E. (2013). Effect of cultivar type and ripening on the polyphenol content of date palm fruit. Journal of Agricultural and Food Chemistry, 61, 2453–2460. https://doi.org/10.1021/jf303951e

Famiani, F., Battistelli, A., Moscatello, S., Cruz-Castillo, G., & Walker, R. P. (2015). The organic acids that are accumulated in the flesh of fruits: Occurrence, metabolism and factors affecting their contents-a review. Revista Chapingo, Serie Horticultura, pp. 97–128. www.chapingo.mx/revistas/horticultura

FAO. (2018). Transforming food and agriculture to achieve the SDGs. 20 interconnected actions to guide decision-makers. Food and Agriculture Organization of the United Nations. Retrieved May 23, 2023, from https://www.fao.org/3/I9900EN/i9900en.pdf

FAO. (2023). FAO Statistical Database (FAOSTAT); Food and Agriculture Organization of Unites National: Roma, Italy, 2023; Food and Agriculture Organization of the United Nations. Retrieved May 24, 2023, from https://www.fao.org/faostat/es/#data/QCL

Fernández-López, J., Viuda-Martos, M., Sayas-Barberá, E., Navarro-Rodríguez de Vera, C., & Pérez-álvarez, J. Á. (2022). Biological, nutritive, functional and healthy potential of date palm fruit (Phoenix dactylifera L.): Current research and future prospects. Agronomy, 12(4). https://doi.org/10.3390/agronomy12040876

Ferrari, C. C., Germer, S. P. M., & de Aguirre, J. M. (2012). Effects of spray-drying conditions on the physicochemical properties of blackberry powder. Drying Technology, 30(2), 154–163. https://doi.org/10.1080/07373937.2011.628429

García-Amezquita, L. E., Tejada-Ortigoza, V., Serna-Saldivar, S. O., & Welti-Chanes, J. (2018). Dietary fiber concentrates from fruit and vegetable by-products: Processing, modification, and application as functional ingredients. Food and Bioprocess Technology, 11, 1439–1463. https://doi.org/10.1007/s11947-018-2117-2

Ghnimi, S., Al-Shibli, M., Al-Yammahi, H. R., Al-Dhaheri, A., Al-Jaberi, F., Jobe, B., & Kamal-Eldin, A. (2018). Reducing sugars, organic acids, size, color, and texture of 21 Emirati date fruit varieties (Phoenix dactylifera, L.). NFS Journal, 12, 1–10. https://doi.org/10.1016/j.nfs.2018.04.002

Gilbert, R., de Louvois, J., Donovan, T., Little, C., Nye, K., Ribeiro, C., et al. (2000). Guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale. Communicable Disease and Public Health, 3(3), 163–167.

Hamad, I., Abdelgawad, H., Al Jaouni, S., Zinta, G., Asard, H., Hassan, S., et al. (2015). Metabolic analysis of various date palm fruit (Phoenix dactylifera L.) cultivars from Saudi Arabia to assess their nutritional quality. Molecules, 20(8), 13620–13641. https://doi.org/10.3390/molecules200813620

Hasan, F., Nazir, A., Sobti, B., Tariq, H., Karim, R., Al-Marzouqi, A. H., & Kamal-Eldin, A. (2022). Dehydration of date fruit (Phoenix dactylifera L.) for the production of natural sweet powder. NFS Journal, 27, 13–20. https://doi.org/10.1016/j.nfs.2022.02.002

Hasnaoui, A., Elhoumaizi, M. A, Borchani, C., Attia, H., & Besbes, S. (2012). Physico-chemical characterization and associated antioxidant capacity of fiber concentrates from Moroccan date flesh. Indian Journal of Science and Technology, 5(7). http://www.indjst.org

Hussain, M. I., Farooq, M., & Syed, Q. A. (2020). Nutritional and biological characteristics of the date palm fruit (Phoenix dactylifera L.) – A review. Food Bioscience, 34, 100509. https://doi.org/10.1016/j.fbio.2019.100509

Ichado, A., & Ayeni, M. (2020). Protein and mineral composition of some fruit juices (Citrus cinesis Spp) in some selected areas in Lokoja metropolis. International Journal of Advanced Multidisciplinary Research, 7(6), 22–26. https://doi.org/10.22192/ijamr

Kulkarni, S. G., Vijayanand, P., & Shubha, L. (2010). Effect of processing of dates into date juice concentrate and appraisal of its quality characteristics. Journal of Food Science and Technology, 47(2), 157–161. https://doi.org/10.1007/s13197-010-0028-y

Leśniewicz, A., Kretowicz, M., Wierzbicka, K., & Żyrnicki, W. (2009). Inorganic micronutrients in food products of plant origin used for breakfast in Poland. International Journal of Environmental Analytical Chemistry, 89, 621–634. https://doi.org/10.1080/03067310902962494

López-Marcos, M. C., Bailina, C., Viuda-Martos, M., Pérez-Alvarez, J. A., & Fernández-López, J. (2015). Properties of dietary fibers from agroindustrial coproducts as source for fiber-enriched foods. Food and Bioprocess Technology, 8(12), 2400–2408. https://doi.org/10.1007/s11947-015-1591-z

Lucas-González, R., Viuda-Martos, M., Pérez Álvarez, J. A., & Fernández-López, J. (2018). Changes in bioaccessibility, polyphenol profile and antioxidant potential of flours obtained from persimmon fruit (Diospyros kaki) co-products during in vitro gastrointestinal digestion. Food Chemistry, 256, 252–258. https://doi.org/10.1016/j.foodchem.2018.02.128

Majzoobi, M., Karambakhsh, G., Golmakani, M. T., Mesbahi, G. R., & Farahnaky, A. (2019). Chemical composition and functional properties of date press cake, an agro-industrial waste. Journal of Agriculture Science and Technology, 21, 1807–1817.

Martín-Sánchez, A. M., Cherif, S., Vilella-Esplá, J., Ben-Abda, J., Kuri, V., Pérez-Álvarez, J. Á., & Sayas-Barberá, E. (2014). Characterization of novel intermediate food products from Spanish date palm (Phoenix dactylifera L., cv. Confitera) co-products for industrial use. Food Chemistry, 154, 269–275. https://doi.org/10.1016/j.foodchem.2013.12.042

Muñoz-Tebar, N., Viuda-Martos, M., Lorenzo, J. M., Fernandez-Lopez, J., & Perez-Alvarez, J. A. (2023). Strategies for the valorization of date fruit and its co-products: A new ingredient in the development of value-added foods. Foods, 12(7), 1456. https://doi.org/10.3390/foods12071456

Nayik, G. A., Amin, T., & Bhat, S. (2013). Microbial analysis of some fruit juices available in the markets of Kashmir Valley, India. Biotechnology and Environmental Sciences, 15, 733–737.

Ogodo, A., Ugbogu, O., Ekeleme, U., & Nwachukwu, N. (2016). Microbial quality of commercially packed fruit juices in southeast Nigeria. Journal of Basic and Applied Research, 2(3), 240–245.

Oladipo, I. C., Oyelami, R., Ogundeji, K. D., Akinteye, E. O., Adewoyin, A. G., & Oladipo, A. O. (2022). Microbial quality, vitamin, mineral and proximate composition of some fresh fruit juice samples. European Journal of Biology and Biotechnology, 3(5), 25–29. https://doi.org/10.24018/ejbio.2022.3.5.397

Pérez-Álvarez, J. A., Muñoz-Bas, C., Candela-Salvador, L., Sanchiz-Sansano, A., Muñoz-Tebar, N., Botella-Martínez, C., et al. (2023). El dátil fresco español, un cultivo emergente. TecniFood. Retrieved May 17, 2023, from https://techpress.es/noticias/datil-fresco-espanol-cultivo-emergente

Rastegar, S., Rahemi, M., Baghizadeh, A., & Gholami, M. (2012). Enzyme activity and biochemical changes of three date palm cultivars with different softening pattern during ripening. Food Chemistry, 134(3), 1279–1286. https://doi.org/10.1016/j.foodchem.2012.02.208

Rusu, I. -E., Marc (Vlaic), R. A., Mure¸san, C. C., Mure¸san, A. E., Filip, M. R., Onica, B. -M., Csaba, K. B., Alexa, E., Szanto, L., & Muste, S. (2021). Advanced characterization of hemp flour (Cannabis sativa L.) from Dacia secuieni and Zenit varieties, compared to wheat flour. Plants, 10, 1237. https://doi.org/10.3390/plants10061237

Sahni, P., & Shere, D. M. (2017). Comparative evaluation of physico-chemical and functional properties of apple, carrot and beetroot pomace powders. International Journal of Food and Fermentation Technology, 7(2), 317–323. https://doi.org/10.5958/2321-5771.2017.00043.6

Salomón-Torres, R., Ortiz-Uribe, N., Valdez-Salas, B., Rosas-González, N., García-González, C., Chávez, D., et al. (2019). Nutritional assessment, phytochemical composition and antioxidant analysis of the pulp and seed of medjool date grown in Mexico. PeerJ, 7, e6821. https://doi.org/10.7717/peerj.6821

Sánchez-Zapata, E., Fernández-López, J., Peñaranda, M., Fuentes-Zaragoza, E., Sendra, E., Sayas, E., & Pérez-Alvarez, J. A. (2011). Technological properties of date paste obtained from date by-products and its effect on the quality of a cooked meat product. Food Research International, 44(7), 2401–2407. https://doi.org/10.1016/j.foodres.2010.04.034

Tian, S., Wei, Y., & Chen, Z. (2022). Effect of mixture design approach on nutritional characteristics and sensory evaluation of steamed bread added rice flour. Frontier in Nutrition, 9, 989090. https://doi.org/10.3389/fnut.2022.989090.

Trigueros, L., Pérez-Alvarez, J. A., Viuda-Martos, M., & Sendra, E. (2011). Production of low-fat yogurt with quince (Cydonia oblonga Mill.) scalding water. LWT- Food Science and Technology, 44(6), 1388–1395. https://doi.org/10.1016/j.lwt.2011.01.012

Vera Zambrano, M., Dutta, B., Mercer, D. G., MacLean, H. L., & Touchie, M. F. (2019). Assessment of moisture content measurement methods of dried food products in small-scale operations in developing countries: A review. Trends in Food Science and Technology, 88, 484–496. https://doi.org/10.1016/j.tifs.2019.04.006

Viuda-Martos, M., Ruiz-Navajas, Y., Fernández-López, J., & Pérez-Álvarez, J. A. (2010). Effect of added citrus fibre and spice essential oils on quality characteristics and shelf-life of mortadella. Meat Science, 85(3), 568–576. https://doi.org/10.1016/j.meatsci.2010.03.007

WHO. (2020). Salt reduction. World Health Organization. Retrieved May 20, 2023, from https://www.who.int/news-room/fact-sheets/detail/salt-reduction

Zhou, L., Nyberg, K., & Rowat, A. C. (2015). How we teach: Classroom and laboratory research projects understanding diffusion theory and Fick’s law through food and cooking. Advances in Physiology Education, 39, 192–197. https://doi.org/10.1152/advan.00133.2014

Acknowledgements

We want to thank “Cátedra Palmeral de Elche” from the UMH for their advice and technological support on selection and classification of fresh dates from the Elche Palm grove.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work is part of the project PID2021-123628OB-C43 funded by MCIN/AEI/10.13039/501100011033 and by “ERDF A way of making Europe.” The author Muñoz-Tebar N is funded by the Margarita Salas Requalification Category Margarita Salas contract of the Universidad Castilla-La Mancha (UCLM, Spain). Part of the analytical equipment used in this study was purchased through the grant EQC2018-004170-P funded by MCIN/AEI/10.13039/501100011033 and by ERDF “A way of making Europe.”

Author information

Authors and Affiliations

Contributions

Juana Fernández-López, Manuel Viuda-Martos, and José Angel Pérez-Alvarez conceived and planned the experiments; Clara Muñoz Bas, Nuria Muñoz Tebar, and Laura Candela Salvador contributed to sample preparation and performed the analysis; Clara Muñoz Bas and Nuria Muñoz Tebar processed the experimental data; Estrella Sayas Barberá and José Angel Pérez Alvarez revised the data processing; Manuel Viuda-Martos, Juana Fernández-López, and Jose Angel Pérez Alvarez contributed to the interpretation of the results. Clara Muñoz Bas and Juana Fernández López took the lead in writing the manuscript. All authors provided critical feedback and helped shape the research, analysis, and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Muñoz-Bas, C., Muñoz-Tebar, N., Candela-Salvador, L. et al. Development of Value-Added Products Suitable for Food Applications from Fresh Date Fruit (Confitera cv.) and its Co-products. Food Bioprocess Technol 17, 1265–1277 (2024). https://doi.org/10.1007/s11947-023-03189-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03189-9