Abstract

In oenology, fungoid chitosan (CH) can be used as an adjuvant for microbial control, haziness prevention, metal chelation, and ochratoxin removal. In acidic media (such as wine), CH can ionise and interact with charged compounds, giving rise to a series of adsorption and/or removal phenomena, some of which potentially impairing the overall quality of wines. In this context, it is worth noting that the interaction between CH and acidic components of wines has been poorly studied so far, and detailed information on this subject is still lacking. To study those interactions, different doses of chitosan (0.5; 1.0; 2.0 g/L) were dispersed in hydro-alcoholic solution (HS), synthetic wine solution (SW), and white wine (W). Results demonstrated that the remotion of tartaric acid and the change of pH were strongly affected by the matrix and dosage. In W and SW, chitosan was found to adsorb tartaric acid up to about 200 mg/g and 350 mg/g CH, respectively. Accordingly, pH values increased; however, the magnitude depended on the matrix as a consequence of different buffer capacities. Interestingly, even in the absence of tartaric acid (e.g. in HS samples) CH addition caused a pH increase (up to 1.2 units for 2 g/L CH addition) which demonstrated that pH variations may not only depend on the amount of organic acids adsorbed. The chitosan dispersed in W showed the highest average diameter D [3,2] (127.96 μm) compared to the ones dispersed in SW (120.81 μm) and in HS (116.26 μm), probably due to the presence of organic acids on the polymer surface. The minor removal of tartaric acid in W compared to SW could probably depend on the competitive adsorption onto chitosan of other families of compounds present in wine such as polyphenols. The data suggested that chitosan addition could affect the pH and organic acid concentration of all matrices, depending on the doses and composition of the solutions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chitin is the main structural component of a large number of organisms (i.e. molluscs, insects, crustaceans, fungi, algae), and marine invertebrates including crabs and shrimps (Alishahi & Aïder, 2012; Rinaudo, 2006). Its chemical structure is characterised by β-(1, 4) glycosidic linkages between n-acetylglucosamine monomers, which make chitin able to form intermolecular hydrogen bonds (Sahraee et al., 2017; Shahidi et al., 1999). The main derivative of chitin is chitosan (CH), a β-1,4-linked 2-amino-2-deoxy-D-glucopyranose polymer produced by N-deacetylation of chitin in aqueous alkaline solution (Lago et al., 2014; Rocha et al., 2017).

CH has attracted notable interest in different fields such as agriculture, biomedicine, biotechnology, and food industry due to its biocompatibility, biodegradability, bioactivity, and low toxicity (Morin-Crini et al., 2019). Moreover, chitosan has been approved by Generally Recognised as Safe notices (GRAS) to US Food and Drug Administration, without rejection, and has been admitted in Europe as food adjuvant and food constituent which helps in maintaining the normal blood LDL-cholesterol concentrations (EFSA Scientific Committee, 2011). Furthermore, it was approved in Japan and South-Korea as a food additive, in 1983 and 1995, respectively (Luck et al., 2015; Lamas et al., 2016).

In the environmental sector, CH has been used for a long time for wastewater remediation and water purification for the removal of heavy metals, pesticides, or salts (Pal et al., 2021), in the form of powder, flakes, or nanoparticles (Alguacil & Robla, 2022).

In the food industry, CH is used as a fining agent for different applications in beer (Gassara et al., 2015; Gernat et al., 2020) and fruit juice production, including apples (Taştan & Baysal, 2017), cucumbers (Eissa et al., 2021), oranges, lemons, and grapes (Chatterjee et al., 2004). CH has several applications, such as metal chelation (Zhang et al., 2016), lipid-lowering activity (Luo & Wang, 2013), antimicrobial (Paniagua-Martínez et al., 2018; Riaz Rajoka et al., 2020) and film-forming properties (de Vargas et al., 2022; Mannozzi et al., 2018). At the same time, there are several applications of CH for the extension of the shelf life of fruits and vegetables, such as coating of tomatoes (Mustafa et al., 2014), fresh-cut bamboo shoots (Yang et al., 2015), passion fruit (Zhong et al., 2022), green bell peppers (Correa-Pacheco et al., 2023) and table grapes (Sun et al., 2018). However, CH behaviour is largely influenced by its physical, chemical, and biological features, such as the average molecular weight (10–1000 kDa), the degree of deacetylation (50–95%), and the sequence of the acetamido and amino groups (Haghighi et al., 2020; Shahidi et al., 1999).

In oenology, the addition of fungoid CH to must and wine as an adjuvant for microbial control (Portugal et al., 2014), prevention of haziness, metals chelation (iron, lead, cadmium, and copper), and ochratoxins removal, has been quite recently admitted (European Commission, 2011). More recently, CH has been reported to reduce the onset of browning in fermented beverages by acting as an active radical scavenger (Castro-Marín et al., 2018) or through metal chelation and H2O2 quenching (Castro-Marín et al., 2021). That which mainly characterises CH with respect to chitin, permitting such a large range of activities in wine and food matrixes, is the combined presence of hydroxyl and amino groups all along the polymeric chain (Crognale et al., 2022; Sahariah & Másson, 2017). In acidic media, amino groups ionise, conferring to CH a polycationic behaviour suitable to interact to various extents with several anion species present in the medium (Rinaudo, 2006). In this context, it is noteworthy that, despite several recent studies on the application of CH in winemaking (Rocha et al., 2017; Tedesco et al., 2022), there are still limited and controversial data on its interaction with acidic components in wine. This subject is of great importance in winemaking, as the modification in organic acid content and titratable acidity may impair the overall quality of wine, affecting both its physicochemical and sensory features and making the use of CH a double-faced matter. A few authors have reported no changes in total acidity and wine pH after CH treatments (Nunes et al., 2016) whereas other authors have indicated an increase in pH and a decrease in titratable acidity due to the unwanted removal of tartaric and malic acids (Colangelo et al., 2018). According to these authors, the addition of this adjuvant to must and wine, particularly when used at high doses, may negatively impact the acidic profile of the products, with possible sensory consequences.

Therefore, the aim of this study was to assess the adsorption capability of CH for the two main organic acids in wines (tartaric and malic acids) by modelling its behaviour with respect to dosage and treatment time in both the model solution and wine. Data on organic acid adsorption, changes in pH, and titratable acidity were collected and commented on the chemical-physical characterisation of the CH formulation used in the study.

Material and Methods

Chemicals

Ethanol, hydrochloric acid, acetic acid, L-( +) tartaric acid, L-( −) malic acid, sodium hydroxide, sodium acetate, and sulphuric acid reagents were purchased from Sigma-Aldrich (St. Louis, MO, USA). All chemicals were of analytical grade. High-performance liquid chromatography (HPLC)-grade water was obtained using a Milli-Q system (Millipore Filter Corp., Billerica, MA, USA). CH of fungoid origin (Aspergillus niger) was kindly supplied by Bioenol s.r.l. (San Cipriano, Po, Pavia, Italy).

Model Wine Solutions and White Wine Sample

The hydro-alcoholic solution (HS) was composed of 12% (v/v) ethanol in Milli-Q water adjusted to pH 3.21 with hydrochloric acid, for similarity with the wine used for the trials. The synthetic wine solution (SW) was constituted of 2.61 g of L ( +)-tartaric acid in 12% (v/v) hydroalcoholic solution buffered at pH 3.15 with sodium hydroxide to simulate the values of the wine used for the trials. The white wine samples (W) obtained from Trebbiano grapes were purchased from a market (Tavernello, traceability code LA1062EO, Caviro, Italy). The oenological parameters of wine were determined according to the OIV methods (OIV, 2014) and are reported in Table S1.

CH Characterisation

Determination of Viscometric Molar Mass

The average molecular mass of CH was determined through viscometric measurements using an Ubbelohde capillary viscometer, according to a previously devised method (Costa et al., 2015). CH (1 g/L) was prepared in 0.3 M acetic acid/0.2 M sodium acetate solution at pH 4.6. The obtained solution was stirred overnight to allow the complete dissolution of the polymer and filtered through 0.45 μm cellulose acetate filters before analysis.

Five replicate readings of the flow time of both the solvent (ts) and the CH solutions (t) were taken at 25 °C. The viscometric molecular weight (M) was calculated according to the Mark–Houwink–Sakurada equation [η] = KMα, where [η] = intrinsic viscosity, K = 0.074 mL/g, and α = 0.79 (Rinaudo et al., 1993). Intrinsic viscosity was derived after a series of single-point measurements, considering 1 g/L as the lowest (near-zero) concentration which permitted consistent and reliable readings of the time needed for the solutions to flow through the capillary (approximately 125 s). After the mean flow time, [η] was calculated using the Solomon-Ciuta equation (Solomon & Ciutǎ, 1962):

where ηsp = (t-ts)/ts (specific viscosity), ηr = t/ts (relative viscosity), and C is the concentration of the CH solution (g/mL). The viscosity-average molecular weight can be expressed as g/mol or KDa (1 KDa = 1000 g/mol).

Determination of the Degree of Acetylation

The degree of acetylation of the CH formulation was determined using titration according to the International Oenological Code (OIV, 2014).

Morphological Characteristics and Elementary Composition

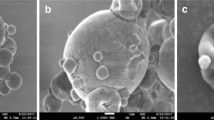

The morphology of the CH dry powder was examined using scanning electron microscope-energy dispersive X-ray analysis (SEM/EDX) measurements, which were performed with a Fei Quanta FEG 250 ESEM emission instrument in high vacuum, equipped with an EDAX TEAM Apollo XL-SDD microanalyser. SEM observation was performed also after the solubilisation of CH (1 g/L) for 180′ in HS, SW, and W and drying at 40 °C for 48 h. The dried powders were analysed after sputter coating with gold under an argon atmosphere (25 mA, 120 s). EDX spectra were interpreted from a mineralogical point of view, and measurements were recorded of particles present in three easily identifiable areas on the CH surface, 450 × 450 µm wide, as shown in Fig. 1.

SEM images (1000x) and EDX spectra of: chitosan dried powder (CHDP) (a); chitosan dissolved in hydro-alcoholic solution (CHHS) (b); chitosan dissolved in synthetic wine (CHSW) (c); and chitosan dissolved in white wine (CHW) (d). In the insets, × 10,000 magnification of a portion of each image is shown

Dissolution of CH in the Different Media

Dissolution tests were performed with HS, SW, and W. Hundred millilitres of each matrix was added to 50, 100, and 200 mg of CH in 125 mL glass bottles (Supelco, Bellefonte, PA, USA). The samples were constantly stirred (150 rpm) at ambient temperature (20 ± 2 °C) and then were vacuum filtered with 0.45 μm polyamid membranes (Sartorius Stedim Biotech GmbH, Heidelberg, Germany). The membranes were 24 h in an oven at 105 °C and then, put in vacuum-dryer at 21 ± 2 °C, finally weighted until constant weight, to obtain the amount of recovered CH. Increasing stirring times (5′, 15′, 30′, 60, and 180 min) were applied until the dissolution plateau was reached.

Analysis of Organic Acids Using HPLC

The organic acids were quantified in W and SW after CH treatments following the method of Izquierdo-Llopart et al. (Izquierdo-Llopart et al., 2020), with some modifications. Briefly, samples were filtered through hydrophilic polyamide (nylon) membranes at a porosity of 0.45 μm (Sartorius Stedim Biotech GmbH, Heidelberg, Germany) and analysed for L-( +) tartaric acid for both SW and W and L-( +) Tartaric, L-( −) malic acid for W using an HPLC Perkin-Elmer Series 200 (Perkin Elmer, Shelton, CT, USA) system coupled with a diode array detector (DAD) set to 210 nm and LC-Net II/ADC communication module with ChromNAV Control Centre software (Jasco, Oklahoma City, OK, USA). The analyses were performed isocratically at 0.5 mL/min and 40 °C using a Phenomenex Rezex ROA-organic Acid H + (8%) (300 × 7. 8 mm) column with 0.005 N sulphuric acid as the mobile phase.

Particle Size Distribution Analysis

The particle size of CH was measured using a Malvern laser particle size analyser (Mastersizer 3000; Malvern Panalytical, UK). An aerosol dispersion system was used to measure the CH powder particle size with a particle refractive index of 1.52. All liquid samples (CH dispersed in HS, SW, and W, as described below for 180′) were measured using a Hydro EV dispersion system. After reaching the obscuration limit, of 5–10%, the particles and the dispersant refractive index used were 1.52 and 1.33, respectively. All the data were analysed using the associated software, and the particle size was expressed both as the average diameter D[3,2] (µm) and Specific Surface Area (m2/dm3). The sample particle size distributions and specific surface areas were automatically measured in triplicate using the instrument.

Statistical Analysis

Data were analysed in a completely randomised design, with a 3 × 3 factorial arrangement of treatments using the general linear model (GLM) procedure of SAS (2003) according to the model:

where Yijk is the dependent variable; m is the overall mean; Mi is the fixed effect of matrix composition (i = HS vs. SW vs. W); Dj is the fixed effect of CH dose (I = 0.5 g/L vs. 1 g/L vs. 2 g/L); (Mi x Dj)ij is the first-order interaction, and eijk is the residual error. Statistical significance was set at p < 0.05. When the first order of interaction was significant, differences among the specific means of interest were verified and reported in the text. The effect of the dose of CH on wine composition was determined using the GLM procedure of SAS (2003) according to the following model:

where Yik is the dependent variable; m is the overall mean; Di is the fixed effect of CH dose (I = 0.5 g/L vs. 1 g/L vs. 2 g/L), and eik is the residual error. Statistical significance was set at p < 0.05. Furthermore, orthogonal polynomial contrast analysis was used to evaluate the effect of CH dose on specific parameters. IML SAS (2003) was used to generate unequally spaced linear and quadratic contrast coefficients, and post-hoc comparisons were performed using the contrast option of the LSMENS statement of SAS (2003).

To define the steady-state condition, the generalised linear model of SAS (9.2) was used by testing the REPEATED statement for the analysis of repeated measurements using opportune contrasts. The covariance was tested using compound symmetric and autoregressive tests, with experimental replicates subjected to repeated measurements.

Results and Discussion

CH Characterization

The physicochemical characteristics of CH are listed in Table 1. Analyses were performed on CH dry powder (CHDP) and after treatments in HS (CHHS), SW (CHSW), and W (CHW). The degree of deacetylation (DD) of CH used in the food industry ranges 60–100%, whereas the molecular weight typically ranges 10–1000 kD (Liu et al., 2011). According to literature (de Alvarenga et al., 2010; Fan et al., 2009), DD strongly affects the solubility, reactivity, and adsorption of many substrates. The CH used in this study showed an average DD of 79% and a molecular weight of 30 kDa, which is consistent with CH of fungal origin (Pochanavanich & Suntornsuk, 2002), and according to Tian et al. (2015), who defined the limit of MW for CH water solubility (from 3.82 to 4.67 × 103 Da), represents an insoluble CH.

The microstructures of the CH as dried powder or after extended agitation in each of the 3 matrixes were analysed by either SEM or the associated EDX and are reported in Fig. 1 and Table 1. Based on the SEM micrograph, chitosan exhibits a plate-like and rough surface, in agreement with the findings of Colangelo et al. (2018). Furthermore, the composition of the matrices seems to affect the roughness of chitosan, the CHDP (Fig. 1a) was characterised by a relatively smooth surface with few wrinkles, whereas the roughness appears to increase in CHHS, CHSW, and CHW powders (Fig. 1b, c, and d, respectively).

As reported in Table 1, the CHHS and CHSW powders showed similar elemental compositions with the only addition of Cl in CHHS (2.3%) due to hydrochloric acid used as an acidifier in HS, whereas in the SW solution, the only organic acid used was tartaric acid. However, CHW was characterised by the presence of sulphur (5.38%) and inorganic anions (0.89% and 0.23% of phosphorus and calcium, respectively) compared to CHDP, CHHS, and CHSW. The detection of sulphur on the CH surface may be related to the presence of sulphur dioxide in the tested wine (Table S1) and the possible consequent adsorption of it by CH. These results are consistent with previous findings by Mende et al. (Mende et al., 2016), which demonstrated the adsorption of sulphate anions by the CH surface. It is noteworthy that the adsorption of calcium may have positive effects on wine stabilisation toward calcium tartrate precipitation (Ponce et al., 2018).

Dissolution Test of CH

A preliminary study was performed to test the recovery of CH at 0.5, 1.0, and 2.0 g/L, after stirring (150 rpm) for 5′, 15′, 30′, 60, and 180′ at room temperature (20 ± 2 °C). The recovery of CHHS was 90.7 ± 2.1 at 5′ and 91.1 ± 1.6 after 180′, without significant changes over time, whereas the recovery curves of CHSW and CHW were similar and was 120.6 ± 3.01 and 125.2 ± 2.61 at 5′ and 129.8 ± 3.80 and 130.2 ± 3.69 at 180′, respectively. The recovery curve of CH reached a plateau after 180′ in all matrices (data not shown). Based on the results obtained in the preliminary study, subsequent trials under different conditions were only carried out at 180′ to replicate the plateau conditions and simulate a winemaking treatment on a real scale.

As shown in Table 2, the recovery of CH was affected by matrix (p < 0.05), the mean percentage of CH retained after filtration was 90.1, 129.8, and 130.2% for HS, SW, and W, respectively. Those values did not take into consideration that commercial CH can contain a certain degree of impurities, as shown by the partial dissolution of CH in HS. The excess weight recorded in SW and W compared to the amount of CH initially dissolved agreed with the assumption of Colangelo et al. (2018) regarding the adsorption of tartaric acid by CH, which was corroborated by the data shown in Fig. 2d. The CH addition at 0.5 g/L led to a significant increase in its recovery (119.8%) compared to those measured after CH treatments at 1 g/L (115.9%) and 2 g/L (115.3%) (Table 2). As shown in Fig. 2a, the effect of the dose × matrix combination (D × M) was significant (p < 0.05), as the recovery decreased with higher doses in SW and W, whereas it appeared to increase in HS. In this study, the maximum tested dose was set at 2 g/L; however, this dose had a significant effect on the percentage recovery of CH (p < 0.05), and further analysis should be carried out to reach the maximum absorption of organic acids by CH.

Effect of matrices (HS; SW; W) and chitosan dose interaction (0.5; 1.0; 2.0 g/L) on the following parameters: a dissolution test (%); b pH value; c specific surface area (m2/dm.3); d tartaric acid removal (g/L); e tartaric acid removal (mg/g CH). Data are the mean (± deviation standard) of three independent experiments. Mean values with different superscript letters are significantly different (p < 0.05)

Effect of CH Treatments on Different Matrices

The adsorption capacity of CH for organic compounds is strongly influenced by its structural and chemical properties, including its surface-to-volume ratio (Vafakish & Wilson, 2019). Therefore, it is necessary to know the available surface area of CH to understand whether changes in pH or ionic strength lead to the formation of aggregates or partial solubilisation of CH (Rocha et al., 2017). Furthermore, the partial solubilisation of CH in acid solutions (Zargar et al., 2015), the adsorption of phenolic compounds (Arenas et al., 2021; Spagna et al., 2000) may lead to a significant change in surface values, and therefore, in particle size. The particle size distribution of the dried powder and dispersed CH measured using laser diffraction, ranged between 6.7 and 586.0 μm, which is of the same order of magnitude as those recorded in the SEM image (Fig. S1). The dispersed CHW showed the highest average diameter D [3,2] (127.96 μm) compared with CHSW (120.81 μm) and CHHS (116.26 μm), according to the dissolution tests reported above. As the recovery of powders increased, the particle size of the dispersed CH increased in W and SW, likely because of the capability of CH to adsorb organic acids (Bornet & Teissedre, 2008; Colangelo et al., 2018). Because D [3,2] and specific surface area (SSA) are inversely correlated, a specular trend of these two parameters is shown in Table 2.

Therefore, the surface-to-volume ratios of both the dry and dispersed CH were calculated. The SSA of treated CH was significantly affected by both dose and matrix (p < 0.05): the SSA was lower in SW and W (49.41 and 47.03 m2/dm3, respectively) compared to HS, which showed the highest value of 51.65 m2/dm3. Furthermore, increasing doses of CH resulted in a significant increase (p < 0.05) in SSA (p < 0.05) for the SW and W solutions (Fig. 2c).

The pH was significantly affected by the CH dose and matrix (Table 2). The pH values increased as the dose increased (p < 0.05); however, the magnitude depended on the matrix. In HS the CH led to pH was 3.97 for a 0.5 g/L addition to 4.65 for a 2 g/L addition; in W it increased from 3.21 to 3.29. The higher increase in pH in HS was due to the absence of buffer capacity. Moreover, these results suggest that CH directly subtracts protons from the system by increasing the pH, mainly because of its polycation nature; therefore, its weak base (Goy et al., 2009). Although SW and W demonstrated similar pH values when treated with 0.5 g/L and 1 g/L of CH, increasing the dose to 2 g/L caused a relevant increase in pH in SW compared to W (Fig. 2b) due to the different buffering capacities of those matrices (Picariello et al., 2019). Therefore, it was evident how the dose, matrix, and D × M influenced the pH after CH addition (p < 0.05).

The effects of CH treatments on tartaric acid removal in SW and W are reported in Table 2 and are expressed as Δ g/L and mg/gCH. The removal of tartaric acid was strongly affected by the matrix and the dose. The tartaric acid removal reached 0.710 g/L and 0.406 g/L with 2 g/L CH treatment in SW and W, respectively, with a significant effect on the matrix (p < 0.05), as demonstrated in Fig. 2d. These differences were likely due to the different compositions of the matrices, and therefore a competitive absorption phenomenon was observed in W compared to SW. It has been widely demonstrated that CH also adsorbs phenolic compounds (Spagna et al., 1996), minerals (Bornet & Teissedre, 2008) and organic acids, in addition to tartaric acid, in wine (Castro Marín et al., 2021). A significant effect of the matrix was also detected in mg/g removal (p < 0.05), whereas in this case, the effect of the dose was not significant (p > 0.05), indicating the absence of substrate saturation (Zou et al., 2011). As indicated for dissolution, further study beyond the studied doses is required to understand the effect of CH over-addition.

Effect of CH in Wine

Tested white wine had an initial value of pH of 3.17 ± 0.01 and a titratable acidity (TA) of 5.27 ± 0.05 g/L mainly due to tartaric acid (2.69 ± 0.02 g/L) and malic acid (1.18 ± 0.01 g/L), the most abundant organic acids in grapes and wines (Waterhouse et al., 2016) (Table S1).

CH, because of its polycationic nature, has been speculated to potentially bind anions from organic acids, causing a reduction in acidity in wines (Bornet & Teissedre, 2008). This study confirmed that the pH of white wine increased with the dose of CH at 3.21, 3.24, and 3.29 with 0.5, 1, and 2 g/L of CH, respectively (p < 0.05). The described trend in pH was confirmed by TA values, which decreased to 5.08, 4.95, and 4.58, with increasing doses of CH; there was a linear correlation between these parameters (p < 0.05), as shown in Table 3 and Fig. 3a, b.

Effect of chitosan dose on the specific wine parameters according to orthogonal polynomial contrast analysis (p < 0.05): a pH value; b titratable acidity; c tartaric acid concentration; d removal of tartaric acid (Δ Tartaric acid); malic acid concentration (e); removal of malic acid (Δ Malic acid) (f) and (g) ΔE

For what concerns the removals of each organic acid detected in wine, tartaric acid decreased to 2.61 g/L, 2.49 g/L, and 2.28 g/L after the addition of 0.5, 1, and 2 g/L of CH, respectively. In addition, the CH dose linearly influenced tartaric acid removal (Fig. 3c, d; p < 0.05). Malic acid removal resulted to be lower (Δ of 0.11 g/L and 0.13 g/L after the addition of 1 and 2 g/L CH, respectively), compared to tartaric acid that reached Δ of 0.19 and 0.41 g/L. As shown in Fig. 3f, the correlation between the removal of malic acid and the dose treatment was linear (p < 0.05). An explanation of this phenomenon may be in pKa values of these organic acids: in fact, pKa1 is 2.98 and 3.40 and pKa2 is 4.34 and 5.11 for tartaric and malic, respectively (Waterhouse et al., 2016) which can determine the respective amount of anions in solution and, eventually, the magnitude of their adsorption on the CH surface.

It can be assumed that the interaction of CH with carboxylic acids can be described as that between a weak acid and weak base and can be illustrated as follows:

-

CH–NH2 + H3O+ ↔ CH–NH3+ + H2O

-

K = [CH − NH3+] / [CH − NH2] [H3O+]

The ionisation of carboxylic acid must be considered:

-

R-COOH + H2O ↔ RCOO− + H3O+

-

Ki = [RCOO −] [H3O+] / [RCOOH]

The protonation of CH will be determined by the equilibrium constant:

-

K = [CH − NH3+] [R − COO −] / [CH − NH2] [RCOOH] Ki

It is well known that at fixed acid and CH concentrations, the protonation process of CH depends only on the strength of the carboxylic acid, specifically the pK value (Shamov et al., 2002). In summary, the data suggest that, in aqueous solutions and water/ethanol mixtures, the sorption of n-carboxylic acids on CH may depend on the pK of the acid. However, when present at lower doses, CH seemed to have the same affinity to both acids: 0.5 g/L of CH removed 0.08 g/L for both tartaric acid and malic acid.

CH can be described as a microporous liquid sorbent with both hydrophilic and hydrophobic active centres. The amine groups of CH are oriented to the bulk of the solution and form hydrophilic active centres, whereas the internal domains of the polymer form hydrophobic micropores. As a result, the ionic interaction between the carboxylic acid functional groups and the amine group of CH can be coupled to the hydrophobic interactions between the carboxylic acid hydrocarbon chains and the internal hydrophobic domains of CH. Such a combination of these two types of interactions may be responsible for the high solubility and stability of CH molecules in a wide concentration range of organic acids (Tian et al., 2015). It is reasonable to assume that the effectiveness of hydrophobic interactions is determined mainly by the structure and length of the hydrocarbon chain of the carboxylic acid. In aqueous solutions, the internal domains of CH helices are hardly accessible, and hydrophobic micropores are significantly narrow (Shamov et al., 2002). Thus, hydrophobic interactions are less effective for carboxylic acids with branched hydrocarbon chains. In a water/ethanol solution, CH changes its conformation, and its internal hydrophobic domains become more accessible for the penetration of the hydrocarbon chains of carboxylic acids. One hypothesis is that carboxylic acids can be trapped inside CH helices due to effective hydrophobic interactions, and the length and structure of the hydrocarbon chain rather than the pK of the carboxyl group determines their sorption values (Shamov et al., 2002). This assumption is consistent with the improved SSA values recorded for W, which increased the CH dose (Fig. 2c). The minor removal of tartaric acid in W compared to SW can be explained by the competitive absorption of CH with other families of compounds present in wine, such as polyphenols (Arenas et al., 2021; Spagna et al., 1996). The total phenols (TPI) were measured before and after each treatment. Untreated W contained 168 mg/L of total phenols as gallic acid equivalents (Table S1). After CH contacts, that value decreased and ΔTPI resulted in 33.59, 34.40, and 31.28 mg/L for 0.5, 1, and 2 g/L of CH, respectively (Table 3). The trend of the removal of phenolics appeared to be different from that of organic acid removal, where the removal increased with the CH dose. In fact, TPI decreased by 20% after 0.5 g/L of CH addition and the decrease remained stable (20.47% and 18.60%) with higher CH doses. Statistical analysis confirmed that there was no correlation between phenolic removal and the CH dose (p > 0.05). Other authors also reported that CH removed maximum values of 30% and 20% of hydroxycinnamic acids and flavanols, respectively, in white wines (Chinnici et al., 2014; Spagna et al., 2000).

Phenolic removal using CH can adsorb oxidised phenolics such as the yellowish xanthylium cations or the carboxymethine-linked ( +)-catechin dimer intermediates, reducing the browning expression (Chinnici et al., 2014). However, in an un-oxidised white wine such as the wine tested in this work, CH treatment can determine a change in colour due to the decrease in yellow colour by means of b* parameter decrease (data not shown). The ΔE* parameters of the treated wines were 9.60, 8.02, and 8.17, after 0.5, 1, and 2 g/L of CH treatment, respectively, compared to the control wine. Colour changes showed the same trend as phenolic removal and did not increase with the dose of the treatment, demonstrating that colour changes are related to phenolic removal. ΔE* values were > 2.7 CIELab units indicate that the colour differences between wines can be perceived by the human eye (Martínez et al., 2001).

Conclusion

This study demonstrates that fungoid CH can adsorb organic acids in white wine and modify its physical and chemical properties. Extensive attention has been given to tartaric acid adsorption in W, an aspect that can be crucial for the wine industry. Different doses of CH were investigated, leading to significant effects on tartaric and malic acid removal, pH, and colour (ΔE). Moreover, in SW, the treatment of CH removed up to 354.9 mg of tartaric acid for every gramme of added CH; however, in W, the removal decreased to 182.4 mg/g, likely due to the presence of other families of compounds that affected this phenomenon. Despite this attenuation, the addition of 2 g/L of CH to W led to significant changes: the pH increased from 3.17 to 3.29; consequently, TA decreased from 5.27 to 4.58 g/L of tartaric acid, and a noticeable colour change was observed. Further investigations are needed to better evaluate the removal of other organic acids from W, and different doses of CH addition must be studied.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Alguacil, F. J., & Robla, J. I. (2022). Toxic metals adsorption from water using chitosan nanoderivatives. Nano-Biosorbents for Decontamination of Water, Air, and Soil Pollution. https://doi.org/10.1016/B978-0-323-90912-9.00018-6

Alishahi, A., & Aïder, M. (2012). Applications of chitosan in the seafood industry and aquaculture: A review. Food and Bioprocess Technology, 5, 817–830. https://doi.org/10.1007/s11947-011-0664-x

Arenas, I., Ribeiro, M., Filipe-Ribeiro, L., Vilamarim, R., Costa, E., Siopa, J., et al. (2021). Effect of pre-fermentative maceration and fining agents on protein stability, macromolecular, and phenolic composition of albariño white wines: Comparative efficiency of chitosan, k-carrageenan and bentonite as heat stabilisers. Foods, 10(3). https://doi.org/10.3390/foods10030608

Bornet, A., & Teissedre, P. L. (2008). Chitosan, chitin-glucan and chitin effects on minerals (iron, lead, cadmium) and organic (ochratoxin A) contaminants in wines. European Food Research and Technology, 226(4), 681–689. https://doi.org/10.1007/s00217-007-0577-0

Castro-Marín, A., Buglia, A. G., Riponi, C., & Chinnici, F. (2018). Volatile and fixed composition of sulphite-free white wines obtained after fermentation in the presence of chitosan. LWT, 93, 174–180. https://doi.org/10.1016/j.lwt.2018.03.003

Castro Marín, A., Colangelo, D., Lambri, M., Riponi, C., & Chinnici, F. (2021). Relevance and perspectives of the use of chitosan in winemaking: A review. Critical Reviews in Food Science and Nutrition, 61(20), 3450–3464. https://doi.org/10.1080/10408398.2020.1798871

Chatterjee, S., Chatterjee, S., Chatterjee, B. P., & Guha, A. K. (2004). Clarification of fruit juice with chitosan. Process Biochemistry, 39(12), 2229–2232. https://doi.org/10.1016/j.procbio.2003.11.024

Chinnici, F., Natali, N., & Riponi, C. (2014). Efficacy of chitosan in inhibiting the oxidation of (+)-catechin in white wine model solutions. Journal of Agricultural and Food Chemistry, 62(40), 9868–9875. https://doi.org/10.1021/jf5025664

Colangelo, D., Torchio, F., De Faveri, D. M., & Lambri, M. (2018). The use of chitosan as alternative to bentonite for wine fining: Effects on heat-stability, proteins, organic acids, colour, and volatile compounds in an aromatic white wine. Food Chemistry, 264, 301–309. https://doi.org/10.1016/j.foodchem.2018.05.005

Correa-Pacheco, Z. N., Bautista-Baños, S., Corona-Rangel, M. L., Ventura-Aguilar, R. I., Barrera-Necha, L. L., & Cuevas-Gómez, K. D. (2023). Effect of chitosan-based natural products nanocoatings on green bell peppers during storage. Food and Bioprocess Technology, 1–13.

Costa, C. N., Teixeira, V. G., Delpech, M. C., Souza, J. V. S., & Costa, M. A. S. (2015). Viscometric study of chitosan solutions in acetic acid/sodium acetate and acetic acid/sodium chloride. Carbohydrate Polymers, 133, 245–250. https://doi.org/10.1016/j.carbpol.2015.06.094

Crognale, S., Russo, C., Petruccioli, M., & D’annibale, A. (2022). Chitosan production by fungi: Current state of knowledge, future opportunities and constraints. Fermentation, 8(2). https://doi.org/10.3390/fermentation8020076

de Alvarenga, E. S., Pereira de Oliveira, C., & Roberto Bellato, C. (2010). An approach to understanding the deacetylation degree of chitosan. Carbohydrate Polymers, 80(4), 1155–1160. https://doi.org/10.1016/j.carbpol.2010.01.037

de Vargas, V. H., Marczak, L. D. F., Flôres, S. H., & Mercali, G. D. (2022). Advanced technologies applied to enhance properties and structure of films and coatings: A review. Food and Bioprocess Technology, 15(6), 1224–1247. https://doi.org/10.1007/s11947-022-02768-6

EFSA Scientific Committee. (2011). Scientific Opinion on the substantiation of health claims related to chitosan and reduction in body weight (ID 679, 1499), maintenance of normal blood LDL-cholesterol concentrations (ID 4663), reduction of intestinal transit time (ID 4664) and reduction of inflammation (ID 1985) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA Journal, 9(6). https://doi.org/10.2903/j.efsa.2011.2214

Eissa, H. A., Ali, H. S., Ragab, G. H., & Ibrahim, W. A. (2021). Effect of inulin and chitosan on the quality of cucumber juice. Annals of the Romanian Society for Cell Biology, 7945–7957.

European Commission. (2011). Commission Regulation (EU) No 53/2011 of 21 January 2011 amending Regulation (EC) No 606/2009 laying down certain detailed rules for implementing Council Regulation (EC) No 479/2008. http://data.europa.eu/eli/reg/2011/53/oj

Fan, M., Hu, Q., & Shen, K. (2009). Preparation and structure of chitosan soluble in wide pH range. Carbohydrate Polymers, 78(1), 66–71. https://doi.org/10.1016/j.carbpol.2009.03.031

Gassara, F., Antzak, C., Ajila, C. M., Sarma, S. J., Brar, S. K., & Verma, M. (2015). Chitin and chitosan as natural flocculants for beer clarification. Journal of Food Engineering, 166, 80–85. https://doi.org/10.1016/j.jfoodeng.2015.05.028

Gernat, D. C., Brouwer, E., & Ottens, M. (2020). Aldehydes as wort off-flavours in alcohol-free beers—origin and control. Food and Bioprocess Technology, 13, 195–216. https://doi.org/10.1007/s11947-019-02374-z

Goy, R. C., De Britto, D., & Assis, O. B. G. (2009). A review of the antimicrobial activity of chitosan. Polimeros, 19(3), 241–247. https://doi.org/10.1590/S0104-14282009000300013

Haghighi, H., Licciardello, F., Fava, P., Siesler, H. W., & Pulvirenti, A. (2020). Recent advances on chitosan-based films for sustainable food packaging applications. Food Packaging and Shelf Life, 26. https://doi.org/10.1016/j.fpsl.2020.100551

Izquierdo-Llopart, A., Carretero, A., & Saurina, J. (2020). Organic acid profiling by liquid chromatography for the characterization of base vines and sparkling wines. Food Analytical Methods, 13(10), 1852–1866. https://doi.org/10.1007/s12161-020-01808-1

Lago, M. A., Sendón, R., de Quirós, A. R. B., Sanches-Silva, A., Costa, H. S., Sánchez-Machado, D. I., Valdez, H. S., Angulo, I., Aurrekoetxea, G. P., Torrieri, E., López-Cervantes, J., & Paseiro, P. (2014). Preparation and characterization of antimicrobial films based on chitosan for active food packaging applications. Food and Bioprocess Technology, 7, 2932–2941. https://doi.org/10.1007/s11947-014-1276-z

Lamas, A., Anton, X., Miranda, J. M., Roca-Saavedra, P., Cardelle-Cobas, A., Ibarra, I. S., et al. (2016). Technological strategies for the development of egg-derived products with reduced content of cholesterol. Food Bioprocess Technology, 9, 81–90. https://doi.org/10.1007/s11947-015-1599-4

Liu, X., Ma, L., Mao, Z., & Gao, C. (2011). Chitosan-based biomaterials for tissue repair and regeneration. Advances in Polymer Science (Vol. 244). https://doi.org/10.1007/12_2011_118

Luck, P., Vårum, K. M., & Foegeding, E. A. (2015). Charge related astringency of chitosans. Food Hydrocolloids, 48, 174–178. https://doi.org/10.1016/j.foodhyd.2015.02.024

Luo, Y., & Wang, Q. (2013). Recent advances of chitosan and its derivatives for novel applications in food science. Journal of Food Processing & Beverages, 1(1), 1–13.

Mannozzi, C., Tylewicz, U., Chinnici, F., Siroli, L., Rocculi, P., Dalla Rosa, M., & Romani, S. (2018). Effects of chitosan based coatings enriched with procyanidin by-product on quality of fresh blueberries during storage. Food Chemistry, 251, 18–24. https://doi.org/10.1016/j.foodchem.2018.01.015

Martínez, J. A., Melgosa, M., Pérez, M. M., Hita, E., & Negueruela, A. I. (2001). Note. Visual and instrumental color evaluation in red wines. Food Science and Technology International, 7(5), 439–444. https://doi.org/10.1106/VFAT-5REN-1WK2-5JGQ

Mende, M., Schwarz, D., Steinbach, C., Boldt, R., & Schwarz, S. (2016). Simultaneous adsorption of heavy metal ions and anions from aqueous solutions on chitosan—Investigated by spectrophotometry and SEM-EDX analysis. Colloids and Surfaces a: Physicochemical and Engineering Aspects, 510, 275–282. https://doi.org/10.1016/j.colsurfa.2016.08.033

Morin-Crini, N., Lichtfouse, E., Torri, G., & Crini, G. (2019). Applications of chitosan in food, pharmaceuticals, medicine, cosmetics, agriculture, textiles, pulp and paper, biotechnology, and environmental chemistry. Environmental Chemistry Letters, 17(4), 1667–1692. https://doi.org/10.1007/s10311-019-00904-x

Mustafa, M. A., Ali, A., Manickam, S., & Siddiqui, Y. (2014). Ultrasound-assisted chitosan–surfactant nanostructure assemblies: Towards maintaining postharvest quality of tomatoes. Food and Bioprocess Technology, 7, 2102–2111. https://doi.org/10.1007/s11947-013-1173-x

Nunes, C., Maricato, É., Cunha, Â., Rocha, M. A. M., Santos, S., Ferreira, P., et al. (2016). Chitosan-genipin film, a sustainable methodology for wine preservation. Green Chemistry, 18(19), 5331–5341. https://doi.org/10.1039/c6gc01621a

OIV. (2014). Compendium of international methods of analysis of wines and musts. International Organisation of Vine and Wine Paris.

Pal, P., Pal, A., Nakashima, K., & Yadav, B. K. (2021). Applications of chitosan in environmental remediation: A review. Chemosphere, 266. https://doi.org/10.1016/j.chemosphere.2020.128934

Paniagua-Martínez, I., Ramírez-Martínez, A., Serment-Moreno, V., Rodrigues, S., & Ozuna, C. (2018). Non-thermal technologies as alternative methods for Saccharomyces cerevisiae inactivation in liquid media: A review. Food and Bioprocess Technology, 11, 487–510. https://doi.org/10.1007/s11947-018-2066-9

Picariello, L., Rinaldi, A., Forino, M., Petracca, F., Moio, L., & Gambuti, A. (2019). Modification of the organic acid profile of grapes due to climate changes alters the stability of red wine phenolics during controlled oxidation. Vitis - Journal of Grapevine Research, 58, 127–133. https://doi.org/10.5073/vitis.2019.58.special-issue.127-133

Pochanavanich, P., & Suntornsuk, W. (2002). Fungal chitosan production and its characterization. Letters in Applied Microbiology, 35(1), 17–21. https://doi.org/10.1046/j.1472-765X.2002.01118.x

Ponce, F., Mirabal-Gallardo, Y., Versari, A., & Laurie, V. F. (2018). The use of cation exchange resins in wines: Effects on pH, tartrate stability, and metal content | El uso de resinas de intercambio catiónico en vinos: Efectos sobre el pH, la estabilidad tartárica, y el contenido de metales. Ciencia e Investigacion Agraria, 45(1), 82–92. https://doi.org/10.7764/rcia.v45i1.1911

Portugal, C., Sáenz, Y., Rojo-Bezares, B., Zarazaga, M., Torres, C., Cacho, J., & Ruiz-Larrea, F. (2014). Brettanomyces susceptibility to antimicrobial agents used in winemaking: In vitro and practical approaches. European Food Research and Technology, 238(4), 641–652. https://doi.org/10.1007/s00217-013-2143-2

Riaz Rajoka, M. S., Mehwish, H. M., Wu, Y., Zhao, L., Arfat, Y., Majeed, K., & Anwaar, S. (2020). Chitin/chitosan derivatives and their interactions with microorganisms: A comprehensive review and future perspectives. Critical Reviews in Biotechnology, 40(3), 365–379. https://doi.org/10.1080/07388551.2020.1713719

Rinaudo, M. (2006). Chitin and chitosan: Properties and applications. Progress in Polymer Science (oxford), 31(7), 603–632. https://doi.org/10.1016/j.progpolymsci.2006.06.001

Rinaudo, M., Milas, M., & Dung, P. L. (1993). Characterization of chitosan. Influence of ionic strength and degree of acetylation on chain expansion. International Journal of Biological Macromolecules, 15(5), 281–285. https://doi.org/10.1016/0141-8130(93)90027-J

Rocha, M. A. M., Coimbra, M. A., & Nunes, C. (2017). Applications of chitosan and their derivatives in beverages: A critical review. Current Opinion in Food Science, 15, 61–69. https://doi.org/10.1016/j.cofs.2017.06.008

Sahariah, P., & Másson, M. (2017). Antimicrobial chitosan and chitosan derivatives: A review of the structure-activity relationship. Biomacromolecules, 18(11), 3846–3868. https://doi.org/10.1021/acs.biomac.7b01058

Sahraee, S., Ghanbarzadeh, B., Milani, J. M., & Hamishehkar, H. (2017). Development of gelatin bionanocomposite films containing chitin and ZnO nanoparticles. Food and Bioprocess Technology, 10, 1441–1453. https://doi.org/10.1007/s11947-017-1907-2

Shahidi, F., Arachchi, J. K. V., & Jeon, Y.-J. (1999). Food applications of chitin and chitosans. Trends in Food Science and Technology, 10(2), 37–51. https://doi.org/10.1016/S0924-2244(99)00017-5

Shamov, M. V., Bratskaya, S. Y., & Avramenko, V. A. (2002). Interaction of carboxylic acids with chitosan: Effect of pK and hydrocarbon chain length. Journal of Colloid and Interface Science, 249(2), 316–321. https://doi.org/10.1006/jcis.2002.8248

Solomon, O. F., & Ciutǎ, I. Z. (1962). Détermination de la viscosité intrinsèque de solutions de polymères par une simple détermination de la viscosité. Journal of Applied Polymer Science, 6(24), 683–686. https://doi.org/10.1002/app.1962.070062414

Spagna, G., Barbagallo, R. N., & Pifferi, P. G. (2000). Fining treatments of white wines by means of polymeric adjuvants for their stabilization against browning. Journal of Agricultural and Food Chemistry, 48(10), 4619–4627. https://doi.org/10.1021/jf0005519

Spagna, G., Pifferi, P. G., Rangoni, C., Mattivi, F., Nicolini, G., & Palmonari, R. (1996). The stabilization of white wines by adsorption of phenolic compounds on chitin and chitosan. Food Research International, 29(3–4), 241–248. https://doi.org/10.1016/0963-9969(96)00025-7

Sun, Z., Hao, J., Yang, H., & Chen, H. (2018). Effect of chitosan coatings enriched with lauroyl arginate ethyl and montmorillonite on microbial growth and quality maintenance of minimally processed table grapes (Vitis vinifera L. Kyoho) during cold storage. Food and Bioprocess Technology, 11, 1853–1862. https://doi.org/10.1007/s11947-018-2146-x

Taştan, Ö., & Baysal, T. (2017). Chitosan as a novel clarifying agent on clear apple juice production: Optimization of process conditions and changes on quality characteristics. Food Chemistry, 237, 818–824. https://doi.org/10.1016/j.foodchem.2017.06.025

Tedesco, F., Siesto, G., Pietrafesa, R., Romano, P., Salvia, R., Scieuzo, C., et al. (2022). Chemical methods for microbiological control of winemaking: An overview of current and future applications. Beverages, 8(3). https://doi.org/10.3390/beverages8030058

Tian, M., Tan, H., Li, H., & You, C. (2015). Molecular weight dependence of structure and properties of chitosan oligomers. RSC Advances, 5(85), 69445–69452. https://doi.org/10.1039/c5ra08358c

Vafakish, B., & Wilson, L. D. (2019). Surface-modified chitosan: An adsorption study of a “Tweezer-Like” biopolymer with fluorescein. Surfaces, 2(3), 468–484. https://doi.org/10.3390/surfaces2030035

Waterhouse, A. L., Sacks, G. L., & Jeffery, D. W. (2016). Understanding wine chemistry. John Wiley & Sons.

Yang, H., Zheng, J., Huang, C., Zhao, X., Chen, H., & Sun, Z. (2015). Effects of combined aqueous chlorine dioxide and chitosan coatings on microbial growth and quality maintenance of fresh-cut bamboo shoots (Phyllostachys praecox f. prevernalis.) during storage. Food and Bioprocess Technology, 8, 1011–1019. https://doi.org/10.1007/s11947-014-1463-y

Zargar, V., Asghari, M., & Dashti, A. (2015). A review on chitin and chitosan polymers: Structure, chemistry, solubility, derivatives, and applications. ChemBioEng Reviews, 2(3), 204–226. https://doi.org/10.1002/cben.201400025

Zhang, L., Zeng, Y., & Cheng, Z. (2016). Removal of heavy metal ions using chitosan and modified chitosan: A review. Journal of Molecular Liquids, 214, 175–191. https://doi.org/10.1016/j.molliq.2015.12.013

Zhong, Z., Zhou, L., Yu, K., Jiang, F., Xu, J., Zou, L., Du, L., & Liu, W. (2022). Effects of microporous packaging combined with chitosan coating on the quality and physiological metabolism of passion fruit after harvest. Food and Bioprocess Technology. https://doi.org/10.1007/s11947-022-02845-w

Zou, X., Pan, J., Ou, H., Wang, X., Guan, W., Li, C., et al. (2011). Adsorptive removal of Cr(III) and Fe(III) from aqueous solution by chitosan/attapulgite composites: Equilibrium, thermodynamics and kinetics. Chemical Engineering Journal, 167(1), 112–121. https://doi.org/10.1016/j.cej.2010.12.009

Acknowledgements

The authors thank Bioenol Italia s.r.l. for supplying fungoid CH.

Funding

Open access funding provided by Università Cattolica del Sacro Cuore within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Elia Romanini and Alice Gruppi: formal analysis, methodology, and writing—original draught; Fabio Chinnici and Andrea Bassani: writing—review and editing; Milena Lambri: funding acquisition and writing—review and editing; Mario Gabrielli: conceptualisation; data curation; writing—review and editing. All the authors approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Alice Gruppi and Elia Romanini contributed equally to this research paper

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gruppi, A., Romanini, E., Bassani, A. et al. Adsorption Capabilities of Fungoid Chitosan Toward Organic Acids in Model Solutions and White Wine. Food Bioprocess Technol 17, 384–395 (2024). https://doi.org/10.1007/s11947-023-03135-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03135-9