Abstract

Soy protein based high moisture meat analogues (HMMAs) were made by extrusion, with incorporation of 0, 5, 10, and 20% whole tomato powder (WTP) or 10% tomato peel powder (TPP). Their color, nutritional, and textural properties were characterized. Results showed that the color, total phenolic content, antioxidant capacity, and bioaccessible lycopene content in the HMMAs were improved with WTP incorporation. However, too much (20%) WTP incorporation led to unacceptable textural properties. On the other hand, TPP incorporation resulted in a conspicuously soft texture, an unevenly distributed color as well as minimal color and nutritional improvements. Compared with TPP, WTP was more suitable to be incorporated into HMMAs to improve the color and nutritional qualities.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The increasing awareness of the environmental issue, human health, as well as animal welfare have prompted tremendous interests in plant-based meat. The Australian plant-based meat market is expected to reach $3 billion by 2030 (He et al., 2020; Lawrence & King, 2019). High moisture meat analogues (HMMA, moisture content 40–80%) produced via extrusion are the most muscle meat-resembled type due to their more fibrous structure than other types of plant-based meat substitutes in the current market such as tofu, tempeh, and low moisture meat analogues (LMMAs) (Zahari et al., 2020). It has been suggested that consumers especially carnivores and flexitarians who like the sensory perceptions of real meat prefer to accept the plant-based meat when it possesses meat-resembled sensorial properties including color and texture (He et al., 2020).

Currently, soy protein is the most common plant protein used in the production of HMMAs because of its techno-functional and nutritional performance (Guyony et al., 2022). However, it gives HMMAs an unappealing beige color, resulting in the failure of mimicking real meat products (Kyriakopoulou et al., 2021). So far, the addition of natural colorants is the main method in mimicking meat color. Lycopene, one of the natural food colorants that has been added in HMMA formulations to impart the attractive red color, is “clean label” and beneficial to nutritional value (Leong et al., 2018; Trottet et al., 2017). In comparison with other natural red colorants such as temperature sensitive betacyanins and pH-sensitive anthocyanins, lycopene displays stable red color over a wide range of pH and temperature, which is more suitable to impart color to meat-like products (Fernández-López et al., 2020). Recently, the red meat-resembled color was achieved in plant-based burgers by mixing tomato paste that naturally contains lycopene with other ingredients (Bohrer, 2019), as well as in meat-free sausages by adding tomato pomace into meat-free emulsion (Savadkoohi et al., 2014). However, there is no report on applying natural ingredients containing lycopene in production of HMMAs by extrusion.

Tomato is the predominant source of lycopene in the human diet (Fraser et al., 2005). Million tons of tomato products are produced annually, and considerable amounts of by-products, such as seeds and peels, are generated and disposed of as wastes (World Processing Tomato Council, 2021). However, tomato by-products still contain rich carotenoids (especially lycopene), phenolic compounds, and ascorbic acid, which are antioxidants contributing to the high antioxidant activity of tomatoes. Additionally, tomato by-products contain large amounts of dietary fibers, which are good for gut health (Lu et al., 2019). To minimize the waste of tomato processing, tomato as whole or tomato by-products acting as colorants and nutritional additives have been incorporated into various food formulations such as bread (Nour et al., 2015), meat products (García et al., 2009; Kim et al., 2011), extruded puffed snacks (Wójtowicz et al., 2018; Yagci et al., 2022), as well as plant-based meat products (i.e., meat-free sausage and patties) (Bohrer, 2019; Savadkoohi et al., 2014), which generally provided positive effects on the color and nutritional quality, and altered the textural quality of incorporated foods due to the presence of dietary fibers.

Currently, neither whole tomato nor tomato by-products has been incorporated in HMMA production by extrusion. Therefore, the aim of this study was to investigate the effect of whole tomato powder or tomato peel powder incorporation on the color, nutritional, and textural properties of soy protein based HMMAs. This study could provide a practical reference to develop meat-resembled color and improve the nutritional quality of HMMAs by incorporation of tomato and tomato by-products.

Materials and Methods

Materials

Tomato peel powder (TPP) prepared from tomato sauce processing by-products, was generously supplied by Kagome (Echuca, VIC, Australia). Whole tomato powder (WTP) was donated by Spice Masters Australia (Kingsgrove, NSW, Australia). Soy protein isolate (SPI) (90% protein, 1.8% carbohydrate, 1.5% fat) was purchased from Bulk Nutrients (Grove, TAS, Australia). All powders were sealed and stored in polyethylene bag under refrigerated condition (4 °C) before use. Moisture content of the SPI, TPP, and WTP were 5.94%, 5.79%, and 14.48% respectively based on the AOAC method 934.01 (AOAC, 2005).

Chemicals

Porcine pancreatin was purchased from Jomar Life Research (Mulgrave, VIC, Australia). Other chemicals and reagents were purchased from Sigma-Aldrich (Castle Hill, NSW, Australia) and Bio 21 (Parkville, VIC, Australia). Lycopene standard, tetrahydrofuran, methanol, dichloromethane, and acetonitrile were of HPLC grade, while other chemicals were of analytical grade.

Production of HMMAs and Post-treatment (Boiling)

The extrusion feeding materials were prepared by thoroughly mixing SPI with different ratios of WTP (5%, 10%, 20%; coded as WTP5, WTP10, and WTP20, respectively) or TPP (10%; coded as TPP10) before the extrusion process. These percentages of tomato powder addition were determined according to preliminary experiments to assure the texturized product after extrusion and acceptable colors by the authors. A control (SPI only) product was also prepared at the same extrusion conditions.

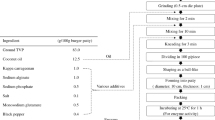

The high moisture extrusion process was conducted using a co-rotating twin screw lab-extruder (Jinan Saibainuo Technology Development Co. Ltd, Jinan, China), with a screw diameter of 30 mm, a screw length/diameter ratio of 23:1, and a fixed screw configuration (Fig. 1). The screws were configured with 295 mm forward conveying section (consisted of 4 × 30 mm pitch and 7 × 25 mm pitch forward conveying screws), 74 mm mixing section (consisted of 4 × 12 mm pitch forward conveying screws with 4 × 5 mm notches and 3 × 8.8 mm kneading blocks), 160 mm forward conveying section (consisted of 8 × 20 mm pitch forward convaying screws), 53 mm mixing section (consisted of 6 × 8.8 mm pitch kneading blocks), and 90 mm metering section (consisted of 6 × 15 mm pitch forward conveying screws elements). The extruder barrel was divided into four different temperature zones at 30 °C, 60 °C, 100 °C, and 90 °C, respectively, which were heated by an electric cartridge heating system and cooled by a running water-cooling system. A long cooling die with dimensions of 300 × 18 × 6 mm (L × W × H) was attached to the end of the extruder. The feed moisture was controlled based on the moisture content of raw materials and water feed, using a FEDOS E8 piston dosing water pump (Lutz-Jesco, NI, Germany). The moisture content (60%), dry powder feed rate (3.0 kg/h), the above barrel temperature profile, and screw speed (300 rpm) were kept in constant for all runs. The residence time in the extruder and the cooling die was about 5 min. These selected conditions were determined based on preliminary trials. Duplicate runs for each formulation group were performed.

After extrusion, samples of Control, WTP10, and TPP10 were cooked in boiling water at 100 °C for 10 min. Only the formulations with more obvious color improvement and acceptable texture were selected to be boiled, and these formulations were selected to compare the effect of WTP and TPP incorporation on the stability of color, nutritional and textural properties after boiling. After cooking, they were placed on blotting paper and cool down to room temperature.

The HMMAs and boiled HMMAs were sealed in polyethylene bags and stored at refrigeration temperature (4 °C) in the dark within 3 days for physical analysis. The samples used for chemical analysis were stored at − 18 °C in the dark before use.

Color Measurement

The color of HMMAs and boiled HMMAs was measured as per the method of Zahari et al. (2020) using a Minolta chromameter (Model CR-400; Konica Minolta Sensing Inc., Osaka, Japan). The calibration was performed with a standard white board before the measurement. The values of L* (lightness-darkness), a* (redness–greenness), and b* (yellowness–blueness) were recorded. The measurements were performed at three randomly selected positions for each sample. The total color change (ΔE) was calculated based on the following equation:

where L*, a*, and b* are the CIE-Lab values of the HMMAs incorporated with WTP or TPP, and L0, a0, and b0 are the values for the Control sample.

Determination of TPC

The extraction of total phenolic content was carried out using the method described by Toor and Savage (2006) with some modifications. Briefly, 4.0 ± 0.01 g of the ground HMMA or boiled HMMA was mixed and shaken with 20 mL of 80% (v/v) acetone on a mixer (Ratek Instruments Pty Ltd., Boronia, VIC, Australia) for 2 h at room temperature, covered by foil and parafilm. The mixture was then centrifuged at 5000 rpm for 10 min at 4 °C and the supernatant was collected and filtered using a Whatman No. 1 filter paper. The extraction procedures were duplicated for each sample.

The method of Liang et al. (2023) was followed to determine the total phenolic content. An aliquot of 100 µL of sample extract was mixed with 2.5 mL 0.2N Folin-Ciocalteu reagent. After 5 min incubation at room temperature in darkness, 2 mL saturated sodium carbonate (75 g/L) was added. The mixture was shaken thoroughly before being incubated for one hour in the dark at room temperature. The absorbance was recorded at 765 nm by a UV–Vis spectrophotometer (Thermo Fisher Scientific, Waltham, MA, USA). Gallic acid was used as standard to prepare a standard curve (20–500 mg/L). Results were expressed as mg gallic acid equivalents (GAE)/100 g sample. Duplicate measurements were carried out for each sample.

Determination of Antioxidant Capacity

The 1,1-diphenyl-2-picrylhydrazyl (DPPH) Radical Scavenging Assay

The DPPH radical scavenging assay was performed using the method of Liang et al. (2023) with some modifications. The DPPH stock solution was prepared by dissolving 24 mg of DPPH in 100 mL methanol. Then the DPPH stock solution was diluted with methanol to prepare a fresh DPPH working solution with absorbance of 1.1 ± 0.02 units at 517 nm. The above total phenolic content (TPC) extract of 75 µL was mixed with 1425 µL of DPPH working solution and the mixture was incubated one hour in the dark at room temperature. The absorbance was determined at 517 nm on the UV–Vis spectrophotometer. A standard curve was prepared using Trolox (20–100 mg/L). Results were expressed as mg Trolox equivalents (Trolox eq.)/100 g sample. Duplicate measurements were carried out for each sample.

FRAP Assay

Ferric reducing antioxidant powder (FRAP) assay was conducted following the method of Liang et al. (2023). About 300 mM acetate buffer (pH 3.6), 10 mM TPTZ solution, and 20 mM FeCl3·6H2O were mixed (10:1:1, v/v/v) to prepare the FRAP reagent. Sample extract of 50 µL was combined with 450 µL Milli-Q water and 1 mL FRAP reagent. The mixture was mixed thoroughly and incubated at 37 °C for 5 min in the dark. The absorbance was measured at 593 nm on the UV–Vis spectrophotometer. Fe2SO4·7H2O was used as standard (5–30 µM) to plot a standard curve. Results were presented as μmol Fe2+ equivalents (Fe2+ eq.)/100 g sample. The analysis was performed in duplicate for each sample.

HPLC–DAD Quantification of Lycopene and Determination of In Vitro Bioaccessibility of Lycopene

Lycopene extraction was performed following the method of Riggi and Avola (2008) with modification. About 5 g of ground HMMA or boiled HMMA was mixed with 25 mL of the extraction solvent comprised of hexane/ethanol/acetone (2:1:1 v/v/v) and shaken for 30 min at room temperature in an incubator shaker (ZWYR-240, Labwit, Ashwood, VIC, Australia). After addition of 10 mL distilled water, the mixture was shaken for another 2 min. The mixture was left for 15 min for phase separation and then the supernatant (hexane layer) was collected. The residues were re-extracted with 12.5 mL hexane following the procedure above. The supernatants were combined and dried under nitrogen gas at 25°C using a nitrogen blow-down system of dry block heaters (Ratek Instruments Pty Ltd., Boronia, VIC, Australia). The dried supernatants were immediately re-dissolved in 400 µL tetrahydrofuran/methanol solution (1/1, v/v) and filtered through 0.45 µm nylon syringe filter before HPLC-DAD analysis. The extraction procedures were conducted in the dark.

The high-performance liquid chromatography (HPLC) analysis was carried out according to the method of Liang et al. (2023) with slight modification. The analyses were performed on an Agilent 1260 Infinity II Prime LC (Agilent Technologies, Santa Clara, CA, USA) equipped with a diode-array detector (DAD). The column was an 80 A LC column (Synergi™ Hydro-RP, 250 × 4.6 mm i.d.) protected by an AQ C18 guard column (4.0 × 3.0 mm i.d.) (Phenomenex, Lane Cove, NSW, Australia). The column temperature was set at 25 °C and the absorbance was recorded at 470 nm. The solvent system consisted of methanol: dichloromethane: acetonitrile (7:2:7, v/v/v) (mobile phase A) and methanol (mobile phase B) with a gradient from 100% to 80% A in 4 min, to 50% A in 4 min, to 20% A in 2 min then to 0% A in 5 min and stayed 0% A isocratic for 20 min and turned to 100% A in 5 min, and stayed 100% A isocratic for 5 min, with a total 45 min running time. The flow rate was 1 mL/min, and the injection volume was 20 μL. Lycopene contents were quantified using a calibration curve prepared with ≥ 98% HPLC-grade lycopene standard. The data was analyzed using Agilent OpenLAB workstation (Agilent Technologies, Santa Clara, CA, USA). HPLC analysis was conducted in duplicate for each sample.

The determination of lycopene bioaccessibility was performed based on the method of Zhang et al. (2020). The bioaccessible lycopene content was quantified after each sample was subjected to the in vitro gastrointestinal digestion model in the “In Vitro Gastrointestinal Digestion Procedure” section, and used the same lycopene extraction and HPLC-DAD analysis procedures as above, but 40 μL injection volume was applied. The bioaccessibility of lycopene was calculated using the equation below:

In Vitro Gastrointestinal Digestion Procedure

The bioaccessible lycopene content was determined using an in vitro gastrointestinal digestion model as reported by Minekus et al. (2014), using the same simulated salivary, gastric, and intestinal fluids as described by the authors. The enzyme activity of pancreatin were determined by a preliminary experiment.

In the oral phase, 4 g of ground HMMA or boiled HMMA was mixed with 2.8 mL simulated salivary fluid, 0.4 mL human salivary α-amylase solution (1500 U/mL), 20 µL CaCl2 (0.3 mol/L), and 780 µL Milli-Q water. The mixture was agitated in an incubator shaker at 100 rpm for 2 min at 37 °C. In the gastric phase, 8 mL oral bolus was combined with 6 mL simulated gastric fluid, 1.28 mL porcine pepsin solution (25,000 U/mL), 4 µL of CaCl2 (0.3 mol/L), and 556 µL of Milli-Q water. After the pH being adjusted to 3.0 with HCl, the mixture was shaken at 100 rpm for 2 h at 37 °C. In the small intestinal phase, 16 mL of gastric-chyme was combined with 8.8 mL simulated intestinal fluid, 4 mL pancreatin solution (800 U/mL), 2 mL bile salts (160 mM), 32 µL CaCl2 (0.3 mol/L), and 1.048 mL of Milli-Q water. After the pH being adjusted to 7.0 with NaOH, the mixture was incubated at 100 rpm for 2 h at 37 °C. The digesta was collected after completion of the small intestinal phase and stored at − 70 °C to stop enzyme reactions. Based on the methods described by Liu et al. (2022) and Rodrigues et al. (2016), the digesta was thawed and centrifuged at 6800 rpm for 45 min at 4 °C. The aliquots of supernatant, in which the lycopene was solubilized, were collected and filtered through a 0.22 µm nylon syringe filter to remove microcrystalline particles of lycopene. The filtrate was assumed as the micelle fraction, in which lycopene could be absorbed in small intestine and considered as bioaccessible.

Determination of Textural Properties

TPA

Texture profile analysis was conducted using the method of Zahari et al. (2020) with a modification. A piece of 1.5 × 1.5 cm HMMAs or boiled HMMAs with 6 mm thickness were compressed using a Lloyd TA1 texture analyzer machine (Largo, FL, USA) equipped with an 18 mm cylindrical probe at a speed of 60 mm/min. Three measurements were taken for each sample. NexygenPlus Materials Testing Software (Largo, FL, USA) was used to determine the parameters including hardness, cohesiveness, chewiness, and springiness.

TI

The texturization index was determined using the method of Mazlan et al. (2020). The 1.5 × 1.5 cm HMMAs or boiled HMMAs were sheared 100% of its original thickness by a Warner–Bratzler stainless steel shear probe with 60° shear angle and 1.00 mm probe thickness attached to the Lloyd TA1 texture machine at a speed of 60 mm/min. Samples were sheared along the vertical (crosswise cutting strength) and parallel (lengthwise cutting strength) directions respectively to the flow direction of extrudate. The texturization index was calculated based on the following equation. Three measurements were conducted for each sample.

Statistical Analysis

Each formulation HMMA was extruded in duplicate, and each sample was analyzed at least duplicate, except lycopene bioaccessibility analysis that was conducted once for each sample. The results were expressed as means ± standard deviations (SD). The data analysis was performed using Minitab® 19 statistical software (2019, USA). The significant difference of means of each parameter (color, TPC, DPPH, FRAP, lycopene quantification, lycopene bioaccessibility, texture profile analysis (TPA), and texturization index (TI)) between formulation groups (four tomato added formulations and one control) and a post extrusion treatment (with or without boiling) were determined by performing one-way ANOVA and Fisher’s least significant difference at 95% confidence level.

Results and Discussion

Color Characteristics

Color is a vital factor affecting consumer acceptability of food products, so color measurement is considered as one of the most critical tests to assess the quality of HMMAs (Fiorentini et al., 2020). As shown in Table 1, the significant decrease of L* as well as increase of a* and b* were observed after incorporation of WTP or TPP in the soy protein based HMMAs (p < 0.05). The total color change (ΔE) for each HMMA incorporated with WTP or TPP to the Control was larger than 2, which means their color changes by WTP or TPP incorporation could be identified by consumers’ naked eyes (Grobelna et al., 2019). It was expected that the decreased L* and increased a* could be ascribed to the presence of lycopene in WTP and TPP (Yagci et al., 2022), while other pigments in tomatoes such as β-carotene and rutin could contribute to the increase of yellowness (Martí et al., 2016). Similar results were found in previous studies, such as addition of tomato peel significantly increased the a* and b* in beef hamburgers (García et al., 2009), and incorporation of tomato powder in corn-based extruded snacks gave a darker, redder, and more yellow color (Wójtowicz et al., 2018). Additionally, with the increase of WTP incorporation, the changes of L*, a*, b*, and consequently the ΔE were increased. Based on literature, the L*, a*, and b* values of dry-cured beef were reported to be 31.61, 11.68, and 5.85, respectively (Liu et al., 2019), and those of commercial cured ham product were 62.72, 20.52, and 12.23 (Sindelar, 2006). Thus, the colors of WTP incorporated HMMAs were relatively cured-meat-product resembled as compared to the Control and TPP incorporated HMMAs, which is in accordance with visual observations shown in Fig. 2 (A–Ea). The color improvement was enhanced with the increase of WTP incorporation. However, addition of 10% TPP in the HMMAs resulted in a higher L* and lower a* (p < 0.05) but similar b* (p > 0.05) as compared with 10% WTP, and the ΔE of TPP10 was significantly lower than WTP10 (p < 0.05), implying the development of red color by adding 10% TPP was limited. This could be attributed to the differences in color characteristics between the raw TPP (L* = 60.21 ± 7.07, a* = 11.69 ± 0.36, b* = 44.49 ± 0.32) and WTP (L* = 39.46 ± 0.13, a* = 31.73 ± 0.3, b* = 36.89 ± 0.94). Moreover, incorporation of TPP gave HMMA an unevenly distributed color that was undesirable. Many orange-red aggregates were randomly located in TPP10 (Fig. 2 (Ea)) and they felt off easily, which led the product to be not meat-resembled. It is understandable that the tomato cells in peel tissue have thicker cell walls than other tissues (e.g., flesh) and they are strongly adhered to each other giving a more compact structure (Segado et al., 2016). Therefore, the carotenoids in TPP would not be easily released and dispersed into soy protein melt during the extrusion processing, inversely they might be entrapped by insoluble cell wall fibers and form the colored aggregates fixed randomly in-between protein structure of HMMAs (Arêas, 1992). The orange-red aggregates were also found in the tomato peel incorporated breads in previous study (Nour et al., 2015). The colored aggregates could also be found in WTP incorporated HMMAs but very limited (Fig. 2 (B–Da)), which did not negatively affect the overall color quality of WTP incorporated HMMAs.

Visual observations of a appearance of HMMAs with different formulations and b their macrostructures. Formulations of WTP5, WTP10, and WTP20 refer to 5%, 10%, and 20% addition of whole tomato powders, respectively, while TPP10 refers to 10% of tomato peel powder incorporation. Only Control, WTP10, and TPP10 samples were boiled

After boiling, the a* of WTP10, a* and b* of TPP10 were significantly decreased after boiling (p < 0.05), while the decrease of b* in WTP10 was not significant (p > 0.05). The decrease of a* and b* could be attributed to the degradation of lycopene and other pigments during boiling, although different pigments have different thermal stability. Nevertheless, the a* and b* of WTP samples were still significantly higher than that of Control after boiling (p < 0.05), and observed in Fig. 2 (C’a). However, the a* and b* of TPP10 were not significantly different from those of Control after boiling (p > 0.05). This could be explained by the lower a* and b* of the initial TPP10 before boiling. Besides, the disengagement of colored aggregates from the surface of TPP10 was observed during boiling, which might result in a large decrease of a* and b* in TPP10. Correspondingly, the ΔE of TPP10 was close to 2 after boiling (Table 1), meaning the color difference between the boiled TPP10 and boiled Control was hard to identify by consumers’ naked eyes (Grobelna et al., 2019), suggesting the 10% TPP incorporation did not give an improved color after cooking. On the other hand, the disappearance of visible red color in TPP10 after boiling could resemable the real red meat cooking process, which is a desirable characteristic.

TPC

Phenolic compounds are desirable phytochemicals with potential in preventing chronic diseases due to their strong antioxidant activity (Wójtowicz et al., 2018). Therefore, the increase of phenolic content could enhance the nutritional quality of food products. The results of TPC are summarized in Table 2, where incorporation of only 5% WTP significantly increased the TPC of HMMAs (p < 0.05). With the increase of WTP concentration, the TPC was significantly increased from 59.38 ± 1.95 mg GAE/100 g of WTP5 to 96.66 ± 3.71 mg GAE/100 g of WTP20 (p < 0.05), mainly because the TPC of WTP (459.89 ± 6.70 mg GAE/100 g) was much higher than that of SPI (134.11 ± 2.9 mg GAE/100 g). Similarly, Wójtowicz et al. (2018) found that increasing the tomato powder concentration resulted in a significant increase of TPC in extruded corn snacks. In another study, Yagci et al. (2022) reported that addition of tomato pomace significantly increased the TPC of extruded snacks. The increase of TPC given by 10% TPP incorporation was also significant (p < 0.05) but lower than that given by 10% WTP incorporation, because the TPC of TPP (282.00 ± 0.75 mg GAE/100 g) was lower than that of WTP.

After boiling, the TPC of WTP10 and TPP10 were significantly decreased (p < 0.05), the TPC of Control also decreased but not significantly (p > 0.05) (Table 2). The decrease of TPC could be explained by the fact that the temperature above 80 °C may cause the heat liable phenolic compounds to decompose (Tonyali et al., 2016). For wate-soluble phenolic compounds, they were likely to be leached during boiling (Minatel et al., 2017). In addition, Minatel et al. (2017) suggested that the rupture of food matrix during boiling can facilitate the release of phenolic compounds into water. In this study, the Control had the most strong and compact protein matrix that could limit the rupture of the matrix and water penetration during boiling as compared to other samples (details discussed in the “TPA” section), thereby lower the leaching of water-soluble phenolic compounds. Nevertheless, the TPC of WTP10 was still significantly higher than the Control (p < 0.05) after boiling. Whereas the TPC of TPP10 was not significantly different from that of the Control (p > 0.05). That means the improvement of TPC given by 10% TPP incorporation was not significant after boiling. This could be due to the lower TPC of the initial TPP10 than that of WTP10 before boiling.

Antioxidant Capacity

Antioxidant capacity is an important factor to reflect the nutritional quality of foods (Wójtowicz et al., 2018). The results of both DPPH and FRAP assays are summarized in Table 2. In both assays, 5% WTP incorporation significantly increased the antioxidant capacity of HMMAs (p < 0.05), mainly because the antioxidant capacity of WTP (DPPH: 540.61 ± 5.98 mg Trolox eq./100 g sample; FRAP: 2837.23 ± 112.84 μmol Fe2+ eq./100 g sample) was substantially higher than that of SPI (DPPH: 66.37 ± 5.98 mg Trolox eq./100 g sample; FRAP: 230.74 ± 2.26 μmol Fe2+ eq./100 g sample). When WTP was added from 5 to 20%, the antioxidant capacity was further significantly increased (p < 0.05). Similarly, Wójtowicz et al. (2018) reported the significantly increased DPPH and FRAP values with the increase of tomato powder incorporation (from 5 to 30%) in the extruded corn snacks. Notably, TPP10 possessed significantly increased antioxidant capacity (p < 0.05) but lower than that of WTP10 because lower antioxidants capacity was found in the raw TPP (DPPH: 195.86 ± 6.38 mg Trolox eq./100 g sample; FRAP:1796.17 ± 9.03 μmol Fe2+ eq./100 g sample). The TPC showed strong positive correlations with DPPH (r2 = 0.929) and FRAP (r2 = 0.907). Based on these results, it was proposed that the phenolic compounds could be the major bioactive compounds contributing to the antioxidant activity of HMMA products. The 80% acetone extract solvent used in this study extracted mainly phenolic compounds but also other antioxidants such as small amount of carotenoids (Luengo et al., 2014). Lycopene, which is a predominant carotenoid in tomato and tomato derivatives, could be responsible to the FRAP activity (Muller & Bohm, 2011), and the presence of lycopene in extracts was expected to produce synergistic effect on DPPH scavenging capacity (Liu et al., 2008).

After boiling, the antioxidant capacity of WTP 10 was significantly decreased by both assays (p < 0.05), which could be attributed to several factors such as loss of phenolic compounds and oxidative degradation of carotenoids during boiling. Nevertheless, both DPPH and FRAP values of WTP10 were still significantly higher than the Control and TPP10 after boiling (p < 0.05). While the antioxidant capacity of TPP10 was not significantly changed after boiling (p > 0.05). The results reflected a higher stability of antioxidant capacity of TPP10 than WTP10, probably because the antioxidants, mainly found in the tomato peel such as quercetin, were water-insoluble and thermal stable (Martí et al., 2016; Stewart et al., 2000). The DPPH value of TPP10 was still significantly higher than the Control (p < 0.05), but their FRAP value were similar to each other (p > 0.05). This could be due to the increased FRAP value of Control after boiling (p < 0.05, Table 2). It was speculated that the content of some antioxidants that perform reducing ability in soy protein might have increased after boiling. However, any reductants that could reduce Fe(III) to Fe(II), even without antioxidant capacity, could also contribute to the FRAP value, causing the possible overestimation of FRAP value (Pinchuk et al., 2012).

Lycopene Content and In Vitro Bioaccessibility of Lycopene

Lycopene is not only a natural colorant that is responsible for attractive red color but also a functional ingredient that can potentially reduce the risks of chronic diseases such as prostate cancer and cardiovascular disease (Martí et al., 2016). The lycopene content, bioaccessible lycopene content, and lycopene bioaccessibility of HMMA samples are shown in Table 3. The lycopene content was increased with increase of WTP incorporation in the formulations, and the sample of WTP20 had the highest level (p < 0.05). Similarly, Wójtowicz et al. (2018) reported that the lycopene content in the extruded corn snacks was increased with the increased incorporation of tomato powder. However, the incorporation of TPP provided much less lycopene content to the HMMAs as compared to same amount of WTP incorporation (p < 0.05). This could be attributed to the lower amount of lycopene in TPP (8.33 ± 0.25 μg/g) than that of WTP (71.09 ± 3.23 μg/g). In a previous study, the addition of 10% tomato pomace only provided the extruded snacks a small amount of lycopene (0.62 μg/g) as well (Yagci et al., 2022).

To exhibit health benefits in various human tissues and organs, lycopene must be bioaccessible. The bioaccessible lycopene content refers to the lycopene content released from the food matrix after digestion, dissolved into lipids, and then incorporated into mixed micelles that are small enough to be absorbed by epithelium cells. The bioaccessibility of lycopene refers to the fraction of total amount of lycopene that is accessible for absorption by epithelial layer in small intestine (Iddir et al., 2020). The bioaccessibility of lycopene of samples in this study were lower than 50% in all samples (Table 3). This could be the entrapment of lycopene in the HMMA matrix, the presence of lycopene in crystalline form which is resistant to micellization, and the instability of lycopene under gastric conditions that have limited the absorption of lycopene (Liang et al., 2019). The results suggested that the bioaccessibility of lycopene in WTP20 was significantly higher as compared to 5% and 10% levels (p < 0.05). The addition of WTP could increase the melt viscosity due to the presence of soluble dietary fibers (Dehghan-Shoar et al., 2010). It was speculated that the shear force to the melt during extrusion was increased when the melt viscosity was increased, resulting in a higher proportion of cells being ruptured, and acceleration of crystalline lycopene dispersion, which made lycopene easier to be released and incorporated into mixed micelles during digestion (Dehghan-Shoar et al., 2011; Kun et al., 2006). Interestingly, the highest bioaccessibility of lycopene was found in TPP10. Consistently, Reboul et al. (2005) stated that 6% tomato peel enrichment in tomato paste increased the bioaccessibility of lycopene in vivo. It was explained that the matrix of lycopene embedded in tomato peel was different from that in the flesh. However, Dehghan-Shoar et al. (2011) reported that the lycopene bioaccessibility of snacks enriched with 10% of tomato peel by-product was about 67.71%, which is higher than that of TTP10 (41.18 ± 0.06%) in this study. The inconsistency could be ascribed to different compositions of food materials and different extrusion conditions (Liang et al., 2019; Tonyali et al., 2016). It has been reported that the presence of soy protein isolates decreased lycopene bioaccessibility because the high protein concentrations could occupy on the lipid surface, thus interfering the incorporation of lycopene into mixed micelles (Iddir et al., 2020). Additionally, fat is known to enhance lycopene bioaccessibility (Arballo et al., 2021) whereas very limited fat (1.5%) was present in the main ingredient of HMMA products (i.e., SPI) in this study. However, in the commercial situation, vegetable oil is used as a significant proportion in production of HMMAs to simulate the texture of meat; thus, a higher lycopene bioaccessibility could be expected.

However, the bioaccessible lycopene content in TPP10 was the lowest (Table 3), which implies that very small amount of lycopene was accessible to be absorbed into human body. This could be ascribed to the lowest lycopene content in TPP10. As expected, the increasing amount of WTP in HMMAs significantly increased the bioaccessible lycopene content (p < 0.05). Similar results were found in extruded corn snack enriched with tomato pomace (Yagci et al., 2022). The results reflected that the bioaccessible lycopene content was largely determined by the lycopene content in the raw ingredients.

After boiling, the lycopene contents of WTP10 and TPP10 were decreased, but the decrease in WTP10 was not significant (p > 0.05). The lycopene was reported to be relatively heat stable, but degradations could also be induced by oxygen and light during boiling (Leong et al., 2018). Due to the lower lycopene content in the raw TPP and the lower lycopene retention in TPP10, the bioaccessible lycopene content was not detected in this sample after boiling (Table 3). That means 10% of TPP could not offer nutritional benefits in terms of bioaccessible lycopene in HMMAs after boiling. It is worth noting that non-bioaccessible lycopene that pass to colon could interact with gut microbiota to offer potential benefits to gut health (Eroglu et al., 2022). Therefore, the lycopene being not absorbed by small intestine in WTP or TPP incorporated HMMAs could potentially be utilised in the colon, which warrant further study.

TPA

TPA is an important test to characterize the textural properties of HMMAs (McClements et al., 2021), where hardness, springiness, chewiness, and cohesiveness were measured in this study (Table 4). Addition of WTP had significant effects on the TPA of the HMMAs with a concentration dependent manner. The hardness, chewiness, and cohesiveness were decreased after incorporation of 5% WTP (p < 0.05), possibly because the replacement of 5% SPI with WTP caused a diluted soy protein concentration but increase of other components in the formulations. It is understandable that whole tomato powder contains lipids, sugars, and dietary fibers, which might form a dispersed phase in soy protein continuous phase and disrupt the protein aggregation, resulting in a less compact and weaker protein matrix (Beniwal et al., 2021; Dehghan-Shoar et al., 2010; Lu et al., 2019).

With the increase of WTP incorporation, the springiness and cohesiveness were decreased while the hardness was increased (Table 4). When the WTP incorporation was up to 20%, the hardness of sample was comparable to the Control (p > 0.05) but the springiness and cohesiveness dropped significantly as compared to other formulation groups (p < 0.05), reflecting a hard and brittle texture which was not a characteristic of a meat product. As shown in Fig. 2 (Da), the surface of WTP20 was rougher and more cracks presented. This could be attributed to the increased concentration of sugars and soluble dietary fibers that absorb water with the increase of WTP incorporation (Dehghan-Shoar et al., 2010), which led to the less availability of water for soy protein and increased viscosity of the melt, resulting in limited unfolding and aggregation behavior of the soy proteins (Oshima & Kinoshita, 2013; Zhang et al., 2022). Grabowska et al. (2014) suggested that the incompletely unfolded proteins due to improper hydration led to the production of hard, less cohesive, and less springy soy protein based meat analogues.

Among all formulation groups, incorporation of 10% TPP gave the largest decreases in hardness and chewiness of HMMA (p < 0.05), which was mainly caused by considerable amount of insoluble fibers in the TPP. Generally, the components of tomato peels are predominantly insoluble fibers (Lu et al., 2019), which were insoluble and physical resistant during extrusion, and they could act as steric hindrances for the protein alignment and cross-linking and aggregated in-between protein matrix (Arêas, 1992). As shown in Fig. 2 (B–Ea), there were much more colored fiber aggregates in TPP10 than other HMMAs incorporated with WTP. Dekkers et al. (2018) also suggested that the substantial insoluble fibers could seriously disrupt the protein cross-linking, resulting in an incoherent and weaken HMMA structure. Moreover, TPP10 had the lowest stability of hardness and chewiness after boiling as compared to WTP10 and Control. More obvious cracks were seen on the surface of TPP10 after boiling (Fig. 2 (E’a)). The protein matrix of TPP10 were the weakest and least compact. After boiling, significant decreases of hardness and chewiness were found in all samples (p < 0.05), because of the water penetration and disruption of protein matrix during boiling (Beniwal et al., 2021). The Control had the most compact and strongest protein network with limited free spaces for water penetration and it could resist disruption of protein network during boiling. Nevertheless, as compared with the TPA of real meat such as boiled chicken (hardness 2332 ± 148 g, springiness 0.8 ± 0.09, chewiness 1679 ± 86 g) and boiled beef (hardness 1645 ± 238 g, springiness 0.9 ± 0.12, chewiness 1087 ± 11 g) (Ferawati et al., 2021), the TPA data of TPP10 after boiling (Table 4) in this study were comparable to those of the real meat.

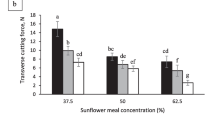

Texturization Index

Texturization index was determined to show the fibrousness of meat analogues, which is also an essential test to evaluate the textural characteristics of HMMAs. Generally, a texturization index of approximately 1 indicates that the cutting strength in both lengthwise and crosswise directions are similar and there is no fibrousness, and the texturization index > 1 or < 1 suggests the layered or/and fibrous structure is formed (Mazlan et al., 2020).

The results of texturization index are summarized in Table 4. The texturization indices were found to be larger than 1 in all samples, indicating that the HMMA sample structures were more texturized in the crosswise direction. Consistently, this phenomenon was also found in commercial soy HMMAs by Ferawati et al. (2021) and Zahari et al. (2020). The texturization index of WTP5 was significantly improved as compared to the Control (p < 0.05), possiblly because of the presence of dispersed phases in WTP5, acting as a breaker in protein matrix to give “fibers” upon tearing, contributed to the fibrousness of HMMAs (Beniwal et al., 2021; Dekkers et al., 2018). However, with the increase of WTP concentration, the texturization index became significantly lower than that of the Control (p < 0.05). That could be attributed to the limited unfolding and aggregation behavior of proteins caused by increased addition of sugars and soluble dietary fibers (Dehghan-Shoar et al., 2010; Oshima & Kinoshita, 2013; Zhang et al., 2022). Additionally, the lower texturization index of TPP10 than Control (p < 0.05) could be mainly attributed to the large amount of insoluble dietary fibers (Dekkers et al., 2018). Moreover, texturization indices of Control, WTP10, and TPP10 were not significantly changed after boiling (p > 0.05), suggesting the stable fibrousness of these HMMA products.

The TI of HMMAs in this study were in accordance with the TI of soy based meat analogues (0.7–1.2) presented by Chen et al. (2010) and Fang et al. (2014) but lower than that of chicken meat (1.23–1.26) (Mazlan et al., 2020). Statistically, the texturization index of WTP 20 was not significantly different to that of WTP10 and TPP10 (p > 0.05). Based on visual observation (Fig. 2 (C–Eb)), some fibers could be found in WTP10 and TPP10 whereas almost no fibrousness was found in WTP20.

Conclusion

In this study, the meat-like color, increased TPC, antioxidant capacity, and bioaccessible lycopene were observed after incorporation of WTP in HMMAs. The color and nutritional properties were improved with increase of WTP incorporation, but TPP incorporation provided an unevenly distributed color and limited nutritional improvements. WTP or TPP incorporation significantly affected the texture profile and texturization index of HMMAs. The improved fibrousness was found in 5% WTP incorporated HMMAs and the softest texture was found in 10% TPP incorporated ones, while incorporation of 20% WTP resulted in unacceptable textural properties of HMMAs. After boiling, the color and nutritional improvements given by 10% WTP incorporation were still significant, and the textural properties of WTP10 and TPP10 were acceptable. Overall, WTP in proper concentrations (about 5–10%) could be feasible in developing meat-resembled color and improved nutritional quality of HMMAs. Future study on sensory analysis of the whole tomato powder incorporated HAMMs is recommended.

Data Availability

The data in this study are all presented in the article.

Abbreviations

- HMMA:

-

High moisture meat analogue

- WTP:

-

Whole tomato powder

- TPP:

-

Tomato peel powder

- TPC:

-

Total phenolic content

- TPA:

-

Texture profile analysis

- TI:

-

Texturization index

References

AOAC International. (2005). AOAC Official Method 934.01: Loss on drying (moisture) at 95–100 °C for feeds/dry matter on oven drying at 95–100 °C for feeds. In Official methods of analysis of AOAC International; AOAC International: Washington, DC, USA.

Arballo, J., Amengual, J., & Erdman, J. W. (2021). Lycopene: A critical review of digestion, absorption, metabolism, and excretion. Antioxidants, 10(3), 342. https://www.mdpi.com/2076-3921/10/3/342

Arêas, J. A. G. (1992). Extrusion of food proteins. Critical Reviews in Food Science and Nutrition, 32(4), 365–392. https://doi.org/10.1080/10408399209527604

Beniwal, A. S., Singh, J., Kaur, L., Hardacre, A., & Singh, H. (2021). Meat analogs: Protein restructuring during thermomechanical processing. Comprehensive Reviews in Food Science and Food Safety, 20. https://doi.org/10.1111/1541-4337.12721

Bohrer, B. M. (2019). An investigation of the formulation and nutritional composition of modern meat analogue products. Food Science and Human Wellness, 8(4), 320–329. https://doi.org/10.1016/j.fshw.2019.11.006

Chen, F. L., Wei, Y. M., Zhang, B., & Ojokoh, A. O. (2010). System parameters and product properties response of soybean protein extruded at wide moisture range. Journal of Food Engineering, 96(2), 208–213. https://doi.org/10.1016/j.jfoodeng.2009.07.014

Dehghan-Shoar, Z., Hardacre, A. K., & Brennan, C. S. (2010). The physico-chemical characteristics of extruded snacks enriched with tomato lycopene. Food Chemistry, 123(4), 1117–1122. https://doi.org/10.1016/j.foodchem.2010.05.071

Dehghan-Shoar, Z., Mandimika, T., Hardacre, A. K., Reynolds, G. W., & Brennan, C. S. (2011). Lycopene bioaccessibility and starch digestibility for extruded snacks enriched with tomato derivatives. Journal of Agricultural and Food Chemistry, 59(22), 12047–12053. https://doi.org/10.1021/jf202582t

Dekkers, B. L., Boom, R. M., & van der Goot, A. J. (2018). Structuring processes for meat analogues. Trends in Food Science & Technology, 81, 25–36. https://doi.org/10.1016/j.tifs.2018.08.011

Eroglu, A., Al’Abri, I. S., Kopec, R. E., Crook, N., & Bohn, T. (2022). Carotenoids and their health benefits as derived via their interactions with gut microbiota. Advances in Nutrition. https://doi.org/10.1016/j.advnut.2022.10.007

Fang, Y., Zhang, B., & Wei, Y. (2014). Effects of the specific mechanical energy on the physicochemical properties of texturized soy protein during high-moisture extrusion cooking. Journal of Food Engineering, 121, 32–38. https://doi.org/10.1016/j.jfoodeng.2013.08.002

Ferawati, F., Zahari, I., Barman, M., Hefni, M., Ahlström, C., Witthöft, C., & Östbring, K. (2021). High-moisture meat analogues produced from yellow pea and faba bean protein isolates/concentrate: Effect of raw material composition and extrusion parameters on texture properties. Foods, 10(4), 843. https://www.mdpi.com/2304-8158/10/4/843

Fernández-López, J. A., Fernández-Lledó, V., & Angosto, J. M. (2020). New insights into red plant pigments: More than just natural colorants. RSC Advances, 10(41), 24669–24682. https://doi.org/10.1039/d0ra03514a

Fiorentini, M., Kinchla, A. J., & Nolden, A. A. (2020). Role of sensory evaluation in consumer acceptance of plant-based meat analogs and meat extenders: A scoping review. Foods, 9(9), 1334. https://doi.org/10.3390/foods9091334

Fraser, M. L., Lee, A. H., & Binns, C. W. (2005). Lycopene and prostate cancer: Emerging evidence. Expert Review of Anticancer Therapy, 5(5), 847–854. https://doi.org/10.1586/14737140.5.5.847

García, M. L., Calvo, M. M., & Selgas, M. D. (2009). Beef hamburgers enriched in lycopene using dry tomato peel as an ingredient. Meat Science, 83(1), 45–49. https://doi.org/10.1016/j.meatsci.2009.03.009

Grabowska, K. J., Tekidou, S., Boom, R. M., & van der Goot, A.-J. (2014). Shear structuring as a new method to make anisotropic structures from soy–gluten blends. Food Research International, 64, 743–751. https://doi.org/10.1016/j.foodres.2014.08.010

Grobelna, A., Kalisz, S., & Kieliszek, M. (2019). The effect of the addition of blue honeysuckle berry juice to apple juice on the selected quality characteristics, anthocyanin stability, and antioxidant properties. Biomolecules, 9(11), 744. https://www.mdpi.com/2218-273X/9/11/744

Guyony, V., Fayolle, F., & Jury, V. (2022). High moisture extrusion of vegetable proteins for making fibrous meat analogs: A review. Food Reviews International, 1–26. https://doi.org/10.1080/87559129.2021.2023816

He, J., Evans, N. M., Liu, H., & Shao, S. (2020). A review of research on plant-based meat alternatives: Driving forces, history, manufacturing, and consumer attitudes. Comprehensive Reviews in Food Science and Food Safety, 19(5), 2639–2656. https://doi.org/10.1111/1541-4337.12610

Iddir, M., Dingeo, G., Yaruro, J. F. P., Hammaz, F., Borel, P., Schleeh, T., Desmarchelier, C., Larondelle, Y., & Bohn, T. (2020). Influence of soy and whey protein, gelatin and sodium caseinate on carotenoid bioaccessibility. Food & Function, 11(6), 5446–5459. https://doi.org/10.1039/D0FO00888E

Kim, I.-S., Jin, S.-K., Mandal, P. K., & Kang, S.-N. (2011). Quality of low-fat pork sausages with tomato powder as colour and functional additive during refrigerated storage. Journal of Food Science and Technology, 48(5), 591–597. https://doi.org/10.1007/s13197-010-0182-2

Kun, Y., Ssonko Lule, U., & Xiao-Lin, D. (2006). Lycopene: Its properties and relationship to human health. Food Reviews International, 22(4), 309–333. https://doi.org/10.4274/tjps.43043

Kyriakopoulou, K., Keppler, J. K., & van der Goot, A. J. (2021). Functionality of ingredients and additives in plant-based meat analogues. Foods, 10(3), 600. https://www.mdpi.com/2304-8158/10/3/600

Lawrence, S., & King, T. (2019). Meat the alternative: Australia's $3B opportunity [Report]. Food Frontier. https://apo.org.au/node/257891

Leong, H. Y., Show, P. L., Lim, M. H., Ooi, C. W., & Ling, T. C. (2018). Natural red pigments from plants and their health benefits: A review. Food Reviews International, 34(5), 463–482. https://doi.org/10.1080/87559129.2017.1326935

Liang, X., Ma, C., Yan, X., Liu, X., & Liu, F. (2019). Advances in research on bioactivity, metabolism, stability and delivery systems of lycopene. Trends in Food Science & Technology, 93, 185–196. https://doi.org/10.1016/j.tifs.2019.08.019

Liang, Z., Zhang, P., Xiong, Y., Johnson, S. K., & Fang, Z. (2023). Phenolic and carotenoid characterization of the ethanol extract of an Australian native plant Haemodorum spicatum. Food Chemistry, 399, Article 133969. https://doi.org/10.1016/j.foodchem.2022.133969

Liu, D., Shi, J., Ibarra, A. C., Kakuda, Y., & Xue, S. J. (2008). The scavenging capacity and synergistic effects of lycopene, vitamin E, vitamin C, and β-carotene mixtures on the DPPH free radical. LWT-Food Science and Technology, 41(7), 1344–1349. https://doi.org/10.1016/j.lwt.2007.08.001

Liu, J., Liu, D., Bi, J., Liu, X., Lyu, Y., Verkerk, R., & Dekker, M. (2022). Micelle separation conditions based on particle size strongly affect carotenoid bioaccessibility assessment from juices after in vitro digestion. Food Research International, 151, Article 110891. https://doi.org/10.1016/j.foodres.2021.110891

Liu, S., Zhang, Y., Zhou, G., Bao, Y., Ren, X., Zhu, Y., & Peng, Z. (2019). Protein degradation, color and textural properties of low sodium dry cured beef. International Journal of Food Properties, 22(1), 487–498. https://doi.org/10.1080/10942912.2019.1591444

Lu, Z., Wang, J., Gao, R., Ye, F., & Zhao, G. (2019). Sustainable valorisation of tomato pomace: A comprehensive review. Trends in Food Science & Technology, 86, 172–187. https://doi.org/10.1016/j.tifs.2019.02.020

Luengo, E., Álvarez, I., & Raso, J. (2014). Improving carotenoid extraction from tomato waste by pulsed electric fields. Frontiers in Nutrition, 1, 12. https://doi.org/10.3389/fnut.2014.00012

Martí, R., Roselló, S., & Cebolla-Cornejo, J. (2016). Tomato as a source of carotenoids and polyphenols targeted to cancer prevention. Cancers, 8(6), 58. https://doi.org/10.3390/cancers8060058

Mazlan, M. M., Talib, R. A., Chin, N. L., Shukri, R., Taip, F. S., Mohd Nor, M. Z., & Abdullah, N. (2020). Physical and microstructure properties of oyster mushroom-soy protein meat analog via single-screw extrusion. Foods, 9(8), 1023. https://doi.org/10.3390/foods9081023

McClements, D. J., Weiss, J., Kinchla, A. J., Nolden, A. A., & Grossmann, L. (2021). Methods for testing the quality attributes of plant-based foods: Meat-and processed-meat analogs. Foods, 10(2), 260. https://doi.org/10.3390/foods10020260

Minatel, I. O., Borges, C. V., Ferreira, M. I., Gomez, H. A. G., Chen, C.-Y. O., & Lima, G. P. P. (2017). Phenolic compounds: Functional properties, impact of processing and bioavailability. In M. Soto-Hernandez, M. Palma-Tenango, M.R. Garcia-Mateos (Eds.), Phenolic Compounds - Biological Activity (pp. 1–24). IntechOpen. https://www.intechopen.com/chapters/53128

Minekus, M., Alminger, M., Alvito, P., Ballance, S., Bohn, T., Bourlieu, C., Carrière, F., Boutrou, R., Corredig, M., & Dupont, D. (2014). A standardised static in vitro digestion method suitable for food–An international consensus. Food & Function, 5(6), 1113–1124. https://doi.org/10.1039/C3FO60702J

Muller, L., & Bohm, V. (2011). Antioxidant activity of β-carotene compounds in different in vitro assays. Molecules, 16(2), 1055–1069. https://doi.org/10.3390/molecules16021055

Nour, V., Ionica, M. E., & Trandafir, I. (2015). Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste. Journal of Food Science and Technology, 52(12), 8260–8267. https://doi.org/10.1007/s13197-015-1934-9

Oshima, H., & Kinoshita, M. (2013). Effects of sugars on the thermal stability of a protein. The Journal of Chemical Physics, 138(24), Article 245101. https://doi.org/10.1063/1.4811287

Pinchuk, I., Shoval, H., Dotan, Y., & Lichtenberg, D. (2012). Evaluation of antioxidants: Scope, limitations and relevance of assays. Chemistry and Physics of Lipids, 165(6), 638–647. https://doi.org/10.1016/j.chemphyslip.2012.05.003

Reboul, E., Borel, P., Mikail, C., & l., Abou, L., Charbonnier, M., Caris-Veyrat, C., Goupy, P., Portugal, H., Lairon, D., & Amiot, M.-J. P. (2005). Enrichment of tomato paste with 6% tomato peel increases lycopene and β-carotene bioavailability in men. The Journal of Nutrition, 135(4), 790–794. https://doi.org/10.1093/jn/135.4.790

Riggi, E., & Avola, G. (2008). Fresh tomato packinghouses waste as high added-value biosource. Resources, Conservation and Recycling, 53(1), 96–106. https://doi.org/10.1016/j.resconrec.2008.09.005

Rodrigues, D. B., Mariutti, L. R. B., & Mercadante, A. Z. (2016). An in vitro digestion method adapted for carotenoids and carotenoid esters: Moving forward towards standardization. Food & Function, 7(12), 4992–5001. https://doi.org/10.1039/C6FO01293K

Savadkoohi, S., Hoogenkamp, H., Shamsi, K., & Farahnaky, A. (2014). Color, sensory and textural attributes of beef frankfurter, beef ham and meat-free sausage containing tomato pomace. Meat Science, 97(4), 410–418. https://doi.org/10.1016/j.meatsci.2014.03.017

Segado, P., Domínguez, E., & Heredia, A. (2016). Ultrastructure of the epidermal cell wall and cuticle of tomato fruit (Solanum lycopersicum L.) during development. Plant Physiol, 170(2), 935–946. https://doi.org/10.1104/pp.15.01725

Sindelar, J. J. (2006). Investigating uncured no nitrate or nitrite added processed meat products. Iowa State University. https://doi.org/10.31274/rtd-180813-218

Stewart, A. J., Bozonnet, S., Mullen, W., Jenkins, G. I., Lean, M. E., & Crozier, A. (2000). Occurrence of flavonols in tomatoes and tomato-based products. Journal of Agricultural and Food Chemistry, 48(7), 2663–2669. https://doi.org/10.1021/jf000070p

Tonyali, B., Sensoy, I., & Karakaya, S. (2016). The effect of extrusion on the functional components and in vitro lycopene bioaccessibility of tomato pulp added corn extrudates. Food & Function, 7(2), 855–860. https://doi.org/10.1039/C5FO01185J

Toor, R. K., & Savage, G. P. (2006). Changes in major antioxidant components of tomatoes during post-harvest storage. Food Chemistry, 99(4), 724–727. https://doi.org/10.1016/j.foodchem.2005.08.049

Trottet, G., Fernandes, S., Grunz, G., Thoma, J., Brunner-Komorek, K., & Nestec, S. (2017). A process for preparing a meat-analogue food product. In: US20180064137A1.

Wójtowicz, A., Zalewska-Korona, M., Jablonska-Rys, E., Skalicka-Wozniak, K., & Oniszczuk, A. (2018). Chemical characteristics and physical properties of functional snacks enriched with powdered tomato. Polish Journal of Food and Nutrition Sciences, 68(3). https://doi.org/10.1515/pjfns-2017-0028

World Processing Tomato Council. (2021, April). World production estimate. https://www.tomatonews.com/en/wptc-2021-crop-estimated-at-387-million-tonnes_2_1489.html

Yagci, S., Calıskan, R., Gunes, Z. S., Capanoglu, E., & Tomas, M. (2022). Impact of tomato pomace powder added to extruded snacks on the in vitro gastrointestinal behaviour and stability of bioactive compounds. Food Chemistry, 368, 130847. https://doi.org/10.1016/j.foodchem.2021.130847

Zahari, I., Ferawati, F., Helstad, A., Ahlström, C., Östbring, K., Rayner, M., & Purhagen, J. K. (2020). Development of high-moisture meat analogues with hemp and soy protein using extrusion cooking. Foods, 9(6), 772. https://www.mdpi.com/2304-8158/9/6/772

Zhang, S., Ji, J., Zhang, S., & Guan, C. (2020). Effects of three cooking methods on content changes and absorption efficiencies of carotenoids in maize. Food & Function, 11. https://doi.org/10.1039/C9FO02622C

Zhang, Z., Zhang, L., He, S., Li, X., Jin, R., Liu, Q., Chen, S., & Sun, H. (2022). High-moisture extrusion technology application in the processing of textured plant protein meat analogues: A review. Food Reviews International, 1–36. https://doi.org/10.1080/87559129.2021.2024223

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions

Author information

Authors and Affiliations

Contributions

Xiaoyu Lyu: conceptualization; data curation; formal analysis; investigation; methodology; software; validation; visualization; writing—original draft. Danyang Ying: conceptualization, extrusion, investigation; writing—review, editing. Pangzhen Zhang: supervision; methodology; investigation; writing—review, editing. Zhongxiang Fang: conceptualization; funding acquisition; methodology; project administration; resources; supervision; writing-review, editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lyu, X., Ying, D., Zhang, P. et al. Effect of Whole Tomato Powder or Tomato Peel Powder Incorporation on the Color, Nutritional, and Textural Properties of Extruded High Moisture Meat Analogues. Food Bioprocess Technol 17, 231–244 (2024). https://doi.org/10.1007/s11947-023-03133-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03133-x