Abstract

Yeasts are feasible and effective bioreactors and, therefore, there is a great interest in their industrial employment for the production of a wide range of molecules. In this study, the production by Saccharomyces cerevisiae of bioactive compounds such as hydroxytyrosol (HT), tyrosol (TYR) and melatonin (MEL) vs. volatile compounds in fermented must was studied. The concentration of the bioactive compounds HT and MEL in fermented must employing different yeast strains revealed that the higher the concentrations, the lower the amount of volatile compounds determined. This inverse correlation was especially remarkable with respect to the production of higher alcohols, especially 2-phenylethanol (2-PE) and esters. Furthermore, the employment of a modified Aro4pK229L S. cerevisiae QA23 yeast strain which overproduces HT, gave rise to fermented must also higher in 2-PE and their corresponding esters but with an outstanding less presence of other important esters such as ethyl hexanoate and ethyl octanoate. Both premises could point out that S. cerevisiae might have different approaches to handling cell stress/toxicity due to their nitrogen metabolism. One detoxifying pathway could be through the production of higher alcohols and these in turn to esters and the other be more related to synthesizing antioxidant molecules such as MEL and HT.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, the industrial employment of yeast to produce a wide range of molecules is booming because they are feasible and effective bioreactors, leading to efficient production performance (Pretorius, 2020). Some of the applications include the production of biodiesel, perfume ingredients, pharmaceuticals, enzymes, pigments, plastic, lubricants, and other bio-based chemicals, etc. (Bettencourt et al., 2020; Diamantopoulou et al., 2020; Franco-Duarte et al., 2017; Huang & Demirci, 2009; Mantzouridou & Paraskevopoulou, 2013; Mata-Gómez et al., 2014; Perpetuini et al., 2020; Vandermies & Fickers, 2019; Zhang et al., 2017). The main primary metabolite from the alcoholic fermentation of a sugar substrate with Saccharomyces cerevisiae is ethanol; however, the molecules derived from the secondary metabolism of the yeast, specifically from nitrogen metabolisms such as aroma and bioactive compounds are of special interest to the industry (Cordente et al., 2019).

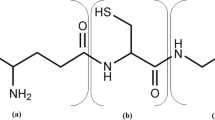

Regarding volatile compounds, depending on the yeast employed, the volatile composition may vary in a huge extent, being one of the main factors responsible for the aroma of a wine (Garde-Cerdán & Ancín-Azpilicueta, 2006; Varela et al., 2009). Moreover, the interaction of some yeasts with other types has been described to influence on the volatile compounds production (Kosel et al., 2017). In addition, it has been demonstrated that the volatile compounds produced by the yeast are strongly linked to the amino acids composition of the substrate and to the amount of yeast available nitrogen (YAN) in the media (Rapp & Versini, 1995; Hernández-Orte et al., 2002, 2005; Garde-Cerdán & Ancín-Azpilicueta, 2008), or even the temperature of fermentation (Morakul et al., 2013) among other factors. Therefore, the elucidation of the clues to modulate yeast aromatic amino acid metabolism is the subject of several research works (Dickinson et al., 2003; Hazelwood et al., 2008). Moreover, a useful system for monitoring fermentative aromas has established a strong relationship between nitrogen sources and the higher alcohols and esters production along winemaking fermentation (Mouret et al., 2014). Apart from these volatile compounds, among the higher alcohols with importance from an organoleptic perspective is tyrosol (TYR), also produced by the yeast, being published evidence of the in-mouth sensory properties related to wine bitterness (Sáenz-Navajas et al., 2012). The origin of higher alcohols by S. cerevisiae derives from α-ketoacids generated either through the anabolic (de novo synthesis from sugar) (Fig. 1a) or the catabolic (from amino acids present in the media-via Ehrlich) pathways (Fig. 1b) (Mas et al., 2014). Some studies have observed that the addition of the corresponding precursor amino acid may yield the specific higher alcohol in increased concentrations (Hernández-Orte et al., 2002, 2005; Garde-Cerdán & Ancín-Azpilicueta, 2008; Bordiga et al., 2016).

Conversely, by using isotopically 13C-labeled amino acid precursors (Crépin et al., 2017; Rollero et al., 2017) and glucose (Nisbet et al., 2014), it has been shown that the vast majority of the higher alcohols are formed through the anabolic pathway. On the other hand, S. cerevisiae prefers ammonium and glutamine as nitrogen sources but in conditions of depletion of these nitrogen sources, the yeast can use amino acids through the Ehrlich pathway (Hazelwood et al., 2008) yielding acids, aldehydes, and higher alcohols which subsequently can give rise to esters, mainly with acetate (Cordente et al., 2021). At the same time, it has been suggested that the production of higher alcohols and their corresponding esters could be a result of a detoxifying mechanism used by the yeast to diminish aldehydes and medium-chain fatty acids (MCFAs) (Borrull et al., 2015; Boulton et al., 1995; Saerens et al., 2010).

In addition to the synthesis of volatile compounds, other molecules with bioactive potential are generated by the metabolism of S. cerevisiae, among them are melatonin (MEL) and hydroxytyrosol (HT) (Álvarez-Fernández et al., 2019a). MEL has been proposed as being a signaling molecule (Fernandez-Cruz et al., 2019; Morcillo-Parra et al., 2019) and also has been shown to possess remarkable antioxidant, neuroprotective, anti-inflammatory and cardiovascular protection properties in humans (Reiter et al., 2007; Sanchez-Barcelo et al., 2012). The secondary metabolism may also yield HT, which is produced from TYR. Hence, HT may be produced by yeast following the Ehrlich pathway from the tyrosine present in the fermentation media or from glucose (anabolic pathway) (Gallardo-Fernández et al., 2022) being therefore closely related to the synthesis of higher alcohols. Certain health benefits, such as cardioprotection and neuroprotection, have been reported for its precursor TYR (Gris et al., 2011; Samuel et al., 2008), but the positive health effects of HT are much more remarkable (Gallardo-Fernández et al., 2022).

The employment of yeast, both as cell factories for the production of valuable volatile and bioactive compounds and as fermentative microorganisms to produce foods with enhanced organoleptic properties as well as a convenient bioactive profile, is feasible and profitable. For this purpose, genetic engineering techniques have been employed for example for the sobreexpresion of those genes responsible for the synthesis of HT (Bisquert et al., 2022). However, the potential for the production of these compounds from the secondary metabolism of a very common yeast such as S. cerevisiae has been scarcely explored. Several research addressing the characterization of the volatile compounds produced by different yeast strains have been published (Albanese et al., 2013; Ivanova et al., 2013; Morakul et al., 2013; Mouret et al., 2014); however, these studies do not approach simultaneous production of bioactive compounds and the influence and relationship with aromatic metabolites as the present work analyzes. Very recently, Cordente et al. (2021) have pointed out the relation between 2-PE and the production of TYR in synthetic and natural grape must, showing that those genetically modified yeast strains able to overproduce 2-PE, are also capable to generate increased concentrations of TYR.

Therefore, the aims of this study were to evaluate the simultaneous production of volatile compounds and the bioactive compounds melatonin, tyrosol, and hydroxytyrosol of some commonly used S. cerevisiae yeast strains trying to ascertain the relationship between aroma and bioactive composition and also the influence of the initial must composition. At the same time, the production of these compounds by a modified S. cerevisiae HT overproductive yeast strain was tested with the purpose of ascertaining if an increased production of the alcohols TYR and HT has an impact on the aroma composition of the fermented must.

Materials and Methods

Chemical Standards

Standards of tyrosol, hydroxytyrosol, and melatonin were purchased from Sigma Aldrich (St. Louis, MO, USA). HPLC grade methanol was supplied from Merck (Darmstadt, Germany) and formic acid was provided by Prolabo (Obregon, Mexico). 4-Methyl-2-pentanol was used as the internal standard for the gas chromatography determinations and was provided by Merck (Darmstadt Germany). An alkane standard mixture C10–C40 purchased by Fluka (Madrid, Spain) was used for calculating the Linear Retention Index (LRI) for GC–MS analysis.

Fermentation Trials

All the samples analyzed in this study are samples at the end of the fermentation. The first set of fermentations was performed employing different commercial S. cerevisiae Uvaferm VRB (UVR), Enoferm M2 (EM2), P23 Lallemand (P23), and a yeast from Murviedro winery (MUW). The fermentations were carried out in glass bottles and they took place as described in Table 1. Each strain was inoculated from a culture grown overnight in YPD in their stationary phase. Fermentations were performed in triplicate. To control the development of the fermentations, 1.5 mL of sample was extracted at 24 h, 48 h and 120 h to measure the density using a Densito 30PX densimeter and the OD600nm with a UVmini-12 spectrophotometer. At the end of the fermentation, the amount of residual sugars and the percentage of ethanol were measured (Pérez et al., 2021). A total of 12 samples (4 yeast × 3 biological replicates) were centrifuged 5 min at 4000 rpm to separate the cells, and the supernatant was stored at −20 °C prior to the analysis.

The second trial of fermentations employing a commercial wine yeast strain of S. cerevisiae Lalvin YSEO QA23 (Lallemand) and its genetically modified yeast was performed. The genetic modifications carried out on QA23 were multiple integration of HpaBC complex under the control of strong constitutive promoters TEF1p and PGK1p into the genome using Ty1Cons2 sequences as homologous recombination targets, and the single integration of allelic variant ARO4K229L under the control of GPD promoter in chromosome X-3. Such modifications were performed according to previous works (Bisquert et al., 2022; Muñiz-Calvo et al., 2020). Briefly, genes hpaB and hpaC and bidirectional promoter TEF1-PGK1 were PCR-amplified from plasmids p426GPD-hpaB, p425GPD-hpaC and pCfB2628 respectively (Germann et al., 2016), while ARO4K229L with GPD promoter was amplified from plasmid p423GPD-ARO4*. In parallel, vectors bearing the Ty1Cons2 and X-3 sequence from the EasyCloneMulti and EasyClone vector set pCfB2988 and pCfB257 (Jensen et al., 2014; Maury et al., 2016), were prepared by sequential treatment with enzymes AsiSI (SfaAI) (Thermo Fisher Scientific, Waltham, MA, USA) and BsmI (New England Biolabs, Ipswich, MA, USA). After purification, PCR products were cloned into pre-treated vectors by USERTM method (New England Biolabs). The ligation product was transformed into E. coli and successful cloning of both vectors was verified by Sanger sequencing (EUROFINS genomics, Ebersberg, Germany). Prior to yeast transformation, the resulting integrative vectors pCfB2988, HpaBC and pCfB257 were linearized by FastDigest NotI (Thermo scientific, Vilnius, Lithuania) and the fragment containing the desired sequences to integrate were purified from agarose gel. Yeast cells were transformed with 1–1.5 µg of the linear fragment from the integrative vectors by the PEG/LiAc method according to Gietz (2014) and selected on selective agar medium according to strain auxotrophic markers.

The fermentations were also carried out following Riou et al. (1997) specifications for synthetic must with some modifications as described: 10 L of SM was prepared for experiment with slight differences following Rebollo-Romero et al. (2020). Sugars: fructose (100 g/L) and glucose (100 g/L); NH4Cl (0.46 g/L); acids: malic acid (5 g/L), citric acid (0.5 g/L) and tartaric acid (3 g/L); the minerals added were: K2SO4 (0.5 g/L), KH2PO4 (0.75 g/L), MgSO4 7H2O (0.25 g/L), CaCl2 (0.155 g/L) and NaCl (0.2 g/L). Also it was added to the SM 1 mL of trace elements was added including 13.09 mL of an amino acids solution composed by isoleucine (2.5 g/L), tyrosine (1.5 g/L), tryptophan (13.4 g/L), threonine (5.8 g/L), aspartic acid (3.4 g/L), glutamic acid (9.2 g/L), leucine (3.7 g/L), glycine (1.4 g/L), histidine (2.6 g/L), glutamine (38.4 g/L), alanine (11.2 g/L), valine (3.4 g/L), methionine (2.4 g/L), cysteine (1.6 g/L), phenylalanine (2.9 g/L), arginine (28.3 g/L), serine (6 g/L), lysine (1.3 g/L), and proline (46.1 g/L). Finally to complete this SM 10 mL of a vitamins solution containing myoinositol (2 g/L), thiamine hydrochloride (0.025 g/L), calcium pantothenate (0.15 g/L), pyridoxine (0.025 g/L), nicotinic acid (0.2 g/L) and biotin (3 mL). The pH was adjusted to 3.31 with NaOH. The final YAN was 210 mg/L.

Six replicate fermentation experiments were used for each strain with the fermentation conditions showed in Table 1. The flasks were weighed daily before and after sampling, in order to monitor the fermentation. The optical density was also measured daily by (Cytoflex S, Beckman Coulter, California, EEUU). The samples of final fermented musts resulting from the fermentations were stored at −80 °C, before the analysis in UHPLC-HRMS and GC–MS.

Tyrosol, Hydroxytyrosol, and Melatonin Extraction

Before the analysis, samples were cleaned up using SPE C18 cartridges (Variant, Agilent). The first step was the conditioning of the cartridge using 2 mL of methanol and sequentially 2 mL of Milli-Q water. Once the cartridge is conditioned, 2 mL of the sample was passed through the cartridge. Then 2 mL of a 10% v/v methanol/water solution was used to wash it.

The compounds of interest were eluted with 1 mL of methanol. A vacuum concentrator (HyperVAC-LITE, Gyrozen, Korea) was used at 2000 rpm at 30 °C for 8 h, to dry samples as previously described (Álvarez-Fernández et al., 2019b). Once the samples were dried, they were reconstituted with 200 μL of 10% v/v acetonitrile/water in the case of hydroxytyrosol and tyrosol and 10% v/v methanol/water with 0.1% formic acid for melatonin, and they were stored at −80 °C until analysis.

UHPLC-HRMS Analyses

A Thermo Scientific Liquid Chromatography system consisting of a binary UHPLC Dionex Ultimate 3000 RS connected to a quadrupole-orbitrap Qexactive hybrid mass spectrometer (ThermoFisher Scientific, USA) with HESI ionization probe (HESI-II) was used for the determination of the bioactive compounds tyrosol, hydroxytyrosol and melatonin. A Zorbax SB-C18 (2.1 × 100 mm, 1.8 µm particle size) column (Agilent) with a flow of 0.4 mL/min for hydroxytyrosol and tyrosol and 0.5 mL/min for melatonin. The chromatographic conditions for melatonin consisted of two mobile phases, water (A) and methanol (B), both with 0.1% formic acid with a gradient elution programmed as follows: 95% A, 5% B (0–2 min); 0% A, 100% B (2–13 min); and 95% A, 5% B (13.1–15 min). The flow selected was 0.5 mL min−1. The gradient for hydroxytyrosol and tyrosol consists of (A) water with 0.2% of acetic acid and (B) acetonitrile. The binary gradient was used with the following profile: 0–1 min 5% B, 1–7 min from 5 to 100% B, 7–8.5 min 100% B, and 8.5–10 min 5% B. 5 μL was the volume elected for the injection. The compounds were dissolved in 10% v/v acetonitrile/water.

A method of parallel reaction monitoring (PRM) was used in a negative mode with a resolution of 35,000 at m/z 200 FWHM and an isolation window of 1 m/z and the normalized collision energy was set at 40 eV. The masses were optimized as follows: tyrosol (137.06080) and hydroxytyrosol (153.05572). HESI source parameters were spray voltage, 3.0 kV; S lens level, 50; capillary temperature, 320 °C; sheath, auxiliary, and sweep gas flow, 50, 15, and 2 respectively (arbitrary units); and probe heater temperature, 425 °C.

For melatonin, the positive mode was used. The following parameters were optimized to carry out the analysis: HESI source parameters were as follows: source voltage 3.5 kV; tube lens voltage 50 V; capillary temperature 230 °C; source heater temperature 440 °C; sheath, auxiliary and sweep gas flow rate (N2) 53, 14 and 3. The masses were optimized as follows for melatonin (233.12845). The data were treated with the TraceFinder 5.1 software.

SPME/GC/MS Analyses

Volatile compounds’ extraction was performed using Headspace Solid Phase Microextraction (HS-SPME), employing a triple fiber of 1 cm DVB (divinylbenzene)/C-WR (carbon wide range)/PDMS (polydimethylsiloxane) (Agilent Technologies, Switzerland). For this purpose, 4 mL of each sample was transferred into 20 mL glass vials with 0.8 g of sodium chloride and 10 µL of 4-methyl-2-pentanol (0.75 mg/L) (used as an internal standard), which were then placed in the autosampler.

For the static headspace extraction, incubation lasted 40 min at 45 °C and 250 rpm agitation speed, and the fiber was then exposed to the headspace for 40 min, with a penetration into the vial of 22 mm. Once the adsorption finished, the fiber was desorbed for 180 s in the injector using the splitless mode.

For the analyses of the samples, a Bruker 450 Gas Chromatograph was employed coupled to a Mass Spectrometer Bruker 300-MS. For the chomatographic analysis, the conditions followed are described in Ubeda et al. (2019).

For identification purposes, linear retention indices (LRIs) were calculated after the injection of C10-C40 alkanes solution by applying the same conditions of sample analysis. The identification was made by matching the LRIs of each compound from the standards NIST library (2.0 version) found in the literature (Pherobase: www.pherobase.com; NIST Mass Spectrometry Data Center: (LRI Odour database: www.odour.org.uk; accessed on March 2022). The data shown in this work were expressed as the relative area with respect to 4-methyl-2-pentanol (internal standard). The relative areas were calculated by dividing the peak area of the target ion of each compound by the peak area of the target ion of the internal standard.

Statistical Analysis

Data obtained were compared using ANOVA and Fisher Least Significant Difference (LSD) Method (p < 0.05) employing the InfoStat software (version 2017p, FCA-Universidad Nacional de Córdoba, Argentina). Principal component analysis (PCA) was performed using IBM SPSS Statistics 26 software (IBM, Barcelona, Spain) and Partial least squares-discriminant analysis (PLS-DA) with the 5.0 version of Metaboanalyst software (Quebec, Canada).

Results and Discussion

Volatile Compounds, Tyrosol, Hydroxytyrosol, and Melatonin Production by Yeast

Samples obtained at the end of the alcoholic fermentations performed with the yeast strains UVR, EM2, P23 and MUW were analyzed for aroma composition. A total of 27 volatile compounds were determined, 11 esters, 8 alcohols, 6 acids, and 2 aldehydes (Table 2). Figure 2 shows tendencies related to the total sum of the relative areas corresponding to each chemical group. Strains EM2, P23 and MUW produced significantly higher amounts of alcohols. Acids and aldehydes followed a similar pattern, with UVR and EM2 reaching lower quantities at the end of fermentation vs P23 and MUW. As shown in Table 2, UVR presented in general the lowest quantities of higher alcohols, especially regarding isobutanol, 3-methyl-1-butanol, and 2-PE compared to the other yeast assayed. This is in agreement with the results from Peris et al. (2016) who employed Uvaferm VRB among other yeast strains to ferment a Macabeo grape must showing a low production of higher alcohols in comparison to the quantities produced by other yeast.

Total amounts of esters, alcohols, acids and aldehydes present in the fermented must produced with every Uvaferm® VRB, Enoferm® M2, P23 Lallemand and Murviedro winery yeast. Bars with different superscript letters indicate statistically significant differences (p < 0.05) by Fisher Least Significant Difference (LSD) among the samples

Our results showed that esters (ethyl and acetate) were in fact present in significantly higher quantities in P23 and MUW than in UVR trials at the end of the fermentation (Fig. 2). While the production of ethyl esters during fermentation occurs via the enzymatic esterification reaction of ethanol and the carboxylic acids present in the media (Lambrechts & Pretorius, 2000), acetate esters are formed by enzymatic acetylation of alcohols, this last being mainly by-products of the amino acid biosynthesis such as 3-methyl-1-butanol or 2-PE (Sumby et al., 2010). Although samples EM2, MUW, and P23 reached higher amounts of ethyl acetate at the end of the fermentation as compared to UVR, with P23 reflecting significance (Table 2). Apart from this predominant ethyl ester, the acetate esters, isoamyl acetate and 2-phenylethyl acetate, stood out among all the ester family. Interestingly, they were present in the sample at levels at least three times lower (Table 2). The correlation between the formation of acetate esters and their corresponding higher alcohol has been described in wines (Cordente et al., 2012) and as can be observed, those fermented musts with a higher quantity of higher alcohols, also presented higher amounts of acetate esters. Regarding acids and aldehydes, UVR and EM2 showed similar abundance, the same happened for P23 and MUW (Fig. 2).

A heatmap was built with results on aroma composition and bioactive compounds (Fig. 3), thus allowing a global insight of data. As can be observed, there is an inverse correlation between HT and MEL and the volatile compounds as a whole. Furthermore, it was observed that TYR concentrations from the strains EM2 and MUW were higher as compared to P23 and UVR (Table 3). UVR resulted in being the lowest producer of tyrosol but the highest producer of HT, probably having a more efficient ability to hydroxylate TYR to HT.

Multivariate analysis by Principal Component Analysis (PCA) was performed employing all the secondary metabolites considered (volatile compounds, TYR, HT, and MEL). Hence, six principal components (PCs) were extracted explaining 93.3% of the total variance. Figure 4a shows the distribution of the samples (scores) in the plot of PC1 (Component 1) and PC2 (Component 2) accounting for 58.5% of the cumulative variance. The corresponding loadings distribution (Fig. 4b) clearly showed that the strain UVR gave rise to fermented musts with a lower content of volatile compounds but higher content of MEL and HT. On the other hand, samples EM2, P23 and MUW were richer in volatile compounds but their concentrations in HT and MEL were lower than those found in UVR. As mentioned above, TYR concentrations were higher in EM2 samples (Table 3); therefore, it is located in the plot closer to the fermented musts.

Principal Component Analysis (PCA) showing the data scores (a) and loading (b) biplot on the plane of the first two principal components (PC1 against PC2) including the 27 volatile compounds, tyrosol, hydroxytyrosol, and melatonin present in Uvaferm® VRB, Enoferm® M2, P23 Lallemand and Murviedro winery yeast

Additionally, a Partial Least-Squares Discriminant Analysis (PLS-DA) was performed to bring out the variables that are more useful to classify the samples thus having discriminant potential. Variable importance in the projection (VIP) score plot shows the major metabolite features (Fig. 5). Among the secondary metabolites analyzed, hexanoic acid was found the best one to classify the samples. This medium-chain fatty acid (MCFA) is produced by the yeast during alcoholic fermentation and depends on several factors such as yeast strain and temperature of fermentation (Torija et al., 2003; Tronchoni et al., 2012). In general, the over-presence of MCFAs can inhibit the growth of S. cerevisiae (Baroň et al., 2017). Specifically, several works have reported the strong relation of hexanoic acid with nitrogen amount in the media both in synthetic must and wine, and also a remarkable association with the yeast strain (Barbosa et al., 2009; Bianchi et al., 2023; Carrau et al., 2008; Csutoras et al., 2022; Ugliano et al., 2010). This could indicate that given the same nitrogen in the must, the different yeast strains tested in this study have metabolized it at different rates.

Also among the most relevant VIP scores (above 1) were HT, 2-PE, 2-phenyl ethyl acetate, 3-methyl-1-butanol, and isoamyl acetate. Among them, the difference in the amounts of 2-PE found in the different fermented samples was the most remarkable (Table 2). As previously noticed, 2-PE is an exception among the higher alcohols since it presents a pleasant scent of rose/honey which is considered a positive attribute in wine, beer and cider (Hirst & Richter, 2016) partially responsible for the floral aroma of these food matrices. In addition, the esters and aldehydes synthesized from 2-PE can be important odorants of food matrices such as wine (Li et al., 2008; San-Juan et al., 2011). As mentioned above, the production of higher alcohols and their corresponding esters could be employed by the yeast to detoxify from the aldehydes and MCFAs (Saerens et al., 2010). Hereby, the difference in the production of volatile compounds and HT might partially be the result of divergent strategies of the yeast to detoxify, which would depend on the microorganism itself.

Thus, the capacity of conversion of TYR to HT could be more feasible for certain yeast, and for other yeast not achievable in the same extent. On the other hand, there might be yeast employing Ehrlich pathway for detoxification as quoted by Cordente et al. (2019) which in turn would explain the increased content of higher alcohols and esters in these samples.

It could be also possible that the production of any of them is being enhanced through the anabolic pathway. Also, considering that the consumption preferences of the different S. cerevisiae yeast are diverse (Scott et al., 2021), the strains with a preference for tyrosine, could create more 4-hydroxyphenylpyruvate (4-HPP) deriving in TYR and in a minor extent HT. Likewise, yeast with a phenylalanine preference would give rise to phenylpyruvate and therefore to increased 2-PE. Apart from HT, MEL was also located just below 1 in the VIP scores (Fig. 5), highlighting the importance of this compound in the classification of the samples under study. Similar trends were observed for HT and MEL which could be partially justified due to the activation of Aro 7. Figure 1 shows that after the condensation of two glucose-derived metabolites erythrose-4-phosphate (E4P) and phosphoenolpyruvate (PEP) in the anabolic pathway, some enzymatic reactions occur leading to chorismate which can form tryptophan or be converted by Aro7 into prephenate and in 4-HPP straightaway (Fig. 1). Therefore it would be plausible that the presence of tryptophan and its consumption by the yeast would generate, on the one hand, MEL, and on the other, the tryptophan in the media could activate Aro7 by tryptophan activating the pathway of HT synthesis. Despite the interesting correlation with melatonin, the most potent negative correlation was clearly stated for the case of HT.

Despite the lack of studies analyzing HT, TYR, and MEL together with volatile compounds produced by non-Saccharomyces yeast strains, and considering that previous reports have pointed out that these strains produce lower concentrations of HT than Saccharomyces (Rebollo-Romero et al., 2020), it would be expectable for non-Saccharomyces to contribute to the synthetic must composition with a remarkable amount of volatile compounds.

Analysis of Volatile Compounds, Tyrosol, and Hydroxytyrosol from Mutated QA23 Yeast

Considering the significant negative correlation between the production of HT by the yeasts tested and the total content in volatile compounds, fermentations were performed employing a usual yeast, QA23 strain, and an HT-overproducing QA23 yeast strain obtained with the integration of multiple copies of the gene ARO4 with point mutation K229L (Bisquert et al., 2022; Muñiz-Calvo et al., 2020). ARO4 is one of the initializing enzymes of the anabolic pathway and the sobreexpresion of modified Aro4pK229L results in tyrosine-insensitive enzymes (Cordente et al., 2018) being the synthesis to TYR continuous (Fig. 1). Thus, the production of TYR and therefore HT was significantly higher and the modification resulted to be successful. This had been observed by Cordente et al. (2018) in fermented must with yeast strains with the ARO4 mutation with point mutation Q166R. They observed that the fermented must with this yeast yielded a higher concentration of TYR in comparison with the other yeast tested.

Regarding the production of volatile compounds, a total of 35 volatile compounds were determined: 16 esters, 12 alcohols, 5 acids, and 2 ketones (Table 4). The biotechnological modification caused significant changes in 23 of the 35 volatile compounds, only keeping 12 of them without significant changes as compared with QA23 strain. Noteworthy, the modified yeast QA23 produced up to 8 times more of 2-PE than the original yeast. This was expected since, as explained above, the inhibitory effect of tyrosine is annulled and thus the pathway to the intermediate prephenate was continuous. Therefore, the production of 2-PE was promoted (Fig. 1). The increased amount of 2-PE in turn resulted in higher content of its derivatives in QA23 modified yeast as compared with the original QA23. This was the case of 2-phenyl ethyl acetate, 2-phenyl ethyl propionate and ethyl-2-phenylethyl butylphosphonate which were present in the fermented must at significantly higher amounts in the modified QA23 yeast than in the original. Conversely, two ethyl esters such as ethyl hexanoate and ethyl octanoate were found in significantly higher quantities in the must fermented by the original QA23 yeast. The concentrations found for these compounds in wines usually exceed their perception thresholds and are described as impact odorants of different types of wines contributing to the fruity nuances of the beverage (Gómez-Míguez et al., 2007; Li et al., 2008; Marcq & Schieberle, 2021). Remarkably, the genetic modification did not affect the amount of ethyl acetate in the media, agreeing with the results obtained by Cordente et al. (2018). Revisiting the above-mentioned detoxification hypothesis, it may be that original QA23 and mutated QA23 yeast have different strategies to avoid oxidation. On the one hand, the original QA23 yeast could extend its life expectancy through esterification, considering that MCFAs and ethanol are toxic to yeast and compromise their survival. On the other hand, the QA23 modified, could be using the hyperproduction of HT and its antioxidant properties to reduce the oxidation and, therefore, fewer esters be produced. This hypothesis would also agree with the significantly lower amount of hexanoic acid found in the original QA23 yeast (Table 4).

Conclusions

For the first time, a detailed analysis of volatile compounds and their relation to the production of TYR, HT, and MEL in several S. cerevisiae strains has been performed. The final concentration of the bioactive compounds HT and MEL in fermented must employing different yeast strains studied revealed that the higher the concentrations, the lower the amount of volatile compounds determined. This inverse correlation was especially remarkable with respect to the production of higher alcohols and esters. The employment of a modified QA23 yeast strain with sobreexpresion of modified Aro4pK229L which overproduces HT gave rise to a fermented must also higher in 2-PE and their corresponding esters but with an outstanding less presence of other important esters such as ethyl hexanoate and ethyl octanoate. Both premises could point out that Saccharomyces cerevisiae might have different approaches to handling cell stress/toxicity due to nitrogen metabolism. Some strains could be more easily detoxified through the production of higher alcohols and these in turn to esters and others have the necessary tools to convert these higher alcohols into antioxidant molecules. In any case, the nitrogenous metabolism of each strain studied has been shown to be very different between strains and to be extremely linked to the production of volatile compounds. These results could be useful with regard to the production of different food-fermented products, mainly beverages, and the use of yeasts as bioreactors for the production of bioactive and volatile compounds. Thus, the determination of the implication of certain genes in the production of antioxidant molecules and volatile compounds can have a direct application to generate improved yeast for the production of these high-value molecules or for the selection of the most proper yeasts to obtain wine with high aromatic intensity.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Albanese, D., Attanasio, G., Cinquanta, L., & Di Matteo, M. (2013). Volatile compounds in red wines processed on an industrial scale by short pre-fermentative cold maceration. Food and Bioprocess Technology, 6, 3266–3272. https://doi.org/10.1007/s11947-012-0798-5

Álvarez-Fernández, M. A., Fernández-Cruz, E., Garcia-Parrilla, M. C., Troncoso, A. M., Mattivi, F., Vrhovsek, U., & Arapitsas, P. (2019a). Saccharomyces cerevisiae and Torulaspora delbrueckii intra-and extra-cellular aromatic amino acids metabolism. Journal of Agriculture and Food Chemistry, 67(28), 7942–7953. https://doi.org/10.1021/acs.jafc.9b01844

Álvarez-Fernández, M. A., Fernández-Cruz, E., Valero, E., Troncoso, A. M., & García-Parrilla, M. C. (2019b). Efficiency of three intracellular extraction methods in the determination of metabolites related to tryptophan and tyrosine in winemaking yeast’s metabolism by LC-HRMS. Food Chemistry, 297, 124924. https://doi.org/10.1016/j.foodchem.2019.05.198

Barbosa, C., Falco, V., Mendes-Faia, A., & Mendes-Ferreira, A. (2009). Nitrogen addition influences formation of aroma compounds, volatile acidity and ethanol in nitrogen deficient media fermented by Saccharomyces cerevisiae wine strains. Journal of Bioscience and Bioengineering, 108(2), 99–104. https://doi.org/10.1016/j.jbiosc.2009.02.017

Baroň, M., Kumšta, M., Prokeš, K., Tomaškova, L., & Tomkova, M. (2017). The inhibition of Saccharomyces cerevisiae population during alcoholic fermentation of grape must by octanoic, decanoic and dodecanoic acid mixture. BIO Web of Conferences, 9, 02025. https://doi.org/10.1051/bioconf/20170902025

Bettencourt, S., Miranda, C., Pozdniakova, T. A., Sampaio, P., Franco-Duarte, R., & Pais, C. (2020). Single cell oil production by oleaginous yeasts grown in synthetic and waste-derived volatile fatty acids. Microorganisms, 8(11), 1809. https://doi.org/10.3390/microorganisms8111809

Bianchi, A., Santini, G., Piombino, P., Pittari, E., Sanmartin, C., Moio, L., & Mencarelli, F. (2023). Nitrogen maceration of wine grape: an alternative and sustainable technique to carbonic maceration. Food Chemistry, 404, 134138. https://doi.org/10.1016/j.foodchem.2022.134138

Bisquert, R., Planells-Cárcel, A., Valera-García, E., Guillamón, J. M., & Muñiz-Calvo, S. (2022). Metabolic engineering of Saccharomyces cerevisiae for hydroxytyrosol overproduction directly from glucose. Microbial Biotechnology, 15(5), 1499–1510. https://doi.org/10.1111/1751-7915.13957

Bordiga, M., Lorenzo, C., Pardo, F., Salinas, M. R., Travaglia, F., Arlorio, M., & Garde-Cerdán, T. (2016). Factors influencing the formation of histaminol, hydroxytyrosol, tyrosol, and tryptophol in wine: temperature, alcoholic degree, and amino acids concentration. Food Chemistry, 197, 1038–1045. https://doi.org/10.1016/j.foodchem.2015.11.112

Borrull, A., López-Martínez, G., Poblet, M., Cordero-Otero, R., & Rozès, N. (2015). New insights into the toxicity mechanism of octanoic and decanoic acids on Saccharomyces cerevisiae. Yeast, 32(5), 451–460. https://doi.org/10.1002/yea.3071

Boulton, R. B., Singleton, V. L., Bisson, L. F., & Kunkee, R. E. (1995). Selection of state of ripeness for harvest and harvesting. Principles and practices of winemaking (pp. 52–60). New York: Chapman & Hall, International Thomson Publishing.

Carrau, F. M., Medina, K., Farina, L., Boido, E., Henschke, P. A., & Dellacassa, E. (2008). Production of fermentation aroma compounds by Saccharomyces cerevisiae wine yeasts: Effects of yeast assimilable nitrogen on two model strains. FEMS Yeast Research, 8(7), 1196–1207. https://doi.org/10.1111/j.1567-1364.2008.00412.x

Cordente, A. G., Curtin, C. D., Varela, C., & Pretorius, I. S. (2012). Flavour-active wine yeasts. Applied Microbiology and Biotechnology, 96(3), 601–618. https://doi.org/10.1007/s00253-012-4370-z

Cordente, A. G., Schmidt, S., Beltran, G., Torija, M. J., & Curtin, C. D. (2019). Harnessing yeast metabolism of aromatic amino acids for fermented beverage bioflavouring and bioproduction. Applied Microbiology and Biotechnology, 103(11), 4325–4336. https://doi.org/10.1007/s00253-019-09840-w

Cordente, A. G., Solomon, M., Schulkin, A., Leigh Francis, I., Barker, A., Borneman, A. R., & Curtin, C. D. (2018). Novel wine yeast with ARO4 and TYR1 mutations that overproduce ‘floral’aroma compounds 2-phenylethanol and 2-phenylethyl acetate. Applied Microbiology and Biotechnology, 102(14), 5977–5988. https://doi.org/10.1007/s00253-018-9054-x

Cordente, A. G., Espinase Nandorfy, D., Solomon, M., Schulkin, A., Kolouchova, R., Francis, I. L., & Schmidt, S. A. (2021). Aromatic higher alcohols in wine: Implication on aroma and palate attributes during chardonnay aging. Molecules, 26(16), 4979. https://doi.org/10.3390/molecules2616497

Crépin, L., Truong, N. M., Bloem, A., Sanchez, I., Dequin, S., & Camarasa, C. (2017). Management of multiple nitrogen sources during wine fermentation by Saccharomyces cerevisiae. Applied Microbiology and Biotechnology, 83(5), e02617–e2716. https://doi.org/10.1128/AEM.02617-16

Csutoras, C., Bakos-Barczi, N., & Burkus, B. (2022). Medium chain fatty acids and fatty acid esters as potential markers of alcoholic fermentation of white wines. Acta Alimentaria, 51(1), 33–42. https://doi.org/10.1556/066.2021.00129

Diamantopoulou, P., Filippousi, R., Antoniou, D., Varfi, E., Xenopoulos, E., Sarris, D., & Papanikolaou, S. (2020). Production of added-value microbial metabolites during growth of yeast strains on media composed of biodiesel-derived crude glycerol and glycerol/xylose blends. FEMS Microbiology Letters, 367(10), fnaa063. https://doi.org/10.1093/femsle/fnaa063

Dickinson, J. R., Salgado, L. E. J., & Hewlins, M. J. (2003). The catabolism of amino acids to long chain and complex alcohols in Saccharomyces cerevisiae. Journal of Biological Chemistry, 278(10), 8028–8034. https://doi.org/10.1074/jbc.M211914200

Fernandez-Cruz, E., González, B., Muñiz-Calvo, S., Morcillo-Parra, M. Á., Bisquert, R., Troncoso, A. M., & Guillamón, J. M. (2019). Intracellular biosynthesis of melatonin and other indolic compounds in Saccharomyces and non-Saccharomyces wine yeasts. European Food Research and Technology, 245(8), 1553–1560. https://doi.org/10.1007/s00217-019-03257-5

Franco-Duarte, R., Bessa, D., Gonçalves, F., Martins, R., Silva-Ferreira, A. C., Schuller, D., & Pais, C. (2017). Genomic and transcriptomic analysis of Saccharomyces cerevisiae isolates with focus in succinic acid production. FEMS Yeast Research, 17(6), fox057. https://doi.org/10.1093/femsyr/fox057

Gallardo-Fernández, M., Valls-Fonayet, J., Valero, E., Hornedo-Ortega, R., Richard, T., Troncoso, A. M., & Garcia-Parrilla, M. D. C. (2022). Isotopic labelling-based analysis elucidates biosynthesis pathways in Saccharomyces cerevisiae for Melatonin, Serotonin and Hydroxytyrosol formation. Food Chemistry, 374, 131742. https://doi.org/10.1016/j.foodchem.2021.131742

Garde-Cerdán, T., & Ancín-Azpilicueta, C. (2006). Contribution of wild yeasts to the formation of volatile compounds in inoculated wine fermentations. European Food Research and Technology, 222, 15–25. https://doi.org/10.1007/s00217-005-0029-7

Garde-Cerdán, T., & Ancín-Azpilicueta, C. (2008). Effect of the addition of different quantities of amino acids to nitrogen-deficient must on the formation of esters, alcohols, and acids during wine alcoholic fermentation. LWT Food Science and Technology, 41(3), 501–510. https://doi.org/10.1016/j.lwt.2007.03.018

Germann, S. M., Baallal Jacobsen, S. A., Schneider, K., Harrison, S. J., Jensen, N. B., Chen, X., Stahlhut, S. G., Borodina, I., Luo, H., Zhu, J., Maury, J., & Forster, J. (2016). Glucose-based microbial production of the hormone melatonin in yeast Saccharomyces cerevisiae. Biotechnology Journal, 11(5), 717–724. https://doi.org/10.1002/biot.201500143

Gietz, R. D. (2014). Yeast transformation by the LiAc/SS carrier DNA/PEG method. Methods in Molecular Biology, 1163, 33–44. https://doi.org/10.1385/1-59259-958-3:107

Gómez-Míguez, M. J., Cacho, J. F., Ferreira, V., Vicario, I. M., & Heredia, F. J. (2007). Volatile components of Zalema white wines. Food Chemistry, 100(4), 1464–1473. https://doi.org/10.1016/j.foodchem.2005.11.045

Gris, E. F., Mattivi, F., Ferreira, E. A., Vrhovsek, U., Filho, D. W., Pedrosa, R. C., & Bordignon-Luiz, M. T. (2011). Stilbenes and tyrosol as target compounds in the assessment of antioxidant and hypolipidemic activity of Vitis vinifera red wines from Southern Brazil. Journal of Agricultural and Food Chemistry, 59(14), 7954–7961. https://doi.org/10.1021/jf2008056

Hazelwood, L. A., Daran, J. M., Van Maris, A. J., Pronk, J. T., & Dickinson, J. R. (2008). The Ehrlich pathway for fusel alcohol production: a century of research on Saccharomyces cerevisiae metabolism. Applied and Environmental Microbiology, 74(8), 2259–2266. https://doi.org/10.1128/AEM.02625-07

Hernández-Orte, P., Cacho, J. F., & Ferreira, V. (2002). Relationship between varietal amino acid profile of grapes and wine aromatic composition. Experiments with model solutions and chemometric study. Journal of Agricultural and Food Chemistry, 50(10), 2891–2899. https://doi.org/10.1021/jf011395o

Hernández-Orte, P., Ibarz, M. J., Cacho, J., & Ferreira, V. (2005). Effect of the addition of ammonium and amino acids to musts of Airen variety on aromatic composition and sensory properties of the obtained wine. Food Chemistry, 89(2), 163–174. https://doi.org/10.1016/j.foodchem.2004.02.021

Hirst, M. B., & Richter, C. L. (2016). Review of aroma formation through metabolic pathways of Saccharomyces cerevisiae in beverage fermentations. American Journal of Enology and Viticulture, 67(4), 361–370. https://doi.org/10.5344/ajev.2016.15098

Huang, E. L., & Demirci, A. (2009). Enhanced human lysozyme production by Kluyveromyces lactis. Food and Bioprocess Technology, 2, 222–228. https://doi.org/10.1007/s11947-008-0062-1

Ivanova, V., Stefova, M., Vojnoski, B., Stafilov, T., Bíró, I., Bufa, A., & Kilár, F. (2013). Volatile composition of Macedonian and Hungarian wines assessed by GC/MS. Food and Bioprocess Technology, 6, 1609–1617. https://doi.org/10.1007/s11947-011-0760-y

Jensen, N. B., Strucko, T., Kildegaard, K. R., David, F., Maury, J., Mortensen, U. H., Forster, J., Nielsen, J., & Borodina, I. (2014). EasyClone: Method for iterative chromosomal integration of multiple genes in Saccharomyces cerevisiae. FEMS Yeast Research, 14(2), 238–248. https://doi.org/10.1111/1567-1364.12118

Kosel, J., Čadež, N., Schuller, D., Carreto, L., Franco-Duarte, R., & Raspor, P. (2017). The influence of Dekkera bruxellensis on the transcriptome of Saccharomyces cerevisiae and on the aromatic profile of synthetic wine must. FEMS Yeast Research, 17(4), fox018. https://doi.org/10.1093/femsyr/fox018

Lambrechts, M. G., & Pretorius, I. S. (2000). Yeast and its importance to wine aroma-a review. South African Journal of Enology and Viticulture, 21(1), 97–129. https://doi.org/10.21548/21-1-3560

Li, H., Tao, Y. S., Wang, H., & Zhang, L. (2008). Impact odorants of Chardonnay dry white wine from Changli County (China). European Food Research Technology, 227(1), 287–292. https://doi.org/10.1007/s00217-007-0722-9

Mantzouridou, F., & Paraskevopoulou, A. (2013). Volatile bio-ester production from orange pulp-containing medium using Saccharomyces cerevisiae. Food Bioproccess Technology, 6, 3326–3334. https://doi.org/10.1007/s11947-012-1009-0

Marcq, P., & Schieberle, P. (2021). Characterization of the key aroma compounds in a commercial Fino and a commercial Pedro Ximenez sherry wine by application of the sensomics approach. Journal of Agricultural and Food Chemistry, 69(17), 5125–5133. https://doi.org/10.1021/acs.jafc.1c01348

Mas, A., Guillamon, J. M., Torija, M. J., Beltran, G., Cerezo, A. B., Troncoso, A. M., & Garcia-Parrilla, M. C. (2014). Bioactive compounds derived from the yeast metabolism of aromatic amino acids during alcoholic fermentation. BioMed Research International., 2014, 898045. https://doi.org/10.1155/2014/898045

Mata-Gómez, L. C., Montañez, J. C., Méndez-Zavala, A., & Aguilar, C. N. (2014). Biotechnological production of carotenoids by yeasts: an overview. Microbial Cell Factories, 13(1), 1–11. https://doi.org/10.1186/1475-2859-13-12

Maury, J., Germann, S. M., Baallal Jacobsen, S. A., Jensen, N. B., Kildegaard, K. R., Herrgàrd, M. J., Schneider, K., Koza, A., Forster, J., Nielsen, J., & Borodina, I. (2016). EasyCloneMulti: a set of vectors for simultaneous and multiple genomic integrations in saccharomyces cerevisiae. PLoS ONE, 11(3), 1–22. https://doi.org/10.1371/journal.pone.0150394

Morakul, S., Mouret, J. R., Nicolle, P., Aguera, E., Sablayrolles, J. M., & Athès, V. (2013). A dynamic analysis of higher alcohol and ester release during winemaking fermentations. Food and Bioprocess Technology, 6, 818–827. https://doi.org/10.1007/s11947-012-0827-4

Morcillo-Parra, M. Á., Valera, M. J., Beltran, G., Mas, A., & Torija, M. J. (2019). Glycolytic proteins interact with intracellular melatonin in Saccharomyces cerevisiae. Frontiers in Microbiology, 10, 2424. https://doi.org/10.3389/fmicb.2019.02424

Mouret, J. R., Perez, M., Angenieux, M., Nicolle, P., Farines, V., & Sablayrolles, J. M. (2014). Online-based kinetic analysis of higher alcohol and ester synthesis during winemaking fermentations. Food and Bioprocess Technology, 7(5), 1235–1245. https://doi.org/10.1007/s11947-013-1089-5

Muñiz-Calvo, S., Bisquert, R., Puig, S., & Guillamón, J. M. (2020). Overproduction of hydroxytyrosol in Saccharomyces cerevisiae by heterologous overexpression of the Escherichia coli 4-hydroxyphenylacetate 3-monooxygenase. Food Chemistry, 308, 125646. https://doi.org/10.1016/j.foodchem.2019.125646

Nisbet, M. A., Tobias, H. J., Brenna, J. T., Sacks, G. L., & Mansfield, A. K. (2014). Quantifying the contribution of grape hexoses to wine volatiles by high-precision [U13C]-glucose tracer studies. Journal of Agricultural and Food Chemistry, 62(28), 6820–6827. https://doi.org/10.1021/jf500947x

Pérez, D., Jaehde, I., Guillamón, J. M., Heras, J. M., & Querol, A. (2021). Screening of Saccharomyces strains for the capacity to produce desirable fermentative compounds under the influence of different nitrogen sources in synthetic wine fermentations. Food Microbiology, 97, 103763. https://doi.org/10.1016/j.fm.2021.103763

Peris, D., Pérez-Través, L., Belloch, C., & Querol, A. (2016). Enological characterization of Spanish Saccharomyces kudriavzevii strains, one of the closest relatives to parental strains of winemaking and brewing Saccharomyces cerevisiae× S. kudriavzevii hybrids. Food Microbiology, 53, 31–40. https://doi.org/10.1016/j.fm.2015.07.010

Perpetuini, G., Tittarelli, F., Battistelli, N., Suzzi, G., & Tofalo, R. (2020). γ-Aminobutyric acid production by Kluyveromyces marxianus strains. Journal of Applied Microbiology, 129(6), 1609–1619. https://doi.org/10.1111/jam.14736

Pretorius, I. S. (2020). Tasting the terroir of wine yeast innovation. FEMS Yeast Research., 20(1), foz084. https://doi.org/10.1093/femsyr/foz084

Rapp, A., & Versini, G. (1995). Influence of nitrogen compounds in grapes on aroma compounds of wines. Developments in food science (Vol. 37, pp. 1659–1694). Elsevier. https://doi.org/10.1016/S0167-4501(06)80257-8

Rebollo-Romero, I., Fernández-Cruz, E., Carrasco-Galán, F., Valero, E., Cantos-Villar, E., Cerezo, A. B., Troncoso, A. M., & García-Parrilla, M. C. (2020). Factors influencing the production of the antioxidant hydroxytyrosol during alcoholic fermentation: yeast strain, initial tyrosine concentration and initial must. LWT, 130, 109631. https://doi.org/10.1016/j.lwt.2020.109631

Reiter, R. J., Tan, D. X., Manchester, L. C., Terron, M. P., Flores, L. J., & Koppisepi, S. (2007). Medical implications of melatonin: receptor-mediated and receptor-independent actions. Advances in Medical Sciences (De Gruyter Open), 52, 11–28.

Riou, C., Nicaud, J. M., Barre, P., & Gaillardin, C. (1997). Stationary-phase gene expression in Saccharomyces cerevisiae during wine fermentation. Yeast, 13(10), 903–915. https://doi.org/10.1128/AEM.00036-21

Rollero, S., Mouret, J. R., Bloem, A., Sanchez, I., Ortiz-Julien, A., Sablayrolles, J. M., & Camarasa, C. (2017). Quantitative 13C-isotope labelling-based analysis to elucidate the influence of environmental parameters on the production of fermentative aromas during wine fermentation. Microbial Biotechnology, 10(6), 1649–1662. https://doi.org/10.1111/1751-7915.12749

Sáenz-Navajas, M. P., Fernández-Zurbano, P., & Ferreira, V. (2012). Contribution of nonvolatile composition to wine flavor. Food Reviews International, 28(4), 389–411. https://doi.org/10.1080/87559129.2012.660717

Saerens, S. M., Delvaux, F. R., Verstrepen, K. J., & Thevelein, J. M. (2010). Production and biological function of volatile esters in Saccharomyces cerevisiae. Microbial Biotechnology, 3(2), 165–177. https://doi.org/10.1111/j.1751-7915.2009.00106.x

Samuel, S. M., Thirunavukkarasu, M., Penumathsa, S. V., Paul, D., & Maulik, N. (2008). Akt/FOXO3a/SIRT1-mediated cardioprotection by n-tyrosol against ischemic stress in rat in vivo model of myocardial infarction: Switching gears toward survival and longevity. Journal of Agricultural and Food Chemistry, 56(20), 9692–9698. https://doi.org/10.1021/jf802050h

Sanchez-Barcelo, E., Mediavilla, M. D., Alonso-Gonzalez, C., & Rueda, N. (2012). Breast cancer therapy based on melatonin. Recent Patents on Endocrine, Metabolic & Immune Drug Discovery, 6(2), 108–116. https://doi.org/10.2174/187221412800604581

San-Juan, F., Ferreira, V., Cacho, J., & Escudero, A. (2011). Quality and aromatic sensory descriptors (mainly fresh and dry fruit character) of Spanish red wines can be predicted from their aroma-active chemical composition. Journal of Agricultural and Food Chemistry, 59(14), 7916–7924. https://doi.org/10.1021/jf1048657

Scott, W. T., Jr., Van Mastrigt, O., Block, D. E., Notebaart, R. A., & Smid, E. J. (2021). Nitrogenous compound utilization and production of volatile organic compounds among commercial wine yeasts highlight strain-specific metabolic diversity. Microbiology Spectrum, 9(1), e00485-e521. https://doi.org/10.1128/Spectrum.00485-21

Sumby, K. M., Grbin, P. R., & Jiranek, V. (2010). Microbial modulation of aromatic esters in wine: current knowledge and future prospects. Food Chemistry, 121(1), 1–16. https://doi.org/10.1016/j.foodchem.2009.12.004

Torija, M. J., Beltran, G., Novo, M., Poblet, M., Guillamón, J. M., Mas, A., & Rozes, N. (2003). Effects of fermentation temperature and Saccharomyces species on the cell fatty acid composition and presence of volatile compounds in wine. International Journal of Food Microbiology, 85(1–2), 127–136. https://doi.org/10.1016/s0168-1605(02)00506-8

Tronchoni, J., Rozès, N., Querol, A., & Guillamón, J. M. (2012). Lipid composition of wine strains of Saccharomyces kudriavzevii and Saccharomyces cerevisiae grown at low temperature. International Journal of Food Microbiology, 155(3), 191–198. https://doi.org/10.1016/j.ijfoodmicro.2012.02.004

Ubeda, C., Kania-Zelada, I., del Barrio-Galán, R., Medel-Marabolí, M., Gil, M., & Peña-Neira, Á. (2019). Study of the changes in volatile compounds, aroma and sensory attributes during the production process of sparkling wine by traditional method. Food Research International, 119, 554–563. https://doi.org/10.1016/j.foodres.2018.10.032

Ugliano, M., Travis, B., Francis, I. L., & Henschke, P. A. (2010). Volatile composition and sensory properties of Shiraz wines as affected by nitrogen supplementation and yeast species: Rationalizing nitrogen modulation of wine aroma. Journal of Agricultural and Food Chemistry, 58(23), 12417–12425. https://doi.org/10.1021/jf1027137

Vandermies, M., & Fickers, P. (2019). Bioreactor-scale strategies for the production of recombinant protein in the yeast Yarrowia lipolytica. Microorganisms, 7(2), 40. https://doi.org/10.3390/microorganisms7020040

Varela, C., Siebert, T., Cozzolino, D., Rose, L., McLean, H., & Henschke, P. A. (2009). Discovering a chemical basis for differentiating wines made by fermentation with ‘wild’ indigenous and inoculated yeasts: Role of yeast volatile compounds. Australian Journal of Grape and Wine Research, 15(3), 238–248. https://doi.org/10.1111/j.1755-0238.2009.00054.x

Zhang, Y., Nielsen, J., & Liu, Z. (2017). Engineering yeast metabolism for production of terpenoids for use as perfume ingredients, pharmaceuticals and biofuels. FEMS Yeast Research, 17(8), fox080. https://doi.org/10.1093/femsyr/fox080

Acknowledgements

The authors want to thank the VI PPIT-US for the pre-doctoral grant of M.Gonzalez-Ramirez and C. Ubeda’s current contract (USE-18644-Z).

Funding

Funding for open access publishing: Universidad de Sevilla/CBUA. This work has been funded with a project from Ministerio de Ciencia, Innovación y Universidades (PID2019-108722RB-C32), a project from Junta de Andalucía-Consejería de Economía y Conocimiento (P18-RT-3098) and Universidad de Sevilla (US-1263469).

Author information

Authors and Affiliations

Contributions

Marina Gonzalez-Ramirez performed the analyses of TYR, HT and MEL; Mar Marin Torres performed the analyses of volatile compounds; Marta Gallardo-Fernandez carried out fermentations of modified yeast; Andres Planells-Carcel executed fermentations of commercial yeast strains; Ricardo Bisquert developed and accomplished the genetic modifications of QA23 yeast; Eva Valero performed the fermentations design; Cristina Ubeda carried out data analysis, prepared figures and manuscript preparation; Ana Maria Troncoso contributed to the work conceptualization, figures and manuscript preparation; Maria Carmen Garcia-Parrilla carried out work conceptualization and manuscript preparation. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gonzalez-Ramirez, M., Marin-Torres, M.M., Gallardo-Fernandez, M. et al. Approaching Study on the Relationship Between Saccharomyces cerevisiae Production of Tyrosol, Hydroxytyrosol, and Melatonin with Volatile Compounds in Fermented Must. Food Bioprocess Technol 17, 154–168 (2024). https://doi.org/10.1007/s11947-023-03108-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03108-y