Abstract

Mushroom production is a growing sector as the demand for this product is increasing. The quantity of waste and by-products generated along the supply chain is however considerable (about 20% of the fresh weight is disposed). Although the recovery of chitosan from mushrooms has been extensively studied, little has been done to optimize the recovery of proteins, which make up to 20% of dry weight. In the present work, six different by-products were studied for their crude composition and their protein fraction was characterized in detail. Then, a comparative study was conducted on three different extraction techniques (environmentally friendly aqueous extraction, ultrasound-assisted extraction, and enzyme-assisted extraction). Enzyme-assisted extraction has proven to be the most efficient technique in terms of protein extraction yield, even though the protein fraction is extracted in the form of peptides and not whole proteins. The lowest degree of hydrolysis is instead given by the ultrasound-assisted extraction, which however shows a rather high degree of racemization which decreases the quality of the proteins. The aqueous extraction, despite the low extraction yield, gave the purest protein extracts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The world production volume of mushrooms and truffles amounted to about 10.24 million metric tons in 2017, with the major world producer being China, with 7.8 million metric tons (Statista, 2020). Italy, the USA, and The Netherlands follow at great distance (0.7, 0.4, and 0.3 million metric tons per year, respectively) (AtlasBig, 2022). The most cultivated edible species in the world is Lentinula edodes (commonly called “Shiitake”), covering about 22% of the global supply. Of the world production of edible mushrooms, 85% is covered by five genera: Lentinula, Pleurotus, Auricularia, Agaricus, and Flammulina (Royse et al., 2017). The consumption of cultivated edible mushrooms has grown very fast in the last decades, due to better conditions in farms and the consumer perception of their high nutritional value (Ramos et al., 2019). In particular, the demand for fresh mushrooms is increasing, due to the tendency of consumers in buying organic food without the addition of preservatives. However, fresh mushroom cannot be stored for long periods because they are highly perishable. So, also frozen, dried, or canned mushrooms are present on the market (Bernaś et al., 2006). The mushroom industry waste amounts to 5 kg for each kilogram of final product, and they are constituted by spent mycelium substrate, by-products of mushroom production, spent growth substrate, or wasted mushroom medium (Schimpf & Schulz, 2016). A possible way to treat mushrooms waste is catalytic pyrolysis, which allows obtaining a production yield of hydrocarbons of 44.5 wt.% (14 wt.% without catalyst) (Wang et al., 2016). During mushroom production, about 20% of the fresh weight is discarded (stipes, broken fruiting bodies, and non-compliant product) (Wang, 2020). However, mushrooms by-products are still a rich source of useful components: chitosan, proteins, umami molecules, and other bioactive compounds. Many works focused on polysaccharides such as chitosan, which can be extracted from mushrooms (Rane & Hoover, 1993) and constitutes a biodegradable alternative to synthetic plastics (Priyadarshi & Rhim, 2020). Other bioactive compounds are less investigated, for example non-compliant mushrooms can also be used for the extraction of D2 vitamin and its precursor ergosterol, valorizing this feedstock for the food and pharmaceutical industries (Papoutsis et al., 2020). Mushrooms are also a relatively unexplored source of bioactive peptides, such as antihypertensive, antioxidant, or antimicrobial. Bioactive peptides can be directly extracted from the mycelia, or they can be produced by a treatment with specific proteases after a protein extraction step (Zhou et al., 2020). For example, proteins were extracted from mushroom by-products using an alkali extraction followed by acid precipitation, and a subsequent proteolysis assisted by ultra-high pressures. Ultra-high-pressure treatment increased soluble protein content, protein solubility, and degree of hydrolysis. The low molecular weight peptides obtained were able to activate alcohol dehydrogenase and aldehyde dehydrogenase in vitro (Zhao et al., 2017). Edible mushrooms are very rich in compounds responsible of the umami taste, such as monosodium glutamate-like amino acids (aspartic and glutamic acid) and 5′-nucleotides (guanosine monophosphate, inosine monophosphate, and xanthosine monophosphate) (Wang et al., 2020); thus, they could be used as taste enhancers. At this regard, umami-responsible compounds can be extracted both with water (Poojary et al., 2017a) and with enzyme-assisted extraction (Poojary et al., 2017b), with the latter improving the extraction yield of up to 20-fold. Among the different mushroom species tested (Lentinus edodes, Pleurotus ostreatus, Agrocybe aegerita, and Agaricus bisporus), white and brown champignons (Agaricus bisporus) were the richest source of free amino acids such as aspartic and glutamic acids (Poojary et al., 2017b). Ultrasound-assisted extraction has been used to extract protein-polysaccharide complexes with bioactive properties from mushrooms and allowed to obtain extracts with higher proteins and lower carbohydrate content than hot water extraction, together with a lower molecular weight of the complexes (Cheung et al., 2012a).

Pressure extraction pulsed electric field–assisted pressure extraction, hot water extraction, and ethanol extraction have already been tested on A. bisporus (Parniakov et al., 2014), as well as the extraction with subcritical water on Pleurotus cornucopiae var. citrinopileatus (Jo et al., 2013). However, subcritical water extraction was mainly aimed at the recovery of phenolic compounds, β-glucans, and antioxidants (Jo et al., 2013). Similarly, ultrasound-assisted extraction has already been applied for mushroom extraction (Cheung et al., 2012b), but with a focus on the polysaccharide fraction and not on proteins. In the work of Parniakov et al. (2014), the most promising technique for producing clear mushroom extracts with high colloid stability and high protein and polysaccharide content was a combination of pressure extraction and pulsed electric field treatments. L. edodes has also been subjected to PLE, ultrasound-assisted extraction (UAE), and hot water extractions. UAE and subcritical water extraction (SWE) were demonstrated to be more effective than hot water extractions to obtain β-glucans (Morales et al, 2019a). Moreover, the combination of extraction of L. edodes can be coupled with crossflow microfiltration and reverse osmosis to obtain β-glucan-rich extracts (Morales et al., 2019b).

Although mushroom by-products have then served as sources of bioactive polysaccharides (Kumari et al., 2018), to our knowledge, no systematic investigation has been conducted to date on the methods of extracting proteins from mushrooms by-products. So, in this work, a deep characterization of the main mushrooms by-products from A. bisporus, L. edodes, and P. ostreatus was carried out for the first time. Thus, the novelty of this work is to study mushrooms by-products as a potential source of upcycled proteins, whereas they are more commonly exploited for the recovery of polysaccharides. The possibility of recycling proteins strongly depends not only on their quantity, but also on their quality and characteristics. In fact, based on the characteristics of the proteins, various applications can be targeted, such as food, feed, supplements, cosmetics, soil improvers, and others. Since the extraction technique can have a strong impact on the quantity and quality of the extracted proteins, three different extraction techniques (environmentally friendly aqueous extraction, ultrasound-assisted extraction, and enzyme-assisted extraction) were compared in this study for their protein extraction capacity on mushrooms.

Materials and Methods

Sampling of the Feedstocks

Six different types of residues have been selected for the characterization and they were provided by Pleurette (La Révolution Champignon, Lille, France). The composition of the residue consists of processing cuttings, leftovers, and mycelium. Sampling was carried out on 12/11/2018 for the following mushrooms strains: Agaricus bisporus white strain (FABw), Agaricus bisporus brown strain (FABb), Lentinus edodes grown on straw (FLEs), Lentinus edodes grown on wood (FLEw), Pleurotus ostreatus HK35 (FPOhk), and Pleurotus ostreatus Spoppo (FPOs). The dry residue of the samples is reported in Table 1. Samples arrived fresh and were immediately ground with a kitchen mill and stored at –20°C until analyses.

Mushroom Pretreatments

The pretreatment was carried out at IGV GmbH (Nuthetal, Germany), according to the following steps.

Cleaning: Because the by-products analyzed are the residual parts of the fungi, adherence of substrates, soil, straw, and other substances occurs. This step is currently done manually. The samples were passed over a sieve with an appropriate mesh size, so the mushroom bodies remain on the sieve and adhering impurities fall through. Parts of the by-products have grown together with dirt, and these embedded impurities were manually removed (due to the uneven shape of the mushroom pieces).

Cutting: The fungal byproducts have a gravimetric water content of over 80%, which allows processes responsible for a rapid decrease in quality. For stabilization and better processing of the fungi, they are dried with uniform drying conditions of the fungal pieces, which ensures a uniform product quality. So, the fungi must be homogenized and crushed by means of a cutter. Pre-comminution of the fungal samples is not necessary, while it is important to ensure that the energy input is not too high; otherwise, liquid will escape from the fungal material. The energy input can be controlled by the duration, number of blades, and rotation speed of the tub and the blades. About 2 kg of fungal sample can be evenly comminuted in 40 s on the lowest setting of the cutter.

Drying: Drying was carried out by means of a rotary kiln with circulating air. In total, 2.5 kg of fungal material was spread out on the trolley per square meter and drying took place at 45–55°C. The drying process is checked at regular intervals and the temperature must be adjusted, if necessary, to avoid quality losses. Fungi were dried to a moisture content of about 10% to guarantee the shelf-life of the fungi.

Milling: The grinding is carried out by means of a cross beater mill, using a 1.0-mm sieve insert. The sample is fed into the milling chamber, broken with pins, and bounced against a sieve. The sample remains in the grinding chamber until its particle size has been reduced so much that it passes through the sieve. Due to the low total fat content of the mushroom samples, it is possible to grind them using a fine sieve insert (1.0 mm). A throughput of 12 kg of dried fungi per hour can be achieved, reflecting good processability. The preparation of the fungal sample is finished at this point and can be fed into the extraction process.

Ultrasound-Assisted Extraction (UAE)

The UAE of proteins from mushrooms by-products was carried out following alkali-acid extraction methodology described by Prandi et al. (2022). It was performed in two stages, as shown in Fig. 1. The first stage was carried out in batch mode using an ultrasonic processor (Hielscher, Germany) that consisted of a transducer for converting electric signals into ultrasonic waves and a probe with a specific diameter. The maximal nominal output power of the device was of 400 W and the ultrasonic frequency was of 20 kHz. In each extraction, 30±1 g of dried mushrooms by products was used and mixed with the corresponding volume of 0.1 mol/L NaOH. The effect of the ratio solvent to solid (mL/g of feedstock), acoustic amplitude (μm), and extraction time (min) on the extraction efficiency (g of protein/g of feedstock) was evaluated. Subsequently, different levels of acoustic energy (Ws) were used to assess the kinetics of the extraction. The temperature of the extraction was controlled and kept below 45°C using an industrial chiller (6 °C) connected to the jacketed vessel where the mixture was placed. All the experiments were carried out in triplicate. Once the optimal conditions (ratio, acoustic amplitude, and acoustic energy) were found, the second stage included the scale-up of the UAE. The mass of feedstock and therefore the volume of solvent increased 10 times. The UAE was carried out using a 1000-W ultrasonic processor (Hielscher, Germany) with an ultrasonic frequency was of 24 kHz. In this stage, the temperature of the extraction was not controlled but it was recorded.

In both cases, after the ultrasound application, the mixture was filtered. The pH of the filtrate was adjusted to 4.0 using HCl (37%) to precipitate the extracted protein. The acid filtrate was centrifuged (4000 rpm, 10 min) and the decanted protein was recovered. Finally, the excess moisture was removed via convective drying (40 °C, 6 h).

Enzyme-Assisted Extraction (EAE)

Protein fractions of mushrooms were extracted by enzyme-assisted extraction using specific proteases (protease from B. licheniformis or papain) finally yielding peptides. The activity of protease from Bacillus licheniformis was 2.59 AU/G; the activity of papain from papaya latex crude powder was 1.5 units/mg solid. The reaction was carried out at the following conditions: reaction media, phosphate buffer 10 mM; enzyme to substrate ratio, 1% (V/w or w/w); hydro-module, 1 to 5 (1 part of sample and 5 parts of reaction media); hydrolysis time, 2 h. pH and temperature for each enzyme were as follows: protease from B. licheniformis pH 6.5–8.5, T 60 °C; papain pH 6.0–7.0, T 65 °C. As control, the extraction was carried out using the same conditions of time, pH, and temperature but without the enzyme.

Environmentally Friendly Aqueous Extraction (EFAE)

The environmentally friendly aqueous extraction (EFAE), based on SSICA patent (Montanari & Zurlini, 2012), and described in a previous research article where the method was applied to legume by-products, has been now used to extract proteins from mushrooms waste. This method operates in neutral conditions, bringing the advantage of a higher environmental and economic sustainability with respect to other stronger conditions, such as for example alkaline conditions. In detail, the starting by-products, after pretreatments explained in the section “Mushroom Pretreatments,” were treated with a neutral phosphate buffer (0.05 M Na3PO4 and 0.1 M NaCl, pH 7.2) in a 1:6 solid to liquid ratio. The treatment in phosphate buffer lasted at least 3 h, under stirring and at room temperature. Then, a separation step through centrifugation (5000 rpm; 10 min, 4°C) followed with the purpose to separate, on one hand, the liquid protein-rich fraction, and, on the other hand, the solid fiber-rich fraction. After this step, the proteins were isolated from the liquid-rich fraction through acidification at pH 4.5 with the addition of HCl 0.1 N, followed by a centrifugation step (10,000 rpm, 20 min, 4°C). The solid obtained from the centrifugation was finally lyophilized.

In a second moment, the EFAE method was little modified, introducing some changes in reference to Ziwei et al. (2018). In detail, the starting by-products, after pretreatments explained in the section “Mushroom Pretreatments,” were treated with a different buffer, specifically a buffer with Tris(hydroxymethyl)aminomethane (Tris)-HCl (0.1 M Tris-HCl, 0.01 M EDTA, 0.1 M KCl, pH 7.35) in a 1:6 solid to liquid ratio. The treatment in buffer was the same with the same conditions (3 h, stirring, room temperature). Successively, the fiber separation step through centrifugation (11,000 rpm; 10 min, 4°C) followed. After this step, the proteins were isolated from the liquid-rich fraction through acidification at pH 3 with the addition of a solution of 6% trichloroacetic acid (TCA), followed by a centrifugation step (11,000 rpm, 20 min, 4°C). The solid obtained from the centrifugation was finally lyophilized.

Proximate Analysis

Dry residue: Total solids are determined by drying the product at 70°C at reduced pressure (700–760 mmHg), or at 100°C at atmospheric pressure, for 4 h, according with the official methods for vegetable products (UNI EN 12145:1999).

Protein: Total protein content was determined according to the Kjeldahl method. The nitrogen to protein conversion factor used is 4.38 (Chandran Priyadarshni et al, 2022).

Fat: Total fat content was determined according to the Soxhlet method.

Fiber: Total fiber content was determined using an enzyme assay, according to the AOAC method.

Starch and sugars: The content of sucrose, D-glucose, and D-fructose is determined with a commercial kit by R-Biopharm, according to the manufacturer instructions. Starch is determined with the same kit, after hydrolysis of starch to D-glucose at pH 4.6, in the presence of the enzyme amyloglucosidase.

SDS-PAGE and High-Resolution Mass Spectrometry (HRMS) Analysis

Electrophoresis was carried out as described in a previous work (Prandi et al., 2020). Solutions obtained from enzyme-assisted extraction were directly analyzed. The protein extracts of mushrooms obtained by EFAE and UAE extraction were dissolved in a water-acetonitrile solution (3:1) containing 0.075 M HCl (25 mg in 4 mL). Briefly, a volume corresponding to 30 μg of protein was dried under nitrogen flow and reconstituted with 25 μL of reducing sample buffer (XT sample buffer 4× and XT reducing agent 20×, suitably diluted with distilled water). Proteins were denatured at 95°C for 5 min and loaded onto a 12% Criterion XT Bis-Tris Gel (Biorad, Hercules, CA, USA). The gel was run at 150 V and stained with Coomassie Brilliant Blue. Selected bands were digested in gel using trypsin. Briefly, the bands were removed from the gel, cut into small pieces (about 1 mm in diameter), and destained by successive washing steps with water/acetonitrile/ammonium bicarbonate. The proteins were then reduced with dithiothreitol and alkylated with iodoacetamide. Then, overnight digestion was performed at 37°C using trypsin from bovine pancreas (1749 BAEE units/mg solid; 3 BTEE units/mg solid; 25 ng/μL). The peptides were extracted from the gel in the subsequent washing steps with water/acetonitrile/ammonium bicarbonate. The collected solution, containing peptides, was dried under nitrogen flow, and reconstituted with 0.1% formic acid in water. Liquid chromatography coupled to mass spectrometry analyses were carried out as described previously. Briefly, the peptides were separated by reversed-phase chromatography and analyzed with an LTQ-OrbiTRAP in data-dependent scan mode. Peptide sequences were assigned based on spectra obtained using Peaks Studio software (Bioinformatic Solutions Inc., Waterloo, ON, Canada).

Amino Acid Analyses

Total amino acids, free amino acids, and racemization degree were determined as previously described (Prandi et al., 2021a).

Briefly, about 500 mg of mushrooms or 100 mg of protein extracts was hydrolyzed for 23 h with 6 mL of 6 M HCl, added with internal standard (7.5 mL of 5 mM norleucine), filtered, and suitably diluted before derivatization with AccQ Tag reagent (Waters, Milford, MA, USA) and UPLC/ESI-MS analysis. For methionine and cysteine, samples were oxidized by addition of 2 mL of performic acid (overnight incubation in ice bath). Then, 0.3 mL of hydrobromic acid was added; the samples were dried under nitrogen flow and subjected to acid hydrolysis as described above. Tryptophan was determined after alkaline hydrolysis with 4 M NaOH at 100°C for 4 h and subsequent neutralization, using α-methyltryptophan as an internal standard and analyzing the samples by UPLC/ESI-MS.

Free amino acids were determined by UPLC/ESI-MS after extracting the samples with water, adding norleucine internal standard, and derivatizing with AccQ tag reagent (Waters, Milford, MA, USA).

The degree of racemization was determined as follows. Forty milliliters of solution resulting from acid hydrolysis of each sample was dried by a rotavapor. The dry sample was reconstituted with 2 mL of 2 M hydrochloric acid in 2-propanol and the derivatization reaction was carried out at 90°C for 1 h. Then, the samples were dried under nitrogen flow, reconstituted with 1 mL of dichloromethane and 0.5 mL of trifluoroacetic anhydride, and incubated for 30 min at 50°C. The samples were dried again under nitrogen flow and reconstituted with 1 mL of dichloromethane just prior to analysis. Separation and detection of the derivatized amino acids were achieved by GC-MS (7820A GC system coupled to 5977B GC/MSD, Agilent, Santa Clara, CA, USA) using a Chirasyl-L-Val column (30 m × 250 μm × 0.25 μm). Run time: 40 min. Temperature ramp: initial temperature 80°C (hold for 2 min), 2°C/min until 100°C, hold 10 min, 5°C/min until 140°C, hold 1 min, 10°C/min until 160°C, hold 2 min, 10°C/min until 180°C, hold 3 min. Injection mode: split (ratio 20:1), heater 250°C. MSD transfer line temperature: 190°C. Flow: 1 mL/min. Acquisition mode: SIM/SCAN; solvent delay: 3 min; acquisition (SIM): 91.0, 126.1, 138.1, 139.1, 140.1, 153.1, 154.0, 164.1, 166.1, 168.1, 171.1, 180.1, 182.1, 184.1, 198.1, 198.2, 203.1); acquisition range (SCAN) 50-400 m/z. The degree of racemization was expressed as:

Hydrolysis Degree (o-Phtaldialdehyde Analysis, OPA)

Samples were prepared as described for the SDS-PAGE analysis. The degree of hydrolysis (DH), which is defined as the percentage of peptide bonds cleaved with respect to the total number of peptide bonds, is calculated using the o-phthaldialdehyde (OPA) method, accordingly to a previously published paper (Anzani et al., 2018). To eliminate any intrinsic absorbance at 340 nm of the samples, control samples were also analyzed. The same procedure was followed in these control samples, but the OPA reagent was replaced by an equal amount of water. The number of free amino acid group was determined from the calibration curve (made with L-Ile); the total number of amino acid groups was calculated dividing the total amount of proteins (determined with the Kjeldahl method) by the average molecular weight of amino acids (110 Da).

Statistical Analysis

The statistical significance was determined by ANOVA test using statistical program IBM SPSS Statistic software (v. 26) (Chicago, IL, USA).

The ANOVA single-factor test was applied to analyze the centesimal analysis data, with the significance threshold set at 0.05, with the aim of comparing the composition of the three mushrooms species (FAB, FLE, and FPO).

For the degree of hydrolysis and free amino acids, Kolmogorov-Smirnov and Shapiro-Wilk tests were used to evaluate the normality of the data. Then, one-way ANOVA was used to evaluate statistically significant differences between sample types. Homogeneity of variance was assessed by Levene’s test; then, Dunnett’s T3 post hoc test was used.

Results and Discussion

By-product Characterization

Six different mushroom types, belonging to three different species, were considered for this study: Agaricus bisporus white strain (FABw), Agaricus bisporus brown strain (FABb), Lentinula edodes grown on straw (FLEs), Lentinula edodes grown on wood (FLEw), Pleurotus ostreatus HK35 (FPOhk), and Pleurotus ostreatus Spoppo (FPOs). The three chosen species are among the most cultivated worldwide: A. bisporus is very diffused in North America and Europe, while L. edodes and P. ostreatus are very common in Asia.

The raw composition of the mushrooms by-products is reported in Table 1. The main difference is the high water content of A. bisporus, which has a dry matter content notably lower than the other two species considered. This difference is mainly due to the low fiber content of A. bisporus. The protein content is similar within the species tested, with the highest protein content found in L. edodes grown on wood (2.3%). This species also showed the highest fiber content, thus being interesting for both protein and chitosan extraction. The sugar and fat contents are very low in all cases (≤ 1.0%).

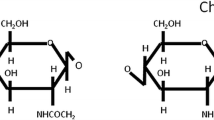

The results found for A. bisporus by-products are fully consistent with literature about the mushroom main product for what concerns dry weight (7.0–7.4%) and slightly lower for the quantity of proteins (2.0–3.0% on wet basis) (Braaksma & Schaap, 1996; Szadzińska et al., 2022). The Kjeldahl method estimates the protein content based on the nitrogen content, so it must be considered that the total protein content can be overestimated because it considers also nitrogen deriving from N-acetylglucosamine of the cell wall, urea, and other non-protein nitrogen compounds. Thus, the protein content will be recalculated later, basing on the total amino acid analysis.

Going more in detail into the protein composition, the protein profile was studied with sodium dodecyl sulphate polyacrylamide gel electrophoresis (Fig. 2). Protein bands are very faded, consistent with the low protein content (thus proportionally many interfering compounds).

SDS-PAGE and degree of hydrolysis of the mushroom by-products. Molecular weights of the marker are expressed in kDa. Statistically significant differences are indicated with asterisks (*p < 0.05; **p < 0.01). Sample labeling: Agaricus bisporus brown strain (FABb), Agaricus bisporus white strain (FABw), Lentinus edodes grown on straw (FLEs), Lentinus edodes grown on wood (FLEw), Pleurotus ostreatus HK35 (FPOhk), and Pleurotus ostreatus Spoppo (FPOs)

In both the strains of A. bisporus analyzed (brown and white), three protein bands are visible. Bands A and B were identified with bottom-up proteomics as the uncharacterized proteins K5X0G3 and K5VXB9 (coverages 50 and 58%, molecular weights 50 and 24 kDa). From a database search on Uniprot using BLAST (Basic Local Alignment Search Tool), the proteins showed a high degree of homology with two enzymes, testicular acid phosphatase and glutathione S-transferase, respectively. Band C was identified as a fragment of fruit-body specific gene D protein (B3GV73, coverage 91%, molecular weight 11 kDa). For L. edodes, bands are visible only when the mushroom was grown on wood, and not on straw. Band A was identified as a testicular acid phosphatase like protein (coverage 65%, molecular weight 67 kDa), consistent with what was previously observed for A. bisporus. Band B was identified as the protein A0A1Q3E0N7 (coverage 48%, molecular weight 19 kDa). Finally, band C was a serine protease inhibitor (P81639, coverage 86%, molecular weight 16 kDa). No protein bands could be detected in P. ostreatus samples, which have indeed a low protein content combined with a high quantity of fibers.

To further investigate if there have been proteolytic events during collection and storage, the degree of hydrolysis (DH%) of the samples was determined with the OPA (o-pthaldialdehyde) (Fig. 2). The degree of hydrolysis was thus measured to understand if the proteins present in the mushroom by-products were whole or if they were hydrolyzed to some extent, and, in the latter case, how much. This information has multiple objectives: it can indicate the need for by-product stabilization procedures, give indications on proteolysis induced by endogenous or exogeneous factors (enzymes, microorganisms, pH, and others), possible applications of the protein fraction according to the degree of hydrolysis, etc. The DH% was relevant for all the species. It is interesting to note that the degree of hydrolysis is very high in those samples (the two strains of P. ostreatus and L. edodes grown on straw) which do not show bands in the SDS-PAGE. So, the results of the OPA assay confirm that protein integrity is highly affected in these by-products. The lowest hydrolysis degrees were observed for A. bisporus, which indeed present some protein bands on the gel electrophoresis. The high hydrolysis degree of the mushroom by-products can have several explanations: proteolysis due to endogenous enzymes, microbial growth, high presence of non-protein nitrogen compounds which can react with the OPA reagent.

As an additional indicator of the protein quality of mushrooms by-products, the degree of racemization was determined in all samples. Following a harsh thermal treatment, or very acid or alkaline pH conditions, part of the amino acids, normally present in food as L-form, change their optical configuration and become D-amino acids. The quantity of D-amino acids formed is proportional to the harshness of the conditions, and decrease the protein quality, since D-amino acids are not recognized and metabolized by our organism. Microbial growth can also lead to a high presence of D-amino acids since some bacteria use D-amino acids to build their cell wall. The racemization degree is reported in Table 2, where five amino acids were found also in the D-form. However, the values of D-amino acids were quite low for Ala, Phe, and Lys (below 3.5%). The amounts of D-Asp and D-Glu were higher, but without any trend for the samples analyzed.

Going more in detail into the amino acid composition, the amino acid profile is reported in Online resource 1. The protein content (determined as sum of the single amino acids) is 11.6% (on dry matter) for FABb, 14.7% for FABw, 7.1% for FLEs, 10.2% for FLEw, 5.5% for FPOs, and 8.5% for FPOhk. Considering the water content of the different mushroom by-products analyzed, it is evident that there is a consistent amount of non-protein nitrogen (given by the difference between the Kjeldahl results and the total amino acids analysis). These values are generally higher than those previously reported for A. bisporus (14.54%) (Goyal et al., 2006). Non-protein nitrogen compounds that can be found in mushrooms are many: chitin, nucleic acids, and urea. Moreover, nucleotides and related compounds, ammonia, several kinds of amines and quaternary ammonium compounds, volatile nitrogen compounds (other than amines), and nitrogen-containing vitamins can also be found in the higher fungi (Kurkela et al., 1980).

The nutritional value of the samples related to the total amino acids content was calculated using the protein content of eggs as reference. The limiting amino acid was methionine in nearly all cases, with the following amino acid scores: FABb1 56, FABw1 58, FLEs1 28, FLEw1 30, FPOhk1 27. The only exception is FPOs in which the limiting amino acid is leucine (score 72). The large variability among P. ostreatus samples has already been observed in literature (Manzi et al., 1999). So, in most cases, the low protein content of the fresh feedstock (due to the high water content) is added to the low nutritional value of the proteins. Sulphur amino acids (methionine) are already known to be the limiting amino acids based on the chemical score for P. ostreatus, even with the highest amino acid score (Dabbour & Takruri, 2002). This difference can be because chemical score is usually determined on the food product, while here we are talking about by-products, whose chemical composition may vary from that of the main product.

Protein Extraction

In the present work, different extraction techniques have been tested for protein extraction from waste mushrooms: enzyme-assisted extraction (EAE), environmentally friendly assisted extraction (EFAE), and ultrasound-assisted extraction (UAE). The protein extraction methods were compared using FLEw (L. edodes grown on wood) by-products, since from the analyses carried out on the feedstocks it was the by-product with the highest protein content on fresh weight. FLEw by-products were subjected to pretreatment as described in “Materials and Methods,” and the final protein amount of the pretreated sample was 9.7 ± 0.0% (as determined with the Kjeldahl method).

EAE is considered a mild extraction technique because it uses non-extreme temperature and pH conditions, and it does not foresee the use of organic solvents or polluting chemicals. It has been previously used to extract proteins from different systems, such as rapeseed, soybean, and microalgae meals (Sari et al., 2013). The tested enzymes in this work were protease from B. licheniformis and papain, which were demonstrated to have a very high protein extraction efficiency from food by-products in previous works (Anzani et al., 2018). An even more green alternative is EFAE, where proteins are extracted exploiting their natural water solubility, and then they are recovered by precipitation at the isoelectric point. This method has already been applied for the extraction of proteins from legume by-products, like lentils (Diaz de Apodaca et al., 2020). Finally, ultrasound-assisted extraction is usually carried out in alkaline media (which enhance cell wall disruption), and sonic waves are applied to produce a cavitation effect that favors the release of proteins from the matrix. This technique has also been previously applied to different food by-products, including sunflower meal (Dabbour et al., 2018) and non-compliant coffee green beans (Prandi et al., 2022).

The extraction efficiency was tested for UAE, EFAE, and EAE using FLEw as substrate, since from the analyses performed (Table 1) it was the one with the highest protein content on fresh weight. The extraction efficiency was calculated as the amount of proteins extracted compared to the initial amount of protein in the feedstock (Table 3). The extraction efficiency varies a lot among the extraction techniques adopted. The highest extraction yields are generally achieved using enzyme-assisted extraction. Papain and protease from B. licheniformis gave analogue yields. On the other hand, the less efficient technique in extracting proteins from mushrooms by-products seems to be environmentally friendly assisted extraction, with very low yields. Ultrasound-assisted extraction was efficient in extracting proteins from L. edodes on medium scale, while efficiencies remain quite low for the laboratory conditions.

The protein profile of the extracted fractions is reported in Online Resource 2.

It can be observed that the protein profile of protein extracts from mushroom by-products is very poor. This finding is consistent with the SDS-PAGE initially ran for the fresh by-products. EAE and UAE are unclear because the proteins were (partially) degraded during the extraction procedure: in EAE enzymes cleaved the proteins into smaller peptides, while in UAE the combination of high temperature and pH caused protein modifications. Indeed, the protein bands are not present when using UAE, resulting in a smear effect indicating some degree of protein degradation and/or many interfering compounds. A certain degree of protein degradation will be also confirmed by the degrees of hydrolysis and racemization (Table 4). The absence of proteins in EAE is instead justified by the fact that the proteases used for the extraction cleave the proteins into shorter polypeptides, whose molecular weight may not be high enough to be observed in the SDS-PAGE, where the lowest molecular weight standard is 6.5 kDa. This hypothesis will also be supported by the high degree of protein hydrolysis observed (Table 4). In fact, the use of proteases during the extraction improves the solubilization of proteins in the form of peptides, precisely going to hydrolyze them into shorter (and more soluble) polypeptides. Based on the protein profile on the electrophoretic gel, EFAE extraction using PBS is the only showing well-defined protein bands, meaning a high integrity of the protein fraction.

Since the lack of proteins might be due to protein hydrolysis during the pretreatment or the extraction process, protein integrity was evaluated by measuring the free amino acids content (Table 4, expressed as % on dry weight) and the degree of hydrolysis. Moreover, another indication of protein degradation due to fermentation side-processes or too harsh processing is given by the racemization degree, calculated as % of D-amino acid on the sum (D-form + L-form) (Table 4, Online Resource 3). The hydrolysis degree agrees with the observations drawn from the gel: the extracts obtained with EFAE have indeed a degree of hydrolysis much lower than that of UAE and EAE, confirming a high integrity of the protein fraction. As expected, the hydrolysis degree of EAE extracts is much higher, given the proteolytic action of protease from B. licheniformis and papain, which allows the extraction of the nitrogen fraction in the form of amino acids and peptides. Consistently, the amount of free amino acid is higher for EAE because they are generated during the extraction process by the action of the proteases; however, there is a consistent amount of free amino acids also in UAE and EFAE extracts. Since during UAE and EFAE no hydrolytic events should occur (on the opposite of EAE where proteases are used to enhance the extraction yield), free amino acids should have already been present in the initial feedstock. The free amino acid present in the highest amount (> 0.4% on dry weight) is glutamine for EAE using papain. However, in all cases, it seems that the free amino acids detected are already present in the initial feedstock, since consistent amounts are found independently from the extraction method applied. The racemization degree found in the extracts is fully consistent with that of the starting feedstock for EAE and EFAE, meaning that the extraction protocol is mild enough to preserve the protein fraction in an intact form from a racemization point of view. In UAE instead, a very high amount of D-Asp is found, together with increased amounts also of D-Phe and D-Glu. This phenomenon is probably due to the high pH use during UAE extraction: to maximize protein extraction, sodium hydroxide 0.1 M is indeed used, corresponding to a nominal pH of 13. Moreover, UAE, in absence of a refrigerating system, induces the heating of the sample, which can reach high temperatures. The alkaline extraction conditions, combined with the high temperatures which can be reached, can induce significant amino acid racemization, as previously found also in other works (Casado et al., 2007). D-Asp is associated to high processing temperatures in alkaline conditions (Lüpke & Brückner, 1998). So, if UAE extraction is applied to extract proteins for food or feed purposes, extraction conditions should be optimized to reduce amino acid epimerization, by lowering the pH and/or by a cooling system that avoid product overheating.

As previously introduced, non-protein nitrogen constitutes an important feature of mushroom products. So, the amount of protein (calculated as sum of amino acids) was calculated (Table 5) and compared to that determined by Kjeldahl to determine if non-protein nitrogen is coextracted with the protein fraction. The amount of non-protein nitrogen coextracted with proteins is particularly high in EAE (between 35 and 42%, depending on the enzyme used). UAE is instead more effective than EAE in selectively extracting proteins, without coextracting other interfering nitrogen compounds. From a nutritional point of view, the limiting amino acids in mushroom EAE extracts are either Cys, Met, or Lys. However, the amino acid scores are quite low for all the conditions tested. The highest protein content is found in EFAE-extracted proteins, particularly those obtained using Tris as a buffer. In this case, the amino acid Met is the limiting one for both the extracts. The amino acid profile of the extracts is available in Online Resource 4.

Unfortunately, data regarding protein extraction from mushrooms is very scarce, so a direct comparison is not possible. However, with the same extraction technique, applied to different by-products, some considerations can be made. Compared to other known protein sources, such as legumes (Prandi et al., 2021a), the extractive efficiency of EFAE (shown in Table 3) is lower (10% for peas and 69% for chickpeas), as is the protein content of the final extract reported in Table 5 (65% for peas and 74% for chickpeas). Regarding EAE, the extraction efficiency was around 41–58% for legumes extracted with protease from B. licheniformis or papain, while it is about half for mushrooms (23–24%, Table 3). The protein content was also higher, from a minimum of 37% to a maximum of 66%, while in the case of mushrooms it is 21–23%. In all cases this may be due to a lower extractability of mushroom proteins compared to legume proteins, and a higher co-extraction of non-protein compounds. Comparing instead EAE of mushrooms and coffee by-products (Prandi et al., 2021b), the extraction efficiency is similar (23–24% for fungi, 14–23% for coffee silverskins, and 31–35% for non-compliant coffee green beans). Even the protein content (determined from LC–MS analysis of amino acids) of the extracts is somewhat comparable (13–14% mushrooms vs. 17% non-compliant coffee green beans and 5–10% coffee silverskins). Finally, UAE was previously applied to extract proteins from non-compliant coffee green beans, with an extraction yield of 7.3% (in the conditions used here), therefore lower than that obtained here from mushrooms but with extracts with a slightly higher protein content (27% coffee and 21–23% mushrooms).

Conclusions

The results presented here deeply characterize the protein fraction of mushroom by-products, both in terms of quality and integrity. The high water content of this raw material makes it necessary to stabilize it immediately to avoid the deterioration of proteins. In addition, different protein extraction methodologies were applied and compared. EAE showed not only the highest extraction yield, but also a consistent amount of non-protein nitrogen. EFAE, on the other hand, has the lowest extractive yield but the protein extracts obtained have the highest protein content. UAE has an intermediate extraction efficiency, but the degree of racemization suggests that strict temperature control is required to avoid overheating during extraction. Therefore, the choice of the extraction technique should be aimed at the desired final type of product (high protein content, or hydrolysates, etc.). Furthermore, a biorefinery approach could also be considered, sequentially extracting proteins, chitosan, and/or other compounds. Hence, this is an additional aspect that should be kept in mind when choosing and applying a protein extraction process. Among the challenges to face are the high water content of the raw material (therefore its necessary rapid stabilization), the presence of substances co-extracted with proteins, and, possibly, the development of an extraction cascade capable of separating and preserving the most possible compounds to be recovered.

Data Availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

Anzani, C., Prandi, B., Tedeschi, T., Baldinelli, C., Sorlini, G., Wierenga, P. A., Dossena, A., & Sforza, S. (2018). Degradation of collagen increases nitrogen solubilisation during enzymatic hydrolysis of fleshing meat. Waste and Biomass Valorization, 9, 1113–1119. https://doi.org/10.1007/s12649-017-9866-4

AtlasBig (https://www.atlasbig.com/en-us/countries-mushroom-truffle-production). Last accessed 16/11/2022.

Bernaś, E., Jaworska, G., & Kmiecik, W. (2006). Storage and processing of edible mushrooms. Acta Scientiarum Polonorum Technologia Alimentaria, 5(2), 5–23.

Braaksma, A., & Schaap, D. J. (1996). Protein analysis of the common mushroom Agaricus bisporus. Postharvest Biology and Technology, 7(1–2), 119–127. https://doi.org/10.1016/0925-5214(95)00034-8

Casado, F. J., Sánchez, A. H., Rejano, L., & Montaño, A. (2007). D-amino acid formation in sterilized alkali-treated olives. Journal of Agricultural and Food Chemistry, 55, 3503–3507. https://doi.org/10.1021/jf0701685

Chandran Priyadarshni, K., Krishnamoorthi, R., Mumtha, C., Ulagan Mahalingam, P. (2022). Biochemical analysis of cultivated mushroom, Pleurotus florida and synthesis of silver nanoparticles for enhanced antimicrobial effects on clinically important human pathogens. Inorganic Chemistry Communications, 142, 109673. https://doi.org/10.1016/j.inoche.2022.109673

Cheung, Y. C., Siu, K. C., Liu, Y. S., & Wu, J. Y. (2012a). Molecular properties and antioxidant activities of polysaccharide–protein complexes from selected mushrooms by ultrasound-assisted extraction. Process Biochemistry, 47(5), 892–895. https://doi.org/10.1016/j.procbio.2012.02.004

Cheung, Y. C., Siu, K. C., Wu, J. Y. (2012b). Kinetic models for ultrasound-assisted extraction of water-soluble components and polysaccharides from medicinal fungi. Food and Bioprocess Technology, 6, 2659–2665 (2013). https://doi.org/10.1007/s11947-012-0929-z

Dabbour, I. R., & Takruri, H. R. (2002). Protein digestibility using corrected amino acid score method (PDCAAS) of four types of mushrooms grown in Jordan. Plant Foods for Human Nutrition, 57, 13–24. https://doi.org/10.1023/a:1013110707567

Dabbour, M., He, R., Ma, H., Musa, A. (2018). Optimization of ultrasound assisted extraction of protein from sunflower meal and its physicochemical and functional properties. Journal of Food Process Engineering, 41(5), e12799. https://doi.org/10.1111/jfpe.12799

Diaz de Apodaca, E., Montanari, A., Fernandez-de Castro, L., Umilta, E., Arroyo, L., Zurlini, C., & Villaran, M. C. (2020). Lentil by-products as a source of protein for food packaging applications. American Journal of Food Technology, 15, 1–10. https://doi.org/10.3923/ajft.2020.1.10

Goyal, R., Grewal, R. B., & Goyal, R. K. (2006). Nutritional attributes of Agaricus bisporus and Pleurotus sajor caju mushrooms. Nutrition and Health, 18, 179–184. https://doi.org/10.1177/026010600601800209

Jo, E. K., Heo, D. J., Kim, J. H., Lee, Y. H., Ju, Y. C., & Lee, S. C. (2013). The effects of subcritical water treatment on antioxidant activity of golden oyster mushroom. Food and Bioprocess Technology, 6, 2555–2561. https://doi.org/10.1007/s11947-012-0793-x

Kumari, B., Tiwari, B. K., Hossain, M. B., Brunton, N. P., & Rai, D. K. (2018). Recent advances on application of ultrasound and pulsed electric field technologies in the extraction of bioactives from agro-industrial by-products. Food and Bioprocess Technology, 11, 223–241. https://doi.org/10.1007/s11947-017-1961-9

Kurkela, R., Koivurinta, J., & Kuusinen, R. (1980). Non-protein nitrogen compounds in the higher fungi—a review. Food Chemistry, 5(2), 109–130. https://doi.org/10.1016/0308-8146(80)90034-5

Lüpke, M., & Brückner, H. (1998). Gas chromatographic evaluation of amino acid epimerisation in the course of gelatin manufacturing and processing. Zeitschrift Für Lebensmitteluntersuchung Und -Forschung A, 206, 323–328. https://doi.org/10.1007/s002170050365

Manzi, P., Gambelli, L., Marconi, S., Vivanti, V., & Pizzoferrato, L. (1999). Nutrients in edible mushrooms: An inter-species comparative study. Food Chemistry, 65(4), 477–482. https://doi.org/10.1016/S0308-8146(98)00212-X

Montanari, A., & Zurlini, C. (2012). Biopolimero da scarti dell’industria alimentare. Italian Industrial Invention Patent, 1, 16.

Morales, D., Smiderle, F. R., Villalva, M., Abreu, H., Rico, C., Santoyo, S., Iacomini, M., & Soler-Rivas, C. (2019a). Testing the effect of combining innovative extraction technologies on the biological activities of obtained β-glucan-enriched fractions from Lentinula edodes. Journal of Functional Foods, 60, 103446. https://doi.org/10.1016/j.jff.2019.103446

Morales, D., Smiderle, F. R., Jimenez Piris, A., Soler-Rivas, C., & Prodanov, M. (2019b). Production of a β-d-glucan-rich extract from Shiitake mushrooms (Lentinula edodes) by an extraction/microfiltration/reverse osmosis (nanofiltration) process. Innovative Food Science & Emerging technologies, 51, 80–90. https://doi.org/10.1016/j.ifset.2018.04.003

Papoutsis, K., Grasso, S., Menon, A., Brunton, N. P., Lyng, J. G., Jacquier, J.-C., & Bhuyan, D. J. (2020). Recovery of ergosterol and vitamin D2 from mushroom waste - potential valorization by food and pharmaceutical industries. Trends in Food Science & Technology, 99, 351–366. https://doi.org/10.1016/j.tifs.2020.03.005

Parniakov, O., Lebovka, N. I., Van Hecke, E., & Vorobiev, E. (2014). Pulsed electric field assisted pressure extraction and solvent extraction from mushroom (Agaricus bisporus). Food and Bioprocess Technology, 7, 174–183. https://doi.org/10.1007/s11947-013-1059-y

Poojary, M. M., Orlien, V., Passamonti, P., & Olsen, K. (2017a). Improved extraction methods for simultaneous recovery of umami compounds from six different mushrooms. Journal of Food Composition and Analysis, 63, 171–183. https://doi.org/10.1016/j.jfca.2017.08.004

Poojary, M. M., Orlien, V., Passamonti, P., & Olsen, K. (2017b). Enzyme-assisted extraction enhancing the umami taste amino acids recovery from several cultivated mushrooms. Food Chemistry, 234, 236–244. https://doi.org/10.1016/j.foodchem.2017.04.157

Prandi, B., Lambertini, F., Varani, M., Faccini, A., Suman, M., Leporati, A., Tedeschi, T., & Sforza, S. (2020). Assessment of enzymatic improvers in flours using LC−MS/MS detection of marker tryptic peptides. Journal of the American Society for Mass Spectrometry, 31(2), 240–248. https://doi.org/10.1021/jasms.9b00109

Prandi, B., Zurlini, C., Cigognini, I. M., Cutroneo, S., Di Massimo, M., Bondi, M., Brutti, A., Sforza, S., & Tedeschi, T. (2021a). Targeting the nutritional value of proteins from legumes by-products through mild extraction technologies. Frontiers in Nutrition, 8, 695793. https://doi.org/10.3389/fnut.2021a.695793

Prandi, B., Ferri, M., Monari, S., Zurlini, C., Cigognini, I., Verstringe, S., Schaller, D., Walter, M., Navarini, L., Tassoni, A., Sofrza, S., & Tedeschi, T. (2021b). Extraction and chemical characterization of functional phenols and proteins from coffee (Coffea arabica) by-products. Biomolecules, 11, 1571. https://doi.org/10.3390/biom11111571

Prandi, B., Di Massimo, M., Tedeschi, T., Rodríguez-Turienzo, L., & Rodríguez, Ó. (2022). Ultrasound and microwave-assisted extraction of proteins from coffee green beans: Effects of process variables on the protein integrity. Food and Bioprocess Technology, 15, 2712–2722. https://doi.org/10.1007/s11947-022-02907-z

Priyadarshi, R., & Rhim, J.-W. (2020). Chitosan-based biodegradable functional films for food packaging applications. Innovative Food Science & Emerging Technologies, 62, 102346. https://doi.org/10.1016/j.ifset.2020.102346

Ramos, M., Burgos, N., Barnard, A., Evans, G., Preece, J., Graz, M., Ruthes, A. C., Jiménez-Quero, A., Martínez-Abad, A., Vilaplana, F., Pham Ngoc, L., Brouwer, A., & Bart van der Burg; M. C. Garrigós; A. Jiménez. (2019). Agaricus bisporus and its by-products as a source of valuable extracts and bioactive compounds. Food Chemistry, 292, 176–187. https://doi.org/10.1016/j.foodchem.2019.04.035

Rane, K. D., & Hoover, D. G. (1993). Production of chitosan by fungi. Food Biotechnology, 7(1), 11–33. https://doi.org/10.1080/08905439309549843

Royse, D. J., Baars, J., & Tan, Q. (2017). Current overview of mushroom production in the world. In C. Z. Diego, & A. Pardo-Giménez (Eds.), Edible and medicinal mushrooms: technology and applications. John Wiley & Sons Ltd (Hoboken, NJ, USA). https://doi.org/10.1002/9781119149446.ch2

Sari, Y. W., Bruin, M. E., & Sanders, J. P. M. (2013). Enzyme assisted protein extraction from rapeseed, soybean, and microalgae meals. Industrial Crops and Products, 43, 78–83. https://doi.org/10.1023/a:1013110707567

Schimpf, U., & Schulz, R. (2016). Industrial by-products from white-rot fungi production. Part I: generation of enzyme preparations and chemical, protein biochemical and molecular biological characterization. Process Biochemistry, 51 (12), 2034–2046. https://doi.org/10.1016/j.procbio.2016.08.032

Statista (www.statista.com). Last accessed 02/04/2020.

Szadzińska, J., Mierzwa, D., & Musielak, G. (2022). Ultrasound-assisted convective drying of white mushrooms (Agaricus bisporus). Chemical Engineering and Processing - Process Intensification, 172, 108803. https://doi.org/10.1016/j.cep.2022.108803

UNI EN 12145: (1999). Fruit and vegetable juices, determination of total dry matter, gravimetric method with loss of mass on drying.

Wang, J., Zhong, Z., Ding, K., & Xue, Z. (2016). Catalytic fast pyrolysis of mushroom waste to upgraded bio-oil products via pre-coked modified HZSM-5 catalyst. Bioresource Technology, 212, 6–10. https://doi.org/10.1016/j.biortech.2016.04.005

Wang, C. Y. (2020). A review on the potential reuse of functional polysaccharides extracted from the by-products of mushroom processing. Food and Bioprocess Technology, 13(2), 217–228. https://doi.org/10.1007/s11947-020-02403-2

Wang, W., Zhou, X., & Liu, Y. (2020). Characterization and evaluation of umami taste: A review. TrAC Trends in Analytical Chemistry, 127, 115876.

Zhao, R.-J., & Huo, C.- Y., Qian, Y., Ren, D.- F., Lu, J. (2017). Ultra-high-pressure processing improves proteolysis and release of bioactive peptides with activation activities on alcohol metabolic enzymes in vitro from mushroom foot protein. Food Chemistry, 231, 25–32. https://doi.org/10.1016/j.foodchem.2017.03.058

Zhou, J., Chen, M., Wu, S., Liao, X., Wang, J., Wu, Q., Zhuang, M., & Ding, Y. (2020). A review on mushroom-derived bioactive peptides: preparation and biological activities. Food Research International, 134, 109230. https://doi.org/10.1016/j.foodres.2020.109230

Ziwei, L., Tui, L., Yuexin, Z., Xiufeng, Y., & Qiuying, P. (2018). Effective protein extraction from mycelium and fruiting body of Auricolaria auricula for proteomics studies. International Journal of Food Properties, 21(1), 2156–2166. https://doi.org/10.1080/10942912.2018.1499111

Acknowledgements

Federica Milani and Martina Di Massimo are gratefully acknowledged for their contribution in sample preparation and analysis. Pleurette (La Révolution Champignon, Lille, France) and IGV GmbH (GmbH, Nuthetal, Germany) are gratefully acknowledged respectively for sample providing and pretreating.

Funding

Open access funding provided by Università degli Studi di Parma within the CRUI-CARE Agreement. This work was carried out as part of the Prolific project, funded by the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation program (GA No 790157).

Author information

Authors and Affiliations

Contributions

Barbara Prandi: formal analysis, investigation, data curation, writing–original draft. Ilaria Maria Cigognini: formal analysis, investigation, data curation, writing–review and editing. Andrea Faccini: formal analysis, investigation. Chiara Zurlini: conceptualization, data curation, writing–review and editing, supervision. Óscar Rodríguez: formal analysis, conceptualization, data curation, writing–review and editing, supervision. Tullia Tedeschi: conceptualization, writing–review and editing, supervision, project administration, funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Prandi, B., Cigognini, I.M., Faccini, A. et al. Comparative Study of Different Protein Extraction Technologies Applied on Mushrooms By-products. Food Bioprocess Technol 16, 1570–1581 (2023). https://doi.org/10.1007/s11947-023-03015-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03015-2