Abstract

Cactus cladodes (Opuntia ficus-indica) is a valuable source of dietary fibers. In this study, peeled cladode powder was produced by air drying at 40 °C and was characterized for its color, dietary fiber content, and rheological behavior. Cladode powder aqueous suspensions of 3% w/w were prepared and the effect of protein (gelatin, sodium caseinate, and whey protein) or salts (NaCl/CaCl2) on the blend’s viscosity was investigated. Additionally, cladode powder was incorporated in a soup model, aiming at substituting corn starch. Our powder had an appealing green color, but its deterioration was fast when it was exposed to light. A shear-thinning behavior was observed in all cladode-protein mixtures, but viscosity values depended considerably on the protein type and the pH values. Notably, gelatin addition led to higher apparent viscosity of cladode powder at pH 6, suggesting interactions with cladode mucilage, but this effect was reversed at pH 4, below gelatin isoelectric point. The Ostwald-de Waele model successfully correlated viscosity-shear rates data, whereas the Casson model presented a good fit mainly in starch containing systems. Corn starch substitution by cladode powder, in the soup model, led to lower consistency coefficient values. In soups, the logarithmic mixing law was applied at different corn starch: cladode powder ratios to highlight their possible interactions. The values obtained diverged slightly downwards from the logarithmic mixing law. When purified mucilage was added—instead of cladode powder—the samples diverged slightly upwards from the logarithmic mixing law.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Prickly pear cactus (Opuntia ficus-indica) is a cactus of the Cactaceae family, originated from Mexico (Griffith, 2004). Cladodes are a valuable source of dietary fiber, vitamin C, minerals, and phytochemical compounds (Méndez et al., 2015). The beneficial health effects of cladode consumption have been documented, with blood sugar control exhibiting the most promising results (Frati et al., 1990). López-Romero et al. (2014) reported that the incorporation of steamed cladodes in a carbohydrate rich meal can improve the glycemic response in patients with type 2 diabetes mellitus, which is considered beneficial for the management of the disease.

The technological aspects of cladode powder also accumulate scientific interest. The soluble fiber fraction of cladode, commonly referred to as mucilage, is a mixture of polysaccharides, which structure has not been fully comprehended so far (Bayar et al., 2016; Di Lorenzo et al., 2017; McGarvie & Parolis, 1981). Mucilage can be extracted from cladodes and isolated with organic solvents, so that it can be used as a thickening agent. Many studies have investigated the rheological behavior of purified mucilage from Opuntia spp. (López-Palacios et al., 2016; Quinzio et al., 2018). Its rheological properties can be influenced by various factors, such as pH, ionic strength, and the presence of multivalent cations (Majdoub et al., 2001; Medina-Torres et al., 2000; Trachtenberg & Mayer, 1982). In addition, the rheological properties of purified mucilage vary depending on its botanical origin, which also determines the yield and its moisture content (De Wit et al., 2019; Du Toit et al., 2019; López-Palacios et al., 2016), the maturity stage of the cladode (Contreras-Padilla et al., 2016), and the part of the cladode that has been used (Majdoub et al., 2001). The last team of researchers reported that the polysaccharides extracted from cladode pulp led to greater apparent viscosity values than those extracted from cladode peels. Finally, it has been shown that processing conditions such as the drying method can alter the rheological profile of mucilage since-freeze drying has been reported to retain the capacity of mucilage to act as thickening agent better than spray drying (León-Martínez et al., 2011).

Cladode powder on the other hand has been studied to a lesser extent in terms of its rheological characteristics. It has been reported that the rheological properties of cladode powder aqueous suspensions are affected by pH (Sáenz et al., 2010) and boiling (Ramírez-Moreno et al., 2013), as well as by processing such as drying and grinding (Chaloulos et al., 2021; Medina-Torres et al., 2011). Cladode powder is much easier to obtain since it does not require the use of organic solvents. Moreover, consumption of cladode powder offers all the aforementioned health benefits. Therefore, incorporation of cladode powder in food applications offers both technological and nutritional benefits.

In order to evaluate cladode’s capacity to act as thickener in food systems, it is important to assess the interactions that may occur with other substances that are commonly present, such as proteins and salts. Purified mucilage has been reported to interact with gelatin (Camelo Caballero et al., 2019; Otálora et al., 2019) and starch (Rivera-Corona et al., 2014). However, it is unknown how such components influence the rheological characteristics of cladode powder aqueous suspensions. Rheological behavior of protein and polysaccharide systems may be altered by slight changes in pH, ionic strength, concentration, and ratio of the hydrocolloids present in the systems. Although such interactions have been studied widely in controlled solutions, most food applications are complex matrices. For example, the addition of milk in aqueous solution leads to the addition of whey proteins, caseins and calcium, among other ingredients. Gelatin may be added either by animal bones and meat or by broths used in various versions of soup systems. Vinegar or juice concentrates (tomato, lemon) decrease the pH, whereas salt increases the ionic strength of the system. Therefore, it is useful to accompany such rheological investigations with a more macroscopic approach. The aim of the present work is to evaluate the rheological properties of peeled cladode powder and the way they are affected by other factors such as proteins and divalent cations. In addition, either cladode powder or extracted mucilage was incorporated in a soup model to substitute cornstarch as thickening agent.

Methods

Materials

Cactus cladodes (Opuntia ficus-indica) were harvested from the region of Heraklion in Crete. The age of cladodes was at least 4 months old, and the mean dimensions were 30.0 × 17.8 × 1.8 cm. Casein sodium salt from bovine milk (CAS; Sigma Aldrich – C8654), gelatin from porcine skin (GEL; Fluka analytical – 04,055), and whey protein isolate (WPI; Arla, Lacprodan DI – 9224) were used as proteins source. All reagents used were of analytical grade.

For cladode powder production, the pads were washed with water, and then, they were cut in pieces 30 × 30 mm. Afterwards, the epidermis was manually peeled from each piece, yielding square plates of cladode pulp. Drying was conducted in an electric oven (SNOL 120/300 LSN11, SnolTherm, Lithuania) at 40 °C for 48 h. Dried cladodes were then ground with a grain mill (EBC mill, Casella Company, London, /2000 W, velocity 25,000 r/ min). Cladode powder was kept in an airtight container, protected from light.

Physical and Chemical Characterization

Moisture content of cladode powder was determined using the AACC International (1999), method 44–15.02. Water activity (aw) was measured using a water activity indicator (Hygrolab C1, Rotronic AG Switzerland) at 25 °C. Total, insoluble, and soluble dietary fiber (TDF, IDF, and SDF, respectively), as well as the available carbohydrates (ACH), were determined according to the method AOAC 991.43, with the MegazymeK-ACHDF assay kit (Megazyme Ltd., Bray, Ireland). Tap density (g/mL) was evaluated by filling a volumetric cylinder with a certain weight of powder (ws ~ 23 g) and gently taping the cylinder at the bench for 100 times. The volume (V) was recorded and tap density was calculated as following:

Color of powders was evaluated with the colorimeter 3nh High-Quality Spectrophotometer NS800S (Shenzhen 3nh Technology, China), according to CIE-L* a* b* uniform color space. Color stability of the powder was evaluated in the absence of light. The powder was kept in an airtight container wrapped with alumimun foil and placed in a cabinet at room temperature. Color measurments were taken for 90 days. In addition, a petri dish was filled with cladode powder (~ 4 mm) and was left exposed to light and oxygen (no direct sunlight). The powder was mixed with a spatula regularly in order to ensure homogeneous degradation. At the end of the storage period, photos were taken both by the powder kept in the container and by the light exposd one.

Mucilage Extraction and Molecular Weight Determination

Mucilage from cladode powder was extracted similarly to a previous study on mucilage extraction from dehydrated cladode powder (Contreras-Padilla et al., 2016). Cladode powder was mixed with deionized water in a ratio 1:35.7, which corresponds to a ratio 1:1 for fresh cladode:water. The suspension was stirred at 40 °C for 3 h and centrifuged for 10 min at 1370 g. Afterwards, the supernatant was filtered and the filtrate was mixed with 2 volumes of ethanol (95.6%). The mixture was left for 1 h at ambient temperature and then centrifuged for 10 min at 1370 g. The precipitate was transferred at glass petri dishes and dried at 40 °C for 24 h. Finally, the dried mucilage was ground in a mortar, yielding a mucilage powder. Preliminary tests were performed for higher water:powder ratio, as well as for higher ethanol:filtrate ratio, but no substantial difference in yield was observed.

Molecular weight (Mw) of mucilage was evaluated with static light scattering (Zetasizer Nano ZS, Malvern Instruments, Worcestershire, UK). Mucilage was mixed with distilled water and the solution was magnetically stirred overnight at ambient temperature in order to let the polysaccharide fully hydrate. Then, further agitation was performed at 70 °C for 1 h. Based on previous study on cladode mucilage (Rodríguez-González et al., 2021), the refractive index was set at 1.333 and dn/dC = 0.13 mL/g. Toluene was used as standard. The concentration range used for the measurement was 0.05–0.3% w/w. The sample was left for 120 s to reach equilibrium and 10 s measurements were performed (10 maximum repetitions).

Soup Model

Cladode powder was used in a soup model to investigate its ability to act as a thickening agent. A soup model containing cornstarch as a thickener and skim milk solids was adopted by Ravindran and Matia-Merino (2009), with slight modifications. All soup systems contained the following ingredients (% w/w): skim milk powder 2.5, sunflower oil 2, vinegar 2, salt 0.9, onion powder 0.1, garlic powder 0.1, sugar 0.1, pepper 0.1, water 89.2. Corn starch and/or cladode powder was also added as thickening agents (Table 1). In soup systems C5, C8, and C10, the same amount of ingredients with C3 were used, with only difference being that extra 2, 5, and 7 g of cladode powder were added, respectively. In addition, soup models with purified mucilage were tested in order to compare it with whole cladode powder. Based on the assumption that the thickening capacity of cladode’s powder comes from mucilage, the concentration of mucilage powder was adjusted based on the mucilage yield from cladode powder. Therefore, 1% cladode suspension is meant to be compared to 0.09% mucilage suspension.

Fifty grams of soup were prepared for each run. All the ingredients were weighted in a 250-mL beaker, except for the cornstarch and the cladode powder, which were added under stirring. The beaker was placed at water bath (preheated) at 90 °C under magnetic stirring. The heating time was 20 min, starting from the moment when soup reached 90 °C. Afterwards, the beaker with the soup was left at room temperature to cool down to ~ 55 °C, and then, the sample was taken for the rheological measurements. Three extra samples were prepared in order to investigate the effect of pH on their rheological properties. Vinegar was replaced with acetic acid, which was used to fix pH at 6.19, 5.02, and 4.29. Ionic strength was adjusted with NaCl.

Rheological Measurements

For the rheological characterization of cladode powder, aqueous suspensions were tested containing 3% w/w cladode powder (C) alone or with the addition of 1% w/w protein (whey protein isolate; C-WPI, sodium caseinate; C-CAS or gelatin; C-GEL). These proteins were selected as they are often added in food systems either from milk (WPI and CAS) or meat and bones (GEL). Twenty-milliliter suspensions were prepared in falcon tubes and mixed for 30 s in a vortex shaker (IKA Vortex Genius 3) at full speed. Citrate buffers (0.1 M) were used for pH 4 and 6 and NaCl was added to fix the ionic strength at 0.6 M. Sodium azide was also added (0.05% w/w) as a preservative and suspensions were left overnight to get fully hydrated. The effect of divalent cations was also investigated with solutions of NaCl and CaCl2 (I = 1.45 M), CaCl2 being the source of divalent cations and NaCl the control with the same ionic strength since an increase in ionic strength could affect the rheological properties regardless of the valence.

Rheological measurements were performed using a stress-controlled rheometer (Discovery HR-3 TA Instruments, TRIOS analysis, USA) with concentric cylinder geometry (30-mm cup diameter, 28-mm Bob diameter, 42-mm Bob length). For the cladode powder aqueous suspensions, flow ramp tests were carried out at 25 °C, at shear rates ranging from 0.1 to 300 s−1. For the soup models, the same test was applied, but the temperature was set to 50 °C. This temperature was chosen because it resembles the serving temperature of the soup. The viscosity-shear rate data were correlated with the Ostwald-de Waele or Power Law model:

where η is the apparent viscosity (Pa s),

\(\dot{\gamma }\) is the shear rate (s−1),

\(K\) is the consistency coefficient (Pa sn), and.

n is the flow behavior index (dimensionless).

In addition, the Casson model (Eq. (3)) was also employed for correlating shear stress and shear rate data since it has been previously reported that it offers good correlation when applied to starch dispersions (Molavi & Razavi, 2018)

where τ is the shear stress (Pa).

koc (Pa0.5) is the square root of Casson yield stress,

kc (Pa0.5 s0.5) is the square root of Casson plastic viscosity,

\(\dot{\gamma }\) is the shear rate (s−1).

The effect of thickening agent concentration on viscosity was also evaluated with the power law model, which has been previously used to express the viscosity of starch (Doublier, 1981), xanthan, and carob gum (Higiro et al., 2006) suspensions as a function of concentration:

where \(k\) the consistency coefficient of the Ostwald-de Waele model for viscosity (Eq. (2)),

C the thickener agent concentration (%, w/w),

\(a\) and \(b\) coefficients of the model.

Interactions between the two thickening agents were evaluated in samples with blends of intermediate concentrations. Various models have been proposed to predict the viscosity of binary polysaccharides mixtures and then assess the existence and kind of interactions based on the divergence from the model (Liang et al., 2011; Potier et al., 2020). In the present study, the logarithmic mixing law was applied to predict the viscosity of polysaccharide blends, assuming no interactions:

where XA and XB the mass fraction of the two polysaccharides.

Statistical Analysis

Statistical analysis of the results was performed with Statgraphics Centurion XV (Statgraphics, Rockville, MD, USA). For the comparison of mean values among samples, the ANOVA test with Fischer’s LSD procedure was applied (0.05 level of significance). All measurements were done in triplicate.

Results and Discussion

Physical and Chemical Characterization

Moisture Content and Water Activity

The final powder reached low moisture values (12.75% w.b.), which led to water activity levels that ensure microbiological stability (aw = 0.58). Regarding the sorption characteristics of the cladode powder, there are large deviations in the available literature. Sáenz et al. (2010) reported water activity 0.53 for cladode powder with moisture 7.14% w.b., while Boukid et al. (2015) reported water activities 0.19–0.36 for three powders dried at different temperatures, having a moisture content 12.66–18.25% w.b. The aforementioned results differ substantially with our findings, as we observed very different water activities (0.58 vs 0.19) for very similar moisture content (12.75% vs 12.66%). If the sorption characteristics were similar, we would expect similar water activity for a given moisture content, which is clearly not the case when we compare our findings with the available literature. Harrak (2021) studied the sorption curves for powders derived from cladodes with different ages (starting from less than 1 year up to 3.5 years) and found important variations among the different ages. Therefore, it seems that the sorption characteristics vary widely. It should be mentioned that in our study the peel had been removed, hence altering the composition of the final powder. Peel has a different composition than cladode pulp (Sepúlveda et al., 2013), which could affect the sorption curves.

Dietary fiber and Mucilage Molecular Weight

Cladode powder properties are presented in Table 2. High amounts of dietary fiber were determined, exceeding 50% in total solids, while the IDF:SDF ratio was strongly in favor of the former. It has been documented that this ratio increases with the aging of the cladode (Contreras-Padilla et al., 2012; Hernández-Urbiola et al., 2015; Rodríguez-Garcia et al., 2007). In the previous studies, a clear trend has been observed, where the soluble fraction exceeds 25% d.b. at young age and decreases as low as 10% d.b. with aging. In addition, Sepúlveda et al. (2013) studied the differences between whole and peeled cladodes and found that peeling led to a decrease in the SDF fraction. These two factors (age > 4 months and peeling) probably explain the low concentration of SDF in our sample (8.94% d.b.).

Extracted mucilage was found to have a molecular weight of 2.18 \(\times\) 106 Da, which is very similar to the values reported from Rodríguez-González et al. (2021), where the Mw ranged from 2.3 \(\times\) 106 up to 11.9 \(\times\) 106 Da, depending on the age of the cladode. The results of Trachtenberg and Mayer (1982) were in the same order of magnitude (4.3 \(\times\) 106 Da). However, much lower values (approx. 103–104 Da) have been reported by other researchers (Espino-Díaz et al., 2010; Medina-Torres et al., 2000). These differences may be attributed to age, environmental factors, or plant cultivar.

Color Stability

The color parameters of the cladode powder throughout the storage period are shown in Fig. 1. The initial powder bore an appealing green color (L = 76.02, a* = -3.05, b* = 21.04), despite the removal of the peels. The peel is the part that has the greenest color since it is responsible for photosynthesis, therefore peeling probably affects the color of the final powder. To our knowledge, there are no studies reporting color of peeled cladode powder. It has also been documented that the color of cladode powder also depends on the age of the cladode, turning paler as the age increases from 6 months to 3.5 years (Harrak, 2021).

Color parameters of cladode powders: panels a–c show the kinetics of the color parameters L, a*, and b* for cladode powder stored in dark for 90 days. Panel d shows the color parameters of the two powders (stored either in dark or exposed to light) after 90 days. Bars indicate standard deviation (n = 3)

Powder color degraded when stored in an airtight container in the dark, which is expressed with a reduction in parameter b* (Fig. 1c). However, an acceptable color has been retained (Fig. 1d). On the other hand, powder exposed to light exhibited greater degradation, leading to a substantially altered appearance. The degradation is expressed not only by a more intense reduction in the parameter b*, but in an increase in parameter a* as well (−3.21 and −0.77 for powder stored in dark and light, respectively). Negative a* values express the green color, so this increase is indicative of the decolorization, which is observed. Consequently, protection from light is a crucial factor for maintaining cladode powder characteristic color.

Rheological Characterization

Aqueous Suspensions

All samples exhibited pseudoplastic behavior. Consistency coefficient of cladode suspensions were 0.051 and 0.059 Pa sn for pH 4 and 6, respectively (Table 3). Medina-Torres et al. (2011) reported values 0.17–0.34 at 25 °C (pH not mentioned) for similar concentration (3% w/v) of cladode powder dried at 45 °C. Chaloulos et al. (2021) also found higher values for 5% w/w cladode suspensions (0.15–0.20 Pa sn) at 25 °C and pH 5.1 for partially vacuum-dried cladodes. The highest values for cladode powder suspensions have been reported by Ramírez-Moreno et al. (2013) both for raw and boiled cladodes at a concentration 3.2% (4.07–6.37 and 2.66–3.53 Pa sn, respectively) at 25 °C and pH ranging from 4.6 to 5.3. The lower values in the present study may be attributed to several factors. Test temperature was the same and pH was in a similar range compared to ours, given that samples in pH 5 exhibited consistency coefficient values similar to pH 4 and 6 (data not shown for pH 5). Age (Contreras-Padilla et al., 2016) and cultivar (Du Toit et al., 2019; López-Palacios et al., 2016) are known to affect the rheological characteristics of cladode. A substantial difference in our study is that we used peeled cladodes. Majdoub et al. (2001) found that polysaccharides extracted from pulp exhibited increased viscosity compared to polysaccharides from cladode peels. However, in our study, low viscosity is observed.

The effects of protein addition were pH dependent (Fig. 2). In pH 6, GEL addition increased apparent viscosity values almost an order of magnitude. It should be noted that solutions of plain gelatin at the same concentration (1% w/w), prepared in the same way, had viscosity similar with pure water (data not shown). Therefore, the increase in viscosity can be attributed to interactions between gelatin and cladode powder. This interaction could be utilized in food applications of low acidity, where cladode powder could be used as a more nutritious choice. CAS had a less potent effect, while WPI did not alter the rheological properties substantially. However, in pH 4, these trends were reversed. C-CAS exhibited similar behavior with C, while C-GEL had even lower values. On the other hand, C-WPI exhibited the greatest viscosity in this pH.

Cladode mucilage, which is responsible for the viscous properties of cladode powder is a polysaccharide, which is negatively charged at pH 2–10, being more negatively charged at pH 6 rather than pH 4 (Quinzio et al., 2018). The three proteins studied here are below their isoelectric point at pH 4, being positively charged, contrary to pH 6, where they are negatively charged. Therefore, at pH 6, proteins and mucilage are both negatively charged, possibly favoring repulsive interactions between molecules. These repulsions are probably responsible for the more viscous character of C-CAS and C-GEL. WPI though did not appear to have any effect on viscosity at this pH, possibly because it is consisted mainly by globular proteins. This could mean that WPI has a weak effect in terms of both steric hindrance and repulsive interactions, as it is a more packed molecule. On the other hand, at pH 4, proteins and mucilage are oppositely charged, favoring electrostatic complexes to occur. Regarding gelatin, the formation of complex coacervates with cladode mucilage has been previously reported at pH below 5, where gelatin is positively charged (Otálora et al., 2019). The formation of such complexes probably indicates that mucilage is bound and cannot contribute as much to the thickening of the suspension.

Salt Solutions

The effect of ions on the rheological properties of cladode powder aqueous suspensions was also evaluated. CaCl2 led to slightly lower viscosity values compared to NaCl (Fig. 3), which is in agreement with Medina-Torres et al. (2000), who found that the presence of divalent cations leads to lower viscosity values for mucilage extracted from cactus cladodes. Du Toit et al. (2019) reported lower values for CaCl2 than NaCl for mucilage extracted from Algerian cactus cladodes but found no difference for the other cultivars tested in that study. On the other hand, Quinzio et al. (2018) reported a viscosity increase with CaCl2. Network formation by absorption of divalent Ca2+ was proposed. Calcium cations can act as a bridge between negatively charged groups, such as the ionized carboxyl groups, which promotes the gelling of low methoxy pectins (Fraeye et al., 2010; Thibault & Ralet, 2003). However, the effect of divalent cations on mucilage suspensions remains unclear. It must be noted that all the previous studies have used purified mucilage, while in our study whole cladode powder was used, which is already rich in calcium (McConn & Nakata, 2004). It can be concluded from our study that little differences were observed between monovalent and divalent cations.

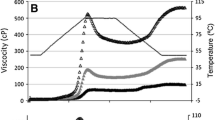

Soup Models

Soup models with cladode and/ or cornstarch were prepared, and their rheological properties were evaluated. Casson model exhibited worse fit than Power law model, apart from S3, in which the R2 values was similar for the two models (Table 4). S3 exhibited high viscosity values (K = 1.20 Pa sn), while its substitution with cladode powder gradually decreased the consistency coefficient down to 0.16 for C3. This means that full substitution of corn starch amount by the same amount of cladode powder would result in an inferior final product in terms of texture. Cladode powder behaves like a pseudoplastic fluid, as many common stabilizers including starch. At higher shear rates, cladode powder leads to lower viscosity values than those shown in soups that contain only starch (Fig. 4A, B). A more pseudoplastic behavior is observed due to cladode’s polysaccharides chains interactions that are easily broken under high shear.

Apparent viscosity values of soup models with A various levels of corn starch substitution by cladode powder and B various cladode powder concentrations; S3: 3% corn starch, S2C1: 2% corn starch + 1% cladode powder; S1.5C1.5: 1.5% cornstarch + 1.5% cladode powder; S1C2: 1% corn starch + 2% cladode; C3: 3% cladode powder; C5: 5% cladode powder; C8: 8% cladode powder; control: no thickener. At C, the consistency coefficient is plotted against the thickening agent concentration and correlated with the Ostwald-de Waele model. Error bars indicate standard deviation (n = 3)

Blends of cladode powder with cornstarch yielded Rivera-Corona et al. (2014) studied the viscoelastic properties of sorghum starch gels, while substituting 5% and 10% of the starch with purified mucilage from cactus cladodes. They observed a substantial increase both in storage and loss modulus with 10% substitution, revealing a network enhancement with mucilage. In our study though, whole cladode powder was used, which would yield only 9% mucilage at most (our soluble fiber fraction was 8.94% d.b.). This means that the addition of 1% cladode powder adds only 0.09% mucilage. Further increase in cladode powder concentration achieved higher values, resembling the S3 sample at a concentration of 8% w/w. Therefore, quite higher concentrations of cladode powder are needed for the same thickening effect. However, the thickening capacity of cladode powder is noticeable since the control soup model with no thickener had a viscosity similar to that of plain water (approximately 1.1 mPa s). On the other hand, when purified mucilage was used, consistency coefficient was diminished to 3 x 10−3 Pa sn (Table 4). Based on these results, cladode powder seems to be a more potent thickening agent compared to the corresponding concentration of purified mucilage. It is hard to address the reason for such differences, but it is possible that the suspended particles in cladode powder suspensions interfere with the measurement. Another possible explanation is that the purification process (ethanol, drying) alters the rheological properties of the polysaccharide. It is also possible that other soluble compounds that may enhance the thickening capacity, such as proteins, remain soluble after the ethanol addition, hence are not isolated along with the mucilage.

The power law model had a satisfactory fit for the consistency coefficient as a function of concentration (Fig. 4C). It has been shown that the index b, representing the slope in logarithmic plot, varies for a given polysaccharide, depending on the concentration range. At low enough concentrations the slope is smaller, while a region of higher slope is expected at concentrations above a critical concentration, where entanglements are thought to be achieved (Doublier, 1981; Lopez et al., 2017; Potier et al., 2020). In the range tested in the present study, above a critical concentration of slope change, satisfactory correlation is observed, with starch exhibiting a greater dependence on concentration (b index 3.27 compared to 2.17 for cladode powder) and contributing more to the consistency of the soup as indicated by the greater slope of the curve.

Based on the logarithmic mixing law (Eq. (5)) slightly negative deviations were observed (Fig. 5), therefore the underlying interactions, if any, are counterproductive in terms of thickening capacity. On the contrary, undisputed synergistic interactions can be shown in other polysaccharides such as xanthan and locust bean gum. Blends of these polysaccharides have been reported to exhibit higher viscosity than any of the two polysaccharides alone in the same total concentration (Higiro et al., 2006; Jo et al., 2018). Samples with purified mucilage exhibited very low viscosity and no substantial interaction was observed. However, our substitution was designed to be compared to the respective cladode concentration. Hussain et al. (2022) used either native or acetylated cactus cladode extract as a cactus mucilage source and studied the effect of cornstarch substitution (2% and 5% of starch) on starch gels. All samples but one (2% acetylated mucilage) exhibited decreased final viscosity, which theoretically agrees with our findings. However, it must be noted that in our study the whole powder was used, which is rich in insoluble material. Rivera-Corona et al. (2014) reported substantial increase in storage and loss modulus of sorghum starch gels when cactus mucilage substituted the starch at 5 and 10%.

Regarding the effect of pH on the viscosity of the C3 soup system, a decreasing trend was observed when pH was lowered from 6.2 to 4.3. However, the differences were small with little importance (Fig. 6).

Conclusions

Cladode powder was produced by peeled cladodes aiming at investigating its rheological properties in respect to some other physical characteristics such as color. Color stability showed that light is an important factor that accelerates the deterioration of the natural appealing color of the final powder. In terms of rheological evaluation, an interesting take away of this study is the observation that cladode powder can interact with gelatin in pH 6, leading to substantial increase in viscosity. This interaction should be further explored on food applications of low acidity, where cladode powder could be used as a more nutritious choice. Trials in soup models showed that cladode powder bears thickening capacity, but higher concentrations may be required for achieving satisfactory results. Cladode powder is a valuable source of dietary fiber and other nutritious compounds; therefore, it could be utilized as a novel and functional thickening agent.

Data Availability

Data are available upon request.

References

AACC International. (1999). Approved methods of analysis, 11th Ed. Method 44–15.02. Moisture—Air-Oven Methods Final. https://doi.org/10.1093/toxsci/kft062

Bayar, N., Kriaa, M., & Kammoun, R. (2016). Extraction and characterization of three polysaccharides extracted from Opuntia ficus indica cladodes. International Journal of Biological Macromolecules, 92, 441–450. https://doi.org/10.1016/j.ijbiomac.2016.07.042

Boukid, F., Boukid, Z., & Mejri, M. (2015). Opuntia cladodes: Physicochemical parameters, functional properties and application in formulation of rolled cake of cladode flour fabric (part 2). International Journal of Advanced Trends in Computer Science and Engineering, 1(4), 30–34.

Camelo Caballero, L. R., Wilches-Torres, A., Cárdenas-Chaparro, A., Gómez Castaño, J. A., & Otálora, M. C. (2019). Preparation and physicochemical characterization of softgels cross-linked with cactus mucilage extracted from cladodes of Opuntia ficus-indica. Molecules, 24(14). https://doi.org/10.3390/molecules24142531

Chaloulos, P., Bazanis, A. E., Georgiadou, M., Protonotariou, S., & Mandala, I. (2021). Effect of drying and grinding or micro-grinding process on physical and rheological properties of whole cladode (Opuntia ficus-indica) flour. LWT - Food Science and Technology, 151(May), 112171. https://doi.org/10.1016/j.lwt.2021.112171

Contreras-Padilla, M., Gutiérrez-Cortez, E., del Valderrama-Bravo, M., & C., Rojas-Molina, I., Espinosa-Arbeláez, D. G., Suárez-Vargas, R., & Rodríguez-García, M. E. (2012). Effects of drying process on the physicochemical properties of nopal cladodes at different maturity stages. Plant Foods for Human Nutrition, 67(1), 44–49. https://doi.org/10.1007/s11130-011-0265-x

Contreras-Padilla, M., Rodríguez-García, M. E., Gutiérrez-Cortez, E., del Valderrama-Bravo, M., & C., Rojas-Molina, J. I., & Rivera-Muñoz, E. M. (2016). Physicochemical and rheological characterization of Opuntia ficus mucilage at three different maturity stages of cladode. European Polymer Journal, 78, 226–234. https://doi.org/10.1016/j.eurpolymj.2016.03.024

De Wit, M., Du Toit, A., Fouché, H. J., Hugo, A., & Venter, S. L. (2019). Screening of cladodes from 42 South African spineless cactus pear cultivars for morphology, mucilage yield and mucilage viscosity. Acta Horticulturae, 1247, 47–55. https://doi.org/10.17660/ActaHortic.2019.1247.7

Di Lorenzo, F., Silipo, A., Molinaro, A., Parrilli, M., Schiraldi, C., D’Agostino, A., Izzo, E., Rizza, L., Bonina, A., Bonina, F., & Lanzetta, R. (2017). The polysaccharide and low molecular weight components of Opuntia ficus indica cladodes: Structure and skin repairing properties. Carbohydrate Polymers, 157, 128–136. https://doi.org/10.1016/j.carbpol.2016.09.073

Doublier, J. -L. (1981). Rheological studies on starch — flow behaviour of wheat starch pastes. Starch - Stärke, 33(12), 415–420. https://doi.org/10.1002/star.19810331205

Du Toit, A., De Wit, M., Seroto, K. D., Fouché, H. J., Hugo, A., & Venter, S. L. (2019). Rheological characterization of cactus pear mucilage for application in nutraceutical food products. Acta Horticulturae, 1247(November), 63–72. https://doi.org/10.17660/ActaHortic.2019.1247.9

Espino-Díaz, M., De Jesús Ornelas-Paz, J., Martínez-Téllez, M. A., Santillán, C., Barbosa-Cánovas, G. V., Zamudio-Flores, P. B., & Olivas, G. I. (2010). Development and characterization of edible films based on mucilage of Opuntia ficus-indica (L.). Journal of Food Science, 75(6), 347–352. https://doi.org/10.1111/j.1750-3841.2010.01661.x

Fraeye, I., Duvetter, T., Doungla, E., Van Loey, A., & Hendrickx, M. (2010). Fine-tuning the properties of pectin-calcium gels by control of pectin fine structure, gel composition and environmental conditions. Trends in Food Science and Technology, 21(5), 219–228. https://doi.org/10.1016/j.tifs.2010.02.001

Frati, A. C., Jiménez, E., & Ariza, C. R. (1990). Hypoglycemic effect of Opuntia ficus indica in non insulin-dependent diabetes mellitus patients. Phytotherapy Research, 4(5), 195–197. https://doi.org/10.1002/ptr.2650040507

Griffith, P. M. (2004). The origins of an important cactus crop, Opuntia ficus-indica (Cactaceae): New molecular evidence. American Journal of Botany, 91(11), 1915–1921.

Harrak, H. (2021). Assessment of technological and nutritional qualities of the powder of prickly pear cladodes at four ages of growth. Materials Today: Proceedings, 45, 7524–7530. https://doi.org/10.1016/j.matpr.2021.02.351

Hernández-Urbiola, M. I., Contreras-Padilla, M., Pérez-Torrero, E., Hernández-Quevedo, G., Rojas-Molina, J. I., Cortes, M. E., & Rodríguez-García, M. E. (2015). Study of nutritional composition of nopal (Opuntia ficus indica cv. Redonda) at different maturity stages. The Open Nutrition Journal, 4(1), 11–16. https://doi.org/10.2174/1874288201004010011

Higiro, J., Herald, T. J., & Alavi, S. (2006). Rheological study of xanthan and locust bean gum interaction in dilute solution. Food Research International, 39(2), 165–175. https://doi.org/10.1016/j.foodres.2005.07.011

Hussain, S., Mohamed, A. A., Alamri, M. S., Ibraheem, M. A., Qasem, A. A. A., Alsulami, T., & Ababtain, I. A. (2022). Effect of cactus (Opuntia ficus-indica) and acacia (Acacia seyal) gums on the pasting, thermal, textural, and rheological properties of corn, sweet potato, and Turkish bean starches. Molecules, 27(3), 1–24. https://doi.org/10.3390/molecules27030701

Jo, W., Bak, J. H., & Yoo, B. (2018). Rheological characterizations of concentrated binary gum mixtures with xanthan gum and galactomannans. International Journal of Biological Macromolecules, 114, 263–269. https://doi.org/10.1016/j.ijbiomac.2018.03.105

León-Martínez, F. M., Rodríguez-Ramírez, J., Medina-Torres, L. L., Méndez Lagunas, L. L., & Bernad-Bernad, M. J. (2011). Effects of drying conditions on the rheological properties of reconstituted mucilage solutions (Opuntia ficus-indica). Carbohydrate Polymers, 84(1), 439–445. https://doi.org/10.1016/j.carbpol.2010.12.004

Liang, S., Li, B., Ding, Y., Xu, B. L., Chen, J., Zhu, B., Ma, M. H., Kennedy, J. F., & Knill, C. J. (2011). Comparative investigation of the molecular interactions in konjac gum/hydrocolloid blends: Concentration addition method (CAM) versus viscosity addition method (VAM). Carbohydrate Polymers, 83(3), 1062–1067. https://doi.org/10.1016/j.carbpol.2010.08.026

López-Palacios, C., Peña-Valdivia, C. B., Rodríguez-Hernández, A. I., & Reyes-Agüero, J. A. (2016). Rheological flow behavior of structural polysaccharides from edible tender cladodes of wild, semidomesticated and cultivated ‘nopal’ (Opuntia) of Mexican highlands. Plant Foods for Human Nutrition, 71(4), 388–395. https://doi.org/10.1007/s11130-016-0573-2

López-Romero, P., Pichardo-Ontiveros, E., Avila-Nava, A., Vázquez-Manjarrez, N., Tovar, A. R., Pedraza-Chaverri, J., & Torres, N. (2014). The effect of nopal (Opuntia ficus indica) on postprandial blood glucose, incretins, and antioxidant activity in Mexican patients with type 2 diabetes after consumption of two different composition breakfasts. Journal of the Academy of Nutrition and Dietetics, 114(11), 1811–1818. https://doi.org/10.1016/j.jand.2014.06.352

Lopez, C. G., Colby, R. H., Graham, P., & Cabral, J. T. (2017). Viscosity and scaling of semiflexible polyelectrolyte NaCMC in aqueous salt solutions. Macromolecules, 50(1), 332–338. https://doi.org/10.1021/acs.macromol.6b02261

Majdoub, H., Roudesli, S., & Deratani, A. (2001). Polysaccharides from prickly pear peel and nopals of Opuntia ficus-indica: Extraction, characterization and polyelectrolyte behaviour. Polymer International, 50(5), 552–560. https://doi.org/10.1002/pi.665

McConn, M. M., & Nakata, P. A. (2004). Oxalate reduces calcium availability in the pads of the prickly pear cactus through formation of calcium oxalate crystals. Journal of Agricultural and Food Chemistry, 52(5), 1371–1374. https://doi.org/10.1021/jf035332c

McGarvie, D., & Parolis, H. (1981). Residues mainly. Carbohydrate Research, 88, 305–314.

Medina-Torres, L., Brito-De La Fuente, E., Torrestiana-Sanchez, B., & Katthain, R. (2000). Rheological properties of the mucilage gum (Opuntia ficus indica). Food Hydrocolloids, 14(5), 417–424. https://doi.org/10.1016/S0268-005X(00)00015-1

Medina-Torres, L., Vernon-Carter, E. J., Gallegos-Infante, J. A., Rocha-Guzman, N. E., Herrera-Valencia, E. E., Calderas, F., & Jiménez-Alvarado, R. (2011). Study of the antioxidant properties of extracts obtained from nopal cactus (Opuntia ficus-indica) cladodes after convective drying. Journal of the Science of Food and Agriculture, 91(6), 1001–1005. https://doi.org/10.1002/jsfa.4271

Méndez, L. P., Flores, F. T., Martín, J. D., Rodríguez Rodríguez, E. M., & Díaz Romero, C. (2015). Physicochemical characterization of cactus pads from Opuntia dillenii and Opuntia ficus indica. Food Chemistry, 188, 393–398. https://doi.org/10.1016/j.foodchem.2015.05.011

Molavi, H., & Razavi, S. M. A. (2018). Steady shear rheological properties of native and hydrothermally modified Persian acorn (Quercus brantii Lindle.) starches. Starch - Stärke, 70(3–4), 1–9. https://doi.org/10.1002/star.201700156

Otálora, M. C., Gómez Castaño, J. A., & Wilches-Torres, A. (2019). Preparation, study and characterization of complex coacervates formed between gelatin and cactus mucilage extracted from cladodes of Opuntia ficus-indica. LWT - Food Science and Technology, 112(June), 108234. https://doi.org/10.1016/j.lwt.2019.06.001

Potier, M., Tea, L., Benyahia, L., Nicolai, T., & Renou, F. (2020). Viscosity of aqueous polysaccharide solutions and selected homogeneous binary mixtures. Macromolecules, 53(23), 10514–10525. https://doi.org/10.1021/acs.macromol.0c02157

Quinzio, C., Ayunta, C., Alancay, M., de Mishima, B. L., & Iturriaga, L. (2018). Physicochemical and rheological properties of mucilage extracted from Opuntia ficus indica (L. Miller). Comparative study with guar gum and xanthan gum. Journal of Food Measurement and Characterization, 12(1), 459–470. https://doi.org/10.1007/s11694-017-9659-2

Ramírez-Moreno, E., Córdoba-Díaz, D., de Cortes Sánchez-Mata, M., Díez-Marqués, C., & Goñi, I. (2013). Effect of boiling on nutritional, antioxidant and physicochemical characteristics in cladodes (Opuntia ficus indica). LWT - Food Science and Technology, 51(1), 296–302. https://doi.org/10.1016/j.lwt.2012.10.005

Ravindran, G., & Matia-Merino, L. (2009). Starch-fenugreek (Trigonella foenum-graecum L.) polysaccharide interactions in pure and soup systems. Food Hydrocolloids, 23(3), 1047–1053. https://doi.org/10.1016/j.foodhyd.2008.08.010

Rivera-Corona, J. L., Rodríguez-González, F., Rendón-Villalobos, R., García-Hernández, E., & Solorza-Feria, J. (2014). Thermal, structural and rheological properties of sorghum starch with cactus mucilage addition. LWT - Food Science and Technology, 59(2P1), 806–812. https://doi.org/10.1016/j.lwt.2014.06.011

Rodríguez-Garcia, M. E., De Lira, C., Hernández-Becerra, E., Cornejo-Villegas, M. A., Palacios-Fonseca, A. J., Rojas-Molina, I., Reynoso, R., Quintero, L. C., Del-Real, A., Zepeda, T. A., & Muñoz-Torres, C. (2007). Physicochemical characterization of nopal pads (Opuntia ficus indica) and dry vacuum nopal powders as a function of the maturation. Plant Foods for Human Nutrition, 62(3), 107–112. https://doi.org/10.1007/s11130-007-0049-5

Rodríguez-González, F., Pérez-González, J., Muñoz-López, C. N., Vargas-Solano, S. V., & Marín-Santibáñez, B. M. (2021). Influence of age on molecular characteristics and rheological behavior of nopal mucilage. Food Science and Nutrition, 9(12), 6776–6785. https://doi.org/10.1002/fsn3.2629

Sáenz, C., Sepúlveda, E., Pak, N., & Lecaros, M. (2010). Chemical and physical characterization of cactus cladode (Opuntia Ficus-Indica) powder. Italian Journal of Food Science, 22(4), 416–422.

Sepúlveda, E., Gorena, T., Chiffelle, I., Sáenz, C., & Catalán, E. (2013). Effect of the cactus cladodes peeling in the functional, technological and chemical characteristics and bioactive compounds in cactus cladodes powders. Acta Horticulturae 995, 269–272. https://doi.org/10.17660/ActaHortic.2013.995.32

Thibault, J. -F., & Ralet, M. -C. (2003). Physico-chemical properties of pectins in the cell walls and After Extraction. Advances in Pectin and Pectinase Research, i, 91–105.

Trachtenberg, S., & Mayer, A. M. (1982). Biophysical properties of Opuntia ficus-indica mucilage. Phytochemistry, 21(12), 2835–2843.

Acknowledgements

We are grateful to the editor and the anonymous reviewers for their critical comments that improved the present manuscript.

Funding

Open access funding provided by HEAL-Link Greece. This research has been co-financed by the European Union and Greek national funds through the Operational Program Competitiveness, Entrepreneurship and Innovation, under the call RESEARCH – CREATE – INNOVATE (project code:T1EDK-04027).

Author information

Authors and Affiliations

Contributions

Panagiotis Chaloulos: conceptualization, methodology, formal analysis, writing—original draft preparation. Nikos Vasilopoulos: investigation, data curation, visualization. Ioanna Mandala: conceptualization, supervision, writing—reviewing and editing, project administration.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chaloulos, P., Vasilopoulos, N. & Mandala, I. Blends of Cactus Cladode Powder with Corn Starch, Milk Proteins and Gelatin: Rheological Evaluation and Application to a Soup Model. Food Bioprocess Technol 16, 1343–1355 (2023). https://doi.org/10.1007/s11947-023-03004-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03004-5