Abstract

Turbo-technology (i.e., a heat/shear treatment) potential in modifying rice flour technological properties (i.e., damaged starch, pasting properties, apparent cold viscosities, and color) depending on cooking temperature (120–200 °C), added water (30–40%), and drying temperature (160–200 °C) was evaluated. Applying a Box–Behnken design, highly significant (p < 0.001) models were found for moisture, damaged starch, pasting properties, and cold viscosities. The most important factor was the added water, significantly (p < 0.001) affecting all treated flour characteristics. The optimization resulted in 200 °C as cooking and drying temperature and 40% added water, but values of damaged starch and cold viscosities in the treated flour were still low. Thus, flour was overnight wetted (40% water) before cooking and drying at 200 °C, obtaining high values of damaged starch (49.5 ± 1.5 g/100 g db) and cold viscosities (from 6213 to 21,436 cP). The study represents a guide for the application of turbo-technology to design flour with tailored technological properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rice (Oryza sativa L.) is one of the leading food crops of the world and is a staple food for over half the world’s population (FAOSTAT, 2018). It is consumed as brown or milled rice, or it is further processed to obtain flour. Rice flour is considered suitable for many consumers’ categories such as infants, elders, coeliacs, vegetarians, and vegans. It is gluten-free (GF) and has a plain taste and color; thus, it can be included in many food products. For instance, untreated rice flour can be used in GF breads and cookies (Cappa et al., 2020a; Kahraman et al., 2018), whereas precooked rice flour is mainly commercialized for baby foods, beverages, puddings, and GF pasta (Arendt et al., 2008; Mariotti et al., 2011). In GF pasta production, to create an alternative to the gluten network, a “scaffold” of retrograded starch is generally created during the technological process by applying subsequent heating and cooling steps or by using pregelatinized starchy flours as raw materials (Mariotti et al., 2011).

Pre-gelatinization of rice flour can be obtained in different ways. Physical treatments have the benefit over the chemical ones of changing protein and starch functionalities while keeping the green label (Ahmed et al., 2007; Jacobs & Delcour, 1998). Thermal treatments are the most common, but they generally require long times and high amounts of water. Thus, faster processes have been developed based, for instance, on high hydrostatic pressures, which influence functional properties of proteins through the disruption and reformation of hydrogen bonds and hydrophobic interactions, leading to denaturation, aggregation, and gelation (Cheftel, 1992; Lopez-Fandino, 2006). Cappa et al. (2016) reported that rice flour treated at 600 MPa for 5 min at 40 °C presented a strong water binding capacity that allowed GF bread doughs to maintain a good consistency and workability, despite the high amount of water required for their formation. Other physical treatments used to modify rice flour functionality involve microwave heating (Villanueva et al., 2018, 2019), enzymatic extrusion (Xu et al., 2017), or extrusion cooking (Chuang & Yeh, 2004; Hagenimana et al., 2006; Martínez et al., 2014). In particular, the latter is a high-temperature short-time cooking process during which flours are subjected to high temperatures and mechanical shearing at relatively low levels of moisture content (Camire et al., 1990). This treatment promotes interesting technological and nutritional modifications, such as starch pre-gelatinization, protein denaturation, reduction of antinutritional factors, and increase of resistant starch content (Camire et al., 1990; Hagenimana et al., 2006; Martínez et al., 2014), the extent of which are dependent on the applied process conditions (e.g., die temperature, feed moisture, feed rate, screw speed, residence time) as well as the extruder configuration (Chuang & Yeh, 2004; Cappa et al., 2020b; Guha et al., 2003).

Another treatment combining heat and shear is based on the turbo-technology patented by VOMM® Impianti e Processi S.p.A. (Rozzano, Italy), which can be used for modifying technological properties of different types of flours. Thanks to a specially designed turbine and a centrifuge, this technology guarantees a rapid and uniform treatment of the product by creating strong turbulence in a thin layer of material in contact with a heated surface (Vezzani & Foti, 1989). For flour treatment, a turbo-cooker and a turbo-dryer are installed in a cascade configuration. Indeed, water is added during cooking to favor starch gelatinization, thus, a following drying step is necessary to assure flour shelf life.

The aim of this study was to investigate the effectiveness of the turbo-technology in modifying the technological properties (i.e., damaged starch amount, starch gelatinization and retrogradation properties, apparent cold viscosity and color) of rice flour as a function of cooking temperature (120–200 °C), added water (30–40%), and drying temperature (160–200 °C). Based on the results of a three-factor Box–Behnken design of experiments (BBD), a technological progress is suggested to improve the suitability of the turbo-treated rice flour as new ingredient with higher values of damaged starch and cold viscosities, needed, for instance, in GF pasta products.

Materials and Methods

Materials and Turbo-Technology Treatments

The trials were carried out using Carnaroli rice belonging to Distretto Rurale “Riso e Rane” (Cassinetta di Lugagnano, Italy). Broken milled rice grain was powdered (down to particle size below 0.75 mm) to obtain the raw flour (sample R) that was then turbo-treated by Zini Prodotti Alimentari S.p.A. (Cesano Boscone, Italy), using the equipment by VOMM® Impianti e Processi S.p.A. (Rozzano, Italy). The turbo-treatment consisted in two subsequent steps: cooking and drying. In the turbo-cooker, the following constant conditions were applied: flour payload, 100 kg/h; turbine rotation, 700 rpm; and process time, 30 s. The turbo-drier worked with a flour payload of 80 m3/h, an air payload of 485 m3/h, and a process time of 60 s. The other process parameters (i.e., cooking temperature, cooking added water, and drying temperature) were changed according to the design of experiments (section Design of Experiments). The treated samples were finally ground to a particle size below 0.75 mm like the raw material and stored at 4 °C in sealed polyethylene bags until their characterization. For comparison, a commercial pregelatinized rice flour (CPF; Molino Favero Antonino srl, Padova, Italy) commonly used in GF products was evaluated.

Design of Experiments

Turbo-treatment of rice flour was studied in terms of cooking temperature (120–200 °C), added water (30–40%), and drying temperature (160–200 °C) by means of a three-factor BBD (Design Expert software, v. 10.0.0.3, Stat-Ease Inc., Minneapolis, MN, USA). The combination of the actual factor levels and the corresponding sample identification are reported in standard order in Table 1. Sample codes consist of capital letters identifying the level (L, low; M, medium; H, high) of the three factors (C, cooking temperature; W, added water; D, drying temperature); the five replicates of the central point are indicated with lowercase letters from “a” to “e.” The 17 trials were performed in a randomized order to avoid systematic errors and minimize the effect of possible external factors.

Rice Flour Evaluation

Particle Size Distribution

The raw sample was characterized in terms of particle size distribution as described by Cappa et al. (2013) by using an analytical sieve shaker Octagon Digital (Endecotts Ltd., London, UK), equipped with four certified sieves (openings, 90, 125, 250, 500 µm). Results were expressed as g/100 g, as the average of three replicates.

Proximate Composition

Raw and turbo-treated flours and CPF were analyzed for moisture (Method 44-15A; AACC, 2000), total starch (TS), and damaged starch (DS) contents (using the designated assays provided by Megazyme International Ireland Ltd., Bray, Wicklow, Ireland). Raw flour was also characterized in terms of total nitrogen amount, according to the Kjeldahl Official Standard Method AOAC 920.87 (AOAC, 1999), protein (calculated adopting 5.95 as nitrogen conversion factor), and lipid (method 923.05; AOAC, 2000) contents. Results were expressed as g/100 g as the average of three replicates.

Color Evaluation

Color of the raw and turbo-treated flours (approximately 50 g) leveled in petri dishes was measured using a tristimulus colorimeter (Chroma Meter II Reflectance, Minolta, Osaka, Japan) with the standard illuminant C. Color was expressed in the CIE L*a*b* space, where L* corresponds to lightness (from 0 = black to 100 = white), a* to the red-green component, and b* to the yellow-blue component. Results are the average of five replicates.

Pasting Properties

Pasting properties of raw and treated flours and CPF were investigated using a Rapid Visco Analyzer (RVA 4500 PerkinElmer Italia S.p.A, Milano, Italy) as reported by Cappa et al. (2020a). From the resulting RVA pattern (evaluated at least in duplicate), the following indices were extrapolated: peak viscosity (PV, cP; maximum paste viscosity achieved during the heating phase); peak temperature (PT, °C; temperature corresponding to PV); peak time (Pt, min; time corresponding to PV); breakdown (BD, cP; index of viscosity decrease during the holding period, corresponding to the PV minus the viscosity after the holding period at 95 °C); final viscosity (FV, cP; paste viscosity reached at the end of the cooling cycle), and setback (SB, cP; index of the paste viscosity increase during cooling, corresponding to the difference between FV and the viscosity reached after the holding period at 95 °C).

Apparent Cold Viscosity

In order to evaluate the effect of the turbo-treatment on the apparent cold viscosity, the RVA (RVA 4500 PerkinElmer Italia S.p.A, Milano, Italy) was unconventionally used. Raw and treated flours and CPF (10 g) were dispersed in distilled water (25 g), scaling both the sample and water weight on a 14 g/100 g sample moisture basis. The suspensions were kept at 30 °C for 10 min while continuous stirring at 160 rpm. The following indices were extrapolated from the RVA patterns: initial cold viscosity (IV30, cP; measured after 0.5 min at 30 °C) and final cold viscosity (FV30, cP; measured after 10 min at 30 °C). Results are the average of at least two replicates.

Data Elaboration

All data were subjected to one-way analysis of variance (ANOVA), followed by the least significant difference test (LSD) to identify significant differences between the samples (p < 0.05). The statistical analysis was carried out using STATGRAPHICS Centurion 18 (StatPoint Inc., The Palins, VA, USA).

BBD data were elaborated by means of response surface methodology (RSM) (Design Expert software, v. 10.0.0.3, Stat-Ease Inc., Minneapolis, MN, USA). A square root transformation was necessary for FV30 to assure a normal distribution of the results. A complete second-order model was applied to each response variable, thus calculating the effect of main factors as well as linear and quadratic interactions. ANOVA was used to determine the significance of each effect, and the model was simplified in case of non-significant coefficients, always supporting hierarchy (Cappa & Alamprese, 2017). The calculated models were also evaluated in terms of coefficient of determination (R2), adjusted R2 (adj. R2), predicted R2 (pred. R2), and lack of fit (LOF, p value).

Results and Discussion

Raw Rice Flour Characteristics

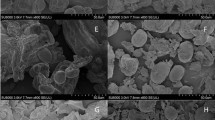

As the turbo-treatment is very fast and flour hydration kinetic is generally affected by granulometry (Cappa et al., 2018; de la Hera et al., 2013a, b; Kadan et al., 2008), the particle size distribution of raw rice flour was evaluated and resulted as follows: 1 g/100 g ≤ 90 µm, 12 g/100 g between 90 and 125 µm, 43 g/100 g between 125 and 250 µm, 40 g/100 g between 250 and 500 µm, and 4 g/100 g > 500 µm.

Total starch, protein, and lipid contents were 85.89 ± 0.57, 5.66 ± 0.26, and 0.65 ± 0.01 g/100 g dry basis (db), respectively. These values are in agreement with Champagne et al. (2004), who reported starch, protein, and lipid content of 90, 5.2–12.2, and 0.3–0.6 g/100 g db, respectively, for milled rice kernels. Lower starch (80–81 g/100 g db) and higher lipid (0.8–1.4 g/100 g db) contents were reported by Yu et al. (2012). The discrepancies could be attributed to the rice variety considered and the rate of milling.

Turbo-Treated Flour Characteristics

As expected, moisture contents of the treated flours (Table 2) were significantly different (p < 0.05) depending on the turbo-treatment conditions adopted, ranging between 5.4 and 14.2 g/100 g. Generally, the treated samples showed moisture values significantly (p < 0.05) lower than that of raw flour (12.28 g/100 g db) due to the drying step. In particular, only the sample MC-HW-LD, whose treatment involved the highest level of added water (i.e., 40%) and the lowest drying temperature (i.e., 160 °C), showed a significantly higher moisture content (14.2 g/100 g) in comparison to raw flour (p < 0.05). On the contrary, samples LC-LW-MD, HC-LW-MD, HC-MW-HD, and MC-LW-HD had moisture content close to 5–6 g/100 g due to the low-to-medium percentage of water added during cooking (30–35%) and the medium-to-high drying temperatures (180–200 °C).

Also damaged starch contents differed significantly (p < 0.05) among samples (from 3.96 g/100 g db for R to 23.9–36.6 g/100 g db for treated flours), indicating that the hydro-thermal process applied somehow modified the starch organization (Table 2) and its gelatinization and retrogradation behavior as detailed below (Table 3). The treated flour with the significantly lowest (p < 0.05) starch damage was LC-LW-MD, which underwent a mild heat treatment in the presence of a low amount of added water (30%). On the opposite, the sample with the significantly highest (p < 0.05) damaged starch content was HC-HW-MD, which was subjected to a more severe treatment, as the cooking and drying temperatures were equal to 200 °C and 180 °C, respectively, and the added water was at the highest level (40%). However, the damaged starch values of the treated samples were not very high (maximum 36.6 g/100 g db), indicating that the applied process was not particularly severe. In fact, CPF, which had a total starch content very similar to R (85.1 ± 1.2 vs. 85.9 ± 0.6 g/100 g db, respectively), showed damaged starch content of 50.3 ± 1.6 g/100 g db.

In order to evaluate the effect of the turbo-treatment on the starch gelatinization and retrogradation level, the pasting properties of raw and treated flours were determined by the standard RVA method 2 (Table 3). Raw rice flour showed a typical pasting curve (Fig. 1a) characterized by a low initial viscosity, followed by a faster viscosity increase due to the swelling of starch granules; the peak viscosity was reached around the maximum temperature applied (i.e., 95 °C), and then a fast decrease of viscosity was detected as a consequence of the starch granule rupture; during the cooling phase, a second increase of viscosity was noticed due to starch retrogradation. Treated flours showed a behavior similar to that of the raw sample, indicating that the hydro-thermal cooking process applied was mild and not able to deeply disorganize the starch structure; this was already evidenced by the medium–low damaged starch values of treated samples as previously discussed. The pasting temperature (PT) and the peak viscosity (PV) of raw flour were 84.5 °C and 3037 cP, while treated samples required significantly (p < 0.05) higher PT (86.5–88.3 °C) and reached similar PV (2703–3116 cP), indicating that the process applied somehow affected the starch granule organization. A higher PT was noticed also by Cappa et al. (2016) as a consequence of high hydrostatic pressure treatments applied on rice flour, whereas lower PT and PV values are typical of extruded rice flours (Bryant et al., 2001).

As the turbo-cooked rice flours are intended as new ingredients for GF production (e.g., pasta and baby foods), their affinity to water was evaluated by means of suitable RVA tests carried out at 30 °C to measure the apparent cold viscosity (Table 3, Fig. 1b). As expected, the raw samples showed a very low viscosity (34–35 cP) during the entire test indicating that raw rice starch – and more in general raw rice flour – is not able to absorb water and increase the suspension viscosity. On the opposite, turbo-treated samples showed an initial viscosity from 5 to 34 times higher than that of raw flour and a further increase during the test, reaching significantly (p < 0.05) higher FV30 values, ranging from 270 to 4244 cP. This behavior suggests that starch was partially gelatinized during the hydro-thermal process applied, allowing treated flours to fast interact with water even at low temperature (30 °C). Similar patterns were reported by Bryant et al. (2001), who evaluated the viscosity of raw and extruded rice flour by running RVA at 25 °C; the authors found an increase in cold viscosity that was attributed to the full cooking of the starch. Furthermore, the same authors reported that RVA profiles agree with the water absorption and water solubility indices, concluding that RVA at constant low temperature can be used to screen thermally treated (i.e., extruded) flours for potential use in value-added products.

In agreement with the mildness of the turbo-treatment, flour color was slightly affected. Generally, when a thermal treatment above 100 °C is applied, a sample browning is noticed as a consequence of caramelization and Maillard reaction (Fernández-Artigas et al., 1999; Giovanelli & Cappa, 2021; Gulzar et al., 2021). In particular, Fernández-Artigas et al. (1999) indicated that rice flour thermal processes, such as toasting and drying, caused a reduction of L* (from 95 to 92) and an increase of a* (from 0.2 to 0.4) and b* values (from 5.1 to 9.1). In addition, Gulzar et al. (2021), who investigated the effects of extrusion process on rice flour properties, found a negative linear effect of temperature on L* value. However, in the present study, raw and turbo-treated flours showed similar chromatic values (data not shown): high lightness (L* = 91–93), a* index between −1.2 and −1.6, indicating a slight prevalence of the green component compared to the red one, and b* values of 3.8–5.4, typical of the slight yellow samples. Thus, it can be concluded that even if the temperatures involved in the turbo-treatment were quite high (i.e., 120–200 °C and 160–200 °C for cooking and drying, respectively), they did not have a great effect on the color parameters presumably due to the short time of the process (i.e., 90 s).

Modeling of Turbo-Treatment

Among the considered response variables, color parameters (L*, a*, and b*) and peak time (Pt) showed very little changes as a function of turbo-treatment conditions; thus, they were not considered in the BBD elaboration. For all the other responses, highly significant (p < 0.001) models were found, mostly linear (Table 4). Only for peak temperature (PT) and apparent initial and final cold viscosities (i.e., IV30 and FV30), linear interaction and/or quadratic effects were significant. All models had a non-significant LOF (p > 0.05), thus confirming their reliability together with the high values of R2, adj. R2, and pred. R2 (> 0.74). The adequate precision was good for all the models, being always higher than 14 (data not shown) compared to a threshold of 4.

The most important process parameter was the amount of added water during turbo-cooking. It significantly (p < 0.001) affected all the characteristics of the treated rice flours. Besides the obvious direct effect on moisture, a direct effect was observed also on damaged starch (DS), PT, IV30, and FV30, while peak viscosity (PV), breakdown (BD), final viscosity (FV), and setback (SB) were inversely affected. These results mean that a higher amount of added water during turbo-cooking increases the extent of starch damaging, thus conferring different pasting properties to the product. Actually, as demonstrated by Wang et al. (2017), starch granule disruption is greater when rice is cooked under higher water content and it leads to lower pasting viscosities and higher pasting temperatures. Moreover, it is interesting to note that the higher values of DS, linked to a higher extent of starch gelatinization, can increase the retrogradation tendency, thus leading to the formation of a higher amount of resistant starch (Gulzar et al., 2021). This is important from a nutritional point of view because the treated rice flours could be exploited in the development of foods with a low glycemic impact for people suffering from diabetes.

In the turbo-treatment, drying temperature resulted more important than cooking temperature in affecting rice flour characteristics. However, it has to be noticed that this effect can also be related to the longer drying time (i.e., 60 s) with respect to the cooking time (i.e., 30 s). Drying temperature had an inverse effect on moisture and BD (p < 0.001) and a direct effect on FV, SB, PT, and IV30 (p < 0.001). The magnitude of the effects was similar to those of the added water (similar absolute values of the significant coefficients in Table 4), except for IV30 on which the influence of the drying temperature was more or less half that of the added water. Conversely, when significant, the cooking temperature had a lower effect on rice flour pasting properties (i.e., FV and SB) compared to the drying temperature and the amount of added water.

As stated above, most of the developed models were linear and highlighted a higher importance of the added water and the drying temperature rather than the cooking temperature. However, more complex models were calculated for PT and cold viscosities (IV30 and FV30) (Table 4). PT was significantly and directly affected by the added water and the drying temperature as the main factors but also by the linear interaction between the added water and the cooking temperature; moreover, an inverse effect of quadratic interaction of the drying temperature was determined. The model resulted therefore in a curved surface (Fig. 2), in which the highest values of PT corresponded to the higher levels of added water and drying temperature. PT decreased faster by reducing the added water rather than the drying temperature.

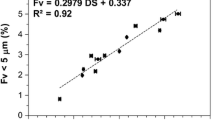

IV30 was linearly and directly affected by all the three main processing factors, and the linear interactions were important as well, whereas for FV30, the drying temperature was not significant (Table 4). The added water had the highest effect, particularly when cooking and drying temperatures were at the maximum values (Fig. 3). This means that turbo-treatment, especially when performed with higher amount of added water and at high temperatures, increases the apparent cold viscosity of rice flour, due to changes in starch granule structure caused by heat and mechanical stress. Higher values of cold apparent viscosities are also related to better hydration properties (Espinosa-Ramírez et al., 2021). Thus, the applied treatment affects the techno-functionality of rice flours intended as new ingredients but to a lesser extent than expected. An optimization of the process conditions was therefore explored.

Optimization and Improvement of Turbo-Treatment

To improve the suitability of the turbo-treated rice flour as ingredient for GF products, higher values of damaged starch and cold viscosities are needed, as highlighted by the comparison of the BBD samples with CPF. Thus, a linear desirability function was applied to the calculated models (Alamprese et al., 2007), with the constraints of maximizing damaged starch and cold viscosities (i.e., IV30 and FV30). The highest desirability value (0.982) was obtained with cooking and drying temperature of 200 °C and 40% of added water. The predicted values of DS, IV30, and FV30 for the optimized sample were 35.8 ± 1.0 g/100 g db, 1373 ± 81 cP, and 4735 ± 72 cP. The real values obtained after turbo-treatment of the rice flour under the optimized conditions resulted as follows: DS, 32.0 ± 1.6 g/100 g db; IV30, 687 ± 25 cP; and FV30, 4937 ± 156 cP. Thus, DS and FV30 were in agreement with predicted values, whereas IV30 was lower even if higher than most of the viscosities recorded for BBD samples, suggesting that the optimized conditions allowed to gelatinize starch the most.

The value of DS was still lower than that of CPF (50.3 ± 1.6 g/100 g db), most probably due to the very short treatment time (i.e., 90 s). Actually, also Chuang and Yeh (2004) for the extrusion cooking technology demonstrated that adequate residence time is required to reach high levels of starch gelatinization. Thus, a technological progress was tested: rice flour was mixed with 40% of water before the treatment and rested overnight to allow a homogeneous hydration of the flour, fundamental for the starch modification to occur. Then, the turbo-treatment was applied with cooking and drying temperature of 200 °C. Indeed, the DS resulted of 49.5 ± 1.5 g/100 g db, very similar to the value of CPF. As a consequence, also cold viscosities definitely increased (IV30, 6213 ± 897 cP; FV30, 21,436 ± 663 cP), reaching values even higher than those of CPF (Fig. 4).

Conclusions

The work allowed to evaluate the potential of the turbo-technology in modifying rice flour technological properties (i.e., damaged starch, pasting properties, apparent cold viscosities, and color). In particular, the role of different processing conditions was deeply investigated, leading to understand the great importance of flour moisture in the cooking phase and of drying temperature to favor starch gelatinization. However, the very short treatment time of the actual configuration of turbo-technology resulted in a small improvement of the technological properties of rice flour. A technology advancement was then suggested and tested, consisting in a pre-wetting step of the flour before the thermal treatment. This new strategy resulted effective, assuring to reach high values of damaged starch and cold viscosities.

The study is of practical importance for food industries, representing a guide for the application of turbo-technology to design new technological features (i.e., damaged starch, pasting properties, and cold viscosities) in rice flour intended as added-value ingredient for food products, especially suitable for GF productions. For instance, high cold viscosities can be desired for beverages, while tailored pasting properties and damaged starch level are preferred for baby foods, puddings, and pasta production.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

AACC. (2000). Method 44–15A. Moisture – Air oven methods. Approved Methods of the American Association of Cereal Chemists (10th ed.). St. Paul, MN, USA.

Ahmed, J., Ramaswamy, H. S., Ayad, A., Alli, I., & Alvarez, P. (2007). Effect of high-pressure treatment on rheological, thermal and structural changes in Basmati rice flour slurry. Journal of Cereal Science, 46(2), 148–156.

Alamprese, C., Datei, L., & Semeraro, Q. (2007). Optimization of processing parameters of a ball mill refiner for chocolate. Journal of Food Engineering, 83(4), 629–636.

AOAC. (1999). Method 920.87. Protein (total) in flour. Official Methods of Analysis of the Association of Official Analytical Chemists (16th ed.). Gaithersburg, MD, USA.

AOAC. (2000). Method 923.05. Lipids in flour. Official Methods of Analysis of the Association of Official Analytical Chemists (17th ed.). Gaithersburg, MD, USA.

Arendt, E. K., Morrissey, A., Moore, M. M., & Dal Bello, F. (2008). Gluten-free breads. In E. Arendt & F. Dal Bello (Eds.), Gluten-Free Cereal Products and Beverages (pp. 289–VII). London, United Kingdom: Academic Press.

Bryant, R. J., Kadan, R. S., Champagne, E. T., Vinyard, B. T., & Boykin, D. (2001). Functional and digestive characteristics of extruded rice flour. Cereal Chemistry, 78(2), 131–137.

Camire, M. E., Camire, A., & Krumhar, K. (1990). Chemical and nutritional changes in foods during extrusion. Critical Reviews in Food Science & Nutrition, 29(1), 35–57.

Cappa, C., & Alamprese, C. (2017). Brewer’s spent grain valorization in fiber-enriched fresh egg pasta production: Modelling and optimization study. LWT-Food Science & Technology, 82, 464–470.

Cappa, C., Kelly, J. D., & Ng, P. K. (2018). Seed characteristics and physicochemical properties of powders of 25 edible dry bean varieties. Food Chemistry, 253, 305–313.

Cappa, C., Kelly, J. D., & Ng, P. K. (2020a). Baking performance of 25 edible dry bean powders: Correlation between cookie quality and rapid test indices. Food Chemistry, 302, 125338.

Cappa, C., Lucisano, M., Barbosa-Cánovas, G. V., & Mariotti, M. (2016). Physical and structural changes induced by high pressure on corn starch, rice flour and waxy rice flour. Food Research International, 85, 95–103.

Cappa, C., Lucisano, M., & Mariotti, M. (2013). Rheological properties of gels obtained from gluten-free raw materials during a short term aging. LWT-Food Science and Technology, 53(2), 464–472.

Cappa, C., Masseroni, L., Ng, P. K., & Alamprese, C. (2020b). Effect of extrusion conditions on the physical and chemical properties of bean powders. Journal of Food Processing and Preservation, 44(8), e14608.

Champagne, E. T., Wood, D. F., Juliano, B. O., & Bechtel, D. B. (2004). The rice grain and its gross composition. Rice Chemistry and Technology, 3, 77–107.

Cheftel, J. C. (1992). Effects of high hydrostatic pressure on food constituents: An overview. In C. Balny, R. Hayashi, K. Heremans, & P. Masson (Eds.), High Pressure and Biotechnology (pp. 195–209). John Libbey Eurotext.

Chuang, G. C. -C., & Yeh, A. -I. (2004). Effect of screw profile on residence time distribution and starch gelatinization of rice flour during single screw extrusion cooking. Journal of Food Engineering, 63, 21–31.

de la Hera, E., Gomez, M., & Rosell, C. M. (2013a). Particle size distribution of rice flour affecting the starch enzymatic hydrolysis and hydration properties. Carbohydrate Polymers, 98(1), 421–427.

de la Hera, E., Martinez, M., Oliete, B., & Gómez, M. (2013b). Influence of flour particle size on quality of gluten-free rice cakes. Food and Bioprocess Technology, 6(9), 2280–2288.

Espinosa-Ramírez, J., Rodríguez, A., De la Rosa-Millán, J., Heredia-Olea, E., Pérez-Carrillo, E., & Serna-Saldívar, S. O. (2021). Shear-induced enhancement of technofunctional properties of whole grain flours through extrusion. Food Hydrocolloids, 111, 106400.

FAOSTAT. (2018). Rice is life. Increased, sustainable rice production key to global food security. Last access January 2022, from www.fao.org/Newsroom/en/focus/2004/36887/index.html

Fernández-Artigas, P., Guerra-Hernández, E., & García-Villanova, B. (1999). Browning indicators in model systems and baby cereals. Journal of Agricultural and Food Chemistry, 47(7), 2872–2878.

Giovanelli, G., & Cappa, C. (2021). 5-Hydroxymethylfurfural formation in bread as a function of heat treatment intensity: Correlations with browning indices. Foods, 10(2), 417.

Guha, M., Ali, S. Z., & Bhattacharya, S. (2003). Screening of variables for extrusion of rice flour employing a Plackett-Burman design. Journal of Food Engineering, 57, 135–144.

Gulzar, B., Hussain, S. Z., Naseer, B., & Naik, H. R. (2021). Enhancement of resistant starch content in modified rice flour using extrusion technology. Cereal Chemistry, 98(3), 634–641.

Hagenimana, A., Ding, X., & Fang, T. (2006). Evaluation of rice flour modified by extrusion cooking. Journal of Cereal Science, 43(1), 38–46.

Jacobs, H., & Delcour, J. A. (1998). Hydrothermal modifications of granular starch, with retention of the granular structure: A review. Journal of Agricultural and Food Chemistry, 46(8), 2895–2905.

Kadan, R. S., Bryant, R. J., & Miller, J. A. (2008). Effects of milling on functional properties of rice flour. Journal of Food Science, 73(4), E151–E154.

Kahraman, G., Harsa, S., Lucisano, M., & Cappa, C. (2018). Physicochemical and rheological properties of rice-based gluten-free blends containing differently treated chickpea flours. LWT-Food Science & Technology, 98, 276–282.

Lopez-Fandino, R. (2006). High pressure-induced changes in milk proteins and possible applications in dairy technology. International Dairy Journal, 16, 1119–1131.

Mariotti, M., Iametti, S., Cappa, C., Rasmussen, P., & Lucisano, M. (2011). Characterisation of gluten-free pasta through conventional and innovative methods: Evaluation of the uncooked products. Journal of Cereal Science, 53(3), 319–327.

Martínez, M. M., Calviño, A., Rosell, C. M., & Gómez, M. (2014). Effect of different extrusion treatments and particle size distribution on the physicochemical properties of rice flour. Food and Bioprocess Technology, 7(9), 2657–2665.

Vezzani, E., & Foti, S. (1989). Precooking of flour by the Vomm turbotechnology method and use of the resulting product in the food industry. Tecnica Molitoria, 40, 797–799.

Villanueva, M., Harasym, J., Muñoz, J. M., & Ronda, F. (2018). Microwave absorption capacity of rice flour. Impact of the radiation on rice flour microstructure, thermal and viscometric properties. Journal of Food Engineering, 224, 156–164.

Villanueva, M., Harasym, J., Muñoz, J. M., & Ronda, F. (2019). Rice flour physically modified by microwave radiation improves viscoelastic behavior of doughs and its bread-making performance. Food Hydrocolloids, 90, 472–481.

Wang, S., Li, P., Zhang, T., Yu, J., Wang, S., & Copeland, L. (2017). In vitro starch digestibility of rice flour is not affected by method of cooking. Lwt, 84, 536–543.

Xu, E., Wu, Z., Li, J., Pan, X., Sun, Y., Long, J., Xu, X., Jin, Z., & Jiao, A. (2017). Residence time distribution for evaluating flow patterns and mixing actions of rice extruded with thermostable α-amylase. Food and Bioprocess Technology, 10(6), 1015–1030.

Yu, S., Ma, Y., Menager, L., & Sun, D. W. (2012). Physicochemical properties of starch and flour from different rice cultivars. Food and Bioprocess Technology, 5(2), 626–637.

Acknowledgements

The authors would like to thank Prof. Alessandra Marti and Dr. Gaetano Cardone (University of Milan) for damaged starch determination.

Funding

Open access funding provided by Università degli Studi di Milano within the CRUI-CARE Agreement. This research was supported by Lombardy Region (Linea R&S per Aggregazioni; project number 145075).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cappa, C., Invernizzi, R., Lucisano, M. et al. Turbo-Treatment of Rice Flour to Improve Technological Functionality. Food Bioprocess Technol 15, 2344–2353 (2022). https://doi.org/10.1007/s11947-022-02882-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02882-5