Abstract

The aim of this research was to study the effect of sous vide temperature (60, 65, and 70 °C) and time (12, 24, and 36 h) combination on the quality of beef short ribs, namely colour, cooking loss (%), shrinkage (%), soluble collagen (%), myofibrillar fragmentation index (MFI), Warner–Bratzler shear force (WBSF), and Texture Profile Analysis (TPA) parameters with different packaging materials. Aluminium and polyethylene, ethylene vinyl alcohol, and polyamide plastic laminate pouch were recommended for sous vide processing due to no detrimental effect on colour owing to its low oxygen permeability. The results showed a significant (p < 0.05) increase in shrinkage in volume (%), cooking loss (%), and the proportion of soluble collagen (%) and MFI when sous vide temperature and the processing time were increased to 70 °C and 36 h. WBSF and the TPA hardness value were significantly lower (p < 0.05) at 70 °C than at 60 °C both for 36 h due to higher level of solubilisation of collagen and myofibrillar fragmentation by prolonged heating in the moist in-pack environment and overpressure created by saturated steam. As the use of a laminate pouch reduced the oxidation of red myoglobin to brown metmyoglobin, the effect of sous vide temperature and time on International Commission on Illumination (CIE) hue angle and Chroma was not significant. Process optimisation using third-order multiple regression was conducted and the results revealed that optimum sous vide processing temperature and time combination for beef short ribs were 60 °C and 34.06 h.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sous vide (French for “under vacuum”) processing has been used in home cooking and by chefs. Sous vide method applies heating at controlled temperature and time regimes inside heat-stable vacuumed plastic pouches (Schellekens, 1996). The precise temperature and time control have benefits of impeccable reproducibility; good control over degree of doneness, no detrimental effect on colour, and improved tenderness of tough lower value meat cuts (Baldwin, 2012). Vacuum sealing the meat in a bag means that heat transfer from the water (or steam) to the food can be very efficient and it ensures the shelf life and safety of the cooked food by eliminating the risk of contamination during storage. It also limits off-flavour development by reducing oxidation or evaporative losses of flavour volatiles and moisture loss during cooking. Packaging in low oxygen permeable films also reduces aerobic bacterial growth, which further increases the shelf life of the food (Church & Parsons, 2000; Gonzalez-Fandos et al., 2004; Lassen et al., 2002; Stea et al., 2007). However, the mild heat treatment may not destroy bacterial spores. In addition, a low oxygen (anoxic) environment and the lack of vegetative bacteria can create conditions that allow anaerobic spores to germinate if the recommended storage temperature for sous vide products (generally below 4 °C) is not maintained (Baldwin, 2012; Smith et al., 2021).

During sous vide processing, the heat applied can be sufficient to denature some of the proteins, which changes the structure and properties of meat proteins ultimately affecting meat quality. The myofibrillar proteins (mostly myosin and actin) shrink transversely and longitudinally, the connective tissue proteins (mostly collagen) contract and solubilise, while the sarcoplasmic proteins aggregate and gel (Baldwin, 2012). The extent and the type of denaturation, contraction, and expansion of meat proteins mainly depend on the rate of heat transfer, temperature, and time (Baldwin, 2012; Dominguez-Hernandez et al., 2018; Tornberg, 2005). The fastest changes in the meat proteins begin at temperature range between 35 and 40 °C with shrinkage of myofibrils, at a linear rate up to 80 °C. The aggregation and gelation of sarcoplasmic proteins start around 40 °C and finishes at around 60 °C. Connective tissues shrink at around 60 °C but contract more intensely at temperatures above 65 °C (Baldwin, 2012).

During heating at temperature of 60–70 °C, meat tenderness increases due to solubilisation of collagen and reduction in inter-fibre adhesion (Baldwin, 2012; Roldán et al., 2013). The collagen fibres begin to shrink at temperature around 60 °C and at above 65 °C, they contract more intensely destroying the triple-stranded helix structure, which transforms the collagen fibres into random coils that are soluble in water, which further enhances tenderness. The denaturation of collagen increases exponentially with an increase in temperature (Baldwin, 2012). Low-temperature long-time sous vide cooking, with temperature range from 58 to75 °C and processing time in the range of 6.5 up to 24 h, has been reported to solubilise collagen and can tenderise tough meat (Alahakoon et al., 2018; Bhat et al., 2020; Bouton & Harris, 1981; Christensen et al., 2013; James & Yang, 2012; Vaudagna et al., 2002).

Out of the 20 myofibrillar proteins present in meat fibres, actin (forming the thin filaments of myofibrils) and myosin (forming the thick filaments of myofibrils) are the two predominant fibrous proteins, comprising about 65–70% of muscle fibres and holding 70–75% of the water in the meat muscle. The water holding capacity (WHC) of meat during cooking is related to the shrinking and swelling of myofibrils, which depends on the heating temperature (Baldwin, 2012; Bertram et al., 2002, 2006). At temperatures between 40 and 60 °C, the muscle fibres shrink transversely, which increases the inter-myofibrillar gaps. Above 60–65 °C, the muscle fibres shrink longitudinally, which reduces their volume and ultimately WHC and hence causes substantial water loss. The extent of longitudinal contraction and the percentage of cooking loss in meat increase with increasing temperature (Baldwin, 2012).

Meat colour is affected by the rate of change in temperature and time at a particular temperature. In general, the faster the heating rate is, the redder the meat colour will be and the longer the holding time occurs, the paler the meat colour becomes (Baldwin, 2012). This is because during heating the oxymyoglobin (red) and deoxymyoglobin (purple) are denatured to metmyoglobin (brown). The ratio of oxymyoglobin, deoxymyoglobin, and metmyoglobin determines the final colour of cooked meat. The paler meat will have higher concentration of metmyoglobin (Baldwin, 2012). Packaging materials used for sous vide processing were polyethylene (PE) (Bouton & Harris, 1981; Davey et al., 1976), nylon-PE-nylon-PE-nylon-low density (LD) PE (Deok Jang & Sun Lee, 2005; García-Segovia et al., 2007; Hansen et al., 1995), polyamide (PA)-polypropylene (PP) (Rinaldi et al., 2014), polyester films (Gok et al., 2019), and PE-aluminium laminate (Bhat et al., 2020). Sous vide processing has been reported to higher CIE redness (a*) than atmospheric cooking due to protection against oxidation of myoglobin by vacuum (Bhat et al., 2020; Botinestean et al., 2016; García-Segovia et al., 2007). The redness (a*) decreased and yellowness (b*) increased with an increase in sous vide temperature and time due to denaturation and oxidation of oxymyoglobin (OxyMb) and dexoymyoglobin (DeoxyMb) to metmyoglobin (MetMb) and sulfomyoglobin (sulfMb) (Christensen et al., 2013; García-Segovia et al., 2007; Roldán et al., 2013; Vaudagna et al., 2002, 2008). However, a comparison of the effect of different packaging materials used during sous vide processing of tougher and more diverse (in terms of fat, connective tissue, and bone content) meat cuts, such as beef short ribs, has not been reported.

Multiple linear regression was initially used to model the linear relationship between the observed outcomes (response variable) and the predictor variables. If there appeared to be a non-linear relationship, the second-order (quadratic) or third-order (cubic) polynomial terms and their interaction were included in the higher order multiple regression model. When the level of significance (p value) was less than 0.5 for each term, a significant association was assumed between the response variable and predictor term. Using a backward elimination method, the insignificant higher order interactions were omitted in hierarchical order until the significant term was found. Response optimisation is commonly used to identify the combination of variable settings that jointly optimise a single response or a set of responses for a significant multiple regression model (Eberly, 2007).

Prolonged cooking (e.g. braising) has been used to make tough meat more palatable. However, tough meat such as pork shoulder and beef chuck, which has large amount of connective tissue, can take up to 10–12 h at 80 °C or 1–2 days at 55–60 °C to become fork-tender (Baldwin, 2012) and the process is not commercially viable on a large scale. So far, the effect of sous vide on bone-in meat like short ribs, which are tough and contain high amount of connective tissue and fat, has received little academic interest. The heterogeneous level of connective tissue varies dramatically according to location on the carcass and among animals. Furthermore, how the degree of meat attachment to the bone changes during cooking needs to be considered. Thus, in order to facilitate the commercial production of sous vide short ribs and to add value to this meat cut, the effect of sous vide on quality parameters of short ribs needs to be studied and optimum sous vide temperature and time should be determined. Therefore, the aim of this study was to investigate the effect of temperature and time during sous vide processing on the quality properties of beef short ribs, namely colour, cooking loss (%), shrinkage (%), soluble collagen (%), myofibrillar fragmentation index (MFI), Warner Bratlzler Shear force (WBSF), and Texture Profile Analysis (TPA) parameters and optimise sous vide time and temperature. In addition, the effect of two packaging materials (a heat stable polybags and polyethylene, ethylene vinyl alcohol and polyamide polymer and aluminium laminate) on the meat colour will be studied.

Material and Methods

Meat Samples

Beef short ribs (Transversus thoracis muscle) from both left and right sides were obtained from five steers (15 months old, Angus breed) raised in the same pasture-based farm. Pre-rigor short ribs were stored at 15 °C for 48 h until rigor, vacuum packed, and frozen to −18 °C. Before commencing the experiments, each short ribs consisting of five bones were cut longitudinally to 3 pieces (~ 8 × 8 × 6 cm3 pieces) and thawed at 4 °C for 16 h. Small size bones were discarded.

The study used a 3 × 3 full factorial design with sous vide temperatures of 60, 65, and 70 °C and sous vide times of 12, 24, and 36 h. To allocate the process variables, sous vide time was allocated to randomised short ribs from bone 1 to 3 (from top to bottom) and sous vide temperature (60, 65, and 70 °C) and a control were assigned using Latin square design and blocked by replicate. The number of replicates for each treatment combination was 10.

Sous vide Treatment

A pre-study investigating the effect of different packaging materials on meat appearance after sous vide treatment was carried out. Thermo-resistant vacuumable plastic polybag pouch and laminate Excel foil pouches (Contour Sales Packaging Systems, Tauranga, New Zealand) were used. The polybag pouches had a thickness of 70 µm, oxygen permeability was 50 cc/m2/day at 23 °C, carbon dioxide permeability was 200 cc/m2/day at 23 °C, nitrogen permeability was 12 cc/m2/day at 23 °C, and the water vapour transmission rate (WVTR) was 8 g/m2/day at 38 °C and a relative humidity of (RH) 90%. The Excel foil pouch was a laminated aluminium and three polymer layer film (polyethylene, ethylene vinyl alcohol, and polyamide) laminate of glued with food-grade adhesives that had a thickness of 79 µm, an oxygen permeability of ≤ 0.1 cc/m2/day at 23 °C, 65% RH, and a WVTR of ≤ 0.1 g/m2/day at 23 °C.

Short rib cuts were vacuum packed (0 bar) in either polybags or laminate bags and sealed by the vacuum packaging machine (Audionvac VMS 153, Derby, UK). The vacuum-packed short ribs were heated by submerging them in a water bath (PolyScience, IL, USA) at the required temperature (60, 65, and 70 °C) for 12, 24, or 36 h. The temperature–time profile of the water bath and inside the packaging was monitored using i-button (Thermochron, Deventer, The Netherlands). At the completion of sous vide treatment, the packed meat was immediately submerged in an ice-water bath for 1 h and the colour assessed by visual inspection and photographs taken. As meat packed in the plastic-aluminium laminate packaging had a more desirable pinkish-brown colour (see Fig. 1), the plastic-aluminium laminate was used for all subsequent sous vide experiments to determine the quality parameters and for the process optimisation. The short ribs were vacuum packed in the plastic-aluminium laminate, heated in the water bath at the required temperature (60, 65, and 70 °C) and time (12, 24, or 36 h) by the same method and using the same equipment. After the completion of sous vide treatment, the packed meat was immediately submerged in an ice-water bath for 1 h. After the completion of sous vide treatment, the package was then opened and Commission Internationale d’Eclairage (CIE) L*a*b* colour parameters, the weight of the meat, and the shrinkage in volume (% change in volume before and after sous vide) were immediately measured. The remaining sample was held at 4 °C until the texture parameters could be measured, which was within 24 h of opening the package. The remaining samples were stored at −80 °C for analysis of the soluble collagen (%) and myofibrillar fragmentation index.

Effect of different packaging materials on colour of beef short ribs processed by sous vide at various temperature and time: A Polybag pouch, thickness 70 µm, tensile strength of 37–52 N/mm2, oxygen permeability (OTR) 50 cc/m2/day at 23 °C, and water vapour transmission rate (WVTR) 8 g/m2/day at 38 °C and 90% relative humidity (RH); B Excel aluminium foil pouch 3-layer laminate of polyethylene, ethylene vinyl alcohol, and polyamide glued by food-grade adhesives, thickness 79 µm, OTR ≤ 0.1 cc/m2/day at 23 °C, 65% RH, and WVTR ≤ 0.1 g/m.2/day

Determination of Meat Colour

CIE–L* (white-black), a* (red-green), and b* (yellow-blue) values were measured using Hunter Lab Mini Scan XE Plus (Hunter Associates Laboratory Inc., Reston, VA, USA) with light source set at D-65 and observer set to 10°. The colorimeter was calibrated on a black tile and then a white enamel tile using Illuminant D-65 as directed by the manufacturer’s specifications. The positive values of L*, a*, and b* correspond to the higher degree of lightness, redness, and yellowness of meat, respectively. Five measurements were taken for each sample and the average values were reported. Chroma (C*), hue angle (h), delta E \((\Delta {E}^{*})\), and delta H (\(\Delta {H}^{*}\)) (Eqs. (1), (2), (3), and (4)) were calculated where \(\Delta {L}^{*}\), \(\Delta {a}^{*}\), \(\Delta {b}^{*}\), and \(\Delta C\) are difference in L*, a*, b*, and C* between the sous vide treated meat and raw meat. Delta E is the difference between two colours in the three-dimensional L*a*b* colour space, whereas delta H is the Euclidean difference, i.e. the direct difference between two points in a three-dimensional colour space.

Determination of Cooking Loss (%)

Cooking loss was measured as a percentage of loss in weight before and after sous vide treatment as described in Eq. (5).

Determination of Texture Parameters

WBSF and TPA were used to assess texture using a TA XT-2i Texture Analyser (Stable Micro Systems Ltd., Surrey, UK). Three cylindrical cores (2.0-cm length; 1.27-cm inner diameter) were obtained from the centre of each sous vide processed short ribs parallel to the direction of muscle fibre using a core borer. WBSF was measured by shearing the cylinders perpendicular to the direction of muscle fibres using a HDP/BS Warner–Bratzler blade with test speed of 10 mm/s. The peak shear force (N) during shearing was reported as WBSF. Load cell (5 kg) was used for determination of WBSF and TPA parameters.

For TPA measurement, each sous vide processed short ribs was cut parallel to the muscle fibre direction to form five 1 cm3 cubes. The short rib cubes were compressed axially in a 2-cycle sequence by a flat cylindrical plunger (P/50) perpendicular to the direction of muscle fibre. First, they were compressed up to a 50% of their original height at a crosshead speed of 2 mm s−1. The plunger then recoiled to the original position and the meat cubes were compressed again to 100% height at the same speed (Alahakoon et al., 2018). The TPA parameters determined from the force deformation curve were hardness, adhesiveness, cohesiveness, springiness, gumminess, chewiness, and resilience. Hardness was recorded on the first compression cycle of the probe. Adhesiveness was the area, in arbitrary instrumental units, of the negative peak beneath the base line of the profile, and represents the work necessary to pull the plunger from the sample. Cohesiveness was defined as a ratio of the area, in arbitrary units, under the second peak and the area under the first peak. Springiness was defined as the rate at which a deformed meat sample returned to its undeformed condition after the deforming force is removed. Gumminess was defined as the energy required to disintegrate the meat to a state ready for swallowing. Chewiness was defined as the energy required to masticate the meat to a state ready for swallowing and resilience was the ability of the meat sample to recover its original height (Nishinari & Fang, 2018; Wee et al., 2018).

Determination of Soluble Collagen (%)

The amount of soluble collagen after sous vide processing was determined using a modified procedure of Hill (1966), in which the piece of meat was thawed overnight at 4 °C and 4 g of minced meat (using mixer, Watson, New Zealand) was heated at 77 °C in 12 ml of 25% strength Ringer’s solution for 70 min, with shaking at 10-min interval. The samples were then centrifuged (2300 × g at 4 °C for 30 min) and the supernatant containing the soluble collagen was collected. Ringer’s solution (8 ml) was added to the meat residue and the mixture was centrifuged (2300 × g at 4 °C for 30 min) and the supernatant was collected. The pooled collected supernatant was hydrolysed in 30 ml H2SO4 (7 N) for 18 h at 105 ± 1 °C and the hydroxyproline concentration and the amount of soluble collagen were determined (Kolar, 1990). To determine the total collagen, 4 g of minced sous vide processed meat was hydrolysed in H2SO4 (7 N) for 18 h at 105 ± 1 °C and the hydroxyproline content determined. This was converted to collagen content by multiplying the hydroxyproline content by 7.25 for total collagen (Goll et al., 1963) and 7.52 for soluble collagen (Cross et al., 1973). The proportion of soluble collagen was expressed as a percentage of total collagen.

Determination of Myofibrillar Fragmentation Index (MFI)

MFI was determined according to a modified method of Aroeira et al. (2020). First, 1-g-thin slices of lean meat were mixed in 40-mL cold (4 °C) buffer solution (100 mM–potassium chloride, 1 mM, 20 mM–potassium phosphate, 1 mM–magnesium chloride, 1 mM–sodium azide, and 1 mM–ethylenediaminetetraacetic acid disodium salt) and homogenised using an ultra-turrax (IKA® Works (Asia) Sdn Bhd, Selangor, Malaysia) at 15,000 rpm for 30 s for three runs. The resulting suspension was centrifuged at 2300 × g for 30 min and the supernatant was discarded. The pellet was re-suspended in ice-cold buffer (40 mL) and re-centrifuged (2300× g, 30 min). The resulting pellet was suspended in buffer (20 mL) and homogenised. Finally, filtrate from a metal sieve (18 mesh) was collected.

The protein concentration of the filtrate was determined using the Lowry method (Wrolstad et al., 2005) after diluting the filtrate to a final protein concentration of 0.5 ± 0.05 mg/mL with buffer. The absorbance of the diluted protein suspensions was measured immediately at 540 nm with a spectrophotometer (Speccord 50 plus, Analytik Jena GmbH, Jena, Germany). The mean of the triplicate absorbance readings was multiplied by 200 to expand the absorbance units to obtain the MFI (Culler et al., 1978).

Visual Grading for the Degree of Meat Attachment to the Bone

The degree attachment of the meat to the bone was visually ranked on 1–5 ordinal scale, with 1 being meat attached completely to the bone and 5 being the meat completely separated from the bone.

Data Analysis

The effect of sous vide processing parameters, temperature (60, 65, and 70 °C) and time (12, 24, and 36 h), on the L*a*b* colour profile, cooking loss, instrumental textural parameters, shrinkage in volume (%), soluble collagen (%), and MFI was analysed by two-way analysis of variance (ANOVA) using a full factorial model (IBM SPSS Statistics for Windows, Version 26.0. Armonk, NY: IBM Corp, USA). The post hoc test for multiple comparisons was done by Student–Newman–Keuls (SNK) tests for temperature and time when there is no significant (P > 0.05) interaction. When there was a significant interaction (p < 0.05), multiple pairwise comparisons for significant temperature or time effects were analysed using LSD multiple comparison for individual time or temperature with adjusted level of significance of 1.6667%. The degree of meat and bone attachment was analysed by nonparametric Kruskal–Wallis test and pairwise comparison was done at significance adjusted by Bonferroni correction.

The optimisation of sous vide temperature and time for response variable was carried out by fitting a third-order multiple regression model (Eq. (7)) using Minitab Version 18.1, Minitab, Inc., USA.

where \(Y\) is the response variable, \({X}_{1}\) and \({X}_{2}\) are sous vide temperature and time, respectively; \({\beta }_{0}\) is the coefficient or constant terms. The linear coefficients for \({X}_{1}\) and \({X}_{2}\) are \({\beta }_{1}\) and \({\beta }_{2}\), respectively; linear interaction coefficient is \({\beta }_{3}\). \({\beta }_{4}\) and \({\beta }_{5}\) are quadratic coefficients; \({\beta }_{6}\) and \({\beta }_{7}\) are higher order interaction coefficients for \({X}_{1}\) and \({X}_{2}\), respectively; \({\beta }_{8}\) and \({\beta }_{9}\) are cubic coefficients; \(e\) is the error term. The model was simplified by backward elimination, with an elimination criteria of α = 0.05, to remove insignificant terms. The optimal area was determined from an overlaid contour plot of the significant response variable terms and optimum value of sous vide process variable temperature and time were calculated by response optimiser using simplified model for cooking loss, WBSF, TPA hardness, hue angle, and Chroma and change in Chroma after and before sous vide.

Results and Discussion

Effect of Different Packaging Materials on Colour of Cooked Meat

The effect of different packaging materials on the colour of sous vide–treated short ribs was investigated at the beginning of this study. The results showed that the use of triple-layer Excel foil laminates could retain the meat colour during sous vide compared to polybag pouches (Fig. 1). When heating the meat in Excel foil laminates either at 60 °C for 12, 24, or 36 h, or at 65 °C for 12 h, the colour of cooked meat was light pink. After heating at 65 °C for 24 and 36 h, the meat colour turned pinkish-brown. The discolouration occurred due to oxidation of myoglobin to metmyoglobin (Abril et al., 2001; Roldán et al., 2013). Heating at 70 °C caused the meat colour to progressively become browner as the cooking time was increased. Heating the meat in vacuum packed polyethylene pouch bags caused the meat colour to turn a blackish-brown at all cooking time–temperature combinations due to the oxidation of myoglobin to metmyoglobin. Increased oxidation of myoglobin took place due to higher oxygen permeability of polybags (50 cc/m2/day) compared to that of plastic-aluminium foil laminate (≤ 0.1 cc/m2/day) at 23 °C. Thus, the plastic-aluminium foil laminate bags were chosen for further sous vide treatments.

Effect of Sous vide Temperature and Time on the Quality Properties of Beef Short Ribs

The most important meat quality parameters are colour, flavour, juiciness, and tenderness (Listrat et al., 2016). Consumers judge meat freshness based on colour whereas tenderness influences their repurchasing decision (Bekhit et al., 2016; Suwandy et al., 2015b). Therefore, a processing technology, which can improve tenderness and flavour, while preserving colour and minimising loss of water, is of significant value (Kantono et al., 2019). The effect of sous vide processing parameters, temperature and time, on the meat quality parameters such as shrinkage in volume (%), cooking loss (%), CIE colour parameters, and instrumental texture parameters was assessed by full factorial two-way ANOVA.

There was a significant (p < 0.05) effect of sous vide temperature and time on the decrease in volume (shrinkage) and cooking loss (Table 1). The interaction effect for both parameters was not significant (p > 0.05). The degree of shrinkage (overall mean) in the short ribs significantly (p < 0.05) increased as the sous vide temperature was increased from 60 to 70 °C. Similarly, the percentage shrinkage (overall mean) of the meat significantly (p < 0.05) increased when the sous vide time was increased from 12 to 24 h; but no difference was observed between 24 and 36 h. It was observed after 24-h cooking that there was a significant (p < 0.05) difference in shrinkage between short ribs cooked at 60 and 70 °C but the difference in shrinkage at these temperatures was not significant (p > 0.05) after 36-h SV.

There was a significant (p < 0.05) increase in cooking loss (%) as sous vide temperature and time were increased. The overall mean cooking loss (%) of short ribs sous vide processed at 70 °C was significantly higher (p < 0.05) than ribs heated at 65 or 60 °C; and at 65 °C, cooking loss was significantly higher than at 60 °C. Significant (p < 0.05) difference in cooking loss (%) at different temperatures was observed in meat processed for 36 h. However, after 24, the difference in cooking loss was only significant between 60 and 70 °C. The cooking losses found in this study were lower compared to other studies on tough meat cuts, even at 70 °C (Bhat et al., 2020; Christensen et al., 2013; Ismail et al., 2019; Rinaldi et al., 2014). Bhat et al. (2020) reported cooking loss (%) of 28.67 ± 0.61, when sous vide processed for 10 h at 60 °C in beef semitendinosus muscle of dairy cows. Christensen et al. (2013) reported 26.6 and 25.9% cooking loss at 60 °C for 10 h for cows (4–6 years old) and young bulls (10–12 months), respectively. Ismail et al. (2019) reported 29.07% cooking loss at 60 °C for 12 h for semitendinosus muscles of Hanwoo steers (24–32 months). Rinaldi et al. (2014) reported 38.9% cooking loss at 75 °C for 36 h for beef semitendinosus muscle. However, the cooking losses in this study may have been reduced due to limited cooking loss of the bone present in the short rib sections. Roseland et al. (2015) stated that the cooking yield is higher in bone-in beef cuts than in bone-less cuts.

The shrinkage in volume reduced the water holding capacity (WHC) of the meat and increased the cooking loss, which is associated with a decrease in juiciness and succulence (Arroyo et al., 2015a; Dominguez-Hernandez et al., 2018). The WHC of meat also affects its texture, tenderness, and flavour (Arroyo et al., 2015a; Roldán et al., 2013). The shrinkage in volume and cooking loss were positively correlated (Pearson correlation coefficient 0.546, p < 0.01). Both significantly increased when sous vide temperature and cooking time were increased. The likely mechanism for the higher cooking loss at higher sous vide temperature and longer cooking time was the increased myofibrillar shrinkage and contraction. This phenomenon decreased the intracellular space and volume between strands of actin and myosin of sarcomere, and this consequently increased the expulsion of intracellular water (Baldwin, 2012; Bertram et al., 2002, 2006; Cheng & Sun, 2008; Micklander et al., 2005; Suwandy et al., 2015a). Intracellular water accounts about 70–75% of total water content of meat (Bertram et al., 2006). Furthermore, the higher the cooking temperature will be, the greater the denaturation of myofibrillar proteins will be. As myofibril proteins hold the major proportion of water in meat, their denaturation, especially of myosin, reduces the meat’s water holding capacity (Wiklund et al., 2001). Bertram et al. (2006) also showed a significant relationship between the increase in denaturation of myofibrillar proteins, seen by major changes in the FT-IR spectroscopic bands in the amide I-region (1700–1600 cm−1) and broadening of T21 (35–50 ms) NMR relaxometry peak, and a decrease in myofibrillar water during heating.

Soluble collagen (%) was significantly affected by sous vide temperature (p < 0.001), time (p = 0.008), and by the interaction between temperature and time (p = 0.01) (Table 1). Therefore, the effect of temperature on soluble collagen of short ribs was affected by the level of processing time and vice versa. The soluble collagen of ribs cooked at 70 °C had significantly higher than when cooked at 65 or 60 °C; and in addition, short ribs cooked at 65 °C were significantly higher than when cooked at 60 °C. This effect was observed for ribs sous vide for 36 h but in ribs cooked for 24 h, soluble collagen was only significantly higher at 70 °C than the other temperatures, and at 12 h soluble collagen was significantly lower at 60 °C than at 65 °C or 70 °C. Rochdi et al. (2000) stated that there was a significant correlation between solubility and the heating time (at 90 °C) of the epimysium and intramuscular connective tissue. Alahakoon et al. (2019) also observed an increase in soluble collagen (%) with an increase in sous vide cooking time from 12 to 24 h at 60 °C cooking temperature. An increase in solubilisation of the collagen with an increase in sous vide time and temperature is attributed to a higher degree of unfolding and breakage of cross-link of collagen fibres in the moist environment of sous vide processing (García-Segovia et al. (2007). When heating at 58–64 °C, collagen is changed from a crystalline helical structure to an amorphous random coiled structure and as the temperature increases from 65 to 70 °C the denaturation, solubilisation, and gelatinisation of the collagen increases (Dominguez-Hernandez et al., 2018). Similarly, the effect of sous vide temperature (p < 0.001) and time (p < 0.001) on the MFI was significant but the interaction term was not significant (p > 0.05) (Table 1). The MFI values increased with an increase in sous vide temperature and time. Jia et al. (2022) reported that there is a greater increase in the MFI of cooked meat compared to raw meat owing to an increase in the degradation of myofibrillar protein during heating. Thus, there may be an increase in degradation of acto-myosin complex with an increase in sous vide time–temperature.

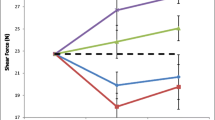

The tenderness of meat and meat products has a dramatic impact on consumer’s repurchasing decisions (Bolumar et al., 2013). The tenderness of a meat cut depends on the amount of connective tissue present and the extent of proteolysis of the myofibrillar proteins, as well as animal (age, breed), environmental, and genetic factors (Anderson et al., 2012). The effect of sous vide temperature and time on tenderness and texture parameters of short ribs instrumental parameters was assessed using WBSF and TPA parameters (Table 2). There was a significant effect of temperature and time (p < 0.05) on WBSF, hardness, cohesiveness, gumminess and chewiness, whereas adhesiveness, springiness, and resilience were only significantly affected by cooking time (p < 0.05).

WBSF (N), which is correlated to the shearing and compression during eating meat, was significantly affected by temperature and time (p = 0.026 and p < 0.001, respectively) (Table 2). However, a significant time–temperature interaction was observed (p = 0.010) indicating that the WBSF did not change the same way with temperature as time was changed. At sous vide time of 12 h, only ribs processed at 60 °C had significantly (p < 0.05) lower WBSF value than at 65 and 70 °C and after 24-h sous vide processing, no significant difference between the three temperatures was observed. However, at 36-h sous vide, a significant difference in WBSF was observed between ribs processed at 60 and 70 °C. However, WBSF values at all temperature and time combinations were lower than the threshold level for beef to be described as tender. Destefanis et al. (2008) and Dufey et al. (2017) concluded separately from consumer testing that beef meat with WBSF < 42.87 N and < 32.57 N (≤ 3.3 kg force), respectively, can be termed tender.

The trends observed for TPA hardness values of sous vide ribs were similar to the WBSF values. In TPA, hardness is maximum force encountered by the first depression of the probe, which is analogous to the hardness encountered upon the first bite; however, hardness perception continues during the subsequent mastication process (Nishinari & Fang, 2018). As with WBSF, a significant temperature–time interaction (p = 0.022) was observed for hardness values. The hardness was significantly lower after sous vide of ribs for 24 and 36 h and at 70 °C compared to sous vide for 12 h, at 60 °C or 65 °C (Table 2). No difference was observed in hardness between ribs sous vide for 12 h at the three sous vide temperatures. However, after sous vide for 24 or 36 h, the hardness of meat sous vide at 70 °C was significantly lower than for sous vide at 60 °C.

Significantly lower WBSF values for sous vide treatment at 60 °C than at 65 or 70 °C after 12 h may be associated with lower degree of myofibrillar protein denaturation and lower level of shrinkage and cooking loss. It is well documented that as the cooking temperature increases, the degree of myofibrillar protein denaturation increases, as does the shrinkage of the sarcomere reducing its volume thereby resulting in meat becoming tough and dry. Higher cooking losses resulted in the tough meat (Roldán et al., 2013). The lower WBSF and hardness values in sous vide ribs after processing for 36 h at 70 °C compared to 60 °C might be due to the higher level of solubilisation and gelation of collagen and sarcoplasmic proteins even though the extent of denaturation may be similar. García-Segovia et al. (2007) concluded that a sous vide temperature of 70 °C even for 60 min resulted in a decrease in the toughness of meat due to increased denaturation, aggregation, and gelation of sarcoplasmic proteins in the saturated steam atmosphere created in sous vide package.

Similar results were observed by Vaudagna et al. (2002) and García-Segovia et al. (2007). Vaudagna et al. (2002) reported lower WBSF at 65 °C than at 50 °C. García-Segovia et al. (2007) reported a significant decrease in WBSF with an increase in sous vide temperature from 60 to 80 °C. This was credited to moist in-pack environment and overpressure created by saturated stream resulting in improved heat transfer, which led to greater unfolding and gelation of sarcoplasmic protein and myofibrillar protein as well as increased breakage of thermolabile bonds of triple helix structure of collagen, which increased its solubilisation (García-Segovia et al., 2007; Tornberg, 2005). This is supported by the observation that the percentage of soluble collagen was significantly higher (p < 0.05) at 70 °C than at 60 °C after 36-h sous vide processing (Table 1). In addition, Zielbauer et al. (2016) reported that the denaturation temperature and enthalpy are lower than the dry heating denaturation temperature and enthalpy of myofibrillar proteins during moist heating techniques, like sous vide emphasising that the same level of denaturation could be achieved at lower temperatures. The importance of solubilisation of collagen for enhancement of tenderness can be stressed from the observation by Alahakoon et al. (2018). They did not observe the significant increase in the amount of soluble collagen of beef brisket when sous vide temperature was increased from 60 to 70 °C processed for same time of 24 h and no subsequent decrease in WBSF values at that sous vide condition.

Meat tenderness is not only affected by the distribution and amount of connective tissues but also affected by the overlapping and disintegration of the myofibrillar structure (Aroeira et al., 2020; Sawdy et al., 2004). It is also stated that increase in tenderness is also due to higher degree of meat proteolysis indicated by MFI (Aroeira et al., 2020; Culler et al., 1978). The results discussed in the current study also agree with the above argument. Significantly lower WBSF and TPA hardness and significantly higher MFI was observed with increase in sous vide temperature and time.

For adhesiveness, which is the force required to separate the plunger and meat (Nishinari & Fang, 2018) indicating meat stickiness due to increased mass transfer towards the surface, short ribs sous vide for 36 h had significantly lower values than that SV for 12 or 24 h. This difference in overall mean was due to the difference in adhesiveness at sous vide time of 36 h at 70 °C which was in significantly lower than 12- and 24-h sous vide at 70 °C.

TPA cohesiveness, which relates to how much the meat regains its structure and is associated with the integrity of meat, was found to have significant time (p < 0.001), temperature (p < 0.00), and time–temperature interaction (p = 0.035). Regardless of whether meat was sous vide at 60, 65, or 70 °C, cohesiveness was significantly lower at 36 h than after 12 h. When assessing the effect of temperature at the same processing time, sous vide at 70 °C the cohesiveness is significantly lower than at 60 °C for 12, 24, or 36 h. These results indicate that the textural coherence and integrity decrease at SV temperature greater than or equal to 65 °C and at SV time of 36 h.

Springiness, previously called elasticity, of sous vide ribs, which is the rate at which deformed ribs return to its undeformed condition after the deforming force is removed, displayed a significant sous vide time–temperature interaction (p = 0.035) in addition to the significant (p < 0.001) time effect. Short ribs processed for 24 or 36 h at 70 °C had significantly lower springiness than that cooked for 12 h. Similarly, the sous vide time–temperature interaction was also significant (p < 0.05) for TPA gumminess. Short ribs sous vide processed for 24 or 36 h had significant gumminess lower than 12 h and these differences were also observed at 60, 65, or 70 °C. Gumminess of ribs sous vide at 70 °C was significantly lower than at 65 or 60 °C after sous vide for 12 h. This difference was observed in ribs sous vide for 24 or 36 h. Gumminess, energy required to disintegrate a semisolid food product to a state ready for swallowing (Nishinari & Fang, 2018), is derived from TPA hardness and cohesiveness. Therefore, based on the findings for hardness and cohesiveness, springiness and gumminess will decrease as the sous vide temperature is increased and sous vide time lengthened.

TPA chewiness is calculated from the primary parameters of hardness, cohesiveness, and elasticity (Nishinari & Fang, 2018). As the temperature was increased from 60 to 70 °C, chewiness significantly decreased and similarly increasing the sous vide time from 12 to 24 or 36 h significantly reduced the chewiness. At longer sous vide times of 24 or 36 h, higher sous vide temperature of 70 °C had significantly lower chewiness than at 60 °C. This effect was not observed at a sous vide time of 12 h, potentially reflecting the significant SV time and temperature interaction (p = 0.011). The same trends were observed for the resilience values where they significantly decreased in ribs sous vide for longer times at higher temperatures.

Meat colour is a critical quality attribute as the visual appearance of raw meat influences the consumer’s decision to purchase and the acceptance of the cooked meat (Arroyo et al., 2015b). The colour of fresh meat depends on the content and physicochemical state of myoglobin, i.e. purple (reduced myoglobin), red (oxymyoglobin), and brown (metmyoglobin) (Abril et al., 2001). The effect of sous vide temperature and time on CIE L*, a*, b*, Chroma (\({C}^{*}\)), and hue angle (h) are summarised in Table 3. Significant (p < 0.05) sous vide time and temperature effects were observed for L*; however, the time–temperature interaction was not significant (p > 0.05). A significant effect of time was also observed for hue angle, and there was a significant (p < 0.05) temperature effect for b*, C*, Δb*, and ΔE*. An interaction of sous vide time and temperature on the colour of ribs was observed for C*. These were the only colour parameters for which significant effects were observed. L* values of the sous vide rib surface were significantly higher at 60 °C than at 65 or 70 °C and ribs sous vide at 65 °C higher than at 70 °C. Similarly, 12-h sous vide had significantly higher L* values than for 24- or 36-h sous vide. The increase in the change in lightness (ΔL*), which is a comparison between the meat before and after sous vide, was significantly higher at 60 °C than at 65 or 70 °C. The higher lightness associated with ribs sous vide at lower temperature and shorter times is due to higher amount of free water on the surface (Sánchez del Pulgar et al., 2012), which is consistent with the cooking loss results.

The overall mean value of hue angle of ribs sous vide for 12 h was significantly higher than those sous vide for 24 or 36 h at 65 °C. C* of ribs sous vide at 60 °C was significantly higher of ribs sous vide at 65 or 70 °C. As C* and hue angle values explain the colour intensity and the relative position of colour between redness and yellowness, respectively (Bekhit et al., 2001), they are good indicators of metmyoglobin formation and increase in meat brownness (Khan et al., 2017; Suwandy et al., 2015c). The hue angle value generally increases because of myoglobin and oxymyoglobin oxidation (Bekhit & Faustman, 2005). The extent of oxidation of myoglobin depends on temperature, oxygen pressure, and lipid oxidation. The rate of myoglobin oxidation increases when the temperature is increased (Faustman et al., 2010). Examining the overall change in colour (ΔE*), ribs sous vide at 60 °C sous vide had a significantly higher ΔE* value than at 65 or 70 °C.

The attachment of the meat and bone after sous vide was measured on an ordinal scale from 1 to 5 (strongest to weakest attachment, respectively). The meat of ribs sous vide at 70 °C for 36 h had become more detached from the bone than all other sous vide conditions, except ribs sous vide at 65 °C for 36 h, based on a significantly higher median and mean rank (Table 4). At all other SV conditions, no significant reduction in the attachment of meat to bone occurred. Having said this, all other sous vide time and temperature combinations, except ribs sous vide at 60 °C for 12, 24 h, and ribs sous vide at 65 °C for 12 h, contained at least one sample where the meat was attached less tightly to the bone.

Optimisation of Sous vide Temperature and Time for Short Ribs

Optimisation of sous vide temperature and time was carried out by fitting a third-order multiple regression model using cooking loss (%), WBSF, TPA parameters, hue angle, and Chroma as response variables. The model was significant (p < 0.05) for all responses, except adhesiveness (Table 5). The lack of fit, which measures the ability of the model to describe the variability of data, was not significant (p = 0.3–0.8) reiterating that the regression equations adequately describe the data and predict the responses at any combination of sous vide temperature and time without significant deviation from the expected values.

The association of cooking loss (%) with the significant positive linear terms for time and temperature reflects that cooking loss increases as sous vide temperature and time increase. The significant quadratic term for time reflects that the rate of increase in cooking loss decreases as sous vide time increases (Fig. 2A). The significant negative coefficient of quadratic term of temperature and negative time–temperature interaction term for WBSF show that the WBSF potentially reaches maximum that varies between 65 and 70 °C depending upon sous vide time (Fig. 2B). In addition, the rate of decrease in WBSF with time increases as the temperature increases.

Surface plot of quality parameters at different sous vide temperature (°C) and time (h) A cooking loss (%), B Warner–Bratzler shear force (N), C TPA hardness (N), D TPA chewiness, E TPA resilience, F lightness (L*) after sous vide, G hue angle (h) after sous vide, H Chroma (C*) after sous vide, I change in chroma (ΔC*) after and before sous vide, and J soluble collagen (%) after sous vide

The linear and quadratic interaction terms in addition to the negative coefficient time and temperature terms for hardness indicate that the decrease in hardness with increase in sous vide time and temperature is complex (Fig. 2C). As sous vide temperature increases, the change in hardness of the ribs with increasing time goes from a very slight decrease at 60 °C, to a slight increase at 65 °C, to a large decrease at 70 °C. In addition, at 12-h sous vide, hardness of the ribs appears to be at a minimum at 65 °C. Significant negative coefficients for temperature and time observed for cohesiveness and gumminess showed that these texture parameters decreased with increasing temperature and time. For resilience in addition to the negative coefficients for sous vide temperature and time, there was a significant quadratic term for sous vide time. This suggests that as the sous vide time and temperature increased the resilience decreased and the rate of decrease with time slowed at time increased. The only significant term for chewiness was negative linear term for temperature indicating that as sous vide temperature increased chewiness of the ribs decreased and that sous vide time did not have a significant effect on chewiness of the ribs.

The significant negative sous vide temperature, time, and quadratic temperature terms for the instrumental colour parameter, L* indicate that as temperature and time increased, L* decreased though the rate of decrease in L* became smaller as the temperature approached to 70 °C (Fig. 2F). Similarly, the significant and negative linear coefficient of SV time and temperature showed that hue decreased with increasing temperature and time (Fig. 2G). The positive and significant quadratic terms of C* for time explained that the minima reached at around 24 h and further increase in C* after that time (Fig. 2H). The change in chroma after and before sous vide (ΔC*) had significant negative term for linear term for time and positive quadratic term for temperature, which depicted that the ΔC* is lowest at 65 °C and time above 34 h. Significant positive linear interaction between temperature and time and quadratic terms of temperature for soluble collagen (%) showed that the rate of its increase enhanced with elevating in temperature and prolonging sous vide time (Fig. 2I). However, the change in hue angle after and before sous vide (Δh) had no significant terms for temperature and time.

The optimal sous vide temperature and time to achieve the highest tenderness, and lowest hue angle, C*, and ΔC* while achieving the lowest cooking loss were calculated by response optimiser to be 60 °C and 34.06 h, respectively, with an optimal desirability of 0.53. This resulted in cooking loss (%), WBSF, TPA hardness, hue angle, C*, and ΔC*of 18.15%, 17.65 N, 20.79 N, 54.58, 18.15, and −1.98, respectively. These values are very near to the experimental values of cooking loss (%), WBSF, TPA hardness, hue angle, and C* for sous vide of ribs at 60 °C for 36 h, which were 17.71%, 18.51 N, 21.091 N, 55.01, 17.95, respectively. Under the optimum sous vide conditions, the attachment of the meat to the bone was not significantly different from the lowest rank value. This is supported by an overlay of all the contour plots which shows the wider optimal window for sous vide conditions of ribs to be a time of 24 to 35 h and temperature of 60 to 63 °C (Fig. 3).

The overlaid contour plot showing effect of sous vide temperature and time on the lower and upper limit of cooking loss (%), Warner–Bratzler shear force (WBSF), TPA hardness, hue angle, and chroma. The white area covering the temperature range of 60 to 63 °C and time range of 24 to 36 h respresents the optimum feasible area of sous vide processing

Conclusion

The shrinkage in volume (%), cooking loss (%), soluble collagen (%), and MFI increased significantly (p < 0.05) with an increase in temperature or time. There was a significantly lower WBSF and TPA hardness value at 70 °C than at 60 °C for 36-h sous vide processing, due to an increase in the level of solubilisation and the gelation of the collagen. This might be credited to moist in-pack environment improved heat transfer due to overpressure created by saturated steam. The effect of sous vide temperature and time was not significant (p > 0.05) on CIE hue angle (h) and increase in hue angle (Δh) may have been due to the lower oxygen permeability of sous vide laminate pouch which reduced the oxidation of red oxymyoglobin and deoxymyoglobin to brown metmyoglobin. Based on a third-order multiple regression model, the optimum sous vide processing regime was found at 60 °C for 34.06 h resulting in the highest tenderness and colour parameters whilst minimizing cooking loss and achieving a cooked rib where meat and bone were well attached. These conditions are recommended for commercial sous vide of beef short ribs.

Data Availability

The data of the experiment are available upon request.

References

Abril, M., Campo, M. M., Onenc, A., Sanudo, C., Alberti, P., & Negueruela, A. I. (2001). Beef colour evolution as a function of ultimate pH. Meat Science, 58(1), 69–78. https://doi.org/10.1016/s0309-1740(00)00133-9

Alahakoon, A. U., Oey, I., Bremer, P., & Silcock, P. (2018). Optimisation of sous vide processing parameters for pulsed electric fields treated beef briskets. Food and Bioprocess Technology, 11(11), 2055–2066. https://doi.org/10.1007/s11947-018-2155-9

Alahakoon, A. U., Oey, I., Bremer, P., & Silcock, P. (2019). Process optimisation of pulsed electric fields pre-treatment to reduce the sous vide processing time of beef briskets. International Journal of Food Science and Technology, 54(3), 823–834. https://doi.org/10.1111/ijfs.14002

Anderson, M. J., Lonergan, S. M., Fedler, C. A., Prusa, K. J., Binning, J. M., & Huff-Lonergan, E. (2012). Profile of biochemical traits influencing tenderness of muscles from the beef round. Meat Science, 91(3), 247–254. https://doi.org/10.1016/j.meatsci.2012.01.022

Aroeira, C. N., Torres Filho, R. A., Fontes, P. R., Ramos, A. L. S., Contreras Castillo, C. J., Hopkins, D. L., & Ramos, E. M. (2020). Comparison of different methods for determining the extent of myofibrillar fragmentation of chilled and frozen/thawed beef across postmortem aging periods. Meat Science, 160, 107955. https://doi.org/10.1016/j.meatsci.2019.107955

Arroyo, C., Eslami, S., Brunton, N. P., Arimi, J. M., Noci, F., & Lyng, J. G. (2015a). An assessment of the impact of pulsed electric fields processing factors on oxidation, color, texture, and sensory attributes of turkey breast meat. Poultry Science, 94(5), 1088–1095. https://doi.org/10.3382/ps/pev097

Arroyo, C., Lascorz, D., O’Dowd, L., Noci, F., Arimi, J., & Lyng, J. G. (2015b). Effect of pulsed electric field treatments at various stages during conditioning on quality attributes of beef longissimus thoracis et lumborum muscle. Meat Science, 99, 52–59. https://doi.org/10.1016/j.meatsci.2014.08.004

Baldwin, D. E. (2012). Sous vide cooking: A review. International Journal of Gastronomy and Food Science, 1(1), 15–30. https://doi.org/10.1016/j.ijgfs.2011.11.002

Bekhit, A. E. -D. A., & Faustman, C. (2005). Metmyoglobin reducing activity. Meat Science, 71(3), 407–439. https://doi.org/10.1016/j.meatsci.2005.04.032

Bekhit, A. E. -D. A., Geesink, G. H., Morton, J. D., & Bickerstaffe, R. (2001). Metmyoglobin reducing activity and colour stability of ovine longissimus muscle. Meat Science, 57(4), 427–435. https://doi.org/10.1016/S0309-1740(00)00121-2

Bekhit, A. E. -D. A., Suwandy, V., Carne, A., van de Ven, R., & Hopkins, D. L. (2016). Effect of repeated pulsed electric field treatment on the quality of hot-boned beef loins and topsides. Meat Science, 111, 139–146. https://doi.org/10.1016/j.meatsci.2015.09.001

Bertram, H. C., Kohler, A., Böcker, U., Ofstad, R., & Andersen, H. J. (2006). Heat-induced changes in myofibrillar protein structures and myowater of two pork qualities. A combined FT-IR spectroscopy and low-field NMR relaxometry study. Journal of Agricultural and Food Chemistry, 54(5), 1740–1746. https://doi.org/10.1021/jf0514726

Bertram, H. C., Purslow, P. P., & Andersen, H. J. (2002). Relationship between meat structure, water mobility, and distribution: A low-field nuclear magnetic resonance study. Journal of Agricultural and Food Chemistry, 50(4), 824–829. https://doi.org/10.1021/jf010738f

Bhat, Z. F., Morton, J. D., Zhang, X., Mason, S. L., & Bekhit, A. E. -D. A. (2020). Sous-vide cooking improves the quality and in-vitro digestibility of Semitendinosus from culled dairy cows. Food Research International, 127, 108708. https://doi.org/10.1016/j.foodres.2019.108708

Bolumar, T., Enneking, M., Toepfl, S., & Heinz, V. (2013). New developments in shockwave technology intended for meat tenderization: Opportunities and challenges. A Review. Meat Science, 95(4), 931–939. https://doi.org/10.1016/j.meatsci.2013.04.039

Botinestean, C., Keenan, D. F., Kerry, J. P., & Hamill, R. M. (2016). The effect of thermal treatments including sous-vide, blast freezing and their combinations on beef tenderness of M. semitendinosus steaks targeted at elderly consumers. LWT-Food Science and Technology, 74, 154–159. https://doi.org/10.1016/j.lwt.2016.07.026

Bouton, P. E., & Harris, P. V. (1981). Changes in the tenderness of meat cooked at 50–65-degrees-C. Journal of Food Science, 46(2), 475–478. https://doi.org/10.1111/j.1365-2621.1981.tb04889.x

Cheng, Q., & Sun, D. W. (2008). Factors affecting the water holding capacity of red meat products: A review of recent research advances. Critical Reviews in Food Science and Nutrition, 48(2), 137–159. https://doi.org/10.1080/10408390601177647

Christensen, L., Ertbjerg, P., Løje, H., Risbo, J., van den Berg, F. W. J., & Christensen, M. (2013). Relationship between meat toughness and properties of connective tissue from cows and young bulls heat treated at low temperatures for prolonged times. Meat Science, 93(4), 787–795. https://doi.org/10.1016/j.meatsci.2012.12.001

Church, I. J., & Parsons, A. L. (2000). The sensory quality of chicken and potato products prepared using cook–chill and sous vide methods. International Journal of Food Science & Technology, 35(2), 155–162. https://doi.org/10.1046/j.1365-2621.2000.00361.x

Cross, H. R., Carpenter, Z. L., & Smith, G. C. (1973). Effects of intramuscular collagen and elastin upon bovine muscle tenderness. Journal of Animal Science, 37(1), 258–258.

Culler, R., Parrish, F., Smith, G., & Cross, H. R. (1978). Relationship of myofibril fragmentation index to certain chemical, physical and sensory characteristics of bovine longissmus muscle. Journal of Food Science, 43, 1177.

Davey, C. L., Niederer, A. F., & Graafhuis, A. E. (1976). Effects of ageing and cooking on the tenderness of beef muscle. Journal of the Science of Food and Agriculture, 27(3), 251–256. https://doi.org/10.1002/jsfa.2740270309

Deok Jang, J., & Sun Lee, D. (2005). Development of a sous-vide packaging process for Korean seasoned beef. Food Control, 16(3), 285–291. https://doi.org/10.1016/j.foodcont.2004.03.008

Destefanis, G., Brugiapaglia, A., Barge, M. T., & Dal Molin, E. (2008). Relationship between beef consumer tenderness perception and Warner-Bratzler shear force. Meat Science, 78(3), 153–156. https://doi.org/10.1016/j.meatsci.2007.05.031

Dominguez-Hernandez, E., Salaseviciene, A., & Ertbjerg, P. (2018). Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms. Meat Science, 143, 104–113. https://doi.org/10.1016/j.meatsci.2018.04.032

Dufey, P. A., Silacci, P., Dougoud, B., Biolley, C., & Messadene, J. (2017). Validation of the standards used for the instrumental measurement of beef tenderness. Agrarforschung Schweiz, 8(7–8), 268–275. https://www.scopus.com/inward/record.uri?eid=2-s2.0-85025593225&partnerID=40&md5=076929791fb772e1b1d44f28dba00541. Accessed 12 Sept 2021

Eberly, L. E. (2007). Multiple linear regression. In W. T. Ambrosius (Ed.), Topics in Biostatistics (pp. 165–187). Humana Press. https://doi.org/10.1007/978-1-59745-530-5_9

Faustman, C., Sun, Q., Mancini, R., & Suman, S. P. (2010). Myoglobin and lipid oxidation interactions: Mechanistic bases and control. Meat Science, 86(1), 86–94. https://doi.org/10.1016/j.meatsci.2010.04.025

García-Segovia, P., Andrés-Bello, A., & Martínez-Monzó, J. (2007). Effect of cooking method on mechanical properties, color and structure of beef muscle (M. pectoralis). Journal of Food Engineering, 80(3), 813–821. https://doi.org/10.1016/j.jfoodeng.2006.07.010

Gok, V., Uzun, T., Tomar, O., Caglar, M. Y., & Caglar, A. (2019). The effect of cooking methods on some quality characteristics of gluteus medius. Food Science and Technology, 39(4), 999–1004. https://doi.org/10.1590/fst.13018

Goll, D. E., Hoekstra, W. G., & Bray, R. W. (1963). Age-associated changes in muscle compositoin- isolation and properties of collagenous residue from bovine muscle. Journal of Food Science, 28(5), 503–510. https://doi.org/10.1111/j.1365-2621.1963.tb00234.x

Gonzalez-Fandos, E., Garcia-Linares, M. C., Villarino-Rodriguez, A., Garcia-Arias, M. T., & Garcia-Fernandez, M. C. (2004). Evaluation of the microbiological safety and sensory quality of rainbow trout (Oncorhynchus mykiss) processed by the sous vide method. Food Microbiology, 21(2), 193–201. https://doi.org/10.1016/s0740-0020(03)00053-4

Hansen, T. B., Knøchel, S., Juncher, D., & Bertelsen, G. (1995). Storage characteristics of sous vide cooked roast beef. International Journal of Food Science & Technology, 30(3), 365–378. https://doi.org/10.1111/j.1365-2621.1995.tb01384.x

Hill, F. (1966). The solubility of intramuscular collagen in meat animals of various ages. Journal of Food Science, 31(2), 161–170. https://doi.org/10.1111/j.1365-2621.1966.tb00472.x

Ismail, I., Hwang, Y. -H., & Joo, S. -T. (2019). Interventions of two-stage thermal sous-vide cooking on the toughness of beef semitendinosus. Meat Science, 157, 107882. https://doi.org/10.1016/j.meatsci.2019.107882

James, B. J., & Yang, S. W. (2012). Effect of cooking method on the toughness of bovine M. Semitendinosus. International Journal of Food Engineering, 8(2). https://doi.org/10.1515/1556-3758.2762

Jia, W., Zhang, R., Liu, L., Zhu, Z., Mo, H., Xu, M., Shi, L., & Zhang, H. (2022). Proteomics analysis to investigate the impact of diversified thermal processing on meat tenderness in Hengshan goat meat. Meat Science, 183, 108655. https://doi.org/10.1016/j.meatsci.2021.108655

Kantono, K., Hamid, N., Oey, I., Wang, S., Xu, Y., Ma, Q., Faridnia, F., & Farouk, M. (2019). Physicochemical and sensory properties of beef muscles after Pulsed Electric Field processing. Food Research International, 121, 1–11. https://doi.org/10.1016/j.foodres.2019.03.020

Khan, A. A., Randhawa, M. A., Carne, A., Mohamed Ahmed, I. A., Barr, D., Reid, M., & Bekhit, A. E. -D. A. (2017). Effect of low and high pulsed electric field on the quality and nutritional minerals in cold boned beef M. longissimus et lumborum. Innovative Food Science & Emerging Technologies, 41, 135–143. https://doi.org/10.1016/j.ifset.2017.03.002

Kolar, K. (1990). Colorimetric determination of hydroxyproline as measure of collagen content in meat and meat -product - NMKL collagorative study. Journal of the Association of Official Analytical Chemists, 73(1), 54–57.

Lassen, A., Kall, M., Hansen, K., & Ovesen, L. (2002). A comparison of the retention of vitamins B1, B2 and B6, and cooking yield in pork loin with conventional and enhanced meal-service systems. European Food Research and Technology, 215(3), 194–199. https://doi.org/10.1007/s00217-002-0554-6

Listrat, A., Lebret, B., Louveau, I., Astruc, T., Bonnet, M., Lefaucheur, L., Picard, B., & Bugeon, J. (2016). How muscle structure and composition influence meat and flesh quality. ScientificWorldJournal, 2016, 3182746. https://doi.org/10.1155/2016/3182746

Micklander, E., Bertram, H. C., Marno, H., Bak, L. S., Andersen, H. J., Engelsen, S. B., & Norgaard, L. (2005). Early post-mortem discrimination of water-holding capacity in pig longissimus muscle using new ultrasound method. LWT-Food Science and Technology, 38(5), 437–445. https://doi.org/10.1016/j.lwt.2004.07.022

Nishinari, K., & Fang, Y. (2018). Perception and measurement of food texture: Solid foods. Journal of Texture Studies, 49(2), 160–201. https://doi.org/10.1111/jtxs.12327

Rinaldi, M., Dall’Asta, C., Paciulli, M., Cirlini, M., Manzi, C., & Chiavaro, E. (2014). A novel time/temperature approach to sous vide cooking of beef muscle. Food and Bioprocess Technology, 7(10), 2969–2977. https://doi.org/10.1007/s11947-014-1268-z

Rochdi, A., Foucat, L., & Renou, J. -P. (2000). NMR and DSC studies during thermal denaturation of collagen. Food Chemistry, 69(3), 295–299. https://doi.org/10.1016/S0308-8146(99)00267-8

Roldán, M., Antequera, T., Martín, A., Mayoral, A. I., & Ruiz, J. (2013). Effect of different temperature–Time combinations on physicochemical, microbiological, textural and structural features of sous-vide cooked lamb loins. Meat Science, 93(3), 572–578. https://doi.org/10.1016/j.meatsci.2012.11.014

Roseland, J. M., Nguyen, Q. V., Williams, J. R., Douglass, L. W., Patterson, K. Y., Howe, J. C., Brooks, J. C., Thompson, L. D., Woerner, D. R., Engle, T. E., Savell, J. W., Gehring, K. B., Cifelli, A. M., & McNeill, S. H. (2015). Protein, fat, moisture and cooking yields from a U.S. study of retail beef cuts. Journal of Food Composition and Analysis, 43, 131–139. https://doi.org/10.1016/j.jfca.2015.04.013

Sánchez del Pulgar, J., Gázquez, A., & Ruiz-Carrascal, J. (2012). Physico-chemical, textural and structural characteristics of sous-vide cooked pork cheeks as affected by vacuum, cooking temperature, and cooking time. Meat Science, 90(3), 828–835. https://doi.org/10.1016/j.meatsci.2011.11.024

Sawdy, J. C., Kaiser, S. A., St-Pierre, N. R., & Wick, M. P. (2004). Myofibrillar 1-D fingerprints and myosin heavy chain MS analyses of beef loin at 36 h postmortem correlate with tenderness at 7 days. Meat Science, 67(3), 421–426. https://doi.org/10.1016/j.meatsci.2003.11.014

Schellekens, M. (1996). New research issues in sous-vide cooking. Trends in Food Science & Technology, 7(8), 256–262. https://doi.org/10.1016/0924-2244(96)10027-3

Smith, C. J., Olszewska, M. A., & Diez-Gonzalez, F. (2021). Selection and application of natural antimicrobials to control Clostridium perfringens in sous-vide chicken breasts. International Journal of Food Microbiology, 347, 109193. https://doi.org/10.1016/j.ijfoodmicro.2021.109193

Stea, T. H., Johansson, M., Jagerstad, M., & Frolich, W. (2007). Retention of folates in cooked, stored and reheated peas, broccoli and potatoes for use in modern large-scale service systems. Food Chemistry, 101(3), 1095–1107. https://doi.org/10.1016/j.foodchem.2006.03.009

Suwandy, V., Carne, A., van de Ven, R., Bekhit, A. E. -D. A., & Hopkins, D. L. (2015a). Effect of pulsed electric field treatment on hot-boned muscles of different potential tenderness. Meat Science, 105, 25–31. https://doi.org/10.1016/j.meatsci.2015.02.009

Suwandy, V., Carne, A., van de Ven, R., Bekhit, A. E. -D. A., & Hopkins, D. L. (2015b). Effect of pulsed electric field treatment on the eating and keeping qualities of cold-boned beef loins: Impact of initial pH and fibre orientation. Food and Bioprocess Technology, 8(6), 1355–1365. https://doi.org/10.1007/s11947-015-1498-8

Suwandy, V., Carne, A., van de Ven, R., Bekhit, A. E. -D. A., & Hopkins, D. L. (2015c). Effect of repeated pulsed electric field treatment on the quality of cold-boned beef loins and topsides. Food and Bioprocess Technology, 8(6), 1218–1228. https://doi.org/10.1007/s11947-015-1485-0

Tornberg, E. (2005). Effects of heat on meat proteins - Implications on structure and quality of meat products. Meat Science, 70(3), 493–508. https://doi.org/10.1016/j.meatsci.2004.11.021

Vaudagna, S. R., Pazos, A. A., Guidi, S. M., Sanchez, G., Carp, D. J., & Gonzalez, C. B. (2008). Effect of salt addition on sous vide cooked whole beef muscles from Argentina. Meat Science, 79(3), 470–482. https://doi.org/10.1016/j.meatsci.2007.11.001

Vaudagna, S. R., Sánchez, G., Neira, M. S., Insani, E. M., Picallo, A. B., Gallinger, M. M., & Lasta, J. A. (2002). Sous vide cooked beef muscles: Effects of low temperature–long time (LT–LT) treatments on their quality characteristics and storage stability. International Journal of Food Science & Technology, 37(4), 425–441. https://doi.org/10.1046/j.1365-2621.2002.00581.x

Wee, M. S. M., Goh, A. T., Stieger, M., & Forde, C. G. (2018). Correlation of instrumental texture properties from textural profile analysis (TPA) with eating behaviours and macronutrient composition for a wide range of solid foods. Food & Function, 9(10), 5301–5312. https://doi.org/10.1039/C8FO00791H

Wiklund, E., Stevenson-Barry, J. M., Duncan, S. J., & Littlejohn, R. P. (2001). Electrical stimulation of red deer (Cervus elaphus) carcasses – Effects on rate of pH-decline, meat tenderness, colour stability and water-holding capacity. Meat Science, 59(2), 211–220. https://doi.org/10.1016/S0309-1740(01)00077-8

Wrolstad, R. E., Acree, T. E., Decker, E. A., Penner, M. H., Reid, D. S., Schwartz, S. J., Shoemaker, C. F., Smith, D. M., & Sporns, P. (2005). Handbook of food analytical chemistry, volume 1: Water, proteins, enzymes, lipids, and carbohydrates. John Wiley & Sons.

Zielbauer, B. I., Franz, J., Viezens, B., & Vilgis, T. A. (2016). Physical aspects of meat cooking: Time dependent thermal protein denaturation and water loss. Food Biophysics, 11(1), 34–42. https://doi.org/10.1007/s11483-015-9410-7

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. This work was supported by the Food Industry Enabling Technologies (FIET) program funded by the New Zealand Ministry of Business, Innovation and Employment (contract MAUX1402). Oey is affiliated to the Riddet Institute, a New Zealand Centre of Research Excellence, funded by the Tertiary Education Commission.

Author information

Authors and Affiliations

Contributions

Roman Karki: data curation, methodology, software, formal analysis, investigation, validation, visualisation, roles/writing–original draft, conceptualisation, roles/writing–original draft and editing. Phil Bremer: conceptualisation, funding acquisition, investigation, methodology, project administration, writing–review and editing. Patrick Silcock: conceptualisation, funding acquisition, investigation, methodology, project administration, writing–review and editing. Indrawati Oey: conceptualisation, funding acquisition, investigation, methodology, project administration, resources, software, supervision, writing–review and editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Karki, R., Bremer, P., Silcock, P. et al. Effect of Sous vide Processing on Quality Parameters of Beef Short Ribs and Optimisation of Sous vide Time and Temperature Using Third-Order Multiple Regression. Food Bioprocess Technol 15, 1629–1646 (2022). https://doi.org/10.1007/s11947-022-02849-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02849-6