Abstract

Okra (Abelmoschus esculentus) has interesting nutritional and technological properties and is naturally gluten-free (GF). This study investigated the physicochemical properties of okra powder obtained by a low-temperature drying process and its impact on GF bread. Its potential synergy with other hydrocolloids (i.e., hydroxypropylmethylcellulose (HPMC) and Psyllium fibre (Psy)) was also studied. As the importance of powder particle size in food design is well known, whole okra powder (WOP; ≤ 1000 µm) and fine okra powder (FOP; ≤ 250 µm) were produced. Compared to the standard formulation, WOP and FOP doughs required less water to reach the desired dough consistency (200 ± 20 Brabender unit) and generally showed higher stability during mixing. Dough development was affected by HPMC more than okra powder particle size. Breads containing WOP or FOP in combination with HPMC exhibited high specific volume and soft texture, while the combination with Psy resulted in a less-developed, harder and darker bread. The combination with HPMC also guaranteed a longer shelf-life, regardless of okra powder particle size. These results may prove useful for the agri-food industry, as they demonstrate that okra can be used as an innovative natural hydrocolloid.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Okra (Abelmoschus esculentus (L.) Moench) is a plant belonging to the Malvaceae family and is native to tropical and subtropical countries, but in recent years has spread to other areas, such as central and southern Italy. The ripe fruit looks like an elongated green pod (for this reason it is also known as “ladies’ fingers”) with violet shades, which can change with the variety of the plant. The whole pod is edible as well as its leaves, buds, and flowers (Farinde et al., 2006). According to Romdhane et al. (2020), okra pods consist of 81.9 g/100 g water, 8.2 g/100 g total dietary fibre (of which 4.7 g/100 g insoluble fibre and 3.4 g/100 g soluble fibre), 4.9 g/100 g carbohydrates, 3.6 g/100 g crude proteins, 1.5 g/100 g ash, 0.07 g/100 g fat and 50.6 kcal/100 g of energy. Furthermore, okra pods contain vitamins (e.g. vitamin A, B C, E and K), minerals (e.g. K and Ca), quercitin compounds, polyphenols, unsaturated fatty acids, essential amino acids, antioxidants, antimicrobials and few antinutritional compounds (Gemede et al., 2016); consequently, okra is sometimes used for cardiovascular, kidney and cerebral protection as well as antitumoural, anti-inflammatory, analgesic, antiulcerous, antibacterial, antidiabetic and anticholesterolemic purposes; okra is also efficient against asthenia and fatigue (Durazzo et al., 2019). Okra is also listed in the “Herbs for Voice Database” as one of the plants traditionally used for voice care, throat affections and respiratory impairments (Calcinoni et al., 2020).

Mucilage, mainly pectins (13.6 g/100 g dry based; dos Santos et al., 2019), can be extracted from fresh okra. Pectins are widely used in the food industry as an agricultural waste recovery agent (Archana et al., 2013), as well as a freezing and stabilizing agent in food emulsions (Alba et al., 2013) and as a flavouring and thickening agent in confectionery (Farinde et al., 2006). For instance, polysaccharides deriving from okra are used as emulsifiers, fat replacers and stabilisers in ice cream, chocolate, mousses, chips, cookies, cakes and tortillas (Datsomor et al., 2019; Kissiedu et al., 2020; Romanchik-Cerpovicz et al., 2002, 2006; Yuennan et al., 2014). However, since fresh okra is not always available in some countries and is highly perishable at room temperature because of its high moisture content, it is necessary to preserve the commodity. The traditional method for preserving okra involves slicing and sun drying (Falade & Omojola, 2010), then the fruit, with or without seeds, can be ground into powder. For example, Wirivutthikorn (2019, 2020), stabilised okra by a hot air oven treatment at 75 °C, while Sonkar et al. (2015) combined sun drying with hot air oven at 55–65 °C. At the industrial level, even other drying technologies (e.g. vacuum drying, microwave-vacuum, etc.) can be used to dehydrate perishable foods, as extensively described by Mujumdar and Law (2010). For instance, Alamri (2014) applied a freeze-drying process to obtain okra mucilage to add to a formulation for gluten-containing bread resulting in a dough with a greater capacity to absorb water and higher kneading tolerance but with weaker viscoelastic properties. Similarly, Bhat and Tharanathan (1987) used mucilage (extracted from okra pods and dried by solvent exchange) in wheat bread demonstrating that okra had interesting gelling and foaming properties due to its high water absorption and retention capacity. Morover, Xu et al. (2020) observed that wheat breads containing okra powder (obtained by air-drying at 40 °C) were characterised by reduced amylase activity, creating a greater sense of satiety because of the reduction in starch digestion rate.

In addition to its high nutritional value, widely discussed in the literature, okra is naturally gluten-free (GF) so it could be used (and valorised) for the production of GF products that have increased enormously in recent decades. In particular, GF breads are often characterised by structural and textural defects because of the lack of gluten, leading to dough that does not rise properly. Furthermore, GF breads are often characterised by crumbly texture that can impact negatively on consumer acceptance (Chakraborty et al., 2020). Hydrocolloids and other ingredients having a high affinity for water (e.g. hydroxypropylmethylcellulose (HPMC), guar gum, carboxymethylcellulose, xanthan, pectin, Psyllium (Psy), etc.) are generally used to modulate the viscoelastic properties of dough and the softness of the final product (Cappa et al., 2016a; Lazaridou et al., 2007; Mariotti et al., 2013; Sciarini et al., 2012). For instance, Mariotti et al. (2013) showed that HPMC limits both the diffusion and the loss of water from the bread crumb and the interactions between starch and protein macromolecules, resulting in a softer GF bread crumb and reducing staling kinetics during storage. Furthermore, the same authors revealed that the incorporation of ingredients having high dietary fibre content (such as buckwheat) improved dough development due to an increased viscosity and to the swelling, gelling and emulsion-forming properties of the flour used. Okra, thanks to its mucilage and fibre contents, could be a potential and unconventional ingredient to develop GF bread, eventually avoiding synthetic hydrocolloid (such as HPMC) that is not always well-accepted by consumers. However, as far as we know, there are no published studies concerning the use of okra in GF bread, especially as a powder.

The aim of this study was to produce okra powder by applying a low-temperature drying process to preserve heat-sensitive materials (e.g. mucilage) before grinding. As powder particle size in food design is known to be important, whole okra powder (WOP; particle size ≤ 1000 µm) and fine okra powder (FOP; particle size ≤ 250 µm) were produced and their physicochemical properties were evaluated. The technological properties of the GF doughs containing the newly produced okra powders and the quality of the resultant fresh and stored breads were investigated in respect to a reference sample containing HPMC and Psy.

Materials and Methods

Materials

Fresh okra (Abelmoschus esculentus) pods, belonging to the Clemson Spineless variety (origin: Honduras), were purchased from a local market in Milan (Italy). As pod size can affect proximate composition (Petropoulos et al., 2018), only pods having a length ranging from 107.7 to 174.3 mm were selected for the present study.

In order to produce GF breads, the following ingredients were used: rice flour (Beneo-Remy, Leuven-Wijgmaal, Belgium), corn starch (Roquette America Inc., IA, USA), pea proteins (IPP-F9 Cosucra, Warcoing, Belgium), Psy (Roeper GmbH, Germany), HPMC (UNIVAR S.p.A., Italy), extravirgin olive oil (Farchioni S.p.A., Giano dell’Umbria, Italy), granular sugar (Pellicano Comprabene S.p.A., Italy), sodium chloride (Carrefour Italia S.p.A, Italy), compressed yeast (Carrefour Italia S.p.A., Italy) and distilled water.

Okra Powder Production and Characterisation

In order to obtain powders, fresh okra pods (Fig. 1) were washed and the ends (i.e. stem, calyx and apex) were removed; the remaining parts were transversely sliced (10 mm thick; FO), and dried at low-temperature (50 ± 2 °C) in a vacuum oven (WIPA, GEASS, Turin, Italy; operating at 0.987 Pa) down to approximately 15 g/100 g of moisture content. The particle size of okra powders were selected considering a compromise between the finest particles obtainable from okra pods by laboratory mills, as later reported, and the common particle size of traditional and unconventional flours (e.g. semolina, buckwheat, wheat flour, bean powder, etc.). For this purpose, the dried okra pieces were ground into powder at room temperature using a disc-mill (MLI 204, Buhler, Italy) and a blender (Heavy Duty Blender, Waring Commercial, USA) in order to obtain whole okra powder (WOP; Fig. 1) having a particle size smaller than 1000 µm. Since powder particle size is important in food design (Cappa et al., 2020; de la Hera et al., 2013a, b), WOP flour was refined excluding particles bigger than 250 µm, thus obtaining fine okra powder (FOP; Fig. 1). Sieving (50 g of powder per time) was conducted for 10 min at amplitude 9 using an analytical sieve shaker Octagon Digital (Endecotts Ltd., London, UK). The particle size distribution of okra powders was determined using a Mastersizer 3000® laser diffractometer (Malvern Instruments Limited, Worcestershire, UK) equipped with AERO S dry dispersion unit. Evaluations were performed at room temperature (25 °C), setting a constant refractive index of 1.52. Dispersion conditions were as follows: 100% air pressure at 2 bar, 2 mm hopper gap and 40% feed rate. According to Gnagne et al. (2017), particle size distributions were evaluated in terms of D10, D50 and D90, i.e. size (µm) below which 10, 50 or 90%, respectively, of the total volume of particles are found, and Span, describing the width of the distribution, calculated by the following formula: \(\mathrm{Span}\hspace{0.17em}=\hspace{0.17em}((\mathrm{D}90\hspace{0.17em}-\hspace{0.17em}\mathrm{D}10)/\mathrm{D}50)\). The okra powders were characterised in terms of moisture (Official Standard Method AACC 44-15A, 2000) and total nitrogen content (Kjeldahl method according to the AOAC, 2000). The protein contents were calculated adopting a conversion factor of 6.25.

In order to explore the technological properties of okra powders, water binding capacity (WBC), foaming capacity and stability were measured. WBC and foaming properties of HPMC and Psy were evaluated for comparison. WBC was determined by adding 50 mL of distilled water to a 0.5 g of sample in a tared 50 mL centrifuge tube. The tube was kept at room temperature and stirred intermittently every 10 min for up to 60 min; then the tube was centrifuged at 2200 × g for 10 min, and the excess water was carefully eliminated. WBC (g H2O/g sample as is) was calculated by subtracting the sample weight from the sample wet weight divided by the sample weight. Foaming capacity was measured by mixing 2.5 g of powdered sample with 50 mL of water then the suspension was stirred for 4 min, using a Whipped Cream Tester CT II mixer (Gerber Instruments, Switzerland), and the temperature was kept constant at 30 °C using a thermostatic bath. The height of the solution before and after mixing was also measured using a calliper. The suspension was then put into a graduated conical cylinder and the total volume, foam volume and liquid phase volume (mL) were measured immediately (t0) and after 30 and 60 min. Foaming capacity was expressed as overrun (%; difference between foam volume and initial solution volume with respect to the initial solution volume) and foaming stability (%; difference between initial foam volume and foam volume after 60 min with respect to the initial foam volume).

The colorimetric indices of powders (approximately 30 g) levelled in petri dishes were measured using a Minolta Chroma Meter II (Minolta, Osaka, Japan) equipped with standard Illuminant C. Results were expressed in the CIE L*a*b* space: L* (lightness; from black (0) to white (100)), a* (from green ( −) to red ( +)) and b* (from blue ( −) to yellow ( +)).

Gluten-Free Dough and Bread Production

Table 1 shows the recipe of GF breads and sample codes. The reference sample (STD) was formulated according to Cappa et al. (2016a) and contains of 1.5 g/100 g of HPMC and of Psy, respectively, as hydrocolloids. In the other breads, HPMC or Psy were substituted with FOP or WOP powders as specified in the sample code. The ingredient amount is expressed on a total recipe weight basis, water excluded.

Dough Mixing and Leavening Properties

The mixing properties of doughs were investigated with a Brabender Farinograph (Brabender® OHG, Duisburg, Germany) set at 30 °C. The dry ingredients (273 g) were pre-mixed for 5 min, before adding the yeast (previously suspended in a part of water), oil and water up to the desired dough consistency of 200 ± 20 Brabender® unit (BU) in accordance with Cappa et al. (2013, 2016a). Kneading was performed for 15 min. For each formulation, water absorption (%; intended as the amount of water required to reach the desired consistency), initial and final consistencies (evaluated at 5 and 15 min, respectively) and kneading stability (%; calculated as the difference between the initial and the final consistencies with respect to the initial consistency) were determined. To evaluate the leavening behaviour, 300 g of the dough produced with the Brabender Farinograph was placed into the Rheofermentometer F3 Chopin (Chopin SA, Villeneuve-La-Garenne, France) and left to rise for 1 h at 35 °C. Dough development (mm) and gas production (mm H2O) were continuously measured during leavening, while the volume of gas produced and retained (mL) were determined at the end of the process. The time when the dough starts to lose the CO2 produced by yeast was measured to determine the proper dough leavening time for the baking trials.

Breadmaking Procedure

Dough produced in the Brabender Farinograph was collected, divided into portions of 60 g and placed into oiled metal moulds (100 × 60 × 45 mm). According to the rheofermentographic data, the dough was leavened at 35 °C for 40 min (Whirlpool, EMEA S.p.A., Biandronno, Varese, Italy) and baked in an electric static oven (Whirlpool, EMEA S.p.A., Biandronno, Varese, Italy) for 30 min at 175 °C. At the end of baking, the loaves were cooled for 30 min at room temperature, before being removed from the moulds. The quality of the GF breads was evaluated immediately after cooling (t0, fresh bread) and after 24 h (t24) and 48 h (t48) of storage at 25 °C in unsealed paper bags to simulate home storage.

GF Bread Characterisation

Breads were characterised as follows: height (mm; using a calliper, taking measurements at the maximum of the loaf); specific volume (mL/g; AACC Official Standard Method 10–05.01, 2000, replacing rapeseeds with sesame seeds); slice and crumb moisture (g/100 g; AACC Official Standard Method 44-15A, 2000); crumb water activity (AquaLab Series CX-3, Decagon Devices Inc. Pullman, USA); baking loss (%; computed as the difference between the weight of the dough before leavening and the weight of the fresh bread with respect to the dough weight); storage loss (%; computed as the difference between fresh and stored bread with respect to the fresh weight). Crust and crumb colour were measured using a tristimulus colour light analyser (Minolta Chroma Meter II Reflectance; Minolta, Osaka, Japan) as previously described for okra powder characterisation. For each analysis, at least six replicates (n = 6) were performed for each bread recipe. Crumb porosity was investigated using Image Analysis: a central crumb portion (crop size = 442.7 mm2) was selected from each bread slice previously scanned in 256 grey scale levels and 600 dpi resolution using an Epson Perfection V850pro scanner (Seiko Epson Corporation, Suwa, Japan). Images were processed using a specific software (Image Pro-Plus 7.0; Media Cybernetics Inc., Rockville, MD, USA) and the objects (holes) were identified, counted and classified into five classes on the basis of their size: (1) 0.1 ≤ x < 0.2 mm2, (2) 0.2 ≤ x < 0.5 mm2, (3) 0.5 ≤ x < 1 mm2, (4) 1 ≤ x < 5 mm2 and (5) 5 ≤ x < 10 mm2. The following parameters were measured: hole number for each class (%; expressed as the percentage of holes having a selected size with respect to the total number of crop holes) and crumb porosity (%; expressed as the percentage of the total alveolate area of the crop with respect to the total surface crop). Bread crumb softness was investigated through a compression test using a TA-HDplus Texture Analyser (Stable Micro Systems, Surrey, UK), equipped with a 500 N load cell. The Texture Exponent TEE32 V 3.0.4.0 Software (Stable Micro System, UK) was used to control the instrument and to process data. Breads were sliced (20 mm thick) and each slice was compressed up to 10% deformation at a compression speed of 1 mm/s, using a spherical probe. The trigger force was equal to 10 g. Crumb resistance (N) to a deformation of 10% was measured as indication of crumb hardness. At least six replicates (n = 6) were performed for each bread recipe. During storage, GF bread loaves were also characterised in terms of slice and crumb moisture, crumb water activity and softness, as previously reported.

Statistical Analysis

If not stated otherwise, triplicate measurements were performed for each sample. Results were expressed as mean ± standard deviation (SD) values. All data were subjected to one-way analysis of variance (ANOVA), followed by the least significant difference (LSD) test to identify significant differences among the samples (P < 0.05). Correlation analysis among variables was performed following the Pearson approach. The Pearson product-moment of correlation (r) was calculated, together with the P value of statistical significance. Data were processed by STATGRAPHIC® Centurion 18 (Statpoint Technologies Inc., The Plains, VA, USA).

Results and Discussion

Fresh and Powdered Okra Characteristics

Table 2 reports the physicochemical properties of fresh and powdered okra. In agreement with Romdhane et al. (2020), dos Santos et al. (2019) and Falade and Omojola (2010) who reported moisture values of 81.9, 84.0 and 90.2 g/100 g, respectively, FO had a moisture content of 90.6 g/100 g that inevitably causes a fast deterioration of the pod at room temperature. As regards protein content, FO had a value of 16.26 ± 0.03 g/100 g db (dry basis), and this is in agreement with Petropoulos et al. (2018) who stated that okra pods were very rich in protein compared to other fresh vegetables suggesting that okra pods could serve as a good source of protein in human diet. However, a wide range of protein content has been reported in the literature for fresh okra: 10.25–26.16 g/100 g db, 19.61 and 29.74 g/100 g db (dos Santos et al., 2019; Gemede et al., 2016; Romdhane et al., 2020, respectively). For instance, Petropoulos et al. (2018) showed that protein content varied with pod size: small pods (30–50 mm) had 17.25–17.92 g/100 g db while large ones (> 70 mm) had 14.62–15.75 g/100 g db. As expected, powdered samples (WOP and FOP; Table 2) had a moisture content around 15 g/100 g, confirming that the low-temperature drying process applied resulted in more stable products at room temperature. Furthermore, their protein contents resulted similar to the values found for thermally treated okra powders (18.98 to 25.65 g/100 g db; dos Santos et al., 2019), regardless of the cultivar of the plant and ripening stage. As okra powders have been suggested as new ingredients for baking application, their particle size and technological properties were evaluated. According to the milling and sieving conditions applied, WOP had 90% of the total particles smaller than 806 µm, while FOP was characterised by a finest particle size (D90 = 310 µm). Even if WOP had smaller surface areas it showed significantly higher WBC than FOP (Table 2); this can be explained by the fact that most of the tissues found in living plants are irregular in terms of composition and resistance to fracture (Xu et al., 2020); thus, after drying and milling, the different fractions collected might differ due to the varying proportions of the tissue parts. WBC of okra powders were lower than Psy (36.7 ± 0.8 g H2O/g), while their foaming properties were comparable (overrun of 0.8% for WOP, FOP and Psy; data not shown); on the contrary, HPMC was able to bind all the water added during the WBC assay and showed an overrun of 34.7 ± 2.3% with a foam characterised by high stability (100% after 60 min; data not shown).

As one of the first quality indicator for consumer is the product colour and it can be altered by thermal processing (e.g., Maillard reaction), the colour of the newly produced okra powders versus FO was evaluated (Table 2). Compared to FO, the process applied (i.e., drying and grinding) significantly (P < 0.05) affected sample colour leading to an increase in brightness (L*) associated with a decrease of the green component (−a*) with respect to the red (+a*); no significant differences were found for the yellow index (b*). Comparing two okra powders having different particle sizes, WOP scored significantly (P < 0.05) brighter (63.48 vs. 58.29, respectively) and was characterised by a higher value for green (−4.52 vs. −2.73, respectively) than FOP, whereas no differences were found for yellowness. These results are in agreement with dos Santos et al. (2019) who characterised okra powder lyophilised and dried in a convective oven at different processing temperatures resulting in L* values in a range of 58.41–70.04, a* values between −5.09 and −1.25, and b* values from 20.73 to 24.51.

Dough Quality Evaluation

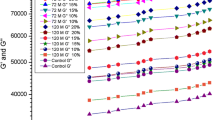

The technological properties of dough are reported in Table 3 and Fig. 2. The amount of water required to reach the desired consistency (200 ± 20 UB according to Cappa et al., 2013, 2016a) ranged from 64.40 to 79.25% according to the ingredients used having different WBCs. Indeed, the standard formulation containing HPMC and Psy required the greatest quantity of water, while samples containing okra powders bound less water. Furthermore, in accordance with WBC values, dough containing WOP required slightly more water than FOP-dough; this result is in agreement also with de la Hera et al. (2014) who studied the effect of rice flour particle size on gluten-free bread. Despite being gluten-free, all the samples exhibited high dough stability (> 93%) during kneading that increased (up to 98%) by substituting Psy with WOP or FOP. The ability of okra to increase dough stability was also observed by Bhat and Tharanathan (1987) and Alamri (2014) in wheat dough. All the samples showed also high CO2 production (Fig. 2; reaching volumes of 862-935 mL of CO2, data not shown), suggesting that yeast was fermenting sugars and the proofing conditions were suitable for their growth. No correlation was found between dough development and gas amount indicating that the leavening performance of the yeast is not the only parameter to consider, indeed the capability of the dough to retain gas is also critical. In fact, STD, HPMC + FOP and HPMC + WOP samples, which had very high retention coefficients (> 99%, data not shown), increased progressively during leavening (with final dough heights of 69.4, 68.4 and 64.9 mm, respectively; Fig. 2); on the contrary, samples without-HPMC resulted in lower dough developments (19.1 and 17.8 mm for Psy + WOP and Psy + FOP, respectively) suggesting that the rheological properties (e.g. viscoelasticity) of dough containing HPMC are more suitable to produce a well-developed bread. Furthermore, as Fig. 2 indicates, all the doughs started rising immediately; this is typical of dough containing compressed yeast, while sourdough generally required a longer time to ferment sugars (Cappa et al., 2016b). Additionally, at the beginning of the leavening all the samples proceeded similarly, then, after approximately 25 min of leavening, the dough height of samples without HPMC plateaued. This behaviour is not surprising as HPMC is one of the most popular hydrocolloids used in gluten-free bread production (Cappa et al., 2013; Hager & Arendt, 2013; Mancebo et al., 2015; Mariotti et al., 2013) and could be explained by the fact that Psy and okra powders possess mainly thickening properties rather than the unique foaming properties of HPMC, as previously discussed. Lastly, all the samples exhibited high CO2 retention (> 98%, data not shown) with no leaching of gas during the test or only tiny losses after 40 min, thus the dough leavening time for the subsequent baking trials was set for 40 min.

Bread Quality Evaluation

Figure 3 shows images of the central slice of fresh bread samples, while bread characterisation is summarised in Table 4. As expected, for all the samples, the crust was darker and characterised by higher red and yellow values in comparison to the crumb; this is mainly due to the Maillard reaction which is more accentuated in the crust which reached higher temperatures, as was also reported by Giovanelli and Cappa (2021). Furthermore, the bread formulation used (i.e. HPMC, Psy, WOP or FOP addition) affected crust and crumb colour. Indeed, breads containing Psy and okra powders resulted significantly (P < 0.05) darker due to the original colour of both ingredients tending to green/brown and characterised by lower L* values (data not shown) compared to the samples containing HPMC which was bright white. These data were in agreement with Alamri (2014) and Xu et al. (2020) who also demonstrated that bread with okra gum or powder was darker. Even if WOP and FOP showed significantly (P < 0.05) different chromatic coordinates (Table 2), slight differences of the colour of bread containing okra powders were observed according to their particle size, probably due to the low amount of okra powder added in the bread recipe (Table 1).

Images of the central slice of fresh GF bread. See Table 1 for sample recipe and code

Figure 3 shows all breads with a well-defined crust and crumb without particular defects (e.g. cracking or crumb discontinuities), and no significant differences were evidenced for crumb porosity with the exception of STD which had the highest value (29 vs. 22–24%; Table 4); furthermore, it was observed that adding HPMC results in bread with the finest crumb structure (> 33% of the holes had the smallest size), whereas samples containing FOP and WOP in combination with Psy showed a crumb structure defined by bigger holes (37 and 48% larger than 0.5 mm2 for Psy + WOP and Psy + FOP, respectively); larger crumb holes were also found by Xu et al. (2020) in wheat bread containing okra powder.

As regards crumb moisture, according to the farinographic water absorption values, STD had the highest moisture content followed by samples containing Psy + okra, and HPMC + okra; indeed a positive linear correlation (r = 0.928, P < 0.05) was found between dough water absorption and bread crumb moisture, while no correlation was found for bread weight and specific volume. No significant differences in bread weights were found for samples containing HPMC, while those containing Psy and okra powders were heavier; this could be due to the presence of fibre which bound water without evaporating excessively during the cooking phase; this behaviour was confirmed by the lowest baking loss and the bread moisture content of Psy + WOP and Psy + FOP which were the highest even if they showed intermediate farinographic water absorption values (Table 3). However, the presence of pericarp parts of Psy seed and okra pod weakened the non-gluten network of the dough resulting in less developed bread (Table 3); this is in agreement with Hřivna et al. (2018) who demonstrated that the presence of bran in wheat dough led to a lower development and lower specific volume of the final bread. The combination of HPMC and okra powders resulted in well-developed breads characterised by high values for height and specific volume (Table 4 and Fig. 3); furthermore, as expected, okra powder particle size affected the bread structure since the powder with the smaller particle size (i.e. FOP) resulted in significantly (P < 0.05) higher specific volume in comparison to WOP (3.89 and 3.07 mL/g, respectively) and was not significantly different from STD bread. Different results were found by de la Hera et al. (2013a) who studied the influence of rice flour particle size on the quality of gluten-free rice bread founding that the finer the powder, the poorer its bread-making properties. Such a discrepancy can be due to the different composition (e.g. protein, starch and fibre content) of okra powder and rice flour and their particle size; in fact, rice flours were very fine (< 80, 80–180 and > 180 µm) in comparison with okra powders. Moreover, Xu et al. (2020) evidenced that very fine (i.e. < 150 µm) particle sizes were not suitable for bread making, since they somehow inhibited the formation of a proper network resulting in a decreased bread volume and increased hardness, while the okra powder fractions obtained from 150 and 270 μm mesh screens—thus similar to FOP—performed better. Nevertheless, according to the bread recipe, a huge range of specific volume values (1.88–3.99 mL/g) were obtained for the experimental GF breads; these values were similar to or even higher than published data related to gluten-free bread (Belorio & Gómez, 2020; Cappa et al., 2016a; Hager & Arendt, 2013; Mariotti et al., 2013; Sciarini et al., 2012) indicating that formulation and process conditions used are suitable to produce well-developed bread. A negative linear correlation was found between specific volume and bread hardness (r = 0.925, P < 0.05) suggesting that volume, one of the visual attributes consumers use to measure bread quality, can be a good indicator of bread softness for pan bread. The evaluation of the crumb texture further indicated that okra powder can be successfully used in combination with HPMC to develop soft GF bread (having hardness not significantly different from STD) and powder particle size somehow affected the texture: lower values for hardness characterised samples containing FOP compared to WOP. Similarly Xu et al. (2020) found that high quality wheat breads could be obtained by using flours having 150–270 μm particle size, especially from okra seed fractions.

Bread Quality Evaluation During Storage

In order to evaluate the effects of okra powder addition on bread shelf-life, samples were also characterised after 24 h (t24) and 48 h (t48) of storage at 25 °C in unsealed paper bags simulating home storage. As expected, all breads dehydrated during storage (Table 5): high bread weight loss (6–19%), low water activity (0.866–0.975) and low crumb and slice moisture (25–46% and 17–33%, respectively) were found; consequently, a hardening of the crumb was evidenced. Samples containing WOP and FOP in combination with Psy exhibited faster staling kinetics reaching values for hardness up to 33 times higher than STD, while the combination of okra powder with HPMC resulted in soft bread that was not significantly different from the reference samples for both storage times. Contrary to expectation, the okra powder having the largest particle size was able to constrain bread hardening better than fine powder, probably due to its higher water binding capacity.

Conclusion

As far as we know, this study is the first to investigate the effect of okra powder of varying particle size on the technological quality of GF dough and bread. Results indicated that okra powder can be used in combination with HPMC to produce GF bread characterised by high specific volume and soft texture typical of pan bread. On the contrary, the combination of okra powder with Psy produced a more compact bread (i.e. low specific volume and high crumb hardness). Powder particle size affected dough and bread properties: samples containing the finest okra powder required less water to reach 200 BU and were characterised by higher dough development and bread specific volume, crumb moisture and crumb softness; however, the largest particle size powder was slightly more effective in limiting bread hardening during storage. Furthermore, the formulations containing okra powders and Psy, while aiming to replace HPMC (synthetic hydrocolloid) with natural ingredients, also yielded interesting results from a technological point of view (i.e. colour and crumb porosity) even if the crumb was more compact (i.e. higher hardness). Further studies should be conducted in order to optimise the amount of okra powder (and water) to use and to explore combinations with other non-synthetic hydrocolloids in order to obtain green labels. In conclusion, the application of okra powder in other bakery and confectionery products seems worthy of investigation since not much data is currently available in the literature, especially regarding GF products.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Change history

22 July 2022

Missing Open Access funding information has been added in the Funding Note.

References

AACC (American Association of Cereal Chemists). (2000). Approved Methods of the AACC (10th ed.). St. Paul, Minnesota.

Alamri, M. S. (2014). Okra-gum fortified bread: Formulation and quality. Journal of Food Science and Technology, 51(10), 2370–2381. https://doi.org/10.1007/s13197-012-0803-z

Alba, K., Ritzoulis, C., Georgiadis, N., & Kontogiorgos, V. (2013). Okra extracts as emulsifiers for acidic emulsions. Food Research International, 54(2), 1730–1737. https://doi.org/10.1016/j.foodres.2013.09.051

AOAC (Association of Official Analitical Chemists). (2000). Official methods of analysis (19th ed., p. 1219) Washington, D.C.

Archana, G., Sabina, K., Babuskin, S., Radhakrishnan, K., Fayidh, M. A., Babu, P. A. S., Sivarajan, M., & Sukumar, M. (2013). Preparation and characterization of mucilage polysaccharide for biomedical applications. Carbohydrate Polymers, 98(1), 89–94. https://doi.org/10.1016/j.carbpol.2013.04.062

Belorio, M., & Gómez, M. (2020). Effect of hydration on gluten-free breads made with hydroxypropyl methylcellulose in comparison with psyllium and xanthan gum. Foods, 9(11), 1548. https://doi.org/10.3390/foods9111548

Bhat, U. R., & Tharanathan, R. N. (1987). Functional properties of okra (Hibiscus esculentus) mucilage. Starch-Stärke, 39(5), 165–167. https://doi.org/10.1002/star.19870390506

Calcinoni, O., Borgonovo, G., Cassanelli, A., Banfi, E., & Bassoli, A. (2020). Herbs for voice database: Developing a rational approach to the study of herbal remedies used in voice care. Journal of Voice. https://doi.org/10.1016/j.jvoice.2019.12.027

Cappa, C., Barbosa-Cánovas, G. V., Lucisano, M., & Mariotti, M. (2016a). Effect of high pressure processing on the baking aptitude of corn starch and rice flour. LWT-Food Science and Technology, 73, 20–27. https://doi.org/10.1016/j.lwt.2016.05.028

Cappa, C., Kelly, J. D., & Ng, P. K. (2020). Baking performance of 25 edible dry bean powders: Correlation between cookie quality and rapid test indices. Food Chemistry, 302, 125338. https://doi.org/10.1016/j.foodchem.2019.125338

Cappa, C., Lucisano, M., & Mariotti, M. (2013). Influence of Psyllium, sugar beet fibre and water on gluten-free dough properties and bread quality. Carbohydrate Polymers, 98(2), 1657–1666. https://doi.org/10.1016/j.carbpol.2013.08.007

Cappa, C., Lucisano, M., Raineri, A., Fongaro, L., Foschino, R., & Mariotti, M. (2016b). Gluten-free bread: Influence of sourdough and compressed yeast on proofing and baking properties. Foods, 5(4), 69. https://doi.org/10.3390/foods5040069

Chakraborty, S. K., Kotwaliwale, N., & Navale, S. A. (2020). Selection and incorporation of hydrocolloid for gluten-free leavened millet breads and optimization of the baking process thereof. LWT-Food Science and Technology, 119, 108878. https://doi.org/10.1016/j.lwt.2019.108878

Datsomor, D. N., Agbenorhevi, J. K., Kpodo, F. M., & Oduro, I. N. (2019). Okra pectin as lecithin substitute in chocolate. Scientific African, 3, e00070. https://doi.org/10.1016/j.sciaf.2019.e00070

de la Hera, E., Martinez, M., & Gómez, M. (2013a). Influence of flour particle size on quality of gluten-free rice bread. LWT-Food Science and Technology, 54(1), 199–206. https://doi.org/10.1016/j.lwt.2013.04.019

de la Hera, E., Martinez, M., Oliete, B., & Gómez, M. (2013b). Influence of flour particle size on quality of gluten-free rice cakes. Food and Bioprocess Technology, 6(9), 2280–2288. https://doi.org/10.1007/s11947-012-0922-6

de La Hera, E., Rosell, C. M., & Gomez, M. (2014). Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chemistry, 151, 526–531. https://doi.org/10.1016/j.foodchem.2013.11.115

dos Santos, F. S., de Figueirędo, R. M., Queiroz, A. J. D. M., de Lima, T. L., & Moreira, I. S. (2019). Effect of dehydration methods on okra chemical and physical composition. Journal of Agricultural Science, 11(5). https://doi.org/10.5539/jas.v11n5p236

Durazzo, A., Lucarini, M., Novellino, E., Souto, E. B., Daliu, P., & Santini, A. (2019). Abelmoschus esculentus (L.): Bioactive components’ beneficial properties—focused on antidiabetic role—for sustainable health applications. Molecules, 24(1), 38. https://doi.org/10.3390/molecules24010038

Falade, K. O., & Omojola, B. S. (2010). Effect of processing methods on physical, chemical, rheological, and sensory properties of okra (Abelmoschus esculentus). Food and Bioprocess Technology, 3(3), 387–394. https://doi.org/10.1007/s11947-008-0126-2

Farinde, A. J., Owolarafe, O. K., & Ogungbemi, O. I. (2006). Assessment of production, processing, marketing and utilisation of okra in Egbedore local government area of Osun State, Nigeria. Journal of Agronomy, 5(2), 342–349.

Gemede, H. F., Haki, G. D., Beyene, F., Woldegiorgis, A. Z., & Rakshit, S. K. (2016). Proximate, mineral, and antinutrient compositions of indigenous Okra (Abelmoschus esculentus) pod accessions: Implications for mineral bioavailability. Food Science & Nutrition, 4(2), 223–233. https://doi.org/10.1002/fsn3.282

Giovanelli, G., & Cappa, C. (2021). 5-hydroxymethylfurfural formation in bread as a function of heat treatment intensity: Correlations with browning indices. Foods, 10(2), 417. https://doi.org/10.3390/foods10020417

Gnagne, E. H., Petit, J., Gaiani, C., Scher, J., & Amani, G. N. (2017). Characterisation of flow properties of foutou and foufou flours, staple foods in West Africa, using the FT4 powder rheometer. Journal of Food Measurement and Characterization, 11(3), 1128–1136. https://doi.org/10.1007/s11694-017-9489-2

Hager, A. S., & Arendt, E. K. (2013). Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocolloids, 32(1), 195–203. https://doi.org/10.1016/j.foodhyd.2012.12.021

Hřivna, L., Zigmundová, V., Burešová, I., Maco, R., Vyhnánek, T., & Trojan, V. (2018). Rheological properties of dough and baking quality of products using coloured wheat. Plant, Soil and Environment, 64(5), 203–208. https://doi.org/10.17221/62/2018-PSE

Kissiedu, K. O., Agbenorhevi, K., & J., & Datsomor, D. N. (2020). Optimization of sensory acceptability of milk chocolate containing okra pectin as emulsifier. International Journal of Food Properties, 23(1), 1310–1323. https://doi.org/10.1080/10942912.2020.1800728

Lazaridou, A., Duta, D., Papageorgiou, M., Belc, N., & Biliaderis, C. G. (2007). Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. Journal of Food Engineering, 79(3), 1033–1047. https://doi.org/10.1016/j.jfoodeng.2006.03.032

Mancebo, C. M., San Miguel, M. Á., Martínez, M. M., & Gómez, M. (2015). Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. Journal of Cereal Science, 61, 8–15. https://doi.org/10.1016/j.jcs.2014.10.005

Mariotti, M., Pagani, M. A., & Lucisano, M. (2013). The role of buckwheat and HPMC on the breadmaking properties of some commercial gluten-free bread mixtures. Food Hydrocolloids, 30(1), 393–400. https://doi.org/10.1016/j.foodhyd.2012.07.005

Mujumdar, A. S., & Law, C. L. (2010). Drying technology: Trends and applications in postharvest processing. Food and Bioprocess Technology, 3(6), 843–852. https://doi.org/10.1007/s11947-010-0353-1

Petropoulos, S., Fernandes, Â., Barros, L., & Ferreira, I. C. (2018). Chemical composition, nutritional value and antioxidant properties of Mediterranean okra genotypes in relation to harvest stage. Food Chemistry, 242, 466-474. https://doi.org/10.1016/j.foodchem.2017.09.082

Romanchik-Cerpovicz, J. E., Costantino, A. C., & Gunn, L. H. (2006). Sensory evaluation ratings and melting characteristics show that okra gum is an acceptable milk-fat ingredient substitute in chocolate frozen dairy dessert. Journal of the American Dietetic Association, 106(4), 594–597. https://doi.org/10.1016/j.jada.2006.01.009

Romanchik-Cerpovicz, J. E., Tilmon, R. W., & Baldree, K. A. (2002). Moisture retention and consumer acceptability of chocolate bar cookies prepared with okra gum as a fat ingredient substitute. Journal of the American Dietetic Association, 102(9), 1301–1303. https://doi.org/10.1016/S0002-8223(02)90287-7

Romdhane, M. H., Chahdoura, H., Barros, L., Dias, M. I., Carvalho Gomes Corrêa, R., Morales, P., Ciudad-Mulero, M., Flamini, G., Majdoub, H., & Ferreira, I. C. (2020). Chemical composition, nutritional value, and biological evaluation of Tunisian okra pods (Abelmoschus esculentus L. Moench). Molecules, 25(20), 4739. https://doi.org/10.3390/molecules25204739

Sciarini, L. S., Pérez, G. T., de Lamballerie, M., León, A. E., & Ribotta, P. D. (2012). Partial-baking process on gluten-free bread: Impact of hydrocolloid addition. Food and Bioprocess Technology, 5(5), 1724–1732. https://doi.org/10.1007/s11947-011-0529-3

Sonkar, S., Saha, T. S., & Singh, A. (2015). Development and standardization of soup mix based on black rice and okra powder value added with barley. Plant Archives, 15(2), 909–911.

Wirivutthikorn, W. (2019). Optimum ratios of okra and tangerine on production of mixed juice with lycopene supplementation. International Journal of GEOMATE, 17(61), 8–13. https://doi.org/10.21660/2019.61.4503

Wirivutthikorn, W. (2020). Appropriate ratios of okra juice and pandan leaf juice on sport drink processisng. International Journal of GEOMATE, 19(72), 20–27. https://doi.org/10.21660/2020.72.5508

Xu, K., Guo, M., Roman, L., Pico, J., & Martinez, M. M. (2020). Okra seed and seedless pod: Comparative study of their phenolics and carbohydrate fractions and their impact on bread-making. Food Chemistry, 317, 126387. https://doi.org/10.1016/j.foodchem.2020.126387

Yuennan, P., Sajjaanantakul, T., & Goff, H. D. (2014). Effect of okra cell wall and polysaccharide on physical properties and stability of ice cream. Journal of Food Science, 79(8), E1522–E1527. https://doi.org/10.1111/1750-3841.12539

Funding

Open access funding provided by Università degli Studi di Milano within the CRUI-CARE Agreement. This research was partially funded by Università Degli Studi di Milano—Dipartimento di Scienze per gli Alimenti la Nutrizione e l’Ambiente, Piano Sostegno per la Ricerca—Linea 2—Assegnazione 2020, PSR2020-CCAPP, CUP: G45F20001720005.

Author information

Authors and Affiliations

Contributions

Deborah Tufaro: investigation, methodology, formal analysis, writing (original draft). Angela Bassoli: resources, supervision. Carola Cappa: conceptualisation, methodology, formal analysis, data curation, resources, project administration, writing (original draft).

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tufaro, D., Bassoli, A. & Cappa, C. Okra (Abelmoschus esculentus) Powder Production and Application in Gluten-Free Bread: Effect of Particle Size. Food Bioprocess Technol 15, 904–914 (2022). https://doi.org/10.1007/s11947-022-02784-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02784-6