Abstract

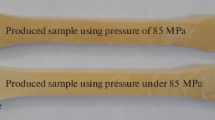

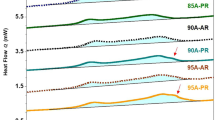

A volume-adjustable cavity of molding machine for polymer foaming was fabricated with renovation of an ordinary injection molding machine. Polypropylene (PP) composite foams were prepared by chemical foaming method via the volume-adjustable cavity of the molding machine. The decompressing and short shot processes in preparing the samples were carried out to adjust the cell structure of the foamed samples. The structures that foamed insufficiently, moderately, and excessively were observed in these two foaming processes. The foamed PP composite samples generated in decompressing process have more desirable cell structure than those generated by short shot process, specifically, the cell structure with the cell size of 46.97 μm, cell density of 3.18×106 cell/cm3, and cell size dispersion of 10.76 μm was achieved in the decompressing process. A controlled foaming process was realized through the decompressing process using the injection foaming equipment with a volume-adjustable cavity. The foamed PP composite has the insufficient, moderate, and excessive foamed structures in these two foaming processes.

Similar content being viewed by others

References

Park C B, Cheung L K. A study of cell nucleation in the extrusion of polypropylene foams [J]. Polymer Engineering & Science, 1997, 37: 1–10.

Auhl D, Stange J, Münstedt H, et al. Long-chain branched polypropylenes by electron beam irradiation and their rheological properties [J]. Macromolecules, 2004, 37: 9465–9472.

Nam G J, Yoo J H, Lee J W. Effect of long-chain branches of polypropylene on rheological properties and foam-extrusion performances [J]. Journal of Applied Polymer Science, 2005, 96: 1793–1800.

Tian J, Yu W, Zhou C. The preparation and rheology characterization of long chain branching polypropylene [J]. Polymer, 2006, 47: 7962–7969.

Wang K, Liang S, Deng J, et al. The role of clay network on macromolecular chain mobility and relaxation in isotactic polypropylene/organoclay nanocomposites [J]. Polymer, 2006, 47: 7131–7144.

Liu Y, Kontopoulou M. The structure and physical properties of polypropylene and thermoplastic olefin nanocomposites containing nanosilica [J]. Polymer, 2006, 47: 7731–7739.

Jiang M, He L, Liu J, et al. Inner voids of octavinyl polyhedral oligomeric silsesquioxane acting as cell embryos for polymer foaming [J]. Asian Journal of Chemistry, 2012, 24: 509–514.

Han C D, Villamizar C A. Studies on structural foam processing I. The rheology of foam extrusion [J]. Polymer Engineering & Science, 2004, 18: 687–698.

Shimoda M, Tsujimura I, Tanigaki M, et al. Polymeric foaming simulation for extrusion processes [J]. Journal of Cellular Plastics, 2001, 37: 517–536.

Ramesh N S, Malwitz N. Non-isothermal model to study the influence of blowing agent concentration on polymer viscosity and gas diffusivity in thermoplastic foam extrusion [J]. Journal of Cellular Plastics, 1999, 35: 199–209.

Jiang M, He L, Gong W, et al. Enhancement of polymer foam quality by modifying structural and decomposition characteristics of chemical blowing agent [J]. Polymer-Plastics Technology and Engineering, 2012, 51: 263–267.

Okamoto M, Nam P H, Maiti P, et al. Biaxial flow-induced alignment of silicate layers in polypropylene/clay nanocomposite foam [J]. Nano Letters, 2001, 1(9): 503–505.

Gong W, Gao J C, Jiang M, et al. Modeling and characterization of the relationship between cell size and mechanical behavior of microcellular PP/mica composites [J]. International Polymer Processing, 2010, 25: 270–274.

Gong W, Gao J C, Jiang M, et al. Influence of cell structure parameters on mechanical properties of microcellular PP materials [J]. Journal of Applied Polymer Science, 2011, 122: 2907–2914.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Supported by the National Natural Science Foundation of China (21264004), the Guizhou Province Inorganic Nonmetallic Key Laboratory of Functional Materials (2012-004) and the Industry Revitalization Plan Project of Guiyang City (2012101-3-9)

Biography: GONG Wei, male, Professor, Ph. D., research direction: structure and properties of polymer.

Rights and permissions

About this article

Cite this article

Gong, W., Zhang, C., Yu, J. et al. Injection processing and foaming behaviors of polypropylene composite foams. Wuhan Univ. J. Nat. Sci. 19, 123–128 (2014). https://doi.org/10.1007/s11859-014-0988-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11859-014-0988-2