Abstract

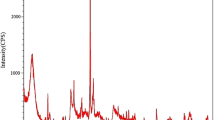

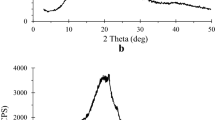

The effect of process parameters of foam injection molding on the morphologicalproperties of acrylonitrile butadiene styrene (ABS)-nanoclay polymeric foam has been investigated. Polymethyl methacrylate (PMMA) was used as the compatibilizer between polymeric matrix and nanoclay. Different nanocomposite polymeric foam samples were produced in a chemical foam injection molding process. X-ray diffraction (XRD) test was carried out to analyze the dispersion of nanoclays with different percentages in the polymeric matrix and scanning electron microscopy (SEM) pictures were used to study the cellular structure of nanocomposite foamed samples. The effect of input parameters including nanoclay weight percentage (0, 2, and 4%), Injection Pressure (110, 125, and 140 MPa), and Holding pressure (110, 125, and 140 MPa) on cell density, cell size and expansion ratio of foamed samples have been investigated. Taguchi approach was used for the design of experiments and statistical analysis of results. Based on the results, 2 wt % of nanoclay and injection and holding pressures of 140 MPa is beneficial in order to have polymeric foam with small cell size. On the other hand, to achieve foams with higher cell density, 2 wt % of nanoclay, injection pressure of 140 MPa, and holding pressure of 110 MPa should be used.

Similar content being viewed by others

REFERENCES

Polymeric Foams: Innovations in Processes, Technologies, and Products, Ed. by S. T. Lee (CRC Press, Boca Raton, 2016).

P. Dallas, V. K. Sharma, and R. Zboril, Adv. Colloid Interface Sci. 166, 119 (2011).

D. Papoulis, S. Komarneni, D. Panagiotaras, E. Stathatos, K. C. Christoforidis, M. Fernández-García, H. Li, Y. Shu, T. Sato, and H. Katsuki, Appl. Catal., B 147, 526 (2014).

R. Eungkee Lee, R. Hasanzadeh, and T. Azdast, Plast., Rubber Compos. 46, 155 (2017).

N. Yousefi, X. Sun, X. Lin, X. Shen, J. Jia, B. Zhang, B. Tang, M. Chan, and J. K. Kim, Adv. Mater. 26, 5480 (2014).

M. C. Altay, E. Y. Malikov, G. M. Eyvazova, M. B. Muradov, O. H. Akperov, R. Puskás, D. Madarász, Z. Kónya, and Á. Kukovecz, Eur. Polym. J. 68, 47 (2015).

R. Hasanzadeh, T. Azdast, A. Doniavi, and R. E. Lee, Polyolefins J. 6, 13 (2019).

A. Tsuchiya, H. Tateyama, T. Kikuchi, T. Takahashi, and K. Koyama, Polym. J. 39, 514 (2007).

P. Saraeian, H. R. Tavakoli, and A. Ghassemi, J. Compos. Mater. 47, 2211 (2013).

B. Azerag, T. Azdast, A. Doniavi, S. M. Shishavan, and R. E. Lee, Int. J. Mech. Mater. Eng. 10, 19 (2015).

A. Doniavi, S. Babazadeh, T. Azdast, and R. Hasanzadeh, J. Elastomers Plast. 49, 498 (2016).

V. Modanloo, R. Hasanzadeh, and P. Esmaili, Int. J. Eng., Trans. A 29, 103 (2016).

T. Azdast, R. Hasanzadeh, and M. Moradian, Mater. Manuf. Processes 33, 343 (2018).

M. Daryadel, T. Azdast, R. Hasanzadeh, and S. Molani, J. Appl. Polym. Sci. 135, 46098 (2018).

R. Eungkee Lee, A. Afsari Ghazi, T. Azdast, R. Hasanzadeh, and M. S. Shishavan, Adv. Polym. Technol. 37, 1737 (2017).

B. K. Deka and T. K. Maji, Composites, Part A 42, 2117 (2011).

D. M. D. Costa, T. I. Paula, P. A. P. Silva, and A. P. Paiva, Int. J. Adv. Des. Manuf. Technol. 87, 825 (2016).

R. Hasanzadeh, T. Azdast, A. Doniavi, S. Babazadeh, R. E. Lee, M. Daryadel, and S. M. Shishavan, Int. J. Eng., Trans. A 30, 143 (2017).

C. Suryanarayana and M. G. Norton, X-ray Diffraction: a Practical Approach (Springer Sci. and Business Media, New York, 2013).

M. Nofar and C. B. Park, Prog. Polym. Sci. 39, 1721 (2014).

B. Notario, J. Pinto, and M. A. Rodríguez-Pérez, Polymer 63, 116 (2015).

Y. Kim, C. B. Park, P. Chen, and R. B. Thompson, Soft Matter 7, 7351 (2011).

X. Cao, L. J. Lee, T. Widya, and C. Macosko, Polymer 46, 775 (2005).

L. J. Lee, C. Zeng, X. Cao, X. Han, J. Shen, and G. Xu, Compos. Sci. Technol. 65, 2344 (2005).

M. Antunes and J. I. Velasco, Prog. Polym. Sci. 39, 486 (2014).

Foam Extrusion: Principles and Practice, Ed. by S. T. Lee and C. B. Park (CRC Press, Boca Raton, 2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Sajjad Mamaghani Shishavan, Azdast, T., Hasanzadeh, R. et al. Comprehensive Investigation of Morphological Properties of ABS/Nanoclay/PMMA Polymeric Nanocomposite Foam. Polym. Sci. Ser. A 61, 334–344 (2019). https://doi.org/10.1134/S0965545X19030131

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X19030131