Abstract

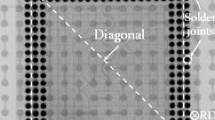

Ag3Sn intermetallic growth within Sn-Bi-Ag alloys during relatively slow cooling rates has a pronounced effect on the performance and reliability of solder joints. In this study, we combined experimental electron backscatter diffraction (EBSD) analysis with first-principles calculations to explore the crystal growth and faceting mechanisms of Ag3Sn intermetallic in solidifying Sn-xBi-1Ag (x = 10, 57 wt.%) alloys. Using EBSD techniques, accommodated for a pseudo-hexagonal setting of Ag3Sn to avoid pseudo-symmetry, and subsequent lattice transformation to an orthorhombic structure (a = 5.97 Å, b = 4.78 Å, c = 5.18 Å, Pmmn), this study reveals predominant (001)orth facets in Sn-10Bi-1Ag, and both (001)orth and more frequent (010)orth facets in Sn-57Bi-1Ag. Stability assessments of various crystal surfaces through first-principles calculations found the (010)orth surface to be most stable, followed by the (001)orth. Variations in stable facets between the two alloys may result from energy minimization influenced by atomic attachment at the liquid/solid interface, dynamic non-equilibrium solidification conditions, Bi concentration, and growth twinning. These findings enhance the understanding of intermetallic compound growth in solder alloys, with implications for solder joint technology improvement.

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

H.N. Khan, D.A. Hounshell, and E.R.H. Fuchs, Nat. Electron. 1, 14–21 https://doi.org/10.1038/s41928-017-0005-9 (2018).

P. Zhang, S. Xue, and J. Wang, Mater. Des. 192, 108726 https://doi.org/10.1016/j.matdes.2020.108726 (2020).

M.Y. Li, S.K. Su, H.S.P. Wong, and L.J. Li, Nature 567, 169 https://doi.org/10.1038/d41586-019-00793-8 (2019).

S. Chung, and J.B. Kwak, Solder. Surface Mount Technol. 27, 137 https://doi.org/10.1108/SSMT-12-2014-0023 (2015).

R. Aspandiar, K. Byrd, K.K. Tang, L. Campbell, S. Mokler, Investigation of low temperature solders to reduce reflow temperature, improve SMT yields and realize energy savings. Paper presented at Proceedings of the 2015 APEX Conference, San Diego, CA, February 2015.

M. Koide, K. Fukuzono, M. Watanabe, T. Yamamoto, S. Sakuyama, Full low temperature solder BGA development for large size BGA package. Paper presented at 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3-30 June 2020.

W.R. Myung, M.K. Ko, Y. Kim, and S.B. Jung, J. Mater. Sci. Mater. Electron. 26, 8707–8713 https://doi.org/10.1007/s10854-015-3546-6 (2015).

T. Yang, X. Zhao, Z. Xiong, W. Tan, Y. Wei, C. Tan, X. Yu, and Y. Wang, Mater. Sci. Eng. A 785, 139372 https://doi.org/10.1016/j.msea.2020.139372 (2020).

A.K. Gain, and L. Zhang, J. Mater. Sci. Mater. Electron. 28, 15718 https://doi.org/10.1007/s10854-017-7465-6 (2017).

Y. Ding, F. Wang, Y. Li, and K. Wang, ES Mater. Manuf. 11, 65 https://doi.org/10.3091/esmm5f1045 (2021).

N. Hou, J.W. Xian, A. Sugiyama, H. Yasuda, and C.M. Gourlay, Metall. Mater. Trans. A 54, 909 https://doi.org/10.1007/s11661-022-06937-2 (2023).

Y. Cui, J.W. Xian, A. Zois, K. Marquardt, H. Yasuda, and C.M. Gourlay, Acta Mater. 249, 118831 https://doi.org/10.1016/j.actamat.2023.118831 (2023).

X.J. Hu, W. Sun, J.L. Liao, J.W. Xian, and G. Zeng, Available at SSRN 466, 2023 https://doi.org/10.2139/ssrn.4661936 (1936).

J.W. Xian, G. Zeng, S.A. Belyakov, Q. Gu, K. Nogita, and C.M. Gourlay, Intermetallics 91, 50 https://doi.org/10.1016/j.intermet.2017.08.002 (2017).

S. Kumar, and J. Jung, Mater. Sci. Eng. B 178, 10 https://doi.org/10.1016/j.mseb.2012.10.003 (2013).

M.M. Billah, S. Das, A.R. Aad, and R. Paul, J. Market. Res. 20, 2094 https://doi.org/10.1016/j.jmrt.2022.07.188 (2022).

I.N. Bakst, H. Yu, M. Bahadori, H. Yu, S.W. Lee, M. Aindow, and C.R. Weinberger, Int. J. Plast. 110, 57 https://doi.org/10.1016/j.ijplas.2018.06.008 (2018).

R.S. Sidhu, and N. Chawla, Scripta Mater. 54, 1627 https://doi.org/10.1016/j.scriptamat.2006.01.013 (2006).

H.T. Lee, and Y.F. Chen, J. Alloy. Compd. 509, 2510 https://doi.org/10.1016/j.jallcom.2010.11.068 (2011).

J.M. Song, J.J. Lin, C.F. Huang, and H.Y. Chuang, Mater. Sci. Eng. A 466, 9 https://doi.org/10.1016/j.msea.2007.04.121 (2007).

J. Gong, C. Liu, P.P. Conway, and V.V. Silberschmidt, Mater. Sci. Eng. A 527, 2588 https://doi.org/10.1016/j.msea.2009.12.020 (2010).

S.K. Kang, D.Y. Shih, N.Y. Donald, W. Henderson, T. Gosselin, A. Sarkhel, N.Y. Charles Goldsmith, K.J. Puttlitz and W.K. Choi, JOM, 55, 61 (2003). https://doi.org/10.1007/s11837-003-0143-6

Z.L. Ma, J.W. Xian, S.A. Belyakov, and C.M. Gourlay, Acta Mater. 150, 281 https://doi.org/10.1016/j.actamat.2018.02.047 (2018).

M. Asta, C. Beckermann, A. Karma, W. Kurz, R. Napolitano, M. Plapp, G. Purdy, M. Rappaz, and R. Trivedi, Acta Mater. 57, 941 https://doi.org/10.1016/j.actamat.2008.10.020 (2009).

C. Li, Y.Y. Wu, H. Li, and X.F. Liu, Acta Mater. 59, 1058 https://doi.org/10.1016/j.actamat.2010.10.036 (2011).

C. Chattopadhyay, S. Sangal, and K. Mondal, Acta Mater. 58, 5342 https://doi.org/10.1016/j.actamat.2010.06.009 (2010).

M.G. Tsoutsouva, T. Riberi-Béridot, G. Regula, G. Reinhart, J. Baruchel, F. Guittonneau, L. Barrallier, and N. Mangelinck-Noël, Acta Mater. 115, 210 https://doi.org/10.1016/j.actamat.2016.06.004 (2016).

H. Ouaddah, G. Regula, G. Reinhart, I. Périchaud, F. Guittonneau, L. Barrallier, J. Baruchel, T.N.T. Caliste, and N. Mangelinck-Noël, Acta Mater. 252, 118904 https://doi.org/10.1016/j.actamat.2023.118904 (2023).

A. Kopač Lautar, D. Kopač, T. Rejec, T. Bančič, and R. Dominko, Phys. Chem. Chem. Phys. 21, 2434 https://doi.org/10.1039/C8CP06171H (2019).

F. Bachmann, R. Hielscher, and H. Schaeben, Solid State Phenom. 160, 63 https://doi.org/10.4028/www.scientific.net/SSP.160.63 (2010).

J. Hafner, J. Comput. Chem. 29, 2044 https://doi.org/10.1002/jcc.21057 (2008).

G. Kresse, and D. Joubert, Phys. Rev. B 59, 1758 https://doi.org/10.1103/PhysRevB.59.1758 (1999).

J.P. Perdew, K. Burke, and M. Ernzerhof, Phys. Rev. Lett. 77, 3865 https://doi.org/10.1103/PhysRevLett.77.3865 (1996).

H.J. Monkhorst, and J.D. Pack, Phys. Rev. B 13, 5188–5192 https://doi.org/10.1103/PhysRevB.13.5188 (1976).

K.N. Reeve, J.R. Holaday, S.M. Choquette, I.E. Anderson, and C.A. Handwerker, J. Phase Equilib. Diffus. 37, 369 https://doi.org/10.1007/s11669-016-0476-9 (2016).

I. Ohnuma, M. Miyashita, K. Anzai, X.J. Liu, H. Ohtani, R. Kainuma, and K. Ishida, J. Electron. Mater. 29, 1137 https://doi.org/10.1007/s11664-000-0004-9 (2000).

P.J. Rossi, N. Zotov and E.J. Mittemeijer, Zeitschrift für Kristallographie-Crystalline Materials, 231: 1 (2016). https://doi.org/10.1515/zkri-2015-1867

C.W. Fairhurst, and J.B. Cohen, Acta Crystallogr. B 28, 371 https://doi.org/10.1107/S0567740872002432 (1972).

H. Becker, and A. Leineweber, Mater Charact 141, 406 https://doi.org/10.1016/j.matchar.2018.05.013 (2018).

F. Birch, Phys. Rev. 71, 809 https://doi.org/10.1103/PhysRev.71.809 (1947).

H. Yan, W. Guo, T. Luan, X. Ma, G. Xu, X. Leng, W. Zhao, and J. Yan, Mater. Des. 212, 110292 https://doi.org/10.1016/j.matdes.2021.110292 (2021).

M. Wołcyrz, R. Kubiak, and S. Maciejewski, Phys. Status Solidi 107, 245 https://doi.org/10.1002/pssb.2221070125 (1981).

G. Ghosh, S. Delsante, G. Borzone, M. Asta, and R. Ferro, Acta Mater. 54, 4977 https://doi.org/10.1016/j.actamat.2006.04.038 (2006).

H. Flandorfer, U. Saeed, C. Luef, A. Sabbar, and H. Ipser, Thermochim. Acta 459, 34–39 https://doi.org/10.1016/j.tca.2007.04.004 (2007).

R.F. Sekerka, Crystal Growth - From Fundamentals to Technology, ed. G. Müller, J. Métois, Jacques and P. Rudolph (Elsevier Science B.V., Amsterdam, 2004), pp 55-93.

R.P. Kauffman, and A.M. Rappe, Phys. Rev. B 67, 085403 https://doi.org/10.1103/PhysRevB.67.085403 (2003).

H.M. Polatoglou, M. Methfessel, and M. Scheffler, Phys. Rev. B 48, 1877 https://doi.org/10.1103/PhysRevB.48.1877 (1993).

W. Kurz, M. Rappaz, and D.J. Fisher, Fundamentals of Solidification: with Solution Manual (Trans Tech Publications Ltd, Baech, 2023), pp33–50.

Acknowledgements

G.Z. acknowledges the funding from National Natural Science Foundation of China (51904352), and Scientific Research Foundation of Hunan Provincial Education Department, China (22A0004). This work is partly supported by the Guangdong Basic and Applied Basic Research Foundation under Grant No. 2021B1515120060. Y. R. Wang would like to thank the financial support from the National Natural Science Foundation of China (52001331), and Huxiang Youth Talent Program of Hunan Province, China (2023RC3052). The computational resource at the High-Performance Computing Center of Central South University is also gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Jieli Liao: Conceptualization, Methodology, Investigation, Data curation, Writing—original draft. Xiaojuan Hu: Methodology, Investigation, Data curation. Yiren Wang: Methodology, Software, Supervision, Writing—review & editing. Wei Sun: Methodology, Investigation, Data curation. Gaoyang Mi: Methodology. Jingwei Xian: Methodology, Writing—review & editing. Guang Zeng: Conceptualization, Software, Writing—review & editing, Supervision, Funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liao, J.L., Hu, X.J., Wang, Y.R. et al. Facets Formation of Ag3Sn Intermetallic in Sn-Bi-Ag Alloys: An EBSD and First-Principles Study. JOM 76, 2741–2753 (2024). https://doi.org/10.1007/s11837-024-06500-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06500-x