Abstract

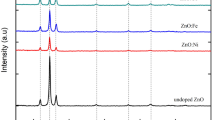

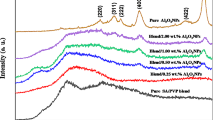

V-, Ce-, and Mn-doped NiO/rGO bilayer nanocomposite thin films were prepared by the sol–gel spin-coating method. The structural, optical, and magnetic properties of the thin films have been investigated by XRD, XPS, Raman, SEM, UV-visible spectra, photoluminescence (PL) spectra, and SQUID-VSM analysis. The XRD patterns revealed the polycrystalline nature of the NiO thin films and the rGO layering decreased the crystallite size. The binding energy of all the thin films have been calculated using XPS spectra, confirming the cubic structure of NiO. Raman spectra analysis revealed the presence of increased defects corresponding to rGO in the layered films. rGO layering changed the surface morphology of all the doped films. Higher transmittance values have been observed for all the NiO and rGO layered NiO thin films in the visible and IR regions. The layering and doping changed the band gap values significantly. A PL quenching was observed in the rGO layered undoped and doped NiO thin films. Analysis of the magnetic properties revealed the increased values of saturation magnetization and magnetic moment in the rGO layered thin films.

Similar content being viewed by others

References

D. Cao, H. Li, Z. Wang, J. Wei, J. Wang, and Q. Liu, Thin Solid Films 597, 1 https://doi.org/10.1016/j.tsf.2015.11.022 (2015).

S.K. Sarkar, K.K. Rahul, S.S. Pradhan, S. Basu, and A. Nayak, Phys. E Low-Dimens. Syst. Nanostruct. 64, 78 https://doi.org/10.1016/j.physe.2014.07.014 (2014).

M.A. Khan, A. Kumar, J. Zhang, and M. Kumar, J. Mater. Chem. C 9, 8129 https://doi.org/10.1039/D1TC01306H (2021).

D. Sharma, J. Yadav, and B.R. Mehta, Renew. Energy 169, 414 https://doi.org/10.1016/j.renene.2021.01.010 (2021).

R. Tarcan, O. Todor-Boer, I. Petrovai, C. Leordean, S. Astilean, and I. Botiz, J. Mater. Chem. C 8, 198 https://doi.org/10.1039/C9TC04916A (2020).

A. Kaulana, A.Y. Nugraheni, D.N. Jayanti, S. Mustofa, M.A. Baqiya, and Darminto, IOP Conf. Ser. Mater. Sci. Eng. 196, 012021 https://doi.org/10.1088/1757-899X/196/1/012021 (2017).

Y. Wang, Y. Huang, Y. Song, X. Zhang, Y. Ma, J. Liang, and Y. Chen, Nano-Letters 9(1), 220 https://doi.org/10.1021/nl802810g (2009).

D. Kaya, H.S. Aydınoğlu, E.Ş Tüzemen, and A. Ekicibil, Thin Solid Films 732, 138800 https://doi.org/10.1016/j.tsf.2021.138800 (2021).

V. Sushmitha, V. Maragatham, P. Deepak Raj, and M. Sridharan, IOP Conf. Ser. Mater. Sci. Eng. 310, 012022 https://doi.org/10.1088/1757-899X/310/1/012022 (2018).

P. Salunkhe, A.V. Muhammed Ali, and D. Kekuda, Appl. Phys. A 127, 390 https://doi.org/10.1007/s00339-021-04501-0 (2021).

A. Hirohata, K. Yamada, Y. NakataniI, L. Prejbeanu, B. Diény, P. Pirro, and B. Hillebrand, J. Magn. Magn. Mater. 509, 166711 https://doi.org/10.1016/j.jmmm.2020.166711 (2020).

Z. Qiu, H. Gong, G. Zheng, S. Yuan, H. Zhang, X. Zhu, H. Zhou, and B. Cao, J. Mater. Chem. C 5, 7084 https://doi.org/10.1039/C7TC01224A (2017).

A. Kumar and P.P. Sahay, Appl. Phys. A 127, 286 https://doi.org/10.1007/s00339-021-04436-6 (2021).

P. Salunkhe, M. Ali, and A.V. Dhananjaya Kekuda, Mater. Res. Express 7, 016427 https://doi.org/10.1088/2053-1591/ab69c5 (2020).

N.N. Ge, C.-H. Gong, X.-C. Yuan, H.-Z. Zheng, and X.-H. Wei, RSC Adv. 8, 29499 https://doi.org/10.1039/C8RA04784G (2018).

D.L. Sun, B.W. Zhao, J.B. Liu, H. Wang, and H. Yan, Ionics 23, 1509 https://doi.org/10.1007/s11581-017-1974-4 (2017).

G. Santamaría-Juarez, E. Gómez-Barojas, E. Quiroga-González, E. Sánchez-Mora, M. Quintana-Ruiz, and J.D. Santamaría-Juárez, Mater. Res. Express 6, 125631 https://doi.org/10.1088/2053-1591/ab4cbf (2020).

V. Kamble, S. Biswas, V.R. Appu, and A. Kumar, in Carbon Nonmaterial Electronics: Devices and Applications. ed. by A. Hazra, and R. Goswami (Springer, Singapore, 2021), pp. 349–369. https://doi.org/10.1007/978-981-16-1052-3_14.

F. Chandoul, H. Moussa, K. Jouini, A. Boukhache, F. Hosni, M.S. Fayache, and R. Schneider, J. Mater. Sci. Mater. Electron. 30, 348 https://doi.org/10.1007/s10854-018-0299-z (2019).

L.P. Yeo, T.D. Nguyen, H. Ling, Y. Lee, D. Mandler, S. Magdassi, A. Iing, and Y. Tok, J. Sci. Adv. Mater. Devices 4, 252 https://doi.org/10.1016/j.jsamd.2019.04.002 (2019).

S. Sadhukhan, A. Bhattacharyya, D. Rana, T. Kumar Ghosh, J.T. Orasugh, S. Khatua, K. Acharya, and D. Chattopadhyay, Mater. Chem. Phys. 247, 122906 https://doi.org/10.1016/j.matchemphys.2020.122906 (2020).

S. Vittorio and S.G. Compagnini, J. Carbon Res. 7, 48 https://doi.org/10.3390/c7020048 (2021).

P. Songkeaw, K. Onlaor, T. Thiwawong, and B. Tunhoo, Mater. Chem. Phys. 226, 302 https://doi.org/10.1016/J.MATCHEMPHYS.2019.01.048 (2019).

Q.A. Khan, A. Shaur, T.A. Khan, Y.F. Joya, and M.S. Awa, Cogenetchemistry 3, 1 https://doi.org/10.1080/23312009.2017.1298980 (2017).

N. Khosla, J. Narayan, R. Narayan, X.G. Sun, and M.P. Paranthaman, Carbon 205, 214 (2023).

J.J. Ding, X.H. Chen, D.Q. Feng, and H.W. Fu, IOP Conf. Ser. Mater. Sci. Eng. 292, 012097 https://doi.org/10.1088/1757-899X/292/1/012097 (2018).

T.M. Kaur, R. Sharma, H. Anjali, G.H. Mustafa, S. Kumar, and J.K. Goswamy, IOP Conf. Ser. Mater. Sci. Eng. 1033, 012053 https://doi.org/10.1088/1757-899X/1033/1/012053 (2021).

P.S. Abid and S. Ahmad, Sci. Rep. 8, 3537 https://doi.org/10.1038/s41598-018-21686-2 (2018).

G. Jeevitha, R. Abhinayaa, D. Mangalaraj, N. Ponpandian, P. Meena, V. Mounasamy, and S. Madanagurusamy, Nanoscale Adv. 1, 1799 https://doi.org/10.1039/C9NA00048H (2019).

A.N. Yadav, A.K. Singh, and P.K. Kumar, Nanoscale Res. Lett. 15, 166 https://doi.org/10.1186/s11671-020-03398-7 (2020).

N. Ali, B. Singh, Z.A. Khan, A.R. Vijaya, K. Tarafder, and S. Ghosh, Sci. Rep. 9, 246 https://doi.org/10.1038/s41598-019-39660-x (2019).

W. Huang, S. Ding, Y. Chen, W. Hao, X. Lai, J. Peng, J. Tu, Y. Cao, and X. Lin, Sci. Rep. 7, 5220 https://doi.org/10.1038/s41598-017-05528-1 (2017).

M. Zhong, W. Wu, H. Wu, and S. Guo, J. Alloys Compd. 765, 69 https://doi.org/10.1016/j.jallcom.2018.06.228 (2018).

M. Coey and S. Sanvito, Phys. World 17(11), 33 (2004).

J. Narayan and N. Khosla, Carbon 192, 301 (2022).

U.K. Panigrahi, P.K. Das, P.D. Babu, N.C. Mishra, and P. Mallick, SN Appl. Sci. 1, 438 https://doi.org/10.1007/s42452-019-0461-0 (2019).

V. Shukla, Nanoscale Adv. 2, 962 https://doi.org/10.1039/C9NA00663J (2020).

Z.N. Kayani, S. Riaz, S. Iram, and S. Naseem, J. Saudi Chem. Soc. 23, 392 https://doi.org/10.1007/s12648-013-0388-z (2019).

P.C. Patel, S. Ghosh, and P.C. Srivastava, Mater. Chem. Phys. 216, 285 https://doi.org/10.1016/j.matchemphys.2018.05.065 (2018).

L.S. Nair, D. Chandran, V.M. Anandakumar, and K. Rajendrababu, Ceram. Int. 43, 11090 https://doi.org/10.1016/j.ceramint.2017.05.155 (2017).

S. Gupta and J. Narayan, Carbon 153, 663 https://doi.org/10.1016/j.carbon.2019.07.064 (2019).

Acknowledgments

N.R. Aswathy acknowledges junior research fellowship from the University of Kerala, Thiruvananthapuram. The authors also acknowledge RUSA, India, for providing sol-gel spin coating unit and UV-visible spectrophotometer for the completion of this research.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Aswathy, and Vinod Kumar R. The first draft of the manuscript was written by Aswathy and corrected by Shree Renjini and Vinod Kumar. All the authors contributed to previous versions of the manuscript. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aswathy, N.R., Vinod Kumar, R. & Nair, S.R. Effect of rGO Layering on the Structural, Optical, and Magnetic Properties of Sol–Gel Spin-Coated V-, Ce-, and Mn-Doped NiO Thin Films. JOM 76, 2352–2361 (2024). https://doi.org/10.1007/s11837-024-06490-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06490-w