Abstract

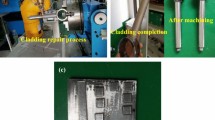

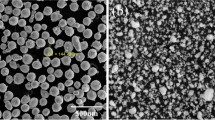

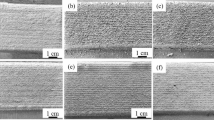

Forty five steel is a commonly used metal material in the machinery manufacturing industry. To improve the hardness and wear resistance of 45 steel, a Stellite6/WC Co-based alloy composite coating with rare earth Y was prepared on a 45 steel substrate by laser cladding technology. The effects of different additions of rare earth Y on the morphology, phase composition, microstructure, microhardness, and wear resistance of Stellite6/WC composite coatings after laser cladding were studied, and the optimal addition of rare earth Y was determined. The results showed that the addition of 0.9 wt.% rare earth Y coating to a Stellite6/WC composite coating has the best comprehensive performance. The X-ray diffraction results showed that new phases such as Y2O3, Co2Y, and Y2Co17 were formed after the addition of rare earth Y. Scanning electron microscopy showed that the coating bonding region was mainly composed of fine cellular crystals and columnar dendrites when the rare earth Y content was 0.9 wt.%, and that the upper region grains also became finer and the volume fraction of eutectics increased. Compared with the coating without the addition of rare earth Y, the maximum average microhardness was 629 HV0.2, and increase of 18.1% and the wear mass loss was reduced by 60.9%.

Similar content being viewed by others

References

L. Zhu, S. Wang, H. Pan, C. Yuan, and X. Chen, J. Manuf. Process. 49, 344 https://doi.org/10.1016/j.jmapro.2019.12.009 (2020).

G.S. Li, Z.Y. Wang, L.G. Yao, J.X. Ding, and J.J. Gao, Surf. Coat. Technol. 455, 129233 https://doi.org/10.1016/j.surfcoat.2023.129233 (2023).

X. Quan and L. Ding, Sci. Adv. Mater. 11, 1798 https://doi.org/10.1166/sam.2019.3610 (2019).

Z.Y. Li, H. Yan, P.L. Zhang, J.L. Guo, Z.S. Yu, and J.W. Ringsberg, Surf. Coat. Technol. 405, 126592 https://doi.org/10.1016/j.surfcoat.2020.126592 (2021).

M. Erfanmanesh, R. Shoja-Razavi, H. Abdollah-Pour, H. Mohammadian-Semnani, M. Barekat, and S.H. Hashemi, Int. J. Refract. Met. Hard Mater. 81, 137 https://doi.org/10.1016/j.ijrmhm.2019.02.025 (2019).

J. Ke, X.B. Liu, M. Wang, J. Liang, Y.S. Luo, and D.Q. Chen, J. Mater. Res. Technol. 9, 6397 https://doi.org/10.1016/j.jmrt.2020.04.023 (2020).

Y.L. Xia, H.N. Chen, X.D. Liang, and J.B. Lei, J. Manuf. Process. 68, 1694 https://doi.org/10.1016/j.jmapro.2021.06.074 (2021).

G.Y. Wang, J.Z. Zhang, R.Y. Shu, and S. Yang, Int. J. Refract. Met. Hard Mater. 81, 63 https://doi.org/10.1016/j.ijrmhm.2019.02.024 (2019).

Y.Z. Zhang, P.Q. Xu, C.G. Liu, J.W. Ren, and H.Y. Gong, Appl. Surf. Sci. 469, 495 https://doi.org/10.1016/j.apsusc.2018.11.084 (2019).

M. Radhakrishnan, M.M. Hassan, B.E. Long, D. Otazu, T.J. Lienert, and O. Anderoglu, Addit. Manuf. 46, 102198 https://doi.org/10.1016/j.addma.2021.102198 (2021).

F. Weng, H.J. Yu, C.Z. Chen, J.L. Liu, and L.J. Zhao, J. Alloys Compd. 650, 178 https://doi.org/10.1016/j.jallcom.2015.07.295 (2015).

X.Y. Zhang, S. Pfeiffer, P. Rutkowski, M. Makowska, D. Kata, J.L. Yang, and T. Graule, Appl. Surf. Sci. 520, 146304 https://doi.org/10.1016/j.apsusc.2020.146304 (2020).

H.B. Ma and W.P. Zhang, Rare Metal Mater. Eng. 39, 1239 (2010).

A. Vi, F. Os, and A. Et, Procedia Manuf. https://doi.org/10.1016/j.promfg.2019.04.089 (2019).

F. Weng, H.J. Yu, J.L. Liu, C.Z. Chen, J.J. Dai, and Z.H. Zhao, Opt. Laser Technol. 92, 156 https://doi.org/10.1016/j.optlastec.2017.01.014 (2017).

D. Bartkowski and G. Kinal, Int. J. Refract. Met. Hard Mater. 58, 157 https://doi.org/10.1016/j.ijrmhm.2016.04.017 (2016).

L. Chen, W.G. Chen, D.Y. Li, P.Y. Jing, H.Z. Yin, H.J. Wu, Y. Xie, and X.N. Wang, Tribol. Int. 169, 107428 https://doi.org/10.1016/j.triboint.2022.107428 (2022).

B.L. Ezquerra, L. Lozada, H. van den Berg, M. Wolf, and J.M. Sánchez, Int. J. Refract. Met. Hard Mater. 72, 89 https://doi.org/10.1016/j.ijrmhm.2017.12.021 (2018).

D. Bartkowski, A. Młynarczak, A. Piasecki, B. Dudziak, M. Gościański, and A. Bartkowska, Opt. Laser Technol. 68, 191 https://doi.org/10.1016/j.optlastec.2014.12.005 (2015).

P.H. Xu, L.D. Zhu, P.S. Xue, Z.C. Yang, S.H. Wang, J.S. Ning, G.R. Meng, Q. Lan, and S.Q. Qin, Ceram. Int. 48, 9218 https://doi.org/10.1016/j.ceramint.2021.12.108 (2022).

T. Wang, L. Zhu, H. Song, and H. Wang, Opt. Laser Technol. 148, 107780 https://doi.org/10.1016/j.optlastec.2021.107780 (2022).

G.J. Xu and M. Kutsuna, Surf. Eng. 22, 345 https://doi.org/10.1179/174329406X98430 (2013).

W.Y. Li, X.F. Yang, J.P. Xiao, and Q.M. Hou, Ceram. Int. 47, 28754 https://doi.org/10.1016/j.ceramint.2021.07.035 (2021).

W.H. Jiang and R. Kovacevic, J. Mater. Process. Technol. 186, 331 https://doi.org/10.1016/j.jmatprotec.2006.12.053 (2007).

A.K. Das, Mater. Today Proceed. 52, 1558 https://doi.org/10.1016/j.matpr.2021.11.236 (2022).

Y. Fan, G. Jin, X. Cui, Y. Li, and Z. Gao, Surf. Coat. Technol. 288, 25 https://doi.org/10.1016/j.surfcoat.2016.01.007 (2016).

I. Radu, D.Y. Li, and R. Llewellyn, Wear 257, 1154 https://doi.org/10.1016/j.wear.2004.07.013 (2004).

B. Han, J.Y. Lin, X.R. Han, H. Wang, and W.H. Cui, Surf. Eng. 37, 982 https://doi.org/10.1080/02670844.2020.1848008 (2020).

S.T. Sun, H.G. Fu, X.L. Ping, X.Y. Guo, J. Lin, Y.P. Lei, W.B. Wu, and J.X. Zhou, Surf. Coat. Technol. 359, 300 https://doi.org/10.1016/j.surfcoat.2018.12.083 (2019).

M.Z. Du, L.L. Wang, Z.N. Gao, X.Y. Yang, T. Liu, and X.H. Zhan, Opt. Laser Technol. 153, 108205 https://doi.org/10.1016/j.optlastec.2022.108205 (2022).

Y.M. Shi, J.B. Li, J. Zhang, B.Q. Wen, L.Q. Li, X.F. Wang, and S.X. Ren, Opt. Laser Technol. 148, 107640 https://doi.org/10.1016/j.optlastec.2021.107640 (2022).

T.G. Zhang, H.Q. Xiao, Z.Q. Zhang, B. Yao, and F. Yang, J. Mater. Eng. Perform. 29, 8221 https://doi.org/10.1007/s11665-020-05316-5 (2020).

Q. Wang, J. Yang, W.J. Niu, Y. Li, X. Mao, Y. Wang, and K. Zhang, Optik 245, 167653 https://doi.org/10.1016/j.ijleo.2021.167653 (2021).

Z.C. Liu, C. He, and D.J. Kong, Opt. Laser Technol. 168, 109801 https://doi.org/10.1016/j.optlastec.2023.109801 (2024).

Q.S. Liu, X.B. Liu, G. Wang, Y.F. Liu, Y. Meng, and S.H. Zhang, Opt. Laser Technol. 156, 108549 https://doi.org/10.1016/j.optlastec.2022.108549 (2022).

M.M. Quazi, M.A. Fazal, A.S.M.A. Haseeb, F. Yusof, H.H. Masjuki, and A. Arslan, J. Rare Earths 34, 549 https://doi.org/10.1016/s1002-0721(16)60061-3 (2016).

K.L. Wang, Q.B. Zhang, M.L. Sun, and X.G. Wei, J. Mater. Process. Technol. 139, 448 https://doi.org/10.1016/s0924-0136(03)00551-x (2003).

M. Erfanmanesh, H. Abdollah-Pour, H. Mohammadian-Semnani, and R. Shoja-Razavi, Ceram. Int. 44, 12805 https://doi.org/10.1016/j.ceramint.2018.04.087 (2018).

J. Nerz, B. Kushner, and A. Rotolico, J. Therm. Spray Technol. https://doi.org/10.1007/BF02659015 (1992).

J. Li, H. Wang, M. Li, and Z. Yu, J. Rare Earths 29, 477 https://doi.org/10.1016/S1002-0721(10)60483-8 (2011).

L.C. Wang and D.Y. Li, Wear 255, 535 https://doi.org/10.1016/s0043-1648(03)00057-7 (2003).

C.L. Wang, Y. Gao, Z.C. Zeng, and Y.K. Fu, J. Alloy. Compd. 727, 278 https://doi.org/10.1016/j.jallcom.2017.08.101 (2017).

L. Ding, S. Hu, X. Quan, and J. Shen, J. Alloys Compd. 659, 8 https://doi.org/10.1016/j.jallcom.2015.11.036 (2016).

K.L. Wang, Q.B. Zhang, M.L. Sun, X.G. Wei, and Y.M. Zhu, Appl. Surf. Sci. 174, 191 (2001).

C.F. Wu, M.X. Ma, W.J. Liu, M.L. Zhong, H.J. Zhang, and W.M. Zhang, J. Rare Earths 27, 997 https://doi.org/10.1016/s1002-0721(08)60377-4 (2009).

Y. Hou, H. Chen, Q. Cheng, L. Fan, and L. Dong, Mater. Express 10, 634 https://doi.org/10.1166/mex.2020.1686 (2020).

Z.Y. Hu, Y. Li, B.W. Lu, N. Tan, L.R. Cai, and Q.S. Yong, Opt. Laser Technol. 155, 108449 https://doi.org/10.1016/j.optlastec.2022.108449 (2022).

Z.Z. Yang, H. Hao, Q. Gao, Y.B. Cao, R.H. Han, and H.B. Qi, Surf. Coat. Technol. 405, 126544 https://doi.org/10.1016/j.surfcoat.2020.126544 (2021).

H. Lv, Y. Liu, H. Chen, W. Zhang, S.Y. Lv, and D.P. He, Surf. Coat. Technol. 464, 129529 https://doi.org/10.1016/j.surfcoat.2023.129529 (2023).

M. Furukawa, Z. Horita, M. Nemoto, R.Z. Valiev, and T.G. Langdon, Acta Mater. 44, 4619 (1996).

X.H. Wang, S.S. Liu, M. Zhang, and K.L. Qu, Tribol. Trans. 63, 345 https://doi.org/10.1080/10402004.2019.1694200 (2019).

P.A. Molian and L. Hualun, Wear, 130, 337 (1989).

Y. Shi, Y.F. Li, J. Liu, and Z.Y. Yuan, Opt. Laser Technol. 99, 256 https://doi.org/10.1016/j.optlastec.2017.09.010 (2018).

Acknowledgements

This work was financially supported by the Natural Science Foundation of Hebei Province (No. E2021209026).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, H., Zhang, H., Hou, S. et al. Effect of Rare Earth Y Addition on the Microstructure and Properties of Stellite6/WC Coating by Laser Cladding. JOM 76, 2143–2153 (2024). https://doi.org/10.1007/s11837-024-06379-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06379-8