Abstract

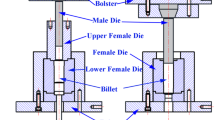

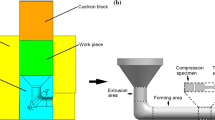

In this study, Mg-Gd-Y-Zn-Zr alloy bars with the height-to-diameter ratio of 6.5 were deformed using a novel large height-to-diameter ratio upsetting–extrusion process. After the initial billets were upset at 460°C, they were extruded at 460–420°C, respectively, and the true strain of one-pass upsetting–extrusion deformation reached 2.46. The results showed that the 420°C extruded samples had the highest recrystallization fraction of 75.2%. Continuous dynamic recrystallization and discontinuous dynamic recrystallization occurred during upsetting and extrusion, and the lower extrusion temperature favored the precipitation of large particles of Mg5(RE) phase and refined the grains through the particle-stimulated nucleation mechanism, and the average grain size decreased from 93.8 μm to a minimum of 15.3 μm. The 440°C extruded samples have the best mechanical properties with yield strength, ultimate tensile strength, and elongation of 260 MPa, 368 MPa, and 13.1%, respectively. Texture strengthening and dislocation strengthening dominate, and the appropriate proportion of coarse grains accommodating deformation has enabled the high elongation. In addition, the anomalous texture of the basal plane perpendicular to the extrusion direction was found in the high recrystallization fraction samples and attributed to the selective growth of recrystallized grains.

Similar content being viewed by others

References

H. Liu, Y. Meng, H. Yu, W. Xu, S. Zhang, L. Jia, and G. Wu, Materials (Basel). https://doi.org/10.3390/ma13153290 (2020).

Q. Deng, Y. Wu, W. Zhu, K. Chen, D. Liu, L. Peng, and W. Ding, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.142139 (2022).

M. Shokri, A. Zarei-Hanzaki, H.R. Abedi, and J.H. Cho, J. Market. Res. 15, 6974–6989 https://doi.org/10.1016/j.jmrt.2021.11.058 (2021).

J. Zheng, Z. Yan, J. Ji, Y. Shi, H. Zhang, Z. Zhang, and Y. Xue, J. Magn. Alloys 10, 1124 https://doi.org/10.1016/j.jma.2021.05.018 (2022).

J. Zheng, Z. Chen, Z. Yan, Z. Zhang, Q. Wang, and Y. Xue, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2021.162490 (2022).

J. Zheng, Z. Chen, Z. Yan, Z. Zhang, and Y. Xue, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.142103 (2021).

J. Shao, Z. Chen, T. Chen, R. Wang, Y. Liu, and C. Liu, Mater. Sci. Eng. A 731, 479 https://doi.org/10.1016/j.msea.2018.06.062 (2018).

C. Xu, M.Y. Zheng, K. Wu, E.D. Wang, G.H. Fan, S.W. Xu, S. Kamado, X.D. Liu, G.J. Wang, and X.Y. Lv, J. Alloys Compd. 550, 50 https://doi.org/10.1016/j.jallcom.2012.09.101 (2013).

S. Zhang, W. Liu, X. Gu, C. Lu, G. Yuan, and W. Ding, J. Alloys Compd. 557, 91 https://doi.org/10.1016/j.jallcom.2012.12.093 (2013).

Y. Xue, Z. Wang, L. Jia, J. Zheng, Z. Zhang, J. Yu, and X. Zhao, Mater. Tehnol. https://doi.org/10.17222/mit.2021.317 (2022).

S. Wenjia, Z. Zhimin, M. Mu, and Y. Yongbiao, Mater. Res. Express. https://doi.org/10.1088/2053-1591/aaa309 (2018).

Q. Wei, L. Yuan, X. Ma, M. Zheng, D. Shan, and B. Guo, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.142144 (2022).

Z. Zhang, J.-H. Zhang, J. Wang, Z.-H. Li, J.-S. Xie, S.-J. Liu, K. Guan, and R.-Z. Wu, Int. J. Miner. Metall. Mater. 28, 30 https://doi.org/10.1007/s12613-020-2190-1 (2020).

H. Yu, S.H. Park, and B.S. You, Mater. Sci. Eng. A 610, 445 https://doi.org/10.1016/j.msea.2014.05.058 (2014).

Y. Wan, B. Tang, Y. Gao, L. Tang, G. Sha, B. Zhang, N. Liang, C. Liu, S. Jiang, Z. Chen, X. Guo, and Y. Zhao, Acta Mater. 200, 274 https://doi.org/10.1016/j.actamat.2020.09.024 (2020).

B. Li, B. Teng, and G. Chen, Mater. Sci. Eng. A 744, 396 https://doi.org/10.1016/j.msea.2018.12.024 (2019).

C. Huang, C. Liu, S. Jiang, Y. Wan, and Y. Gao, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.140853 (2021).

Z. Yan, Z. Zhang, X. Li, J. Xu, Q. Wang, G. Zhang, J. Zheng, H. Fan, K. Xu, J. Zhu, and Y. Xue, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.153698 (2020).

G. Jialin, L. Wei, W. Hongxia, Z. Xingguo, and B. Liping, Rare Metal Mater. Eng. 42, 1800 https://doi.org/10.1016/s1875-5372(14)60008-4 (2013).

S. Amani, and G. Faraji, Int. J. Min. Met. Mater. 25, 672 https://doi.org/10.1007/s12613-018-1614-7 (2018).

X. Chen, C. Liu, S. Jiang, and Y. Wan, Mater. Lett. https://doi.org/10.1016/j.matlet.2021.130995 (2022).

W.T. Sun, X.G. Qiao, M.Y. Zheng, Y. He, N. Hu, C. Xu, N. Gao, and M.J. Starink, Mater. Sci. Eng. A 728, 115 https://doi.org/10.1016/j.msea.2018.05.021 (2018).

H. Liu, J. Ju, J. Bai, J. Sun, D. Song, J. Yan, J. Jiang, and A. Ma, Metals. https://doi.org/10.3390/met7100398 (2017).

S.M. Ramezani, A. Zarei-Hanzaki, H.R. Abedi, A. Salandari-Rabori, and P. Minarik, J. Alloys Compd. 793, 134 https://doi.org/10.1016/j.jallcom.2019.04.158 (2019).

Y. Meng, J. Yu, K. Liu, H. Yu, F. Zhang, Y. Wu, Z. Zhang, N. Luo, and H. Wang, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.154454 (2020).

G. Zhang, Z. Zhang, Y. Du, Z. Yan, and X. Che, Materials (Basel). https://doi.org/10.3390/ma11112092 (2018).

X. Zhao, S. Li, Y. Zheng, Z. Liu, K. Chen, J. Yu, Z. Zhang, and S. Zheng, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2021.160871 (2021).

L. Jia, J. Yu, W. Xu, G. Wu, Q. Xia, and Z. Zhang, Mater. Res. Express. https://doi.org/10.1088/2053-1591/abe8e8 (2021).

Y. Ye, C. Liu, and Y. Xue, Mater. Lett. https://doi.org/10.1016/j.matlet.2023.134047 (2023).

G. Zhang, Y. Meng, F. Yan, Z. Gao, Z. Yan, and Z. Zhang, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2019.152452 (2020).

J.-K. Kim, W.-S. Ko, S. Sandlöbes, M. Heidelmann, B. Grabowski, and D. Raabe, Acta Mater. 112, 171 https://doi.org/10.1016/j.actamat.2016.04.016 (2016).

P. Maier, M. Schmahl, B. Clausius, C. Joy, and C. Fleck, Crystals. https://doi.org/10.3390/cryst12111673 (2022).

C. Liu, L. Liu, J. Zheng, Z. Yan, Z. Zhang, Q. Wang, X. Li, and Y. Xue, J. Mater. Eng. Perform. 31, 9829 https://doi.org/10.1007/s11665-022-07022-w (2022).

T. Chen, Z. Chen, J. Shao, R. Wang, L. Mao, and C. Liu, Mater. Sci. Eng. A 750, 31 https://doi.org/10.1016/j.msea.2019.02.040 (2019).

S.Z. Wu, T. Nakata, G.Z. Tang, C. Xu, X.J. Wang, X.W. Li, X.G. Qiao, M.Y. Zheng, L. Geng, S. Kamado, and G.H. Fan, J. Mater. Sci. Technol. 73, 66 https://doi.org/10.1016/j.jmst.2020.09.020 (2021).

D. Yue, Z. Zhimin, Z. Guanshi, Y. Zhaoming, and Y. Jianmin, Rare Met. Mat. Eng. 47, 1422 https://doi.org/10.1016/s1875-5372(18)30144-9 (2018).

G. Zhang, Z. Zhang, X. Li, Z. Yan, X. Che, J. Yu, and Y. Meng, J. Alloys Compd. 790, 48 https://doi.org/10.1016/j.jallcom.2019.03.207 (2019).

C. Liu, J. Ji, J. Zheng, Q. Wang, Z. Zhang, and Y. Xue, J. Market. Res. 23, 391 https://doi.org/10.1016/j.jmrt.2023.01.029 (2023).

K. Wang, J. Wang, S. Huang, X. Dou, J. Wang, and C. Wang, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.142270 (2022).

S. Lyu, W. Xiao, G. Li, D. Xia, Y. Huang, S. Gavras, N. Hort, R. Zheng, and C. Ma, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2019.153477 (2020).

M.G. Jiang, C. Xu, H. Yan, T. Nakata, Z.W. Chen, C.S. Lao, R.S. Chen, S. Kamado, and E.H. Han, J. Magn. Alloys 9, 1797 https://doi.org/10.1016/j.jma.2020.09.001 (2021).

J.H. He, L. Jin, F.H. Wang, S. Dong, and J. Dong, J. Magn. Alloys 5, 423 https://doi.org/10.1016/j.jma.2017.09.004 (2017).

J. Zheng, L. Liu, W. Liu, Y. Huang, Z. Zhang, Q. Wang, Z. Yan, and Y. Xue, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2022.166920 (2022).

Acknowledgements

The study was supported by the National Natural Science Foundation of China (Grant no. 52075501 and 52205428) and the Fundamental Research Program of Shanxi Province (no. 20210302124206).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiao, W., Liu, C., Zhang, Z. et al. Effect of a Large Height-to-Diameter Ratio Upsetting–Extrusion Process on the Microstructure and Mechanical Properties of Mg-Gd-Y-Zn-Zr Alloys. JOM 76, 1831–1843 (2024). https://doi.org/10.1007/s11837-023-06215-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06215-5