Abstract

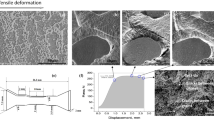

In this study, Bi was added to pure Sn to improve its strength and thermal properties. The presence of 2.5 and 5 wt.% Bi in the Sn matrix lowered the melting point of Sn from 232°C to 229°C and 225°C, respectively. The hardness was improved by increasing the Bi content; 2.5 wt.% Bi caused solid-solution hardening, whereas 5 wt.% Bi caused solid-solution, fine-grain, and Bi precipitation hardening. Sn with 5 wt.% Bi was reinforced by aging, which was attributed to dispersion hardening by Bi redistribution in the Sn matrix, and possessed good wettability on Cu. This study demonstrated that Sn with 5 wt.% Bi with good wettability has a good melting point, excellent hardness, and aging enhancement compared to pure Sn. Thus, this study provides mechanistic insights into the hardening of Sn-Bi alloys.

Similar content being viewed by others

Data Availability

The datasets used and analyzed during the current study are available from the corresponding author upon reasonable request.

References

K.N. Tu, Microelectron. Reliab. 51, 517 https://doi.org/10.1016/J.MICROREL.2010.09.031 (2011).

J.H. Lau, FOWLP: PoP Fan-Out Wafer-Level Packaging (Springer, Singapore, 2018), pp207–216.

H. Wang, X. Hu, and X. Jiang, Mater. Charact. 163, 110287 https://doi.org/10.1016/J.MATCHAR.2020.110287 (2020).

K. Xu, X. Fu, X. Wang, Z. Fu, X. Yang, S. Chen, Y. Shi, Y. Huang, and H. Chen, Materials 15, 108 https://doi.org/10.3390/MA15010108 (2021).

Y.-A. Shen and J.A. Wu, Materials 15, 5086 https://doi.org/10.3390/MA15145086 (2022).

Y. Li, X. Ren, S. Chen, Y. Qiao, and N. Zhao, J. Mater. Sci. 57, 4369 https://doi.org/10.1007/S10853-022-06918-1 (2022).

P. Zhang, S. Xue, and J. Wang, Mater. Des. 192, 108726 https://doi.org/10.1016/j.matdes.2020.108726 (2020).

L.S. Ramos, R.V. Reyes, L.F. Gomes, A. Garcia, J.E. Spinelli, and B.L. Silva, Mater. Sci. Eng. A 776, 138959 https://doi.org/10.1016/j.msea.2020.138959 (2020).

J. Qiu, Y. Peng, P. Gao, and C. Li, Materials 14, 2335 https://doi.org/10.3390/MA14092335 (2021).

Q. Xu, Y. Mei, X. Li, and G.Q. Lu, J. Alloys Compd. 675, 317 https://doi.org/10.1016/j.jallcom.2016.03.133 (2016).

H. Gao, F. Wei, Y. Sui, and J. Qi, Mater. Des. 174, 107794 https://doi.org/10.1016/J.MATDES.2019.107794 (2019).

W.H. Lin, A.T. Wu, S.Z. Lin, T.H. Chuang, and K.N. Tu, J. Electron. Mater. 36, 753 https://doi.org/10.1007/s11664-007-0139-z (2007).

Z.L. Ma, C. Li, S.Y. Yang, and X.W. Cheng, Acta Mater. 194, 422 https://doi.org/10.1016/j.actamat.2020.04.059 (2020).

M.B. Zhou, H.Q. Zhang, X.P. Zhang, and W. Yue, Shear strength and fracture behavior of locally-melted hybrid Cu/Sn3.0Ag0.5Cu/Sn58Bi/Cu joints under different loading rates. in 2019 20th International Conference Electronic Packaging Technology (ICEPT) (Institute of Electrical and Electronics Engineers Inc., 2019). https://doi.org/10.1109/ICEPT47577.2019.245207

Y.-A. Shen, X.-M. Yang, C.-Y. Tsai, Y.-H. Ouyang, M.-H. Tsai, and T.-T. Shun, Intermetallics 144, 107530 https://doi.org/10.1016/J.INTERMET.2022.107530 (2022).

G. Kim, K. Son, J.-H. Lee, Y.-C. Joo, and Y.-B. Park, Electron. Mater. Lett. 2022, 1 https://doi.org/10.1007/S13391-022-00356-6 (2022).

M.J. Rizvi, C. Bailey, Y.C. Chan, and H. Lu, J. Alloys Compd. 438, 116 https://doi.org/10.1016/j.jallcom.2006.08.048 (2007).

K. Zeng and K.N. Tu, Mater. Sci. Eng. R Rep. 38, 55 https://doi.org/10.1016/S0927-796X(02)00007-4 (2002).

K.N. Tu, A.M. Gusak, and M. Li, J. Appl. Phys. 93, 1335 https://doi.org/10.1063/1.1517165 (2003).

X. Chen, J. Zhou, F. Xue, and Y. Yao, Mater. Sci. Eng. A 662, 251 https://doi.org/10.1016/J.MSEA.2016.03.072 (2016).

S. Zhou, C. Yang, S. Lin, A.N. AlHazaa, O. Mokhtari, X. Liu, and H. Nishikawa, Mater. Sci. Eng. A 744, 560 https://doi.org/10.1016/j.msea.2018.12.012 (2019).

F. Iacoviello, T. Yang, Y. Chen, K. You, Z. Dong, Y. Jia, G. Wang, J. Peng, S. Cai, X. Luo, C. Liu, and J. Wang, Materials 15, 4727 https://doi.org/10.3390/MA15144727 (2022).

J. Ren and M.L. Huang, Sci. Technol. Weld. Join. 26, 205 https://doi.org/10.1080/13621718.2021.1882147/FORMAT/EPUB (2021).

J. Zhou, Y. Sun, and F. Xue, J. Alloys Compd. 397, 260 https://doi.org/10.1016/J.JALLCOM.2004.12.052 (2005).

J.A. Wu, A. Luktuke, and N. Chawla, J. Electron. Mater. 52, 1 https://doi.org/10.1007/S11664-022-10126-7/METRICS (2022).

S.A. Belyakov, J. Xian, G. Zeng, K. Sweatman, T. Nishimura, T. Akaiwa, and C.M. Gourlay, J. Mater. Sci. Mater. Electron. 30, 378 https://doi.org/10.1007/S10854-018-0302-8/FIGURES/13 (2019).

Y.-A. Shen, H.-M. Hsieh, S.-H. Chen, J. Li, S.-W. Chen, and H. Nishikawa, Appl. Surf. Sci. 546, 148931 https://doi.org/10.1016/j.apsusc.2021.148931 (2021).

H.Y. Zahran, H.N. Soliman, A.F. Abd El-Rehim, and D.M. Habashy, Crystals 11, 481 https://doi.org/10.3390/CRYST11050481 (2021).

Y.-A. Shen, H.-Z. Chen, S.-W. Chen, S.-K. Chiu, X.-Y. Guo, and Y.-P. Hsieh, Appl. Surf. Sci. 578, 152108 https://doi.org/10.1016/J.APSUSC.2021.152108 (2022).

Y.-A. Shen, S. Zhou, and H. Nishikawa, Materialia 6, 100309 https://doi.org/10.1016/J.MTLA.2019.100309 (2019).

Z. Hou, X. Zhao, Y. Gu, C. Tan, Y. Huo, H. Li, S. Shi, and Y. Liu, Mater. Sci. Eng. A 848, 143445 https://doi.org/10.1016/J.MSEA.2022.143445 (2022).

Y.A. Shen and Y.H. Ouyang, A study on strengthening mechanisms in Sn−0.7Cu via microstructural observation, elemental distribution, and grain-size analysis. in 2022 International Conference Electronics Packaging (ICEP) (Institute of Electrical and Electronics Engineers Inc., 2022), p. 41–42. https://doi.org/10.23919/ICEP55381.2022.9795497

C.M. Lin, H.L. Tsai, and H.Y. Bor, Intermetallics 18, 1244 https://doi.org/10.1016/j.intermet.2010.03.030 (2010).

E.M. Rebikov, V.V. Kashirtsev, V.V. Sosnin, and E.Y. Roshchupkina, Steel Transl. 51, 229 https://doi.org/10.3103/S0967091221030098/TABLES/4 (2021).

E.W. Hart, Acta Metall. 20, 275 https://doi.org/10.1016/0001-6160(72)90190-3 (1972).

Y. Tang, G.Y. Li, and Y.C. Pan, Mater. Des. 55, 574 https://doi.org/10.1016/j.matdes.2013.10.033 (2014).

Z. Liu, L. Yang, K.J. Lu, Y.C. Zhang, Y.H. Xu, F. Xu, and H.M. Gao, J. Electron. Mater. 50, 3326 https://doi.org/10.1007/S11664-021-08844-5 (2021).

Y.Z. Peng, C.J. Li, J.J. Yang, J.T. Zhang, J.B. Peng, G.J. Zhou, C.J. Pu, and J.H. Yi, Metals 11, 538 https://doi.org/10.3390/MET11040538 (2021).

Acknowledgements

Yu-An Shen expresses gratitude to the National Science and Technology Council of Taiwan for their support under Project NSTC 111-2221-E-035-054. The author also acknowledges the support from the Ultra HR SEM at the National Yang Ming Chiao Tung University Instrument Resource Center (EM002800) under Project MOST 111-2731-M-A49-001, the EPMA (EPMA000100) of The Center for High-Value Instrumentation at National Sun Yat-sen University under Project NSTC112-2740-M-110-002, and the Precision Instrument Support Center and all administration teams of Feng Chia University. The simulations presented in this paper were performed using Pandat software and released databases, and the authors express their gratitude to CompuTherm for providing the simulation tools. YA Shen also thanks the undergraduate students of his affiliation for laying out a few preliminary research directions for this study.

Funding

National Science and Technology Council of Taiwan, NSTC (111-2221-E−035-054), Yu-An Shen, Ministry of Science and Technology of Taiwan, MOST (109-2222-E−035-008-MY2), Yu-An Shen.

Author information

Authors and Affiliations

Contributions

YAS—Conceptualization, Methodology, Validation, Formal analysis, investigation, data curation, validation, writing—original draft, writing—review and editing, visualization, supervision, project administration, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, YA. Bi Dispersion Hardening in Sn-Bi Alloys by Solid-State Aging. JOM 75, 4922–4930 (2023). https://doi.org/10.1007/s11837-023-06079-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06079-9