Abstract

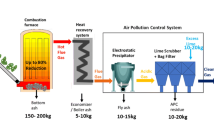

The discharge of industrial solid/hazardous wastes (such as aluminum dross, spent cathode carbon blocks, coal gangue, and carbide slag) causes potential environmental problems and wastes resources. An innovative method for preparing molecular sieves using varied solid/hazardous wastes is proposed. Aluminum dross is deeply denitrified to extract alumina source under a high concentration of sodium hydroxide. Denitrified aluminum dross, desilicated coal gangue, spent cathode carbon blocks, and carbide slag are synergistically reacted at high temperature to further extract alumina source. Alumina and silica sources are obtained via desilication of coal gangue which is used as raw materials to synthesize molecular sieve materials. The results show that the reaction rate of aluminum nitride in aluminum dross after leaching with high-concentration alkali solution reaches more than 99%, while the extraction rate of alumina reaches 40% (the extraction rate of alkali-soluble alumina is almost 100%). The highest sodium oxide recovery rate for various solid/hazardous wastes is 96.23%, and the alumina extraction rate is 95.2%. The molecular sieve prepared from silica and alumina sources has good crystallinity with an average particle size of 4.46 μm, a whiteness of 94.9, and a calcium exchange capacity of 310 mg/g.

Similar content being viewed by others

References

M.Z. Xie, H.L. Zhao, Z.G. Wu, W. Liu, R.B. Li, and F.Q. Liu, J. Sustain. Metall. 6, 715 https://doi.org/10.1007/s40831-020-00311-5 (2020).

H. Lv, H.L. Zhao, Z.P. Zuo, R.B. Li, and F.Q. Liu, J. Mater. Res. Technol. 9, 9735 https://doi.org/10.1016/j.jmrt.2020.06.051 (2020).

L. Chao, J.H. Wan, H.H. Sun, and L.T. Li, J. Hazard. Mater. 179, 515 https://doi.org/10.1016/j.jhazmat.2010.03.033 (2010).

Y.J. Wang, B.F. Ye, Z.C. Hong, Y.H. Wang, and M.H. Liu, J. Clean. Prod. 253, 119930 https://doi.org/10.1016/j.jclepro.2019.119930 (2020).

M. Mahinroosta, and A. Allahverdi, J. Environ. Manage. 223, 452 https://doi.org/10.1016/j.jenvman.2018.06.068 (2018).

B.R. Das, B. Dash, B.C. Tripathy, I.N. Bhattacharya, and S.C. Das, Miner. Eng. 20, 252 https://doi.org/10.1016/j.mineng.2006.09.002 (2007).

A. Meshram, and K.K. Singh, Resour. Conserv. Recycl. 130, 95108 https://doi.org/10.1016/j.resconrec.2017.11.026 (2018).

Y.X. Guo, H.B. Lv, X. Yang, and F.Q. Cheng, Sep. Purif. Technol. 151, 177 https://doi.org/10.1016/j.seppur.2015.07.043 (2015).

Y.X. Guo, K.Z. Yan, L. Cui, F.Q. Cheng, and H.H. Lou, Int. J. Miner. Process. 131, 51 https://doi.org/10.1016/j.minpro.2014.07.001 (2014).

Y.X. Guo, K.Z. Yan, L. Cui, and F.Q. Cheng, Powder Technol. 302, 33 https://doi.org/10.1016/j.powtec.2016.08.034 (2016).

Y.X. Guo, Q. Zhao, K.Z. Yan, F.Q. Cheng, and H.H. Lou, Ind. Eng. Chem. Res. 53, 4518 https://doi.org/10.1021/ie500295t (2014).

X.J. Ren, J.P. Xia, and Z.S. Zhang, NonMet. Mines 35, 12 (2012).

X.L. Wang, and Y. Zhang, Sci. Adv. Mater. 11, 277 https://doi.org/10.1166/sam.2019.3468 (2019).

J. Xiao, F.C. Li, Q.F. Zhong, H.G. Bao, B.J. Wang, J.D. Huang, and Y.B. Zhang, Hydrometallurgy 155, 118 https://doi.org/10.1016/j.hydromet.2015.04.018 (2015).

J.M. Zhu, H.W. Cai, and N.N. Dang, Adv. Mat. Res. 997, 614 https://doi.org/10.4028/www.scientific.net/AMR.997.614 (2014).

Y.Y. Teng, Y.F. Zhang, J. Bai, J.M. Shun, and L.X. Yang, Chem. Ind. Eng. Prog. 30, 456 https://doi.org/10.16085/j.issn.1000-6613.2011.02.003 (2011).

Q.L. Ge, M. Moeen, Q. Tian, J.J. Xu, and K.Q. Feng, Sci. Pollut. Res. 27, 7398 https://doi.org/10.1007/s11356-019-07412-z (2020).

F.Q. Liu, M.Z. Xie, G.Q. Yu, C.Y. Ke, and H.L. Zhao, ACS Sustain. Chem. Eng. 9, 10318 https://doi.org/10.1021/ACSSUSCHEMENG.1C03276 (2021).

M.Z. Xie, F.Q. Liu, H.L. Zhao, C.Y. Ke, and Z.Q. Xu, J. Mater. Res. Technol. 14, 2281 https://doi.org/10.1016/J.JMRT.2021.07.129 (2021).

M.Z. Xie, R.B. Li, H.L. Zhao, W. Liu, T.T. Lu, and F.Q. Liu, J. Clean. Prod. 249, 119370 https://doi.org/10.1016/j.jclepro.2019.119370 (2020).

N. Li, L. Gao, K. Chattopadhyay. Migration behavior of fluorides in spent potlining during vacuum distillation method. Light Met. 2019, Part of the The Minerals, Metals & Materials Series book series (MMMS), Pittsburgh, pp 867–872.

G. Hollywell, and R. Breault, JOM 65, 1441 https://doi.org/10.1007/s11837-013-0769-y (2013).

X.D. Zhao, G.M. Xiang, C.Y. Ma, and C.H. Chen, Chem. Eng. 34, 59 https://doi.org/10.1016/S1872-2040(06)60041-8 (2006).

X. Xin, Y.J. Li, W.J. Wang, and L. Shi, Appl. Energy 135, 391 https://doi.org/10.1016/j.apenergy.2014.08.098 (2014).

Y.J. Li, H.L. Liu, R.Y. Sun, S.M. Wu, and C.M. Lu, J. Therm. Anal. Calorim. 110, 685 https://doi.org/10.1007/s10973-011-1901-2 (2012).

Acknowledgements

This study was supported by the National Key Research and Development Program of China (2022YFC2904401).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, M., Liu, F. & Zhao, H. Detoxification and Extraction of Solid and Hazardous Wastes for the Preparation of Molecular Sieves. JOM 75, 4680–4688 (2023). https://doi.org/10.1007/s11837-023-06071-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06071-3