Abstract

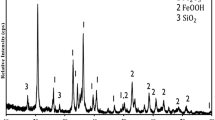

Due to increasing environmental and economic concerns, the recycling of metals has been increasing in the last decades. Aluminum saves up to 95% of energy when recycled, and magnesium is one of the most common alloying elements in aluminum alloys, contributing to oxidation behavior. Both aluminum and magnesium have a high oxidation tendency during remelting, which raises the necessity for salt flux usage. Salt fluxes remove oxides and other surface contaminants from the target metal. Salt fluxes allow molten metal pieces to coagulate and form the molten bath. Furthermore, it prevents further oxidation of the metal. The presence of fluorides increases the metal yield by promoting coalescence. Although metals and salts are frequently interacting in such processes, there is still a lack of knowledge of the final and intermediate products of the interaction reactions. This study aims to contribute to the literature by investigating the interaction of aluminum and magnesium scraps with salt flux. As a result of the experiments, AlF3, MgF2, Al2O3, MgO, and MgAl2O4 were observed as the main phases in the aluminum and magnesium scraps dross. The presence of CaF2 in the salt flux, which is insoluble in water, was also observed in the analysis results. In addition, fluorine-containing compounds were observed as a result of chemical interactions among the F-, K-, and oxide layers.

Similar content being viewed by others

References

P.E. Tsakiridis, J. Hazard. Mater. 217–218, 1–10 https://doi.org/10.1016/j.jhazmat.2012.03.052 (2012).

Global Aluminium Recycling: a cornerstone of sustainable development, International Aluminium Institute (IAI), London, (2009), pp. 1–36.

M. E. Schlesinger, Aluminium Recycling, 2nd ed., (2013), pp. 1–85.

Y. Xiao, M.A. Reuter, and U. Boin, J. Environ. Sci. Health Part A Toxic/Hazard. Subst. Environ. Eng. https://doi.org/10.1080/10934520500183824 (2005).

Y. Yang and M. A. Reuter, in Extraction and Processing Division Meeting on Recycling and Waste Treatment in Mineral and Metal Processing: Technical and Economic Aspects, (2002), pp. 527–537.

Y. Yang, Y. Xiao, B. Zhou, and M. A. Reuter, in Proceedings of the John Floyd International Symposium :Sustainable Developments in Metals Processing, Melbourne, July 3–6, (2005), pp. 251–263.

A. Vallejo-Olivares, S. Høgåsen, A. Kvithyld, and G. Tranell, J. Sustain. Metall. 8(4), 1485 https://doi.org/10.1007/s40831-022-00612-x (2022).

L.F. Zhang, and T. Dupont, Mater. Sci. Forum 546–549, 25–36 https://doi.org/10.4028/www.scientific.net/msf.546-549.25 (2007).

S. Gül, R. Dittrich, and B. Friedrich, in Proceedings of EMC (2013), pp.1–7.

S. Akbari and B. Friedrich, , in International Workshop on Metal-Slag Interaction, Yalta, Crimea – Ukraine, (2010), pp. 67–92.

L. Martin-Gar In, A. Dinet, and J. M. Hicter, J. Mater. Sci. 2366 (1979).

R.R. Roy, J. Ye, and Y. Sahai, Mater. Trans. JIM 38(6), 566–570 (1997).

J.A.S. Tenorio, M.C. Carboni, D. Crocce, and R. Esinosa, J. Light Met. 1, 195–198 (2001).

R.R. Roy, and Y. Sahai, Mater. Trans. JIM 38(6), 571–574 (1997).

R. Bolivar, and B. Friedrich, World Metall. 62(6), 366–371 (2009).

A.H. Sully, H.K. Hardy, and T.J. Heal, J. Inst. Metals 82, 2 (1953).

J.H. Linden, D.L. Stewart, and Y. Sahai, in Second International Symposium, Recycling of Metals and Engineered Materials (1990).

R.D. Peterson, in Second International Symposium on Recycling of Metals and Engineered Materials, TMS, Warrendale, PA, (1990), p. 85.

J. Ye, and Y. Sahai, . Materi.Trans. JIM 37(9), 1479–1485 (1996).

E.G. West, Trans. Inst. Weld. 4(50) (1941).

J.H.L. Van Linden and D.L. Stewart, Light Metals 391 (1988).

J. Courtenay and W. Schneider, Pyrotek Engineering and VAW Aluminium AG R&D (2000).

C. Qiu, S.M. Opalka, O.M. Løvvik, and G.B. Olson, Calphad 32(4), 624–636 https://doi.org/10.1016/j.calphad.2008.08.005 (2008).

R. Önen and M. Gökelma, in 10 th International Aluminnium Symposium, (2022), pp. 206–210.

T. Hiraki, T. Miki, K. Nakajima, K. Matsubae, S. Nakamura, and T. Nagasaka, Materials 7(8), 5543–5553 https://doi.org/10.3390/ma7085543 (2014).

I. Ansara, N. Dupin, H. L. Lukas, and B. Sundman, J. Alloys Compd. 20 (1997).

Z. Zhu, Y. Du, L. Zhang, H. Chen, H. Xu, and C. Tang, J. Alloys Compd. 460(1–2), 632 https://doi.org/10.1016/j.jallcom.2007.06.033 (2008).

P.M. Sathyaraj, K. Ravichandran, and T.S.N. Sankara Narayanan, J. Magn. Alloys 10(1), 295 https://doi.org/10.1016/j.jma.2021.06.005 (2022).

D.L. Stewart, J.H.L. Van Linden, A.F. LaCamera, T.V. Pierce, J.O. Parkhill, J.M. Urbanic, T.R. Hornack, United States Patent, 5,057,194 (1991).

J. Alberto, S. Tenorio, D. Crocce, and R. Espinosa, J. Light Metals 2(2), 89 (2002).

Acknowledgements

This research was funded by the Scientific and Technological Research Council of Turkey (TÜBITAK) under the BIDEB-2232 program with grant number 118C311.Center for Materials Research at İzmir Institute of Technology is gratefully acknowledged for the sample analyses.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Çapkın, İ.Y., Gökelma, M. An Investigation on Inclusions Forming During Remelting of Aluminum and Magnesium Scraps Under a Salt Flux. JOM 75, 4269–4274 (2023). https://doi.org/10.1007/s11837-023-06070-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06070-4