Abstract

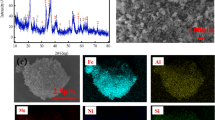

This article mainly studies the process optimization and kinetics of leaching magnesium from low-grade magnesite in ammonium bisulfate (NH4HSO4) solution. The effects of leaching time, leaching temperature, ammonium bisulfate concentration and excess rate of ammonium bisulfate on the magnesium leaching rate were investigated, and the composition and microstructure of magnesite before and after leaching were analyzed. Through optimization based on the response surface method based on the center combination design, the optimal leaching conditions are determined as follows: the leaching time is 7.7 h, the leaching temperature is 94°C, the mass concentration of NH4HSO4 is 19.2%, and the excess rate of NH4HSO4 is 18.7%. Under the optimal conditions, the leaching rate of magnesium was 95.9%. Using a shrinking core model, dissolution curves were evaluated. The leaching kinetics of magnesite in ammonium bisulfate solution show that the leaching was controlled by a surface chemical reaction with an activation energy of 43.40 kJ/mol.

Similar content being viewed by others

References

T.C. Xu, Y. Yang, X.D. Peng, J.F. Song, and F.S. Pan, J. Magnes. Alloys. https://doi.org/10.1016/j.jma.2019.08.001 (2019).

J. Song, J. She, D.L. Chen, and F.S. Pan, J. Magnes. Alloys. https://doi.org/10.1016/j.jma.2020.02.003 (2020).

M. Yeganeh and N. Mohammadi, J. Magnes. Alloys. https://doi.org/10.1016/j.jma.2018.02.001 (2018).

K. Luo, L. Zhang, G.H. Wu, W.C. Liu, and W.J. Ding, J. Magnes. Alloys. https://doi.org/10.1016/j.jma.2019.03.002 (2019).

Y.H. Ali, D. Qiu, B. Jiang, F.S. Pan, and M.X. Zhang, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2014.09.061 (2015).

I. Bentli, N. Erdogan, N. Elmas, and M. Kaya, Sep. Sci. Technol. https://doi.org/10.1080/01496395.2017.1281307 (2017).

C. Sadik, O. Moudden, A. El Bouari, and I. El Amrani, J. Asian Ceram. Soc. https://doi.org/10.1016/j.jascer.2016.06.006 (2016).

Y. Cui, D.L. Qu, X.D. Luo, X. Liu, and Y.X. Guo, Ceram. Int. https://doi.org/10.1016/j.ceramint.2020.09.150 (2021).

Y.N. Zhao and G.C. Zhu, Int. J. Miner. Process. https://doi.org/10.1016/j.minpro.2013.11.006 (2014).

Q.D. Hou, X.D. Luo, M.T. Li, D. An, and Z.P. Xie, Int. J. Appl. Ceram. TEC. https://doi.org/10.1111/ijac.13708 (2021).

N. Raza, Z.I. Zafar, and M. Najam-ul-Haq, Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2014.08.008 (2014).

H.R. Sun, B. Yang, Z.L. Zhu, W.Z. Yin, Q.Y. Sheng, and Y. Hou, Miner. Eng. https://doi.org/10.1016/j.mineng.2020.106660 (2021).

N. Raza, W. Raza, and M. Asif, Russ. J. Non-Ferr. Met. https://doi.org/10.3103/S1067821216040106 (2016).

J.F. Wang, Z.B. Li, A. Park, and C. Petit, AICHE J. https://doi.org/10.1002/aic.14789 (2015).

N. Raza, Z.I. Zafar, A. Najam-ul-Haq, and R.V. Kumar, Int. J. Miner. Process. https://doi.org/10.1016/j.minpro.2015.04.008 (2015).

M. Kyslytsyna, P. Raschman, Ľ Popovič, and G. Sučik, Acta Montan Slovaca. https://doi.org/10.46544/AMS.v25i1.4 (2020).

F. Demir, O. Laçin, and B. Dönmez, Ind. Eng. Chem. Res. https://doi.org/10.1021/ie0507629 (2006).

N. Raza and Z.I. Zafar, Int. J. Met. https://doi.org/10.1155/2013/352496 (2013).

B. Bayrak, O. Laçin, and H. Saraç, J. Ind. Eng. Chem. https://doi.org/10.1016/j.jiec.2010.01.055 (2010).

F. Demir, O. Laçin, and B. Dönmez, J. Ind. Eng. Chem. https://doi.org/10.1021/ie0507629 (2006).

P. Raschman, Hydrometallurgy. https://doi.org/10.1016/S0304-386X(00)00078-5 (2000).

S. Klochkovskii, A. Smirnov, and U. Shabalina, Defect Diffus. Forum. https://doi.org/10.4028/www.scientific.net/DDF.309-310.261 (2011).

Y.S. Wu, X. Yang, L.S. Li, Y.Z. Wang, and M.C. Li, Chem. Pap. https://doi.org/10.1007/s11696-019-00779-w (2019).

R.F. Gunst, R.H. Myers, and D.C. Montgomery, Technometrics. https://doi.org/10.2307/1270613 (1996).

M.A. Bezerra, R.E. Santelli, E.P. Oliveira, L.S. Villar, and L.A. Escaleira, Talanta. https://doi.org/10.1016/j.talanta.2008.05.019 (2008).

S.M.J. Mirazimi, F. Rashchi, and M. Saba, Sep. Purif. Technol. https://doi.org/10.1016/j.seppur.2013.05.032 (2013).

Živorad R. Lazić, Design of Experiments in Chemical Engineering A Practical Guide, (Weinhem, Euros, 2005), p610.

X.B. Zhu, Y.M. Zhang, J. Huang, T. Liu, and Y. Wang, Int. J. Miner. Process. https://doi.org/10.1016/j.minpro.2012.07.001 (2012).

O. Levenspiel, Chemical Reaction Engineering (John Wiley & Sons, New York, 1998), p120.

E.A. Abdel-Aal, Hydrometallurgy. https://doi.org/10.1016/S0304-386X(00)00059-1 (2000).

T. Rosenqvist, Principles of Extractive Metallurgy (Tapir academic press, Norway, 2004), p22.

C.Y. Wen, Ind. Eng. Chem. https://doi.org/10.1021/IE50705A007 (1968).

Acknowledgements

This work is supported by the Liaoning Province Applied Basic Research Program Project 2023JH2/101300245, the National Natural Science Foundation of China (Grant no. 51974188) and the Liaoning Revitalization Talents Program (No. XLYC2008014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Li, L., Wu, Y. et al. Process Optimization and Kinetics of Leaching Magnesium from Low-Grade Magnesite with Ammonium Bisulfate. JOM 75, 4385–4396 (2023). https://doi.org/10.1007/s11837-023-06058-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06058-0