Abstract

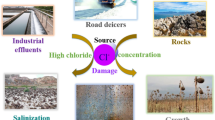

Since the high chloride ion concentration will have a serious impact on the zinc electrolysis process, the copper slag price adjustment method for dechlorination and the copper slag price adjustment synergistic high-activity copper deep dechlorination method are proposed, and a comparative experimental study is carried out. The single-stage chloride ion removal rate of the copper slag valence adjustment method was 86.1%, and the copper slag valence adjustment was synergistic with the deep dechlorination of highly active copper. This method can increase the chloride ion removal effect to 92.43%. Both can reduce the chloride ion concentration to below 100 mg/L, while the latter can reduce the chloride ion concentration to 30 mg/L due to the high activity of copper. Under ultrasonic condition, the removal rate of chloride ion can be further increased to 96.6%, and the chloride ion can be reduced to less than 20 mg/L, to achieve the effect of deep dechlorination.

Similar content being viewed by others

References

M. Mechili, C. Vaitsis, N. Argirusis, P.K. Pandis, G. Sourkouni, and C. Argirusis, Renew. Sustain. Energy Rev. 156, 111970 (2022).

I. Daigo, S. Osako, Y. Adachi, and Y. Matsuno, Resour. Conserv. Recycl. 82, 35–40 (2014).

X. Zhang, Y. Hu, Z. Xia, X. Zhao, Z. Zhou, and L. Ye, Sep. Purif. Technol. 283, 120221 (2022).

E. Rudnik, Miner. Eng. 139, 105871 (2019).

H.-F. Xiao, Q. Chen, H. Cheng, X.-M. Li, W.-M. Qin, B.-S. Chen, D. Xiao, and W.-M. Zhang, J. Membr. Sci. 537, 111–118 (2017).

W. Liu, L. Lü, Y. Lu, X. Hu, and B. Liang, Chin. J. Chem. Eng. 27, 1037–1043 (2019).

R. Raghavan, P.K. Mohanan, and S.K.J.H. Verma, ScienceDirect 51, 187–206 (1999).

I. Mazurek, A. Skawińska, and M. Sajdak, J. Energy Inst. 94, 337–351 (2021).

W. Dou, X. Peng, L. Kong, and X. Hu, Sci. Total Environ. 824, 153909 (2022).

H. Cheng, H.-F. Xiao, Q. Chen, X.-M. Li, W.-M. Qin, B.-S. Chen, D. Xiao, and W.-M. Zhang, J. Membr. Sci. 563, 142–148 (2018).

Z.-Y. Guo, T. Lei, W. Li, H.-L. Luo, S.-H. Ju, J.-H. Peng, and L.-B. Zhang, Chem. Eng. Process. 92, 67–73 (2015).

H. Liu, Y.-Y. Wang, L.-Y. Chai, H.-J. Xiao, F. Pei, and Y.-D. Shu, Trans. Nonferrous Metals Soc. China 21, 1665–1672 (2011).

E. Rudnik, and E. Bayaraa, Hydrometallurgy 159, 110–119 (2016).

X. Wu, Z. Liu, and X. Liu, Hydrometallurgy 134–135, 62–65 (2013).

K.F. Cao, Z. Chen, Y.H. Wu, Y. Mao, Q. Shi, X.W. Chen, Y. Bai, K. Li, and H.Y. Hu, Water Res. 215, 118271 (2022).

M. Nicol, C. Akilan, V. Tjandrawan, and J.A. Gonzalez, Hydrometallurgy 173, 125–133 (2017).

C. Bolognesi, and G. Morasso, Trends Food Sci. Technol. 11, 182–187 (2000).

S.S. Raut, S.P. Kamble, and P.S. Kulkarni, Chemosphere 159, 359–366 (2016).

Deepti, A. Sinha, P. Biswas, S. Sarkar, U. Bora, and M.K. Purkait, J. Water Process Eng. 33, 101108 (2020).

I. Ali, Z.A. Alothman, and A. Alwarthan, J. Mol. Liq. 241, 123–129 (2017).

T.A. Khan, M. Nazir, I. Ali, and A. Kumar, Arab. J. Chem. 10, S2388–S2398 (2017).

W. Liu, Z. Xiong, H. Liu, Q. Zhang, and G. Liu, China Agr. Ecosyst. Environ. 216, 147–154 (2016).

T.A. Saleh, and V.K. Gupta, Sep. Purif. Technol. 89, 245–251 (2012).

D. Wang, R. Zhu, J. Lou, J. Yuan, J. Xu, and X. Fan, J. Environ. Chem. Eng. 9, 106434 (2021).

Y. Li, Z. Yang, K. Yang, J. Wei, Z. Li, C. Ma, X. Yang, T. Wang, G. Zeng, G. Yu, Z. Yu, and C. Zhang, Sci. Total Environ. 821, 153174 (2022).

W. Liu, R. Zhang, Z. Liu, and C. Li, Hydrometallurgy 160, 147–151 (2016).

X. Wang, Y. Du, H. Yang, S. Tian, Q. Ge, S. Huang, and M. Wang, J. Ind. Eng. Chem. 93, 170–175 (2021).

X. Hu, F. Zhu, L. Kong, and X. Peng, J. Hazard. Mater. 410, 124540 (2021).

H. Li, L. Zhu, S. Wu, Y. Liu, and K. Shih, Int. J. Coal Geol. 170, 69–76 (2017).

D.K. Kozlica, A. Kokalj, and I. Milošev, Corros. Sci. 182, 109082 (2021).

P. Cornette, S. Zanna, A. Seyeux, D. Costa, and P. Marcus, Corros. Sci. 174, 108837 (2020).

S. Liu, X. Jiang, G.I.N. Waterhouse, Z.-M. Zhang, and L.-M. Yu, J. Electroanal. Chem. 897, 115558 (2021).

G. Dong, B. Du, L. Liu, W. Zhang, Y. Liang, H. Shi, and W. Wang, Appl. Surf. Sci. 399, 86–94 (2017).

Acknowledgements

This work was supported by National Natural Science Foundation of China Regional Foundation (No. 52264050), Yunnan Provincial Science and Technology Key Project (No. 202201AS070031), 2022 The central government guides the local “development of key technologies for clean and efficient utilization of copper resources” project and Yunnan Province Top young talents of The Ten Thousand Project. The authors are grateful for The Central Government Guides Local Science and Technology Development Plans (No. 202107AA110002), the National Key R&D Program of China (No. 2019YFC1904204), Kunming Key Laboratory of Special Metallurgy, Kunming Academician Workstation of Advanced Preparation for Super hard Materials Field, Kunming Academician Workstation of Metallurgical Process Intensification, and Yunnan Chihong Zinc Germanium Co., Ltd. Non-ferrous Metal Electrodeposition Technology Provincial Innovation Team.

Funding

National Natural Science Foundation of China Regional Foundation (No. 52264050). 2022 The central government guides the local “development of key technologies for clean and efficient utilization of copper resources” project. Yunnan Provincial Science and Technology Key Project (No. 202201AS070031). The Central Government Guides Local Science and Technology Development Plans (No. 202107AA110002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, J., Li, J. & Wang, S. Comparative Experimental Study on Copper Slag Valence-Controlled and its Synergistic High-Activity Copper Preparation Deep Dechlorination Method in the Ultrasonic Field. JOM 75, 3097–3104 (2023). https://doi.org/10.1007/s11837-023-05851-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05851-1