Abstract

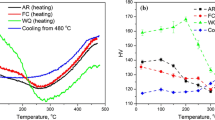

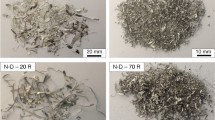

We investigated the correlation between the cooling rate and the cooling γ′ (γ′c) precipitate size in a Rene 95 alloy. The alloy powders were prepared through an electrode induction gas atomization, and the powders were consolidated by hot isostatic pressing. The solution heat treatment was performed using a gas-quenching furnace, which can control the cooling rate via the gas pressure. The samples were annealed at a sub-solvus temperature of 1135°C, and argon was used as the quenching gas. Experiments were carried out under four conditions with quenching gas pressures of 1, 2, 3, and 9 bar. At these pressures, the cooling rate increased to 114.5°C/min, 157.1°C/min, 201.1°C/min, and 282.9°C/min, respectively. The average size of the γ′c at the cooling rate of 114.5°C/min was 133 nm, and it decreased to 88 nm at 282.9°C/min. The power law relation was used to derive the equation for predicting the γ′c size concerning the cooling rate, while the data obtained from this study and the results from a previous study were used to fit the power law equation. From the analysis, parameters of A and n were determined to 179.4 and 0.493, respectively.

Similar content being viewed by others

References

J. Xie, S. Tian, X. Zhou, X. Yu, and W. Wang, Mater. Sci. Eng. A. 538, 306 (2012).

R.I. Ramakrishnan, and T.E. Howson, JOM. 44, 29 (1992).

K.O. Lee, K.H. Bae, and S.B. Lee, Mater. Sci. Eng. A. 519, 112 (2009).

W.M. Kane, U. Krupp, T. Jacobs, and C.J. McMahon, Mater. Sci. Eng. A. 402, 42 (2005).

C.E. Shamblen, R.E. Allen, and F.E. Walker, Metall. Mater. Trans. A. 6, 2073 (1975).

Z.Z. Lu, C.L. Liu, Z.F. Yue, and Y.L. Xu, Mater. Sci. Eng. A. 395, 153 (2005).

J. Xie, S. Tian, L.J. Shang, and X. Zhou, Mater. Sci. Eng. A. 606, 304 (2014).

A. Shyam, W.W. Milligan, S.A. Padula II., and S.I. Marras, Metall. Mater. Trans. A. 33, 1948 (2002).

M.T. Kim, D.S. Kim, and O.Y. Oh, Mater. Sci. Eng. A. 480, 218 (2008).

H. ElRakayby, H.K. Kim, S.S. Hong, and K.T. Kim, Adv. Powder Technol. 26, 1314 (2015).

W. Guo, J. Wu, F. Zhang, and M. Zhao, J. Iron Steel Res. Int. 13, 65 (2006).

T. Sugui, X. Jun, Z. Xiaoming, Q. Benjiang, L. Jianwei, Y. Lili, and W. Wuxiang, Mater. Sci. Eng. A. 528, 2076 (2011).

S. Terzi, R. Couturier, L. Guétaz, and B. Viguier, Mater. Sci. Eng. A. 483, 598 (2008).

S. Tian, J. Li, X. Zhou, A. Li, and F. Liang, Rare Met. 30, 457 (2011).

D. Locq, P. Caron, S. Raujol, F. Pettinari-Sturmel, A. Coujou and N. Clément, superalloys. 2004, 179 (2004).

H.Y. Li, J.F. Sun, M.C. Hardy, H.E. Evans, and S.J. Williams, Acta Mater. 90, 355 (2015).

T. Xin, S. Tang, F. Ji, L. Cui, B. He, X. Lin, X. Tian, H. Hou, Y. Zhao, and M. Ferry, Acta Mater. 239, 118248 (2022).

Z. Huda, Mater. Des. 28, 1664 (2007).

T. Sugui, L. Yang, Z. Xiaoming, Z. Zhonggang, B. Xianyu, and W. Wuxiang, Chin. J. Aeronaut. 22, 444 (2009).

H. Ding, G. He, W. Xin, F. Liu, L. Huang, and L. Jiang, Trans. Nonferrous Met. Soc. China 28, 451 (2018).

H. Wu, Z. Huang, N. Zhou, J. Chen, P. Zhou, and L. Jiang, Mater. Sci. Eng. A. 739, 473 (2019).

M.P. Jackson, and R.C. Reed, Mater. Sci. Eng. A. 259, 85 (1999).

S.A. Sajjadi, H.R. Elahifar, and H. Farhangi, J. Alloy. Compd. 455, 215 (2008).

Y.Q. Chen, E. Francis, J. Robson, M. Preuss, and S.J. Haigh, Acta Mater. 85, 199 (2015).

L. Gong, B. Chen, L. Zhang, Y. Ma, and K. Liu, J. Mater. Sci. Technol. 34, 811 (2018).

X. Fan, Z. Guo, X. Wang, J. Yang, and J. Zou, Mater. Charact. 139, 382 (2018).

G. Huang, G.Q. Liu, M. Feng, M. Zhang, B. Hu, and H. Wang, J. Alloy. Compd. 747, 1062 (2018).

Q. Wang, Z. Zhao, P. Bai, W. Du, H. Liao, Y. Li, M. Liang, P. Huo, L. Zhang, and D. Tie, Adv. Compos. Hybrid Mater. 4, 195 (2021).

W. Chen, Y. Zhao, S. Yang, D. Zhang, and H. Hou, Adv. Compos. Hybrid Mater. 4, 371 (2021).

S. Cai, X. Luo, J. Peng, Z. Yu, H. Zhou, N. Liu, and X. Wang, Adv. Compos. Hybrid Mater. 4, 379 (2021).

Y. Zhao, K. Liu, H. Hou, and L.Q. Chen, Mater. Des. 216, 110555 (2022).

Z. Zhao, R. Zhao, P. Bai, W. Du, R. Guan, D. Tie, N. Naik, M. Huang, and Z. Guo, J. Alloy. Compd. 902, 163484 (2022).

B. Liu, G. Dong, X. Ren, Y. Zhang, and Y. Wei, Int. J. Mater. Res. 111, 872 (2020).

Z. Zhao, X. Xu, Q. Wang, P. Bai, W. Du, L. Zhang, and W. Wang, Adv. Compos. Hybrid Mater. 4, 332 (2021).

C. Papadaki, W. Li, and A.M. Korsunsky, Materials. 11, 1528 (2018).

D.U. Furrer, and H. Fecht, Scr. Mater. 40, 1215 (1999).

F. Masoumi, D. Shahriari, M. Jahazi, and J. Cormier, Sci Rep. 6, 28650 (2016).

P.R. Bhowal, E.F. Wright, and E.L. Raymond, Metall. Mater. Trans. A. 21, 1709 (1990).

C. Hou, W. Yang, H. Kimura, X. Xie, X. Zhang, X. Sun, Z. Yu, X. Yang, Y. Zhang, B. Wang, B.B. Xu, D. Sridhar, H. Algadi, Z. Guo, and W. Du, J. Mater. Sci. Technol. 142, 185 (2023).

W. Yang, D. Peng, H. Kimura, X. Zhang, X. Sun, R.A. Pashameah, E. Alzahrani, B. Wang, Z. Guo, W. Du, and C. Hou, Adv. Compos. Hybrid Mater. 5, 3146 (2022).

Y. Zhang, L. Liu, L. Zhao, C. Hou, M. Huang, H. Algadi, D. Li, Q. Xia, J. Wang, Z. Zhou, X. Han, Y. Long, Y. Li, Z. Zhang, and Y. Liu, Adv. Compos. Hybrid Mater. 5, 2601 (2022).

A.A.N. Németh, D.J. Crudden, D.E.J. Armstrong, D.M. Collins, K. Li, A.J. Wilkinson, C.R.M. Grovenor, and R.C. Reed, Acta Mater. 126, 361 (2017).

C.L. Qiu, M.M. Attallah, X.H. Wu, and P. Andrews, Mater. Sci. Eng. A. 564, 176 (2013).

M.O. Alniak, and F. Bedir, Mater. Sci. Eng. B. 130, 254 (2006).

M.S. Chiou, S.R. Jian, A.C. Yeh, C.M. Kuo, and J.Y. Juang, Mater. Sci. Eng. A. 655, 237 (2016).

J. Mao, K. Chang, W. Yang, K. Ray, S.P. Vaze, and D.U. Ferrer, Metall. Mater. Trans. A 32, 2441 (2001).

J. Mao, K. Chang, W. Yang, D.U. Furrer, K. Ray, and S.P. Vaze, Mater. Sci. Eng. A. 332, 318 (2002).

Acknowledgements

This research was supported by the Creative Materials Discovery Program (No. NRF-2019M3D1A1079227) through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, D.H., Park, JY., Hong, S.J. et al. Correlation Between Cooling Rate and γ' Precipitate Size in Rene 95 Alloy Fabricated Through a Powder Metallurgy Process. JOM 75, 2489–2496 (2023). https://doi.org/10.1007/s11837-023-05822-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05822-6