Abstract

Phase relations in the CaO-Al2O3-Nd2O3 system were investigated in the temperature range between 1330°C and 1600°C using equilibration technique followed by characterization using x-ray diffraction and scanning electron microscopy combined with energy-dispersive x-ray spectroscopy (SEM/EDX). Melting relations were investigated using differential thermal analysis followed by microstructure study using SEM/EDX. It was found that CaNdAlO4 (τ1) compound melted congruently at 1808°C, while CaNdAl3O7 (τ2) compound melted incongruently at 1766°C. The sample in the stability fields adjacent to lowest eutectic in the CaO-Al2O3 system (CaAl2O4 + Ca3Al2O6) and τ2 as well as samples in the stability field τ2 + CaAl2O4 + CaAl4O7 and τ1 + τ2 + Ca3Al2O6 were completely melted at 1600°C. The Ca12Al14O33 phase considered as not stable in anhydrous atmosphere was found instead of Ca3Al2O6 phase after heat treatment at 1330°C. After melting Ca12Al14O33 formed glass. The obtained results are important for selection of conditions for process of rare earth recycling from waste permanent NdFeB magnets.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The phase relations in the CaO-Al2O3-Nd2O3 system are important for the recycling process of Nd from NdFeB magnets using pyrometallurgy. During reductive smelting, rare earth elements are selectively oxidized and dissolved in slag while Fe, Co, and other metals are kept in the metal melt.1 It should be noted that other rare earth elements (REE) such as Dy, Sm, Pr, Gd, Tb, etc., are used as additives to improve the properties of magnets, e.g., to increase the temperature of de-magnetization and corrosion resistance. Up to 10 mass% Dy can be contained in the NdFeB magnet.2 Recently, a two-stage process incorporating (1) an oxidative smelting step with use of CaO, Al2O3 as additives for NdFeB magnet dissolution and (2) a reductive smelting step for metal alloy phase and a CaO-REE2O3-Al2O3 slag phase generation has been presented;3 however, the process could be optimized to a single step process. Leaching and precipitation methods to selectively separate REE2O3 from the resulting CaO-REE2O3-Al2O3 slag have also been proposed.4 To study rare earth dissolution in molten slag the simplified model system CaO-Nd2O3-Al2O3 was selected. Experimental phase diagram data for the CaO-Nd2O3-Al2O3 system are minimal. Only an isothermal section at 1300°C is available based on experimental investigations of two works.5,6 Two ternary compounds with compositions CaNdAlO4 and CaNdAl3O7 were found. These phases can be considered for concentrating rare earth elements in slag. The phase NdAlO3 with perovskite structure congruently melting at 2083°C ± 50°C7 can also be of interest for Nd concentration. An array of methods could be considered for their separation from the bulk slag including high temperature filtration, since respective compounds form potentially two-phase regions with a bulk liquid slag phase at high temperatures.3 According to the phase diagram of the CaO-Al2O3 system, the lowest eutectic reaction occurred at 1360°C ± 5°C and 36 mol.% Al2O3.8 Therefore, the system CaO-Al2O3-Nd2O3 is of interest for rare earth recycling because of the presence of low-temperature eutectic in the CaO-Al2O3 binary system, two ternary compounds and one binary compound NdAlO3 concentrating rare earth elements. Since recycling processes include contact of oxidized rare earth elements with molten slag for concentrating of the former in the latter, it is especially important to address investigation of melting relations in the ternary system which are not known so far except for the melting point of the CaNdAlO4 compound. The aim of this study is to determine/verify the melting point of ternary compounds and to investigate melting of compositions in the ternary system close to lowest eutectic in the CaO-Al2O3 binary system.

Literature Survey

The thermodynamic database for the CaO-Al2O3 system is available. Four intermediate compounds are considered as stable Ca3Al2O6 (C3A), CaAl2O4 (CA), CaAl4O7 (CA2) and CaAl12O19 (CA6). The assessments of thermodynamic parameters were based on experimental data on phase equilibria and thermodynamic values such as activity for liquid phase, heat capacity, standard entropy, heat of formation, and heat of melting for intermediate compounds, which were reviewed in the works.8,9 Different variants of two-sublattice partially ionic liquid models and the same description of solid phases were published.8,10,11 In work of Eriksson and Pelton,9 solid phases were described using different Gibbs energy expressions than in Ref. 8, and a modified quasi-chemical model was applied for liquid. It should be noted that in several publications phase Ca12Al14O33 (C12A7) was found while it was assumed to be stabilized in moisture atmosphere and not stable in strictly anhydrous conditions (see details in Ref. 8).

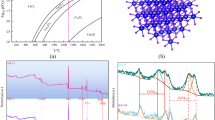

New experimental studies of the Nd2O3-Al2O3 system were undertaken to establish stability ranges of the intermediate compound β-NdAl11O18.7 Stability limits of the β-NdAl11O18 phase were determined using differential thermal analysis (DTA) and equilibration technique followed by x-ray analysis and SEM/EDX. The temperatures and compositions of eutectic reactions L ↔ Nd2O3 + NdAlO3 and L ↔ NdAlO3 + β-NdAl11O18 as well as the temperature of eutectoid reaction β-NdAl11O18 ↔ NdAlO3 + Al2O3 were experimentally determined for the system of Nd2O3-Al2O3.7 Review of literature data on the phase diagram and experimental thermodynamic data were presented.12 The obtained experimental results7 together with experimental data from literature were used for the assessment of thermodynamic parameters in the Nd2O3-Al2O3 system.7 Phase diagrams of the CaO-Al2O3 and Nd2O3-Al2O3 systems are presented in Fig. 1a and b.

The experimental data for the Nd2O3-CaO system are limited by one temperature of 885°C, at which the solubility of CaO in Nd2O3 (hexagonal phase A) was found to reach up 33 mol.% and no intermediate compounds were indicated.13 It should be noted that Lopato14 reported stability of intermediate compound corresponding to composition CaNd4O7 (beta-phase) having narrow homogeneity ranges, melting congruently and being stable in the range of 1850–2120°C. However, no experimental details were reported, and no phase diagram was presented. The thermodynamic description of Le et al.15 was obtained as an extrapolation from the ternary system without accounting solubility of CaO in the Nd2O3 phase. According to thermodynamic calculations, there is a eutectic reaction at 1800°C. However, a congruently melting phase CaNd4O7 should substantially change phase relations in the system.

Phase diagrams of the CaO-Al2O3-Nd2O3 system at 1300°C are presented in works of Jantzen and Glasser5 and Jantzen and Neurgaonkar.6 Two ternary compounds were found in the system CaNdAlO4 (τ1, tetragonal, K2NiF4 structure I4/mmm) and CaNdAl3O7 (τ2, tetragonal, melilite structure, P-421 m). Phases with the same structures were found in the systems with other rare earth oxides La, Ce, Gd and Y.16,17,18,19 Samples in the CaO-Al2O3-Nd2O3 system were synthesized by co-precipitation method6 that allow reaching equilibrium faster than by using solid state reactions. Notably, the phase diagram presented in Ref. 6 contains more details, and the tie line between τ2 and Nd2O3 was changed to τ1 and NdAlO3. However, the tie line between CaAl4O7 (CA2) and τ2 was not shown. It should be also noted that solubility of CaO in NdAlO3 was shown in Ref. 5 in contrast with another work.6 Various properties of the CaNdAlO4 compound were extensively studied. Melting temperature was reported in two works as 1820°C20 and 1860°C.21 The growth from melt was used to obtain a single crystal of τ1 in Ref. 21, which indicates congruent melting of this compound. Enthalpy of formation from oxides was determined using solution calorimetry (− 65.91 kJ/mol ± 8.23 kJ/mol) at 298.15 K and enthalpy increment from room temperature to 973 K equal to 110.43 kJ/mol.22

Experimental

Five samples were synthesized from oxide powders using solid state reaction method. Their compositions are presented in Table I. Calcium oxide (97+ %) and aluminum oxide (99.7+ %), both produced by Acros Organics (Belgium), and neodimium (III) oxide (min 99.8%), produced by supplier S3 Chemicals (Germany), were used. Powders were ball-milled and pelletized at 300 MPa (pellet size: 5 mm diameter and about 2–3 mm in height). Pellets were placed in Pt crucibles and heat treated in a muffle furnace (NABERTHERM, Germany) in air at chosen temperatures followed by furnace-cooling. Samples were heat treated at 1330°C for 168 h and at 1600°C for 96 h. Two other temperatures for heat treatment (1400°C and 1500°C) were selected for sample ACN-3 for interpretation of differential thermal analysis (DTA) results.

After heat treatment, the obtained samples were characterized using x-ray diffraction (XRD) and scanning electron microscopy combined with energy-dispersive x-ray spectroscopy (SEM/EDX). The powdered samples were investigated at room temperature using an URD63 x-ray diffractometer (Seifert, FPM, Freiberg, Germany) with CuKα radiation (λ = 1.5418 Å). ICSD (Inorganic Crystal Structure Database, 2017, Karlsruhe, Germany)23 was used for interpretation of the powder diffraction patterns. Qualitative and quantitative analyses of the XRD patterns were performed by Rietveld analysis using MAUD software.24,25 The microstructure of samples after heat treatment and after DTA was examined using a JEOL JSM-7800F (Japan) field emission gun (SEM) equipped with an EDX detector.

Melting of sample materials was investigated using a SETSYS EVOLUTION 2400 (TG-DTA) instrument (SETARAM, France) in open W crucibles in He atmosphere at temperatures up to 2000°C. The selection of highest temperature for DTA investigation was based on the results of equilibration experiments and literature data. The heating rate was 20 K min−1 up to 1200°C and then 10 K min−1; cooling rate was 30 K min−1. Temperature calibration was carried out using melting points of Al and Al2O3 and temperature of solid-state transformation in LaYO3.

Preliminary Calculations

Thermodynamic descriptions of the CaO-Al2O310 and Nd2O3-Al2O37 systems were combined, and the presence of the compound CaNd4O7 in the CaO-Nd2O3 system as well as solubility of CaO in Nd2O3 was not considered, similar to the assumptions made in Ref. 15. The calculated phase diagram of the CaO-Nd2O3 system presents a simple eutectic diagram with the eutectic temperature of 1989°C and composition of 50.2 mol.% Nd2O3. The thermodynamic functions of τ1 and τ2 were fitted to reproduce experimental data of Jantzen and Neurgaonkar6 at 1300°C. The isothermal sections of the CaO-Al2O3-Nd2O3 system calculated at 1300°C and 1600°C using Thermo-Calc software26 are shown in Fig. 2a and b, respectively. The calculations were performed assuming that phase C12A7 is metastable, although it was shown as a stable one in Refs. 5 and 6. Nevertheless, including data for this phase from Ref. 8 would result in an additional tie line between C12A7 and τ2 phase at 1300°C. At 1600°C, C12A7 is no longer stable.8

Results and Discussions

XRD and SEM/EDX Investigation of Samples Heat Treated at 1330°C and 1600°C

The results of XRD and SEM/EDX investigation of samples heat treated at 1330–1600°C are presented in Table I. Compositions of samples ACN-1 and ACN-2 correspond to the compositions of the phases τ1 and τ2, respectively. Compositions of the next three samples were selected to be in three phase fields: ACN-3 in τ2 + CA + C3A, ACN-4 in τ2 + CA + CA2 and ACN-5 in τ1 + τ2 + C3A based on the phase diagram of the CaO-Nd2O3-Al2O3 system at 1300°C (see Fig. 2a).

According to XRD, reactions in samples ACN-1 and ACN-2 at 1330°C were not completed. Sample ACN-1 heat treated at 1600°C was single-phase τ1, while SEM/EDX indicated a very small amount of NdAlO3 and the phase having composition C12A7. The sample ACN-2 heat treated at 1600°C contained 81.5 vol.% τ2-phase and 18.5 vol.% CA2; the phases present were confirmed by SEM/EDX. Samples ANC-1 and ANC-2 heat treated at 1600°C were investigated using DTA. Samples ACN-3, ACN-4 and ACN-5 were investigated using DTA after heat treatment at 1330°C, since they completely melted after heat treatment at 1600°C. According to XRD, the phases found in ACN-4 and ACN-5 after heat treatment at 1330°C correspond to expected phase assemblages CA + CA2 + τ2 and τ1 + τ2 + C3A, respectively. Results of SEM/EDX investigations confirmed phase assemblage in ACN-4, but in sample ACN-5 the phase with composition C12A7 was found instead of C3A. However, a more detailed investigation indicated that the phase having a composition close to C12A7 was not homogeneous and consisted of several phases (e.g., the black phase on the microstructure of ACN-2, see below). In sample ACN-3 heat treated at 1330°C, the metastable cubic phase C12A7 was indicated to coexist with CA and τ2 instead of C3A according to both XRD and SEM/EDX. As mentioned above, C12A7 phase was observed in the CaO-Al2O3 system according to the literature (see details in Ref. 8). However, the presence of this phase does not substantially affect the melting temperature in the CaO-Al2O3 system. It should be also mentioned that phase C12A7 was found in the ternary CaO-Nd2O3-Al2O3 system.5,6

After heat treatment of sample ACN-3 at 1600°C, C12A7 phase was not found by XRD, but the phase with this composition was found in the microstructure. Probably glass of C12A7 composition was formed during cooling. The data from the literature confirm our assumption. According to Refs. 27 and 28, molten composition C12A7, which coincides with the lowest eutectic in the CaO-Al2O3 system, can readily form glass by quenching. Sample ACN-4 after heat treatment at 1600°C contained the same phases as after heat treatment at 1330°C according to XRD and SEM/EDX. After heat treatment of sample ACN-5 at 1600°C, only two phases determined by XRD were τ1 and NdAlO3; however, several remaining peaks in the XRD pattern could not be fitted by any known phases in the system. Microstructure investigation using SEM/EDX confirmed the presence of two phases, τ1 and NdAlO3. Notably, substantial solubility of CaO in the NdAlO3 was found. Additionally, the phase with C12A7 composition was observed, but it was not found by XRD. Probably it was glassy phase, similar to one found in sample ACN-3 after heat treatment at 1600°C.

DTA Investigations

According to DTA, shown in Fig. 3a, sample ACN-1 contained single phase τ1 melted at 1808°C as evidenced by a sharp single thermal effect on heating, which indicates congruent melting. To support this statement, the microstructure of the sample after DTA presents only τ1 phase (Fig. 3b). The melting temperature is in good agreement with that in Ref. 20, but lower than obtained in Ref. 21.

As Table I shows, sample ACN-2 heat treated at 1600°C before it was investigated by DTA consisted of two phases identified by XRD τ2 (81.5 vol.%) and CA2 (18.5 vol.%). SEM/EDX indicated additionally a small amount of NdAlO3. Microstructure investigation of the sample after DTA showed that melting of the τ2 phase was incongruent (i.e., with decomposition, Fig. 4b). The primary crystallizing phase was NdAlO3 (white phase), which dissolved a substantial amount of CaO (~ 11 mol.% CaO, 53 mol.% Al2O3, 36 mol.% Nd2O3). Then, τ2 (gray phase) was growing on the primary phase NdAlO3. The last liquid was crystallizing as eutectic, probably CA + CA2 + τ2. The eutectic microstructure is very fine so that it is impossible to measure the phase compositions formed in the eutectic area. Consequently, as shown in Fig. 4a, the first heat effect at 1675°C observed on the DTA heating curve can be related to CA2 + τ2 melting and the second one at 1766°C with melting of τ2.

Presented in Fig. 5a, DTA for sample ACN-3 shows two effects on heating at 1357°C and 1546°C. Microstructure of sample ACN-3 after DTA presented in Fig. 5b shows that τ2 (white phase) solidified first and then a mixture of CA (black) and the phase corresponding to composition C12A7 (gray). However, XRD of the completely melted sample ACN-3 at 1600°C did not reveal the C12A7 phase. Actually, only τ2 and CA were identified by XRD. Probably the phase C12A7 was glassy. Therefore, the first effect on the DTA heating curve can be explained as melting of eutectic (τ2 + CA + C12A7) since it is below the calculated eutectic L ↔ CA + C12A7 in the binary CaO-Al2O3 system (1445°C8), and the last one is liquidus. To verify this idea, heat treatment of sample ACN-3 was additionally done at 1400°C and 1500°C. XRD investigation of sample ACN-3 after heat treatment at 1400°C confirmed that the sample was still solid and contained the CA, C12A7 and τ2 phases. Therefore, melting of the ACN-3 sample occurred at higher temperature, and the thermal effect at 1357°C is related to a reversible solid-state transformation. Visual investigation followed by microstructure investigation of sample ACN-3 heat treated at 1500°C indicated that it was partially melted. After partial melting pores disappeared, but typical eutectic microstructure was not observed. The last phase to form had composition C12A7 with ~ 1% Nd2O3. As mentioned above, the composition C12A7, which is close to the lowest eutectic in the CaO-Al2O3 system, readily forms glass during cooling, and this explains why a eutectic microstructure was not observed.

DTA for sample ACN-4 shows two heat effects at 1579 and 1632°C (Fig. 6a). According to XRD, the sample contained phases τ2, CA and CA2 before DTA investigation. Therefore, the first peak is due to melting of τ2 + CA + CA2 assemblage. It is probably ternary eutectic because the temperature is below the temperature of eutectic L ↔ CA + CA2 (1600°C) in the CaO-Al2O3 system. The second effect is for melting of CA and CA2 up to liquidus. The shape of the second effect shows that there were several reactions until the whole sample melted. Three phases can be observed in the microstructure after DTA presented in Fig. 6b. The gray phase is CA, while the light gray phase is similar to CA in composition but contains more Nd (~ 2 mol.% Nd2O3). It is possible that this is due to overlapping of τ2 and CA. Grains of τ2 can be also observed in the CA phase. The black phase is CA2. Area of eutectic with the composition close to CA2 but containing more Nd can be observed. Probably it is binary eutectic since only two phases, τ2 and CA2, can be seen clearly, while the presence of the CA phase cannot be clearly seen.

For sample ACN-5, DTA indicated one thermal effect at 1594°C (Fig. 7a). Microstructure investigation after DTA indicated three phases (Fig. 7b). White contrast squares are NdAlO3, and white contrast sticks are τ1. The areas of the gray phase are τ2. The black phase has a composition similar to C12A7, but the metastable phase C12A7 was not identified by XRD in the sample which was heat treated at 1600°C and completely melted at this temperature. Notably, C12A7 does not appear after melting according to the literature. As mentioned above, glass formed during cooling of this composition in the CaO-Al2O3 system.

The Importance of the CaO-Nd2O3-Al2O3 Phase Diagram for a Tailored Permanent Magnet Recycling Process

Hydrometallurgy is the main method for rare earth elements recovery from waste electronics and electrical equipment. Wherein, the leaching method is based on the dissolution of scrap in mineral or organic acids followed by precipitation, ion exchange, solvent extraction, and electrochemical methods.29 For example, leaching with sulfuric acid followed by the use of alkali metal hydroxides to precipitate double salts of neodymium which can be further transformed to neodymium oxide allows achieving up to 98% recovery of Nd.29 Though hydrometallurgical methods allow to achieve high recovery of REEs, the disadvantage of this process is multiple steps to enhance leaching selectivity, consumption of large amounts of chemicals, compromised precipitate purity due to the presence of iron in solution and rapid (undesired) evolution of hydrogen.29,30 In pyrometallurgical processes, e.g. during oxidative treatment, rare earth elements with a high affinity for oxygen are concentrated in the slag, while elements with a lower affinity for oxygen (predominantly iron) form a metallic liquid. The slag phase comprising mainly of CaO-REE2O3-Al2O3 (REE2O3 is mainly Nd2O3 but also Pr2O3, Dy2O3) can be achieved through a two-stage process, i.e. the first oxidative smelting of the magnet containing the waste stream, and the second stage of the reductive smelting stage to remove any metal components (predominantly iron) from slag concentrating the REE elements. The above-mentioned recycling process demonstrated in Ref. 3 can be further tailored through the melting relations established in the present study. The combination of pyrometallurgical and hydrometallurgical methods makes it possible to reduce the impact on the environment and economy.31

In order to enhance the rare earths recycling in a pyrometallurgical process, the melting relations, i.e. REEs distribution in the slag and the precipitation behavior of REE-containing compounds, are of primary importance. In the works of Le et al.,15,31 the CaO-SiO2 system with eutectics at 1454°C and 1441°C was selected to concentrate Nd2O3 in the slag. Based on melting relations in the CaO-SiO2-Nd2O3 system, two possible schemes for recycling were proposed: (1) precipitation of rare earth solid phase Ca2+xNd8-x(SiO4)6O2–0.5x with an apatite structure in the two-phase region (apatite and liquid), and (2) concentrating REE in liquid equilibrated with CaSiO3.

Different slag systems have already been suggested for collecting Nd in slag, e.g. the systems of CaO-SiO2,15,31,32 CaO-SiO2-P2O5,32 CaO-SiO2-CaF2,33 and Al2O3-CaO-MgO-SiO2-P2O5.1 The main criteria for selecting a slag system are the presence of low-temperature eutectics in the bounding systems serving as flux additives and the presence of ternary and binary compounds concentrating Nd2O3 in the slag-Nd2O3 systems. Both criteria should be met for compositions selected for Nd recycling, when aiming to achieve REE-enriched phases. Alternatively, liquids (slags) with high Nd2O3 solubility can be directed to leaching after solidification. In the present work, the CaO-Al2O3 system was selected as flux since there is a low-temperature eutectic at 1365°C in the binary system, and compounds concentrating Nd, i.e. two ternary compounds τ1 and τ2 as well as the NdAlO3 binary compound. The compositions for experimental investigation were selected in the fields of three phase coexistence: τ2 + C3A + CA, τ2 + CA + CA2, and τ1 + τ2 + C3A. It was found that the selected samples completely melted at a temperature of 1600°C. Thus, Nd2O3 will completely dissolve in the oxide liquid and separate from the metal. Therefore, the selected compositions are of interest for Nd recycling. In sample ACN-3, the τ2 phase crystallized first and therefore during the process of solidification it can be separated from the melt having a low concentration of Nd. In sample ACN-4, τ2 and binary eutectic τ2 + CA2 crystallizing as first and secondary phases can be also separated in the process of solidification from the melt enriched in CaO and Al2O3. Especially interesting for application was sample ACN-5 concentrating Nd in the NdAlO3, τ1 and τ2 phases which can be separated from the liquid of C12A7 composition forming glass at the last stage of cooling process. It should be mentioned that NdAlO3 was not found after heat treatment at 1330°C and appeared only after complete melting of the sample. The solidification of this phase is very important, since more Nd2O3 is concentrated in it than in the τ1 and τ2 phases.

Therefore, it is demonstrated that using of CaO and Al2O3 additives presents interest for Nd recycling. It should be mentioned that melting temperature of the τ2 compound of 1766°C and its incongruent melting behavior were investigated for the first time in the present work. Though the melting temperature is relatively high, the NdAlO3 phase with the highest concentration of Nd forming first during solidification followed by τ2 formation also presents interest for Nd recycling. However, more detailed experimental investigations of melting relations as well as thermodynamic property measurements are necessary to develop thermodynamic database for the system CaO-Al2O3-Nd2O3. The calculations using preliminary database obtained in the present work indicated melting of the τ2 phase below 1600°C that is not consistent with the experimental results of the present work. Additional studies can indicate other compositions interesting for Nd recycling applications. Using thermodynamic database liquidus and solidus surfaces will be calculated establishing primary crystallization fields of Nd-containing phases, temperature ranges of their solidification and series of liquidus isotherms showing composition ranges of liquid stability changing with temperature. These are especially important information for the pyrometallurgical recycling of Nd.

Conclusion

-

1.

Phase relation in the CaO-Al2O3-Nd2O3 system were investigated in the temperature range of 1330–1600°C by equilibration technique followed by characterization using XRD and SEM/EDX. Melting relations were studied using DTA followed by microstructure characterization. It was shown that the ternary phase τ1 melted congruently at 1808°C and τ2 melted incongruently at 1766°C. After melting of τ2 substantial amount of NdAlO3 was found. Samples with the compositions in the tie-triangles τ2 + CA + C3A, τ2 + CA + CA2 and τ1 + τ2 + C3A were completely molten after heat treatment at 1600°C. In some cases, the cubic phase C12A7, which was considered in literature as metastable, formed after heat treatment at temperatures below melting. After DTA when samples were completely melted the phase with the composition C12A7 was found using SEM/EDX. However, according to XRD investigation of the completely molten sample at 1600°C indicating the same microstructure as after DTA this phase was not found. To explain these results, it was assumed that the C12A7 phase was glassy, which readily formed during quenching according to literature.

-

2.

Comparison of the obtained results with the calculated diagram at 1600°C indicated that the phase τ2 should be still stable at 1600°C that contradicts calculations. Therefore, ternary interaction parameters should be introduced into thermodynamic modelling of the liquid phase to fit experimental data.

-

3.

It was found that after melting of several samples substantial amount of NdAlO3 was formed in contrast to samples of the same compositions which were not melted during heat treatment. Formation of the NdAlO3 phase concentrating more Nd2O3 than other phases is important for selection of compositions for Nd2O3 recycling. Relatively low temperatures of melting and formation of phases concentrating Nd2O3 are the main criteria for the selection of compositions for Nd2O3 recycling. Concerning the low temperature of melting and formation of τ2, which is the Nd2O3 concentrating phase, all three compositions selected in stability fields of τ2 + C3A + CA, τ2 + CA + CA2, and τ1 + τ2 + C3A are of interest. The latter one is of particular interest since the τ1 compound and NdAlO3 formed after the complete melting of a sample concentrate more Nd2O3 than the τ2 phase.

-

4.

Experimental results on melting relations can be used for optimization of thermodynamic parameters at least partially. It should be noted that further phase equilibria studies and heat capacity measurements are necessary to get a reliable thermodynamic database for the CaO-Al2O3-Nd2O3 system.

References

T. Elwert, D. Goldmann, T. Schirmer, and K. Strauß, Chem. Ing. Tech. 86(6), 840 (2014).

T.W. Ellis, F.A. Schmidt, and L.L. Jones, Methods and opportunities in the recycling of rare earth based materials. In: Metals and materials waste reduction, recovery, and remediation. Paper presented at The Metallurgical Society (TMS) conference, Rosemont (IL) USA 10–15 Oct. 1994.

L. Blenau, O. Fabrichnaya, O. Lonski, D. Vogt, and A. Charitos, Chancen pyrometallurgischen magnetrecyclings durch angepasste Schlackensysteme. Paper presented at 51. Metallurgische Seminar der GDMB, Clausthal Zellerfeld, Germany, 11–12 May 2022 (In German).

A. Abrar: Investigation on the leaching behavior of neodymium-rich slags from pyrometallurgically treated NdFeB magnets and development of a selective hydrometallurgical recovery process of neodymium (Master thesis, academic supervisor: A. Charitos 30.09.2022).

C.M. Jantzen and F.P. Glasser, Mater. Res. Bull. 14, 1601 (1979).

C.M. Jantzen and R.R. Neurgaonkar, Mater. Res. Bull. 16, 519 (1981).

O. Fabrichnaya, G. Savinykh, G. Schreiber, and H.J. Seifert, J. Eur. Ceram. Soc. 32, 3171 (2012).

B. Hallstedt, J. Am. Ceram. Soc. 73, 15 (1990).

G. Eriksson and A.D. Pelton, Meter. Trans. B 24, 807 (1993).

B. Hallstedt, J. Am. Ceram. Soc. 78, 193 (1995).

H. Mao, M. Selleby, and B. Sundman, Comput. Coupl. Phase Diag. Thermochem. 28, 307 (2004).

O. Fabrichnaya and H.J. Seifert, Comput. Coupl. Phase Diag. Thermochem. 32(1), 142 (2008).

W. Wong-Ng, W. Laws, K.R. Talley, Q. Huang, Y. Yan, J. Martin, and J.A. Kaduk, J. Solid State Chem. 215, 128 (2014).

L.M. Lopato, Ceramurgia Int. 2(1), 18 (1976).

T.H. Le, K. Tang, S. Arnout, A. Malfiet, B. Blanpain, and M. Guo, Comput. Coupl. Phase Diag. Thermochem. 55(2), 157 (2016).

P.N. Babin, F.M. Menzhulina, N.V. Kirchanova, and Z.G. Shkarubo, Kompleksn Ispol’z. Miner. Syr’ya 8, 58 (1984).

R. Kitano and K. Morita, ISIJ Int. 56(11), 1893 (2016).

E.V. Doronin, M.A. Grintsova, E.P. Shevyakova, Yu.F. Konotop, N.P. Odeichuk, and A.S. Kamenev, Inorg. Mater. 27(9), 1564 (1991).

A. Richter and M. Göbbels, J. Phase Equilib. Diffus. 31, 157 (2010).

M. Berkowski, A. Pajaczkowska, P. Gierłowski, S.J. Lewandowski, and R. Sobolewski, Appl. Phys. Lett. 57, 632 (1990).

A. Pajaczkowka and A. Gloubokov, Prog. Cryst. Growth Charact. Mater. 36, 123 (1998).

L.N. Komissarova, M.A. Ryumin, G.Y. Pushkina, G.V. Zimina, A.V. Novoselov, A. Pajaczkowska, M.A. Borik, and A. Ilinskii, Inorg. Mater. 41, 850 (2005).

M. Hellenbrandt, Crystallogr. Rev. 10, 17 (2004).

L. Lutterotti, S. Matthies, and H.R. Wenk, CPD Newsl. 21, 14 (1999).

L. Lutterotti, M. Bortolotti, G. Ischia, I. Lonardelli, H.R. Wenk, and Z. Kristallogr, Z. Kristallogr. Suppl. 26, 125 (2007).

J.O. Andersson, T. Helander, L. Höglund, P.F. Shi, and B. Sundman, Comput. Coupl. Phase Diag. Thermochem. 26, 273 (2002).

P.L. Higby, R.J. Ginther, I.D. Aggarwal, E.J. Friebele, and J. Non-Crystal, Solids 126, 209 (1990).

Y.-M. Sun and S.-J. Kwon, J. Mater. Sci. Lett. 18, 1267 (1999).

V. Prakash, Z.H.I. Sun, J. Sietsma, and Y. Yang, Electrochemical recovery of rare earth elements from magnet scraps—a theoretical analysis. Paper presented at the 1st European Rare Earth Resources Conference (ERES 2014), Milos, Greece, 4–7 Sep. 2014.

J. Niskanen, M. Lahtinen, and S. Perämäki, Clean. Eng. Technol. 10, 100544 (2022).

T.H. Le, A. Malfliet, B. Blanplain, and M. Guo, Metall. Mater. Trans. B 47B, 1736 (2016).

T.H. Le, M. Aketagawa, A. Malfliet, B. Blanplain, and M. Guo, In-situ observation of rare earth containing precipitated phase crystallization and solidification of CaO-SiO2-Nd2O3 and CaO-SiO2-Nd2O3-P2O5 melts. Paper presented at the 10th International Conference on Molten Slags, Fluxes and Salts (MOLTEN16), Seatle, WA, USA, 22–26 May 2016.

T. Müller and B. Friedrich, J. Power Sour. 158, 1498 (2006).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ilatovskaia, M., Lonski, O., Löffler, M. et al. Phase Relations in the CaO-Nd2O3-Al2O3 System in Application for Rare Earth Recycling. JOM 75, 1993–2002 (2023). https://doi.org/10.1007/s11837-023-05731-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05731-8