Abstract

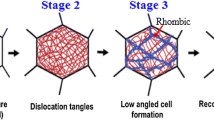

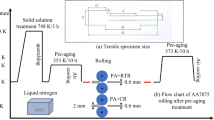

Ultrafine-grained AA1060 sheets were fabricated by a combination of accumulative roll-bonding and subsequent cryorolling. The effect of rolling temperature on the microstructure evolution and plastic anisotropy was studied. The decrease of rolling temperature resulted in significant grain refinement and strength improvement. The smallest plane anisotropy index and largest cupping value were obtained by the sheet rolled at 83 K, resulting in the best plastic anisotropy and formability. With the decrease of rolling temperature, the severity of Goss texture and Copper texture in the sheet was gradually weakened. The texture component of ARB AA1060 sheets could be optimized by subsequent cryorolling. A reasonable proportion of texture components can be obtained for aluminum alloy, thereby reducing or eliminating earing.

Similar content being viewed by others

Data Availability

The data sets generated and analyzed during the current study are available from the corresponding authors on reasonable request.

References

M. Naseri, E. Borhani, O. Imantalab, H.W. Jang, M. Shokouhimehr, and A. Fattah-alhosseini, J. Mater. Res. Technol. 18, 4256 (2022).

J. Li, K. Lu, X. Zhao, X. Ma, F. Li, H. Pan, and J. Chen, J. Mater. Sci. Technol. 131, 185 (2022).

M. Mesbah, G. Faraji, and A.R. Bushroa, Mater. Sci. Eng. A 590, 289 (2014).

M. Naseri, M. Reihanian, and E. Borhani, Mater. Sci. Eng. A 656, 12 (2016).

X. Chen, G. Huang, S. Liu, T. Han, B. Jiang, A. Tang, Y. Zhu, and F. Pan, Trans. Nonferr. Met. Soc. China 29(3), 437 (2019).

L. Chen, G. Chen, J. Tang, G. Zhao, and C. Zhang, Mater. Charact. 158, 109953 (2019).

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, and Y.T. Zhu, Acta Mater. 52, 4589 (2004).

A. Loucif, R.B. Figueiredo, T. Baudin, F. Brisset, R. Chemam, and T. Langdon, Mater. Sci. Eng. A 532, 139 (2012).

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong, Scr. Mater. 39, 1221 (1998).

N. Tsuji, Y. Saito, H. Utsunomiya, and S. Tanigawa, Scr. Mater. 40, 795 (1999).

S. Zhang, X. Luo, G.Y. Zheng, N.Z. Zhai, Y.Q. Yang, and P.T. Li, Mater. Sci. Eng. A 832, 142482 (2022).

G.L. Shi, K. Zhang, X.G. Li, Y.J. Li, M.L. Ma, and J.W. Yuan, Rare Met. Mater. Eng. 44, 2954 (2015).

A.E. Medvedev, O.O. Zhukova, V.U. Kazykhanov, A.F. Shaikhulova, N.A. Enikeev, V.N. Timofeev, and M.Y. Murashkin, Int. J. Lightweight Mater. Manuf. 5(4), 484 (2022).

H.L. Yu, L.H. Su, C. Lu, K. Tieu, H.J. Li, J.T. Li, A. Godbole, and C. Kong, Mater. Sci. Eng. A 674, 256 (2016).

Y. Ito and Z. Horita, Mater. Sci. Eng. A 503, 32 (2009).

H.L. Yu, H. Wang, C. Lu, K. Tieu, H.J. Li, A. Godbole, X. Liu, C. Kong, and X. Zhao, J. Mater. Res. 31, 797 (2016).

Q.L. Du, C. Li, X.H. Cui, C. Kong, and H.L. Yu, Trans. Nonferr. Met. Soc. China 31, 3370 (2021).

O.B. Bembalge and S.K. Panigrahi, Int. J. Mech. Sci. 191, 106100 (2021).

M. Hussain, P.N. Rao, D. Singh, R. Jayaganthan, S. Goel, and K. Saxena, Mater. Sci. Eng. A 811, 141072 (2021).

W.B. Hutchinson, A. Oscarsson, and A. Karlsson, Mater. Sci. Technol. 5, 1118 (2013).

G.G. Wang, G.S. Huang, K. Liu, J. Zhang, B. Jiang, A. Tang, and F. Pan, Met. Mater. Int. 27, 4322 (2021).

Z.J. Wang, M. Ma, Z.X. Qiu, J.X. Zhang, and W.C. Liu, Mater. Charact. 139, 269 (2018).

M.S. Lee, M.K. Ji, Y.T. Hyun, E.Y. Kim, and T.S. Jun, Mater. Charact. 172, 110834 (2020).

H. Fang, H. Liu, Y. Yan, Y. Li, X. Xu, X. Chu, Y. Lu, and K. Yu, Mater. Lett. 292, 129600 (2021).

F. Shen, D. Yi, B. Wang, H. Liu, Y. Jiang, C. Tang, and B. Jiang, Mater. Sci. Eng. A 675, 386 (2016).

A. Medjahed, H. Moula, A. Zegaoui, M. Derradji, A. Henniche, R. Wu, L. Hou, J. Zhang, and M. Zhang, Mater. Sci. Eng. A 732, 129 (2018).

Z. Li, L. Chen, J. Tang, G. Zhao, C. Zhang, and X. Chu, Mater. Charact. 164, 110299 (2020).

Y. Yao, C. Liu, Y. Gao, S. Yu, S. Jiang, and Z. Chen, Mater. Charact. 144, 641 (2018).

X. Ren, Y. Huang, W. Zhou, L. Zhao, Q. Wang, and X. Min, Mater. Sci. Eng. A 764, 138159 (2019).

H. Inoue and T. Takasugi, Mater. Trans. 48(8), 2014 (2007).

H.J. Bunge, Texture Analysis in Material Science (Butterworths, London, 1982).

H.W. Yang, I.P. Widiantara, and Y.G. Ko, Mater. Lett. 213, 54 (2018).

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, M.Z. Ma, Q. Jing, and R.P. Liu, Mater. Des. 43, 367 (2013).

K.V. Jata, A.K. Hopkins, and R.J. Rioja, Mater. Sci. Forum 217–222, 647 (1996).

A. Medjahed, H. Moula, A. Zegaoui, M. Derradji, A. Henniche, R. Wu, L. Hou, J. Zhang, and M. Zhang, Mater. Sci. Eng. A 732(8), 129 (2018).

E. Nes and H.E. Vante, Int. J. Mater. Res. 87(6), 448 (1996).

J. Hjeln, L. Sund, and E. Nes, Acta Metal. Mater. 39, 1377 (1991).

M.M. Amiri and F. Fereshteh-Saniee, Trans. Nonferr. Metal Soc. China 31, 901 (2021).

R. Narayanasamy, R. Ravindran, K. Manonmani, and J. Satheesh, Mater. Des. 30, 1804 (2009).

P.D. Wu, K.W. Neale, E. Giessen, M. Jain, S. MacEwen, and A. Makinde, Metal. Mater. Trans. A 29(2), 527 (1998).

Q.Y. Yang, Y.L. Zhou, Y.B. Tan, S. Xiang, M. Ma, and F. Zhao, J. Alloys Compd. 884, 161135 (2021).

O. Engler and K. Knarbakk, J. Mater. Process Technol. 288, 116910 (2021).

Acknowledgements

The authors thank the National Natural Science Foundation of China (Grant Nos. 51674303 and 52105419), China Postdoctoral Science Foundation (Grant Nos. 2022M713505 and 2022T150736) and Natural Science Foundation of Hunan Province, China (Grant No. 2022JJ40596), for the financial support. The authors also thank Dr. Zhengyu Wang at Shimadzu (China) Co., Ltd., for discussion of the XRD results.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Du, Q., Gao, H., Li, J. et al. Plasticity Anisotropy and Texture of AA1060 Sheets Through a Combination of Accumulative Roll-Bonding and Cryorolling. JOM 75, 3015–3024 (2023). https://doi.org/10.1007/s11837-023-05716-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05716-7