Abstract

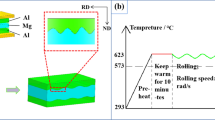

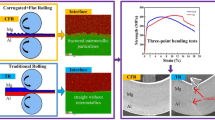

Mg/Al composites were successfully fabricated by the differential temperature + asymmetrical rolling (DTAR) and the isothermal + symmetrical rolling (ISR), respectively. The effects of DTAR and ISR on the tensile properties, bonding strength, interface morphology, and microstructure of composite plates were investigated. The results indicated that grains near the Mg layer of the Mg/Al interface were fine and equiaxed because of the occurrence of dynamic recrystallization on the Mg layer. In contrast, the grains at the center and near the Al side interface were elongated. DTAR enhanced the recrystallization degree of Mg side grains. The tensile properties and bonding strength of the composite plates increased gradually with increase in reduction rate, while the interface morphology was gradually flat with increase in reduction rate. The ultimate tensile strength of DTAR sample reaches 205 MPa, which is 25% higher than that of ISR sample.

Similar content being viewed by others

References

K. Kondoh, J. Umeda, H. Sannomiya, T. Luangvaranunt, and H. Nishikawa, Mater Charact. 157, 109879 (2019).

Z. Chen, D. Wang, X. Cao, W. Yang, and W. Wang, Mater. Sci. Eng. A 723, 97 (2018).

H. Zuo, Z. Yang, X. Chen, Y. Xie, and H. Miao, Compos Struct. 131, 248 (2015).

S. Chen, Z. Zhai, J. Huang, X. Zhao, and J. Xiong, Int. J. Adv. Manuf. Tech. 82, 631 (2016).

Q. Wang, B. Jiang, A. Tang, C. He, D. Zhang, J. Song, T. Yang, G. Huang, and F. Pan, Mater. Sci. Eng. 746, 259 (2019).

M. Yi, S. Fukushima, S. Sugiyama, and J. Yanagimoto, Mater. Sci. Eng. A 624, 148 (2015).

Y. Song, E.H. Han, K. Dong, D. Shan, D.Y. Chang, and B.S. You, Corros. sci. 72, 133 (2013).

J. Tang, L. Chen, G. Zhao, C. Zhang, and J. Yu, J. Alloy Compd. 784, 727 (2019).

T.T. Zhang, W.X. Wang, J. Zhou, X.Q. Cao, Z.F. Yan, Y. Wei, and W. Zhang, JOM. 70, 504 (2018).

W. Yang, F. Bo, Y. Xin, H. Rui, H. Yu, and Q. Liu, Mater. Sci. Eng. 640, 454 (2015).

X.L. Cui, P. Lin, Y.Y. Ma, C.K. Yan, and G. Liu, JOM. 71, 1696 (2018).

S.K. Lee, S.Y. Lee, and N.Y. Kwon, Mater. Sci. Eng. A 628, 1 (2014).

J.S. Kim, K.S. Lee, N.K. Yong, B.J. Lee, Y.W. Chang, and S. Lee, Mater. Sci. Eng. A 628, 1 (2015).

W. Jia, Y. Tang, Q. Le, and J. Cui, J. Alloys Compd. 695, 1838 (2017).

K.J. Tam, M.W. Vaughan, L. Shen, M. Knezevic, and G. Proust, Int J Mech sci. 182, 105727 (2020).

C. Tan, S. Xv, L. Wang, Z. Chen, F. Wang, and H. Cai, Trans. Nonferrous Met. Soc. China. 17, 41 (2007).

Z.Z. Shi, J.Y. Xu, J. Yu, and X.F. Liu, Mater. Sci. Eng. 712, 65 (2018).

Y. Chai, B. Jiang, J. Song, B. Liu, G. Huang, D. Zhang, and F. Pan, Mater. Sci. Eng. A. 746, 82 (2019).

G. Nayyeri, R. Mahmudi, and F. Salehi, Mater. Sci. Eng. A. 527, 5353 (2010).

Q. Wang, Y. Shen, B. Jiang, A. Tang, J. Song, Z. Jiang, T. Yang, G. Huang, and F. Pan, Mater. Sci. Eng. A 731, 184 (2018).

D. Chang, P. Wang, and Y. Zhao, J. Alloys Compd. 746, 259 (2019).

D. Chang, X. Dong, and P. Wang, Rare Met. Mater. Eng. 49, 85 (2020).

X. Li, G. Zu, and P. Wang, Mater. Sci. Eng. A 562, 92 (2013).

W. Xia, J. Cai, and Z. Chen, Chin. J. Nonferrous Met. 20, 1247 (2010).

R. Ding, B. Wang, and C. Ren, Chin. J. Rare Met. 34, 34 (2010).

H. Xiao, Z. Qi, C. Yu, and C. Xu, J. Mater. Process. Technol. 249, 285 (2017).

H. Nie, W. Liang, L. Zheng, X. Ren, and H. Fan, J. Mater. Eng. Perform. 25, 4695 (2016).

J. Zhang, L. Wei, Y. Liu, X. Zhao, X. Li, and B. Zhou, Mater. Sci. Eng. A 590, 314 (2014).

L. Zhang, Q. Wang, W. Liao, W. Guo, B. Ye, W. Li, H. Jiang, and W. Ding, Mater Charact. 126, 17 (2017).

S.H.S. Ebrahimi, K. Dehghani, J. Aghazadeh, M.B. Ghasemian, and S. Zangeneh, Mater. Sci. Eng. 718, 311 (2018).

G. Nussbaum, P. Sainfort, G. Regazzoni, and H. Gjestland, Scr. Metall. 23(7), 1079 (1989).

H. Nie, L. Wei, H. Chen, L. Zheng, C. Chi, and X. Li, Mater. Sci. Eng. A. 732, 6 (2018).

C. Zhi, L. Ma, Q. Huang, Z. Huang, and J. Lin, J. Mater. Process. Tech. 255, 333 (2017).

Z. Hua, W. Cheng, J. Fan, B. Xu, and H. Dong, Mater. Sci. Eng. A 637, 243 (2015).

H. Nie, W. Liang, H. Chen, F. Wang, T. Li, C. Chi, and X.R. Li, Mater. Sci. Eng. A 732, 6 (2018).

T. Han, G. Huang, Q. Deng, G. Wang, B. Jiang, A. Tang, Y. Zhu, and F. Pan, J. Alloys Compd. 745, 599 (2018).

M.G. Jiang, C. Xu, H. Yan, G.H. Fan, T. Nakata, C.S. Lao, R.S. Chen, S. Kamado, E.H. Han, and B.H. Lu, Acta Mater. 157, 53 (2018).

M.Y. Amegadzie, and D.P. Bishop, Mater. Today Commun. 25, 101283 (2020).

T. Wang, S. Li, H. Niu, C. Luo, and M.U. Bashir, J. Mater. Res. Technol. 9, 5840 (2020).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (U1910213), Taiyuan University of Science and Technology Scientific Research Initial Funding (Grant nos. 20202039 and 20212052)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cai, Z., Wu, Z., Ma, L. et al. Fabrication of Mg-Sn-Y/Al6061 Composite Plates by Asymmetrical Rolling with Differential Temperatures and their Microstructures and Mechanical Properties. JOM 75, 2924–2934 (2023). https://doi.org/10.1007/s11837-022-05694-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05694-2