Abstract

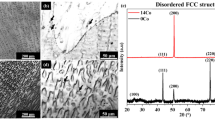

A high level of recognition has been given to high-entropy alloys (HEAs) in recent years because of their excellent properties over conventional superalloys. Consequently, research focus has shifted to the development and characterization of high-performing HEAs. The objective of this work was to develop and characterize Ti36-Al16-V16-Fe16-Cr16 HEA with the aim of determining its performance over conventional superalloys in engineering applications. Spark plasma sintering was the fabrication technique used. SEM–EDS and XRD were used in the characterization while a nano indenter and tribometer were used in the Vickers hardness and wear testing, respectively. Results obtained showed that a sintering temperature of 1000°C was optimal. The developed HEA had a Vickers hardness improvement of 136% over the Ti6Al4V alloy; and a wear rate improvement of 157% over Inconel 718 alloy, and 614% over TiAl alloy. It was concluded that the developed HEA can perform much better than conventional Ti6Al4V and other superalloys in engineering applications.

Similar content being viewed by others

References

A.K. Kasar, K. Scalaro, and P.L. Menezes, Materials 14(19), 5814. (2021).

H. Cheng, Y. Fang, J. Xu, C. Zhu, P. Dai, and S. Xue, J. Alloys Compd. 817, 153305. (2020).

M.-H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, and J.W. Yeh, Acta Mater. 59(16), 6308. (2011).

J.W. Yeh, S.J. Lin, T.S. Chin, J.Y. Gan, and S.K. Chen, Metall. Mater. Trans. A. 35(8), 2533. (2004).

B. Cantor, I. Chang, P. Knight, and A. Vincent, Mater. Sci. Eng. A 375, 213. (2004).

W. Zhang, P.K. Liaw, and Y. Zhang, Sci. China Mater. 61(1), 2. (2018).

M. Bondesgaard, N.L.N. Broge, A. Mamakhel, M. Bremholm, and B.B. Iversen, Adv. Funct. Mater. 29(50), 1905933. (2019).

M. Liu, Z. Zhang, F. Okejiri, S. Yang, S. Zhou, and S. Dai, Adv. Mater. Interfaces 6(7), 1900015. (2019).

Y. Yao, Z. Huang, P. Xie, S.D. Lacey, R.J. Jacob, H. Xie, F. Chen, A. Nie, T. Pu, and M. Rehwoldt, Science 359(6383), 1489. (2018).

S. Gao, S. Hao, Z. Huang, Y. Yuan, S. Han, L. Lei, X. Zhang, R. Shahbazian-Yassar, and J. Lu, Nat. Commun. 11(1), 1. (2020).

C. Ujah, A. Popoola, and O. Popoola, J. Mater. Sci. 2022, 1. (2022).

U.C. Oliver, A.S. Victor, E.I. Christian, and M.M. Elizabeth, Int. J. Adv. Manuf. Technol. 2021, 1. (2021).

C. Ujah, O. Popoola, and V. Aigbodion, Int. J. Adv. Manuf. Technol. 100(5–8), 1563. (2019).

M.-R. Chen, S.-J. Lin, J.-W. Yeh, M.-H. Chuang, S.-K. Chen, and Y.-S. Huang, Metall. Mater. Trans. A. 37(5), 1363. (2006).

C.-Y. Hsu, T.-S. Sheu, J.-W. Yeh, and S.-K. Chen, Wear 268(5–6), 653. (2010).

M. Löbel, T. Lindner, T. Mehner, and T. Lampke, Entropy 20(7), 505. (2018).

Agapovichev, A., Sotov, A., Kokareva, V., and Smelov, V., Possibilities and limitations of titanium alloy additive manufacturing, in MATEC Web of Conferences. 2018. EDP Sciences.

P. Popoola, O. Popoola, V. Aigbodion, and P. Oladijo, Trans. Nonferrous Met. Soc. China 30(2), 333. (2020).

M.B. Shongwe, S. Diouf, M.O. Durowoju, and P.A. Olubambi, J. Alloys Compd. 649, 824. (2015).

J. Cahoon, W. Broughton, and A. Kutzak, Metall. Trans. 2(7), 1979. (1971).

C. Ujah, A. Popoola, O. Popoola, and V. Aigbodion, J. Compos. Mater. 2019, 0021998319848055. (2019).

E. Tyne, and C.J. Van Pavlina, J. Mater. Eng. Perfor. 17, 888. (2008).

S.C. Krishna, N.K. Gangwar, A.K. Jha, and B. Pant, J. Mater. 2013, 1. (2013).

R. Rajendran, M. Venkateshwarlu, V. Petley, and S. Verma, J. Mech. Behav. Mater. 23(3–4), 101. (2014).

W. Zhou, J. Zuo, X. Zhang, and A. Zhou, J. Compos. Mater. 48(20), 2517. (2014).

K. Miyake, Y. Hirata, T. Shimonosono, and S. Sameshima, Materials 11(7), 1137. (2018).

S. Ankem, and C. Greene, Mater. Sci. Eng., A 263(2), 127. (1999).

L. Yuan, C. Min, L. Yanxiang, and C. Xiang, Rare Met. Mater. Eng. 209, 9. (2009).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.-H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6(5), 299. (2004).

R. Chen, G. Qin, H. Zheng, L. Wang, Y. Su, Y. Chiu, H. Ding, J. Guo, and H. Fu, Acta Mater. 144, 129. (2018).

X. Ou, Mater. Sci. Technol. 33(7), 822. (2017).

C. Papandrea, and L. Battezzati, Philos. Mag. 87(10), 1601. (2007).

Ibrahim, S., Seleman, M., Ahmed, H., and Hannora, A., Phase stability of mechanically alloyed Ti-Fe-Al alloys, in IOP Conference Series: Materials Science and Engineering. 2020. IOP Publishing.

J.-W. Yeh, JOM 67(10), 2254. (2015).

M. Xiao, J. Chen, J. Kang, K. Chen, D. Wu, and N. Gao, AIP Adv. 8(9), 095322. (2018).

A.K. Mukherjee, Mater. Sci. Eng., A 322(1–2), 1. (2002).

P. Sathiyamoorthi, J. Basu, S. Kashyap, K. Pradeep, and R.S. Kottada, Mater. Des. 134, 426. (2017).

S.S.D. Rocha, G.L. Adabo, G.E.P. Henriques, and M.A.D.A. Nóbilo, Braz. Dental J. 17, 126. (2006).

J.-M. Oh, K.-H. Heo, W.-B. Kim, G.-S. Choi, and J.-W. Lim, Mater. Trans. 54(1), 119. (2013).

R. Casati, and M. Vedani, Metals 4(1), 65. (2014).

X. Liu, H. Yin, and Y. Xu, Materials 10(11), 1312. (2017).

S. Dineshkumar, S. Sriram, R. Surendran, and V. Dhinakaran, Int. J. Recent Technol. Eng. 8(12), 103. (2019).

J. Barber, Tribol. Lett. 49(3), 539. (2013).

A.B. El Shalakany, B.M. Kamel, A. Khattab, T. Osman, B. Azzam, and M. Zaki, Fullerenes Nanotubes Carbon Nanostruct. 26(4), 185. (2018).

C. Zhang, S. Zhang, S. Song, G. Yang, L. Yu, Z. Wu, X. Li, and P. Zhang, Tribol. Lett. 54(1), 25. (2014).

M.G. Poletti, G. Fiore, F. Gili, D. Mangherini, and L. Battezzati, Mater. Des. 115, 247. (2017).

S. Alvi, and F. Akhtar, Wear 426, 412. (2019).

Y. Tian, J. Ju, H. Fu, S. Ma, J. Lin, and Y. Lei, J. Mater. Eng. Perform. 28(10), 6428. (2019).

H. Cheng, X. Liu, Q. Tang, W. Wang, X. Yan, and P. Dai, J. Alloys Compd. 775, 742. (2019).

J. Archard, J. Appl. Phys. 24(8), 981. (1953).

S.O. Yilmaz, Tribol. Int. 40(3), 441. (2007).

C.O. Ujah, A.P. Popoola, O.M. Popoola, and V.S. Aigbodion, Materials Res. Express 6(11), 116592. (2019).

X. Guo, X. Jin, X. Shi, H. Yang, M. Zhang, and J. Qiao, Metals 11(10), 1561. (2021).

J. Cheng, J. Ma, Y. Yu, L. Fu, Z. Qiao, J. Yang, J. Li, and W. Liu, J. Tribol. 136, 2. (2014).

M. Niu, X. Zhang, and J. Yang, Vacuum 154, 315. (2018).

H. Mishina, and A. Hase, Wear 432, 202936. (2019).

J.-M. Wu, S.-J. Lin, J.-W. Yeh, S.-K. Chen, Y.-S. Huang, and H.-C. Chen, Wear 261(5–6), 513. (2006).

J. Quintelier, P. De Baets, P. Samyn, and D. Van Hemelrijck, Wear 261(7–8), 703. (2006).

C. Ujah, A.P. Popoola, O.M. Popoola, and V.S. Aigbodion, J. Mater. Sci. 54(22), 14064. (2019).

Acknowledgements

The authors appreciate and acknowledge Tshwane University of Technology, Pretoria, South Africa, and the Africa Centre of Excellence for Sustainable Power and Energy Development (ACE-SPED), University of Nigeria, Nsukka, for their support.

Funding

The funding was provided by Tshwane University of Technology (Post-Doctoral Research Fellowship Fund, 2022).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest whatsoever.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ujah, C.O., Popoola, A.P.I., Popoola, O.M. et al. Analysis of the Microstructure and Tribology of Ti36-Al16-V16-Fe16-Cr16 HEA Developed with SPS for Engineering Applications. JOM 74, 4239–4249 (2022). https://doi.org/10.1007/s11837-022-05509-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05509-4